Filename: Eco-Line_Signal_Converters_User_Manual.docx 02 May 2020

Version: 1.17

©danntech – PROCESS INSTRUMENTATION Page 1 of 22

Eco-Line Signal Converters User Manual

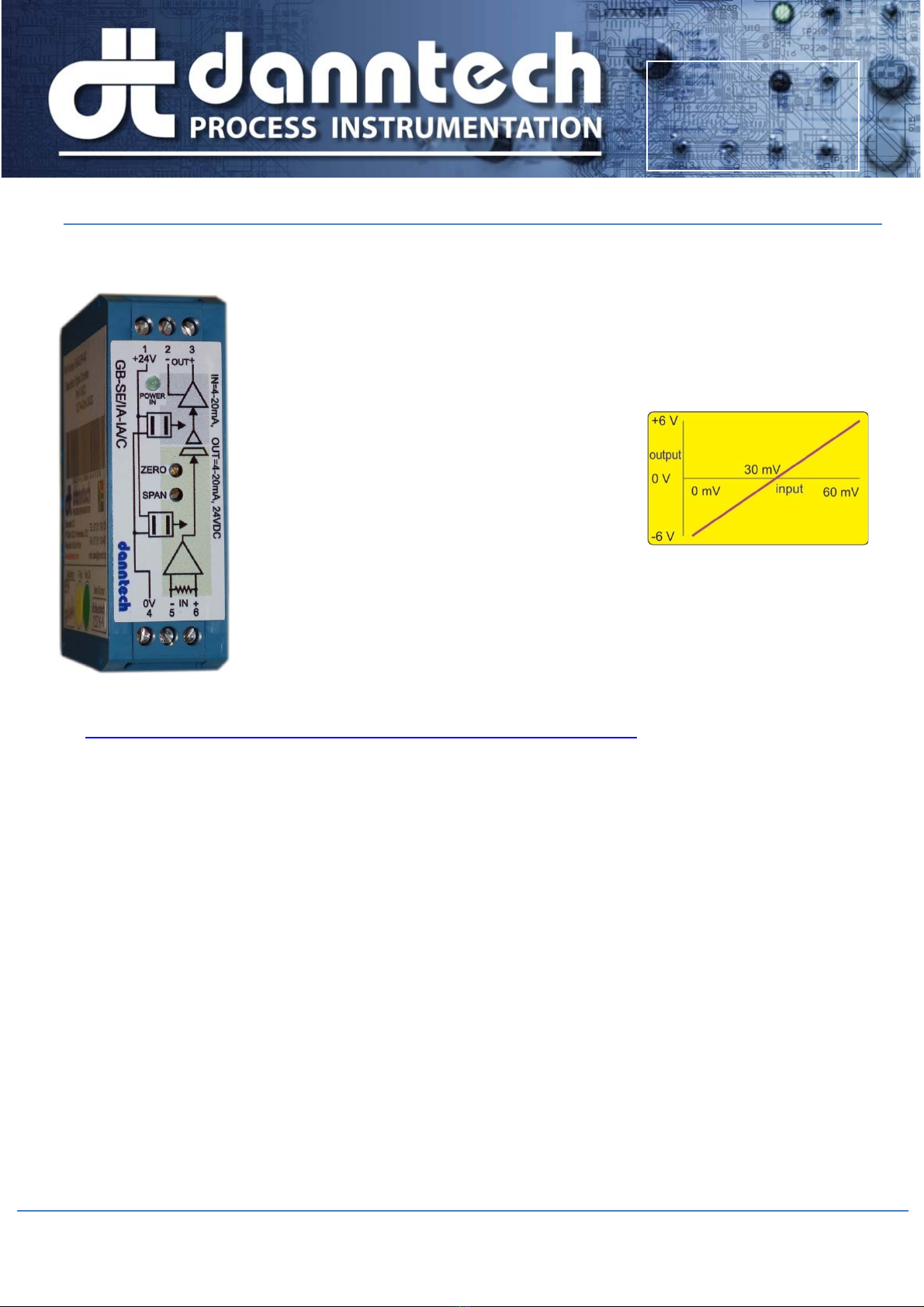

The Eco-Line range of signal converters has been designed using a low-cost, powerful microprocessor

which enables us to offer flexibility, reliability and accuracy at a really good price in a small package.

Using miniature DIP switches, a variety of standard inputs and outputs can be

selected and with the ‘one button’ calibration, accurate operation in any

configuration is assured. Having selected the required input and output ranges,

these can be adjusted to be anything within the selected range using the ‘one

button’ calibration.

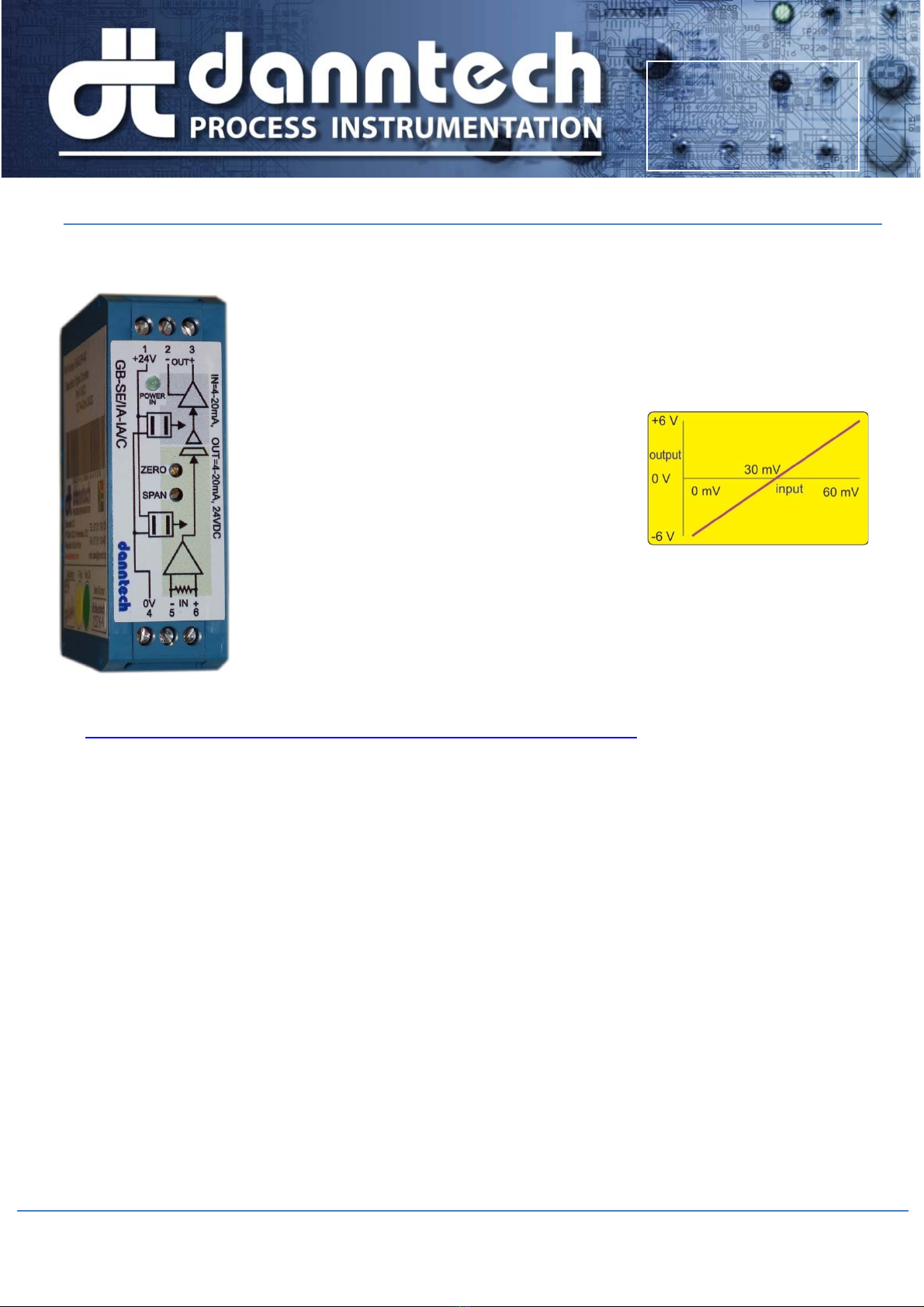

For example, with a 0 to 100 mV input and ±10V

output selected, one can calibrate the device to

have say 0 to 60 mV input where 30 mV input gives

an output of 0 V, 60 mV an output of +6 V and for

0 mV input and output of – 6 V. Output inversion is

also easily accommodated.

The Zero and Span trimpots can be disabled or switched to a wider adjustment

range using the DIP switches. Filtering is also DIP switch selectable in four ranges

up to 60 seconds.

We can also make firmware changes if you have a special application that we have

not catered for.

If you have any comments or suggestions which could improve this User Manual please e-mail them to me

Configuration ................................................. 2

How it Works ................................................. 4

Quick Configuration Guide ............................ 5

DIP Switches Push Button (PB) and Push

Button Link .................................................... 8

Input Range Selection ................................... 9

Input Setup: ................................................... 9

Output Range Selection .............................. 10

Output Setup ............................................... 10

Test Mode ................................................... 12

DIP SW1 Operational Settings .................... 14

Power Up .................................................... 16

Application Examples .................................. 16

Typical Results ........................................... 16

Other Eco-Line Versions ............................. 17

Using the Eco-Line Signal Converter as a

Preset Signal Source .................................. 17

Serial Communications ............................... 17

Setting up without a Process Signal Calibrator

................................................................... 18

Opening the Enclosure ............................... 19

Some other interesting things about the Eco-

Line Signal Converters ............................... 20

Specifications ............................................. 21

Part Numbering .......................................... 22

Danntech makes no warranty of any kind with regard to this material, including, but not limited to, the implied warranties of merchantability and fitness for a particular

purpose. Danntech shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance or use of this

material. This document contains proprietary information, which is protected by copyright. No part of this document may be photocopied, reproduced, or translated into

another language without the prior written consent of Danntech. The information in this document is subject to change without notice.

©danntech 2020

www.danntech.com

www.danntech.co.za

www.danntech.biz