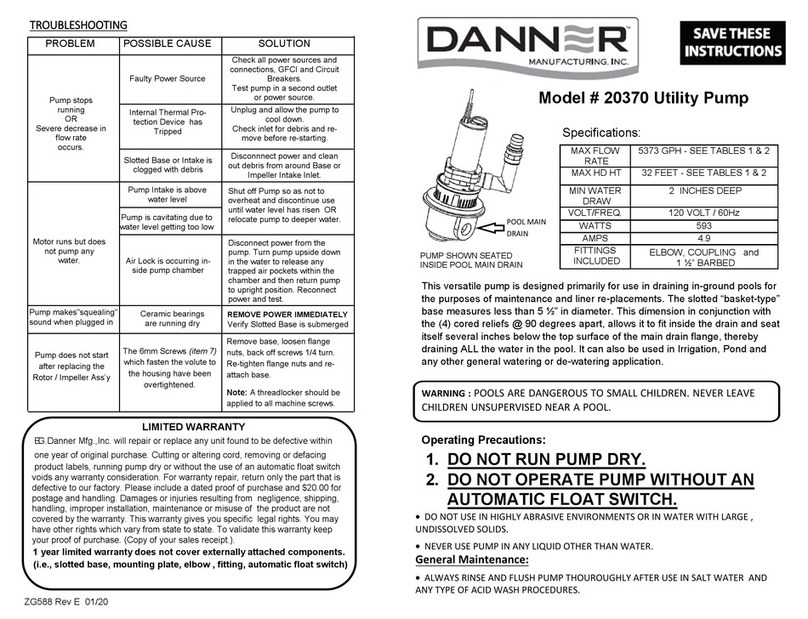

PUMP SHOWN SEATED

INSIDE POOL MAIN DRAIN

MAX FLOW

RATE 5373 GPH - SEE TABLES 1 & 2

MAX HD HT 32 FEET - SEE TABLES 1 & 2

MIN WATER

DRAW 2 INCHES DEEP

VOLT/FREQ. 120 VOLT / 60Hz

WATTS 593

AMPS 4.9

FITTINGS

INCLUDED ELBOW, COUPLING and

1 ½” BARBED

Specifications:

Model # 20370 Utility Pump

Operating Precautions:

• DO NOT USE IN HIGHLY ABRASIVE ENVIRONMENTS OR IN WATER WITH

LARGE , UNDISSOLVED SOLIDS.

• NEVER USE PUMP IN ANY LIQUID OTHER THAN WATER.

• DO NOT RUN PUMP DRY.

General Maintenance:

• RINSE AND FLUSH PUMP THOROUGHLY AFTER USE IN SALTWATER AND

ANY TYPE OF ACID WASH PROCEDURES.

This versatile pump is designed primarily for use in draining in-

ground pools for the purposes of maintenance and liner re-

placements. The slotted “basket-type” base measures less than

5 ½” in diameter. This dimension in conjunction with the (4)

cored reliefs @ 90 degrees apart, allows it to fit inside the drain

and seat itself several inches below the top surface of the main

drain flange, thereby draining ALL the water in the pool. It can

also be used in Irrigation, Pond and any other general watering

or de-watering application.

WARNING : POOLS ARE DANGEROUS TO SMALL CHILDREN.

NEVER LEAVE CHILDREN UNSUPERVISED NEAR A POOL.

PROBLEM POSSIBLE CAUSE SOLUTION

Pump stops

running

OR

Severe decrease in

flow rate

occurs.

Faulty Power Source

Check all power sources and

connections, GFCI and Circuit

Breakers.

Test pump in a second outlet

or power source.

Internal Thermal Pro-

tection Device has

Tripped

Unplug and allow the pump to

cool down.

Check inlet for debris and re-

move before re-starting.

Slotted Base or Intake is

clogged with debris

Disconnnect power and clean

out debris from around Base or

Impeller Intake Inlet.

Motor runs but does

not pump any

water.

Pump Intake is above

water level

Shut off Pump so as not to

overheat and discontinue use

until water level has risen OR

relocate pump to deeper water.

Pump is cavitating due to

water level getting too low

Air Lock is occurring in-

side pump chamber

Disconnect power from the

pump. Turn pump upside down

in the water to release any

trapped air pockets within the

chamber and then return pump

to upright position. Reconnect

power and test.

TROUBLESHOOTING

ZG588 Rev B 01/18

POOL MAIN

DRAIN

Pump does not start

after replacing the

Rotor / Impeller Ass’y

The 6mm Screws (item 7)

which fasten the volute to

the housing have been

overtightened.

Remove base, loosen flange

nuts, back off screws 1/4 turn.

Re-tighten flange nuts and re-

attach base.

Note: A threadlocker should be

applied to all machine screws.

LIMITED WARRANTY

E.G.Danner Mfg.,Inc. will repair or replace any unit found to be defective within

one year of original purchase. Cutting or altering cord, removing or defacing

product labels voids any warranty consideration. For warranty repair, return only

the part that is defective to our factory. Please include a dated proof of purchase

and $20.00 for postage and handling. Damages or injuries resulting from

negligence, shipping, handling, improper installation, maintenance or misuse of

the product are not covered by the warranty. This warranty gives you specific

legal rights. You nay have other rights which vary from state to state. To validate

this warranty keep your proof of purchase. (Copy of your sales receipt.).

1 year limited warranty does not cover externally attached components

(i.e., slotted base, mounting plate, elbow)