TEL: 631-234-5261 or 800-458-5876 FAX: 631-234-7809 or 631-234-4778

E-mail: sales@dannermfg.com Website: www.dannermfg.com

E G Danner Mfg. Inc. 160 Oval Drive Islandia, NY 11749

LIMITED WARRANTY

Danner pumps arewarranted against failure due todefects in materials and/or

workmanship as follows: Pump body and cover within 5 years, impeller and included

accessories within one year of original date of purchase. This warranty covers defects

occurring under normal use. The warranty and remedies set forth herein are conditional

upon proper installation, use, maintenance, storage, and conformance with the applicable

use. It will bebased upon Danner Mfg. discretion as towhether the defects are

of manufacturing origin. For warranty repair, return only the part that is defective to our

factory. Please include a dated proof of purchase and $5.00 for postage and handling.

Any damages due toimproper installation arenot covered bythis warranty. This

warranty does not apply toappearance or accessory items. This warranty does not

includedamage due to handling, transportation, unpacking, setup, installation, repair or

replacement of parts supplied by any other than Danner Mfg.; improper maintenance,

modification or repairs by the purchaser; abuse, misuse, neglect, accident, fire, flood, or

other acts of God. Any oral statements about this product made bythe seller,the

manufacturer, their representatives or any other parties do not constitute warranties

and shall not be relied upon by the user and are not part of this contract. Neither the

seller nor the manufacturer shall beliable for any injury, loss or damages, direct,

incidental, or consequential, including but not limited to incidental or consequential

damage for lost profits, lost sales, injury, and inability to use the product and the user

agrees that no other remedy is available. Before using, the user shall determine the

suitability of the product for their intended use and the user shall assume all risk liability

whatsoever in connection therewith. To validate this warranty, keep your proof of

purchase (copy of sales receipt). Warranty covers the repair or prorated replacement of the

Danner Mfg. products. Danner Mfg. denies all liability for any other loss including but not

limited to loss of equipment, income,livestock, or personal injury.

THE FOLLOWING VOIDS WARRANTY: LINE CORD OR PLUG ISALTERED OR

CUT, PRODUCT LABELS ARE DEFACED OR REMOVED. PRODUCT IS IMPROPERLY

INSTALLED OR MAINTAINED BY USER OR THEIR AGENT. PRODUCT IS ABUSED,

MISUSED, OR DAMAGED BY USER OR THEIR AGENT. PRODUCT IS NOTREMOVED

FROM SERVICE AND DRIED DURING FREEZING CONDITIONS.

# Description

1 Filter Cover*

2 Foam Filter

3 Fiber Filters

4 Filter Bottom*

5 Bell Fountain*

6 Bell Fountain*

7 Foam Block

FILTER & FOUNTAIN

PARTS REFERENCE

02019 POND FILTER 02273 BELL

FOUNTAIN

*NOTE:

Parts with

asterisk (*)

are listed

here for

reference

only and

may not be

available.

ITEM # 12195

Filter pad replacement pack for

Garden Pond Filter includes:

Foam Filter 1 pc

Fiber Filters 2 pcs

ITEM # 12600

Replacement foam block

for Bell Fountain includes:

Foam Block 1 pc

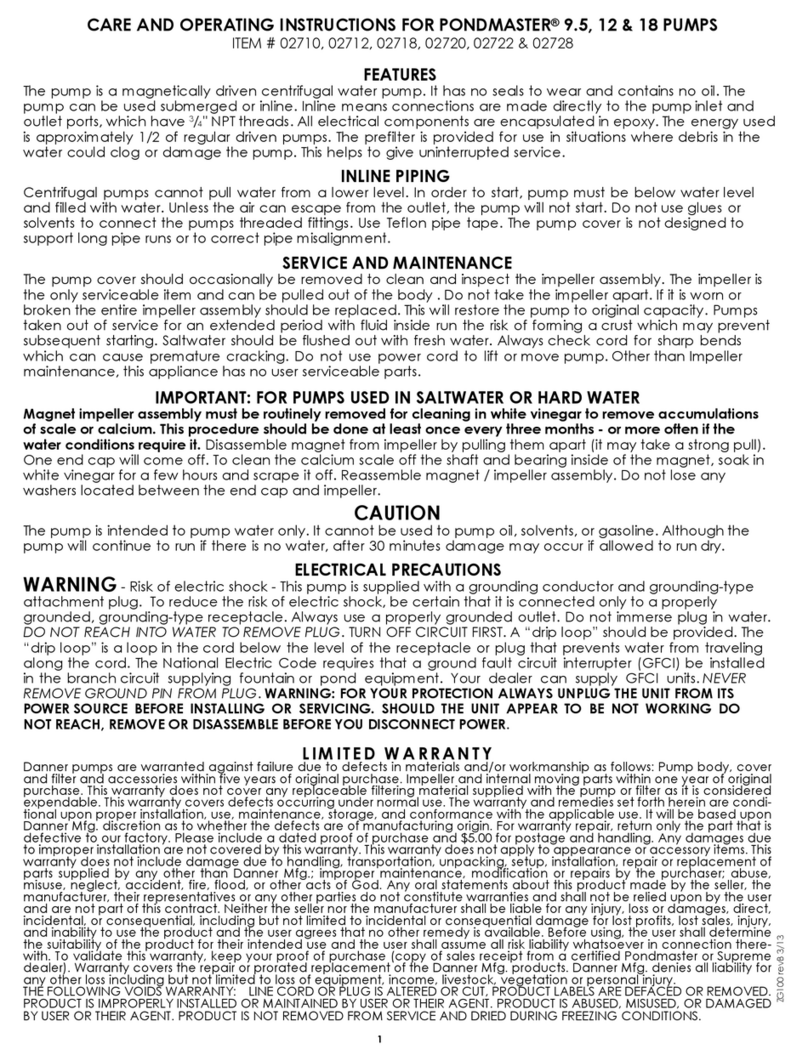

Danner Magnetic Drive Pump

for Submersible or In-Line use

INTRODUCTION

Thank you for purchasing this Dannerwater pump. This submersible or in-line pump

provides a continuous stream of water with an adjustable flow control. Danner

pumps are carefully inspected and tested to insure both safety and operating

performance. However, failure to follow the instructions and warnings in this manual

may result in pump damage and/or serious injury. Be sure to read and save this

manual for future reference.

The Model 1.9 pump has a number of features which make it versatile.

A 1/2” inside diameter tube may be slipped over the outlet or a 1/4” pipe thread fitting

can be used.The pump also comes with an elbow which will accept 3/8” ID tubing or a

1/2” ID soft tubing. The elbow is for submersible use only. The elbow directs the soft

tubing horizontally to prevent kinks.When there is limited room in the base of

statuary, the pump can be placed with the screen inlet down for operation in shallow

water.

The kits that utilize the 190 pump both include filtration media and a bell shaped

fountain.The filter media keep the water clean and protect the pump.In most set-ups

they can be can be rinsed and re-used several times before needing replacement.

SAVE THESE

INSTRUCTIONS

CARE AND OPERATING INSTRUCTIONS

Model 1.9

ITEM # 02519

ITEM # 40120

Model 1.9 Pump With filter

ITEM # 02019

Model 1.9 Pump

With Fountain & Block Foam Filter

ITEM # 02273

Shown with and without pre-filter

cover and elbow adapter

Always use a properly grounded outlet. Do not immerse plug in water. DO NOT

REACH INTO WATER TO REMOVE PLUG.TURN OFF CIRCUIT FIRST.A“drip loop”should

be provided.The“drip loop”is a loop in the line cord below the level of the receptacle

or plug that prevents water from running along the cord.The National Electric Code

requires that a ground fault circuit interrupter (GFCI) be installed on the branch

circuit supplying fountain or pond equipment. Your dealer can supply GFCI units.

NEVER REMOVE THE GROUND PIN FROM PLUG. WARNING: FOR YOUR PROTECTION

ALWAYS UNPLUG THE UNIT FROM ITS POWER SOURCE BEFORE INSTALLING OR

SERVICING. SHOULD THE UNIT APPEAR TO BE NOT WORKING DO NOT REACH,

REMOVE OR DISASSEMBLE UNIT BEFORE YOU DISCONNECT POWER. The pump is

intended to pump water only.It cannot be used to pump oils,solvents or gasoline.

WARNING!! PONDS ARE DANGEROUS TO SMALL CHILDREN!

NEVER LEAVE CHILDREN UNSUPERVISED NEAR A POND

ZG125 revE7/17

ELECTRICAL PRECAUTIONS

Subscribe to our YouTube Channel and view all of our product videos.