Dantel 46034 User manual

CAUTION

Install or remove modules from the shelf only when the power is off.

If you install a module in the shelf with the power on, the internal

circuitry may suffer damage and the product warranty will be void.

Remove and install circuit boards only in a static-safe environment

(use antistatic wrist straps, smocks, footwear, etc.).

Keep circuit boards in their antistatic bags when they are not in use.

Do not ship or store circuit boards near strong electrostatic, electromag-

netic, magnetic, or radioactive fields.

For more complete information on electrostatic discharge safety

precautions, refer to BellcoreTM Technical Reference #TR-NWT-000870.

Copyright 1997 by Dantel, Inc. • Dantel is a registered trademark of Dantel, Inc. • ISO 9001 Registered

Printed in the U.S.A.

INSTALLATION&OPERATION MANUAL

46034-0997<90-00030>

46034

HUBBING MODULE

About this Practice:

• This practice has been reformatted

to meet ISO 9001 requirements.

Issue date: September 1997

Reissued Practices: Updated and

new content can be identified by a

banner in the right margin.

UPDATED

Table of Contents

Ordering Information ........................................................................... 2

General Description.............................................................................. 2

Circuit Description ............................................................................... 2

Application Information ....................................................................... 6

Installation.......................................................................................... 11

Operation ............................................................................................ 16

Technical Specifications ..................................................................... 17

Warranty ............................................................................................. 18

46034-00 REV__

46034-00

HUBBING

MODULE

RX 1

RX 2

RX 3

RX 4

RX 5

RX 6

RX 7

RX 8

TX 1

TX 2

TX 3

TX 4

TX 5

TX 6

TX 7

TX 8

RXD

TXD

PAGE 2 46034-0997<90-00030>

ORDERING INFORMATION

NOTE: This section lists the different options available for this product. To order any of the avail-

able options, contact Dantel Inside Sales through our toll-free number, 1-800-432-6835.

OPTION NUMBER FEATURES

B11-46034-00 Hubbing Module

GENERAL DESCRIPTION

The 46034 Hubbing Module provides nine data ports for

digital data summing, distribution or bridging.

Each port connects through six individual communication buses.

Ports one through eight can accept data through RS-232 and

RS-422 interfaces, depending on the strapping selection. Port

nine operates with an optional on-board communications subas-

sembly. The interface type depends on the selected subassembly.

If handshaking is required with RS-232 communications, the

module can operate up to five RS-232 data ports. One of those

five RS-232 data ports is port nine, operating with a 49029

RS-232 Current Loop Interface Subassembly.

The module comes with a TTL subassembly (bypass card) that

allows port nine to function as a TTL data bus interface in the

absence of a subassembly.

Interface and data connections are set using module switch and

strap options. Ports one through eight operate at a maximum of

38,400 baud. The maximum data rate for port nine depends on

the subassembly installed. Refer to the subassembly documenta-

tion for more information.

The 46034 Hubbing Module is a plug-in printed circuit module

that fits into any Dantel 400-type or similar equipment housing.

The module operates on -21 to -56 VDC input power.

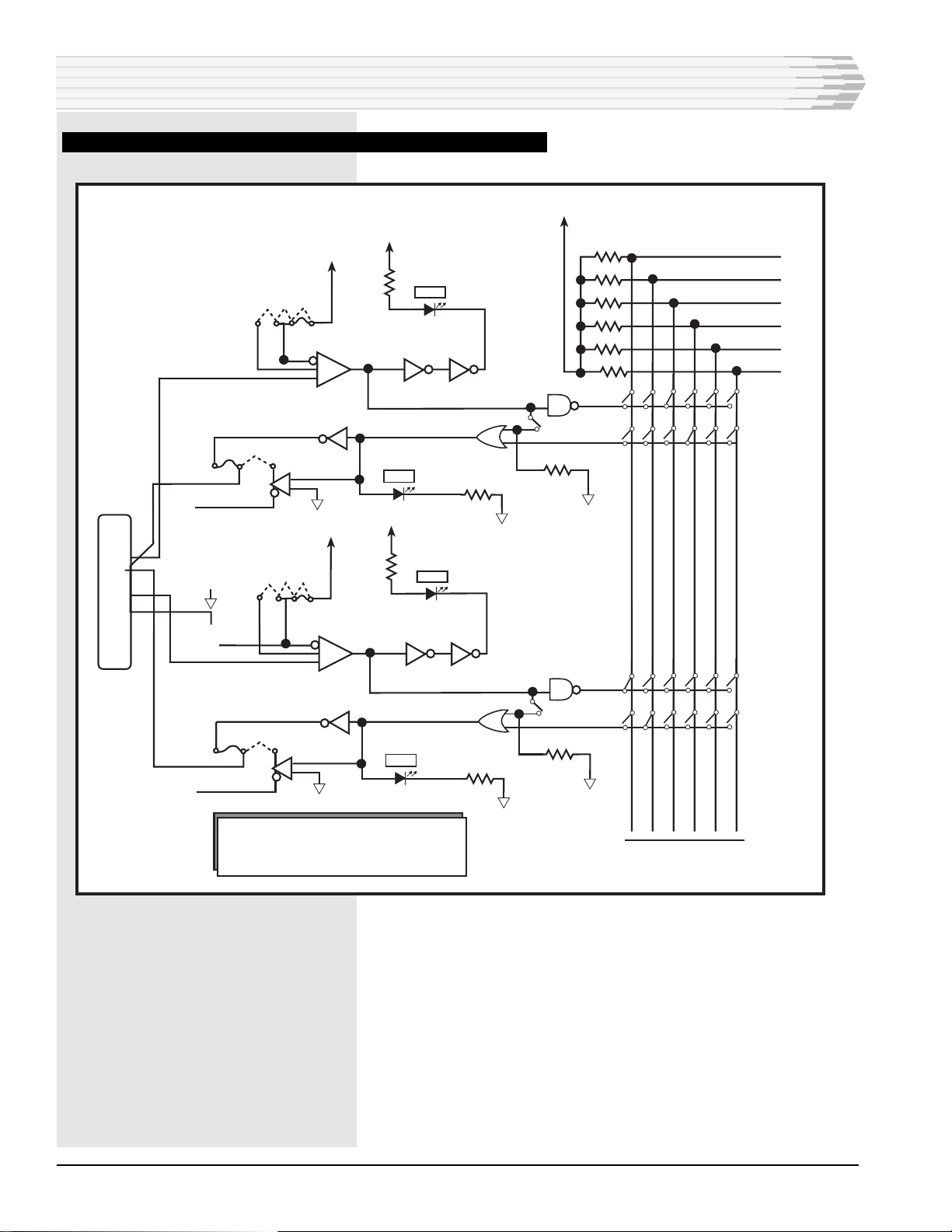

CIRCUIT DESCRIPTION

Fig. 1 shows the 46034 Hubbing Module functional schematic.

Ports one through eight operate identically. Refer to Tables A

and B for specific pin assignments. Mini-jumpers 1A through 8A

selects port operation of RS-232, RS-422 terminated, or RS-422

unterminated data. Received data is inverted and goes to the

data bus for distribution. The received signal illuminates the

front panel RX LED.

46034-0997<90-00030> PAGE 3

The data bus consists of six individual, switch selectable data

lines which route the data to the desired ports. Data received

from the data bus applies to one input of a two-input OR gate.

The other OR gate input connects to switch S22 for full- or

half-duplex operation.

When switch S22 is in full-duplex mode (switch open), a con-

stant low applies to the input, which passes all data received

from the data bus to the port transmit circuitry. When S22 is in

half-duplex mode (switch closed), the input operates with the

port receive circuitry.

When the port is not receiving data, the input holds in the low

state and the OR gate passes data received from the data bus.

When the port receives data the input fluctuates between high

and low, enabling and disabling the OR gate and preventing port

data transmission.

The OR gate output applies to a driver that transmits data

through the RS-232 or RS-422 interface, depending on the strap

selection of mini-jumpers 1B through 8B. The signal illuminates

the front panel TX LED.

The ninth data port provides a mounting for installing various

communication subassemblies. With the five six-lever DIP

switches, the port supports the following interfaces:

♦TTL

♦RS-232

♦RS-422

♦RS-485

♦202 tone modem

The ninth data port has CA (pin 36) and CF (pin 18) control

leads for RS-232 subassembly applications.

When using a tone modem subassembly, strap C may be config-

ured to allow modem control by RTS command or strapped for

RTS always enabled. Use strap D for full- or half-duplex opera-

tion. When the strap is in the 1 position, the port operates in

full-duplex mode; when in the 2 position, the port operates in

half-duplex mode.

When the ninth data port is used with a bypass card subassem-

bly, front panel LEDs indicate RXD (receive data) and TXD

(transmit data) activity. When the ninth port is used with any

other communications subassembly, module and subassembly

LEDs indicate receive and transmit activity. Refer to the subas-

sembly documentation for LED operation information.

The 46034 Hubbing Module has an on-board power supply that

operates on -21 to -56 VDC input power. The unit supplies

±12 VDC and +5 VDC that powers the module circuits and an

on-board subassembly.

CIRCUIT DESCRIPTION

PAGE 4 46034-0997<90-00030>

CIRCUIT DESCRIPTION

FIG. 1 - 46034 HUBBING MODULE FUNCTIONAL SCHEMATIC

TX+

+5 VDC

1

49

50

47

48

45

46

A

B

C

D

E

F

REF

RXD

RX1

TX1

1

RS-232

+5 VDC

REF

STRAP 1A-8A

2RS-422

3

1

4

3

RX1 +

RS-232 RS-422

Input

Data

Port

Data Port 1 S22 1-8

RS-232

12

2

TX1 +

Strap 1B-8B

RS-422

Output

Data

Port

+5 VDC

TDX

+5 VDC

TX-

CA

RX+

RX-

CF

54

53

36

56

55

18

RXD

TXD

CTS

RTS

DCD

DTR

DSR

1

2

Strap D

Strap

C

2

+5 VDC

-12 VDC

+12 VDC

RXD

TXD

CTS

RTS

DCD

39

41

43

42

40

-21 to -56

VDC

35

17

TTL

PORT

RX1 -RD1

TD1

TX1 -

Data

Port

9

(Subassembly)

Refer to Fig 8 in

Installation

Section for

specific

pin usage

Power

Supply

Note: Data ports

2 thru 8 are identical

in operation to port 1

(pins 5-16, 19-34)

Bypass

Card

or Subass'y

Modem,

Current

Loop

Etc.

DATA

DATA

DATA

DATA

DATA

DATA

TTL

PORT

46034-0997<90-00030> PAGE 5

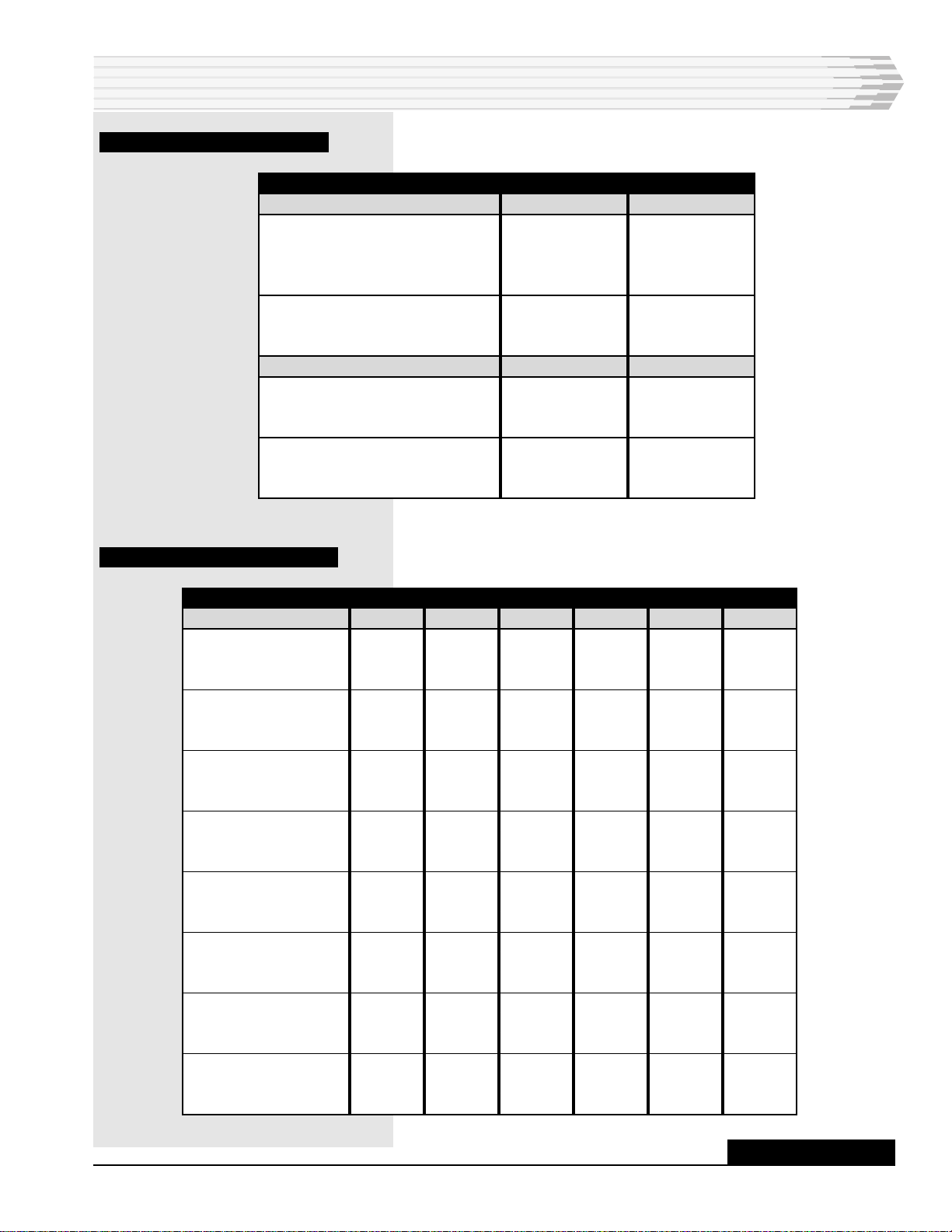

TABLE A - PC PIN ASSIGNMENT FOR RS-422 PORTS

CIRCUIT DESCRIPTION

PORT NUMBER

1

2

3

4

5

6

7

8

RS-422 TX+

Pin 2

Pin 6

Pin 10

Pin 14

Pin 20

Pin 24

Pin 28

Pin 32

RS-422 TX-

Pin 1

Pin 5

Pin 9

Pin 13

Pin 19

Pin 23

Pin 27

Pin 31

RS-422 RX+

Pin 3

Pin 7

Pin 11

Pin 15

Pin 21

Pin 25

Pin 29

Pin 33

RS-422 RX-

Pin 4

Pin 8

Pin 12

Pin 16

Pin 22

Pin 26

Pin 30

Pin 34

TABLE B - PC PIN ASSIGNMENT FOR RS-232 PORTS

PORT NUMBER

1

2

3

4

5

6

7

8

RS-232 TD

Pin 2

Pin 6

Pin 10

Pin 14

Pin 20

Pin 24

Pin 28

Pin 32

RS-232 RD

Pin 4

Pin 8

Pin 12

Pin 16

Pin 22

Pin 26

Pin 30

Pin 34

PAGE 6 46034-0997<90-00030>

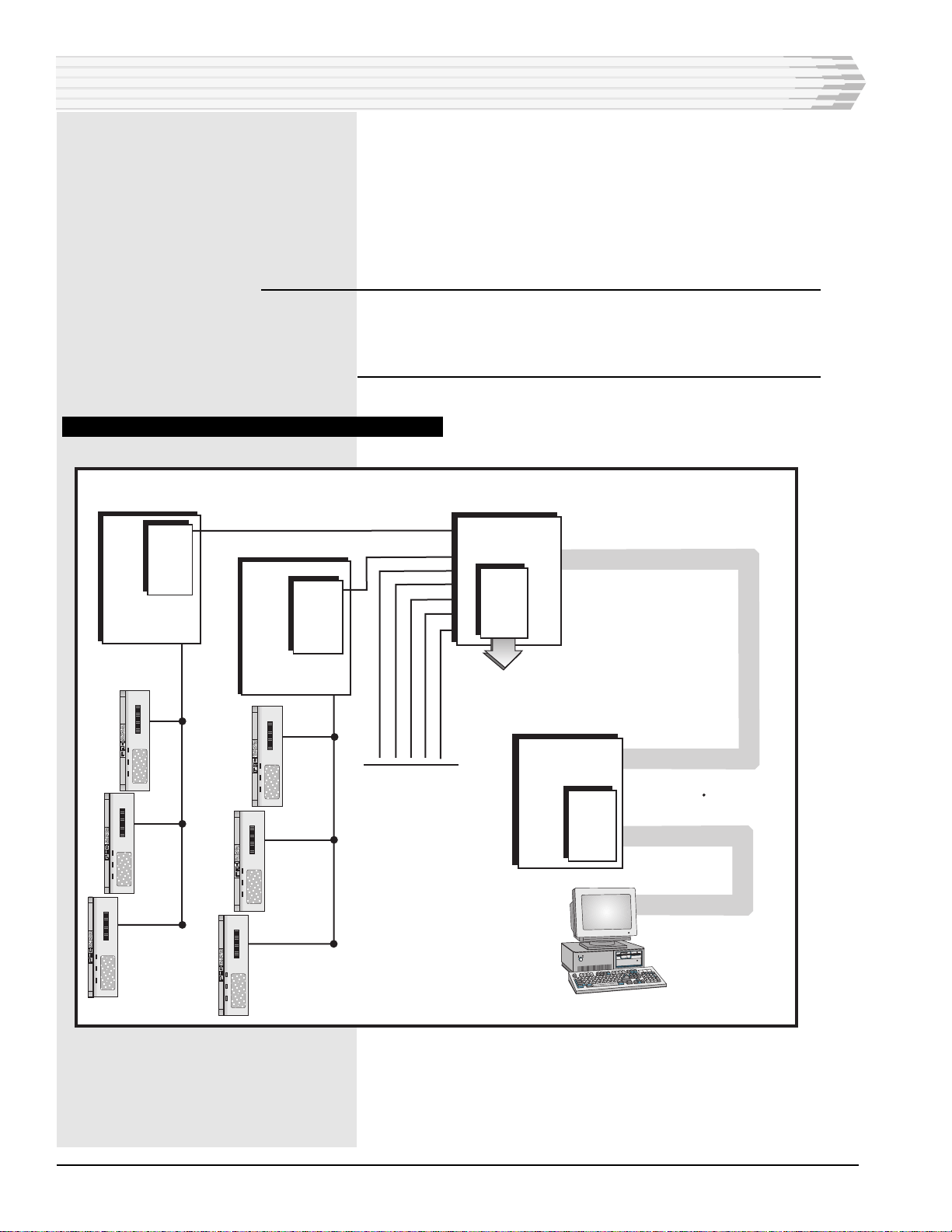

APPLICATION INFORMATION

Fig. 2 shows a 46034 Hubbing Module application diagram.

The 46034 Hubbing Module is used primarily with Dantels

460 Alarm and Control System (460 ACS) and provides digital

data summing, distribution and bridging for the 460 ACS data

polling function. The unit can also be used with an on-board

subassembly for other data communications features such as a

modem or current loop interface.

Note: Use each of the six buses carrying data between the data

communication ports for one data polling system only. If more

than one alarm polling systems data routes to a bus, the

system does not function properly.

FIG. 2 - 46034 HUBBING MODULE APPLICATION DIAGRAM

46020

Multple Alarm

Processor

Comm.

Subass'y

(RS-232) Master Port

Data Port (TTL)

46034

Hubbing

Module

Floor 1

46030

Control Point

Module

(CPM)

Floor 2

46030

Control Point

Module

(CPM)

Floor 3

To / From Other

CPM's

Comm. Subass'y

MAT

MAT

MAT

MAT

Alarm Center

RS-422

RS-422

Local Site

(At Building)

49008

Comm.

Subass'y

49008

Comm.

Subass'y

Comm.

Subass'y

To / From

Remote Sites

MAT

MAT

46034-0997<90-00030> PAGE 7

APPLICATION INFORMATION

SUMMING AND DISTRIBUTION APPLICATIONS

Fig. 3 shows a switch setting diagram for summing applications.

Each data port to be summed has its bus output switched to the

bus. The data port that is to receive the summed data from the

contributing data ports has only its bus input switched to the

bus. The switches also can be set for distribution of communica-

tions using a common data bus. The input from one port distrib-

utes to the output of the other ports.

The modules data communication buses route to the edge

connector which allows for bus expansion (pins 45 through 50).

Additional 46034 Hubbing Modules can share any or all of the

same buses which provides data summing/distribution/bridging

between data ports in different modules.

BRIDGING APPLICATIONS

Fig. 4 shows a switch setting diagram for bridging applications

using half-duplex communication. Each data port on the data

bridge must have bus input and output switches set to the bus

being used. Because each data ports bus input and output feed

to a common OR gate, the data port putting data on the bus

cancels its own input at the OR gate.

Fig. 5 shows a switch setting diagram for an RS-232 bridging

application using full-duplex communication. Module strapping

lets each data port provide either an RS-232 or RS-422 data

interface to the six data buses.

When strapped for RS-422 data, each of the eight data ports

receives and transmits data. When strapped for an RS-232

interface, two data ports may be required for each interface,

which limits the functioning data ports to four (not including

port nine). If CF and CA leads are not used, all eight ports are

available.

PAGE 8 46034-0997<90-00030>

APPLICATION INFORMATION

DIP Switch S1

All Switches=Off

Data Ports 4 through 8 are treated the same

as 1, 2 and 3 shown above strapped for RS-422

DIP Switch S9-4=On

All Others=Off

DIP Switch S2-4=On

All Others=Off

DIP Switch S10

All Switches=Off

DIP Switch S3-4=On

All Others=Off

DIP Switch S11

All Switches=Off

49

50

47

48

45

46

A

B

C

D

E

F

REF

7

8

3

21

+5 VDC

RX1

S22-7

TX1

12

6

5

Strap 1B - 8B

REF

11

12

3

21

+5 VDC

RX1

S22-6

TX1

12

10

9

Strap 1B - 8B

REF

3

4

3

21

+5 VDC

RX1

S22-8

TX1

12

2

1

Strap 1B - 8B

DATA

DATA

DATA

DATA

DATA

DATA

RS-232

RS-422

RS-232

RS-422

RS-232

RS-422

RS-232 RS-422

RS-232

RS-422

RS-232 RS-422

+5 VDC

Buses A-F

To Other

Data Ports

Data

Port

1

(Summed

Output)

Input

(NC)

Strap

1A - 8A

Data

Port

2

(Input

Only)

Input

Strap

1A - 8A

Data

Port

3

(Input

Only)

Input

Strap

1A - 8A

Output

(NC)

Output

(NC)

TTL PORT

FIG. 3 - SWITCH SETTING DIAGRAM FOR SUMMING APPLICATIONS

46034-0997<90-00030> PAGE 9

APPLICATION INFORMATION

DIP Others=Off

Data Ports 1 and 2 are shown strapped for RS-422

as examples. all other Data Ports are treated similarly

DIP Switch S9-1=On

All Others=Off

DIP Switch S2-1=On

All Others=Off

DIP Switch S10-1=On

All Switches=Off

49

50

47

48

45

46

A

B

C

D

E

F

REF

7

8

3

21

+5 VDC

RX1

S22-7

TX1

12

6

5

Strap 1B - 8B

3

4

3

21

+5 VDC

RX1

S22-8

TX1

12

2

1

Strap 1B - 8B

RS-232 RS-422

RS-232 RS-422

REF

RS-422 RS-232

RS-422 RS-232

+5 VDC

Buses A-F

To Other

Data Ports

Data

Port

1

Input

Strap

1A - 8A

Data

Port

2

Input

Strap

1A - 8A

Output

Output

DATA

DATA

DATA

DATA

DATA

DATA

TTL

PORT

FIG. 4 - SWITCH SETTING DIAGRAM FOR BRIDGING APPLICATIONS (HALF-DUPLEX)

PAGE 10 46034-0997<90-00030>

APPLICATION INFORMATION

49

50

47

48

45

46

A (BB)

B (BA)

C (CF)

D (CA)

E

F

REF

7

CF 8

3

21

+5 VDC

RX1

S22-7

TX1

12

CA 6

5

Strap 1B - 8B

REF

RX (BB) 4

3

21

+5 VDC

RX1

S22-8

TX1

12

Unused 1

Strap 1B - 8B

RS-232 (2 Data Ports = RS-232 Port)

TX (BA) 2

Input

Only

Switched

To Data

Buses

Input

Only

Switched

To Data

Buses

RX (BB)

TX (BA)

(CF)

(CA)

To External

Equipment

TTL

PORT

DATA

DATA

DATA

DATA

DATA

DATA

+5 VDC

Buses A-F

To Other

Data Ports

Data Port 1 RS232

Strap

1A - 8A

Data Port 2

RS-232

Strap

1A - 8A

Unused

Two ports are required for each RS-232, if the CA and

CF leads are to be used. For bridging application, put

BB and BA on same bus; CA and CF on same bus. For

summing application, put output BB port on BA bus; put

output CA port on CF bus.

17

RS-232 RS-422

RS-232

RS-422

RS-422

RS-232

RS-422 RS-232

FIG. 5 - SWITCH SETTING DIAGRAM FOR RS-232 APPLICATION (FULL-DUPLEX)

46034-0997<90-00030> PAGE 11

INSTALLATION

Installation consists of installing the subassembly, setting the

module straps and switches, wiring the connector, and install-

ing the module in the equipment housing.

1. Install the subassembly.

If a different subassembly is to be installed, remove the three

screws from the subassembly mounting standoffs and carefully

pull the subassembly out of its connections.

If a TTL subassembly (bypass card) was installed, remove the

blue hole plug from the front panel subassembly window.

Install the new subassembly. Refer to Fig. 6. Ensure the subas-

sembly connector pins go into module receptacles J4 and J5. The

subassembly should sit down on the standoffs and the subas-

sembly front panel (except for the TTL subassembly) should

appear straight in the module front panel opening.

Reinstall the screws on the mounting standoffs.

FIG. 6 - SUBASSEMBLY AND POWER SUPPLY LOCATIONS

CONTINUED . . .

Current Loop

or

Tone Modem

Retaining

Screws

Power Supply

Retaining

Screws

PAGE 12 46034-0997<90-00030>

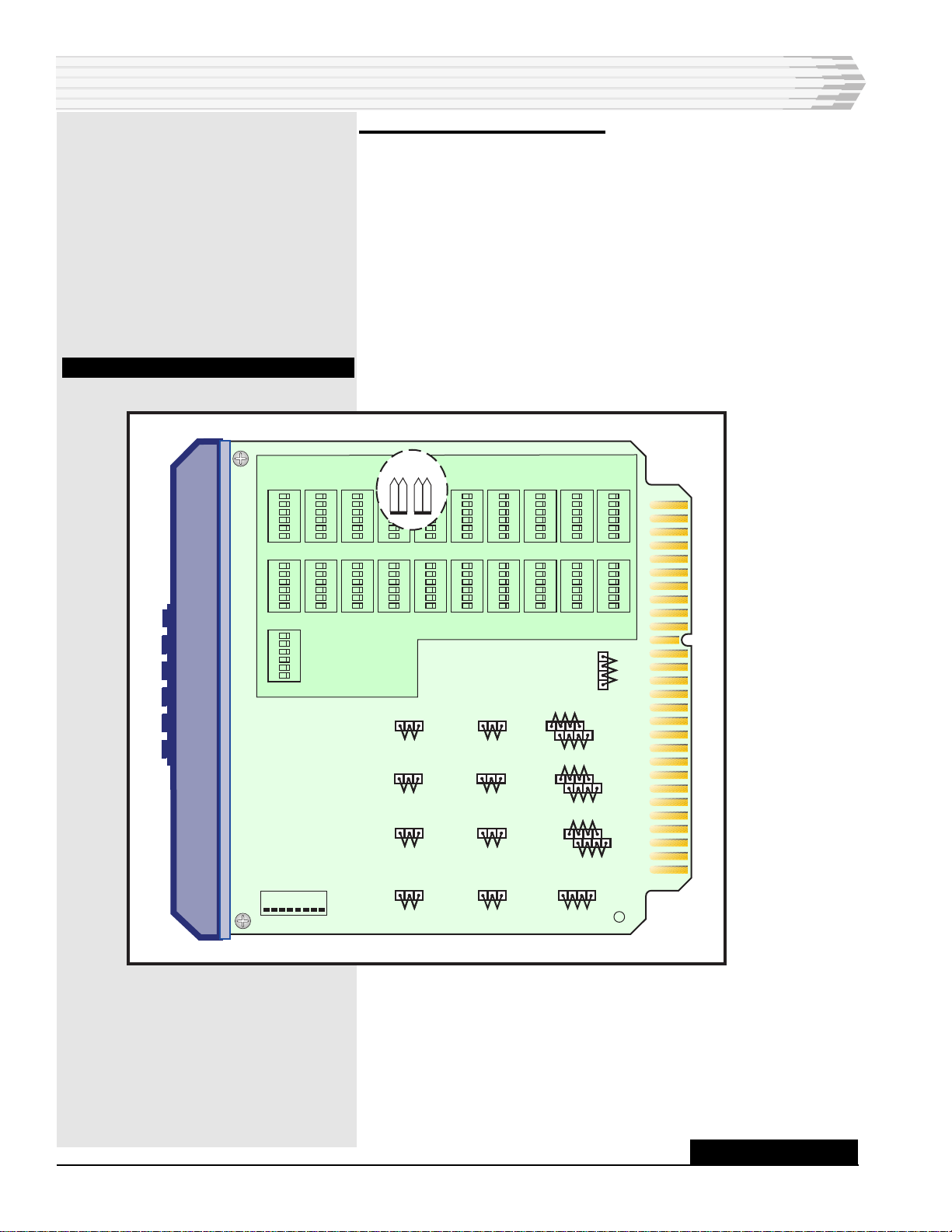

2. Set the straps and switches.

Set the straps by removing the power supply. Remove the three

retaining screws from the subassembly and carefully pull the

subassembly out of its connections.

Once strapping had been verified or corrected, replace the power

supply subassembly by aligning the module connector pins with

the subassembly connector pins. Gently press the power supply

into place. Install the three retaining screws.

Refer to Fig. 7 and Tables C and D for setting straps and

switches.

FIG. 7 - SWITCH AND STRAP LOCATIONS

INSTALLATION

CONTINUED . . .

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

O

123456

ON

123456

O

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

ON

123456

O

S17 S18 S1 XX XX S4 S5 S6 S7 S8

S19 S20 S9 S10 S11 S12 S13 S14 S15 S16

S21

D

1 2

C

1 2

3A 2A

2 1 3

2 1 3

5A 4A

2 1 3

6A

2 1 3

1A

2 1 3

2B

1 2

4B

1 2

6B

1 2

8B

1 2

1B

1 2

3B

1 2

5B

1 2

7B

1 2

3

1

2

S22

1 8

8A

7A

46034-0997<90-00030> PAGE 13

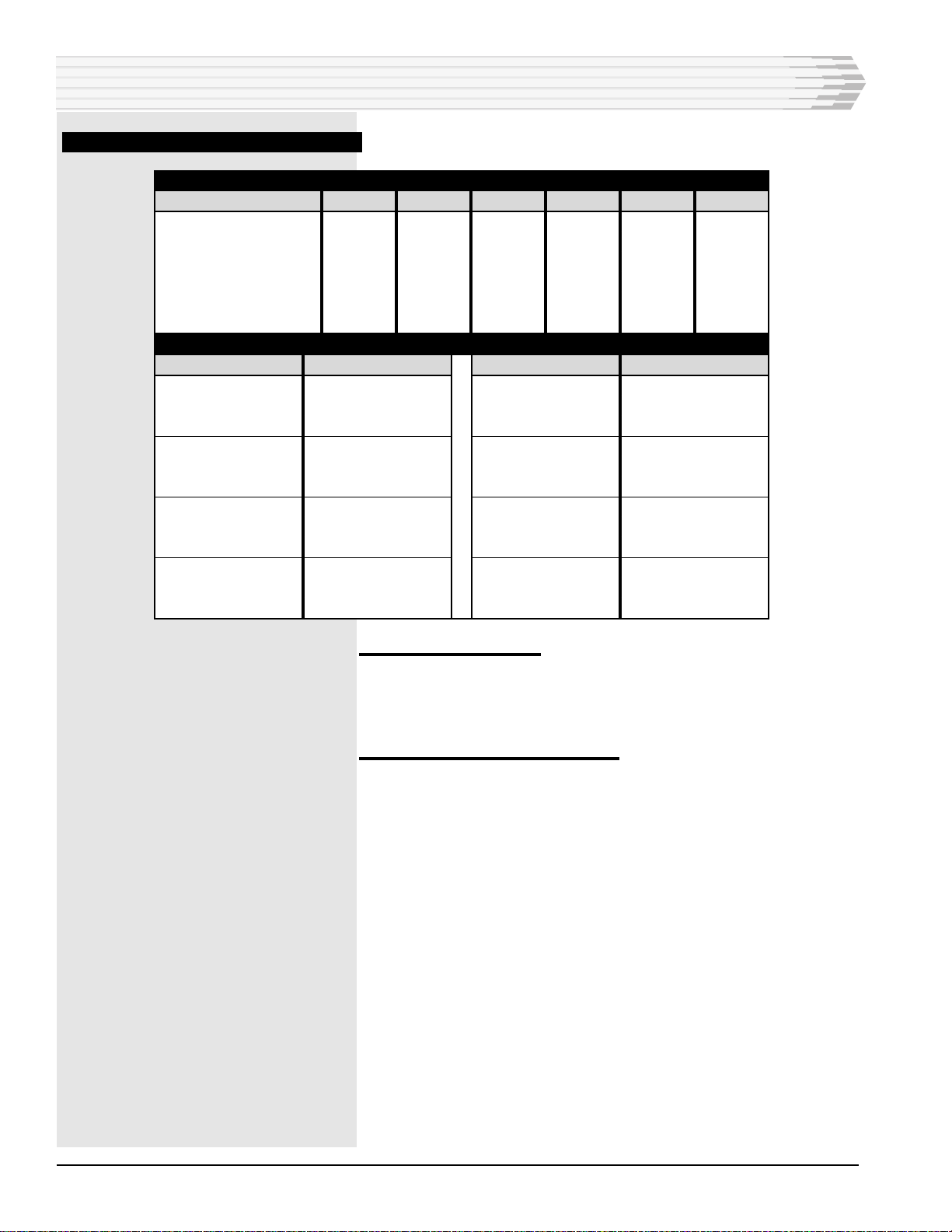

TABLE C - STRAP OPTIONS

TABLE D - SWITCH SETTINGS

INSTALLATION

DATA PORT NUMBER SWITCH

Port 1

Input

Output

Port 2

Input

Output

Port 3

Input

Output

Port 4

Input

Output

Port 5

Input

Output

Port 6

Input

Output

Port 7

Input

Output

Port 8

Input

Output

BUS A

S1-1

S9-1

S2-1

S10-1

S3-1

S11-1

S4-1

S12-1

S5-1

S13-1

S6-1

S14-1

S7-1

S15-1

S8-1

S16-1

BUS B

S1-2

S9-2

S2-2

S10-2

S3-2

S11-2

S4-2

S12-2

S5-2

S13-2

S6-2

S14-2

S7-2

S15-2

S8-2

S16-2

BUS C

S1-3

S9-3

S2-3

S10-3

S3-3

S11-3

S4-3

S12-3

S5-3

S13-3

S6-3

S14-3

S7-3

S15-3

S8-3

S16-3

BUS D

S1-4

S9-4

S2-4

S10-4

S3-4

S11-4

S4-4

S12-4

S5-4

S13-4

S6-4

S14-4

S7-4

S15-4

S8-4

S16-4

BUS E

S1-5

S9-5

S2-5

S10-5

S3-5

S11-5

S4-5

S12-5

S5-5

S13-5

S6-5

S14-5

S7-5

S15-5

S8-5

S16-5

BUS F

S1-6

S9-6

S2-6

S10-6

S3-6

S11-6

S4-6

S12-6

S5-6

S13-6

S6-6

S14-6

S7-6

S15-6

S8-6

S16-6

CONTINUED . . .

OPTION

DATA PORTS 1 THROUGH 8

Receive

RS-232

RS-422 unterminated

RS-422 terminated

Transmit

RS-232

RS-422

COMMUNICATIONS SUBASSEMBLY

Subassembly RTS Select

Command RTS

RTS always ON

Subassembly Duplex Control

Half-duplex

Full-duplex

STRAP

1A through 8A

1A through 8A

1A through 8A

1B through 8B

1B through 8B

C

C

D

D

POSITION

3

1

2

1

2

1

2

2

1

PAGE 14 46034-0997<90-00030>

INSTALLATION

TABLE D (CONTINUED)- SWITCH SETTINGS

3. Wire the connector.

The 56-pin connector is usually prewired at the factory. If you

wire the connector, refer to Fig. 8 for the module connector pin

wiring assignments.

4. Install the module in the shelf.

DATA PORT NUMBER SWITCH

Port 9 (subassembly)

RXD

RTS

TXD

DCD

CTS

BUS A

S17-1

S18-1

S19-1

S20-1

S21-1

BUS B

S17-2

S18-2

S19-2

S20-2

S21-2

BUS C

S17-3

S18-3

S19-3

S20-3

S21-3

BUS D

S17-4

S18-4

S19-4

S20-4

S21-4

BUS E

S17-5

S18-5

S19-5

S20-5

S21-5

BUS F

S17-6

S18-6

S19-6

S20-6

S21-6

DUPLEX ON PORTS 1-8

SWITCH

S22-8 OFF

S22-8 ON

S22-7 OFF

S22-7 ON

S22-6 OFF

S22-6 ON

S22-5 OFF

S22-5 ON

PORT

Port 1

Full-duplex

Half-duplex

Port 2

Full-duplex

Half-duplex

Port 3

Full-duplex

Half-duplex

Port 4

Full-duplex

Half-duplex

SWITCH

S22-4 OFF

S22-4 ON

S22-3 OFF

S22-3 ON

S22-2 OFF

S22-2 ON

S22-1 OFF

S22-1 ON

PORT

Port 5

Full-duplex

Half-duplex

Port 6

Full-duplex

Half-duplex

Port 7

Full-duplex

Half-duplex

Port 8

Full-duplex

Half-duplex

46034-0997<90-00030> PAGE 15

INSTALLATION

FIG. 8 - 46044 HUBBING MODULE PIN DESIGNATIONS

56 55

54 53

52 51

50 49

48 47

46 45

44 43

42 41

40 39

38 37

36 35

34 33

32 31

30 29

28 27

26 25

24 23

22 21

20 19

18 17

16 15

14 13

12 11

10 9

87

65

43

21

CIRCUIT SIDE

OF PC BOARD

COMPONENT SIDE

OF PC BOARD

Subassembly (See table below)

Subassembly (See table below)

Subassembly (See table below)Subassembly (See table below)

Bus ABus B

Bus CBus D

Bus EBus F

CTS

TXDRTS

RXDDCD

-Battery Input (-21 to -56VDC)Subassembly (See table below)

Port 8: RS-422 RX+Port 8: RS-422 RX-; RS-232 RD

Port 8: RS-422 TX-Port 8: RS-422 TX+; RS-232 TD

Port 7: RS-422 RX+Port 7: RS-422 RX-; RS-232 RD

Port 7: RS-422 TX-Port 7: RS-422 TX+; RS-232 TD

Port 6: RS-422 RX+Port 6: RS-422 RX-; RS-232 RD

Port 6: RS-422 TX-Port 6: RS-422 TX+; RS-232 TD

Port 5: RS-422 RX+Port 5: RS-422 RX-; RS-232 RD

Port 5: RS-422 TX-Port 5: RS-422 TX+; RS-232 TD

GroundSubassembly (See table below)

Port 4: RS-422 RX+Port 4: RS-422 RX-; RS-232 RD

Port 4: RS-422 TX-Port 4: RS-422 TX+; RS-232 TD

Port 3: RS-422 RX+Port 3: RS-422 RX-; RS-232 RD

Port 3: RS-422 TX-Port 3: RS-422 TX+; RS-232 TD

Port 2: RS-422 RX+Port 2: RS-422 RX-; RS-232 RD

Port 2: RS-422 TX-Port 2: RS-422 TX+; RS-232 TD

Port 1: RS-422 RX+Port 1: RS-422 RX-; RS-232 RD

Port 1: RS-422 TX-Port 1: RS-422 TX+; RS-232 TD

INTERFACE

RS-422

RS-232

202 Tone

PIN 56

RX+

RD

RCV

PIN 55

RX-

DTR*

RCV

PIN 54

TX+

GND/CTS*

XMT

PIN 53

TX-

TD

XMT

PIN 36

-

RTS

DIST XMT

PIN 18

-

DCD

DIST RCV

* Available for 49029-00 subassembly only.

PAGE 16 46034-0997<90-00030>

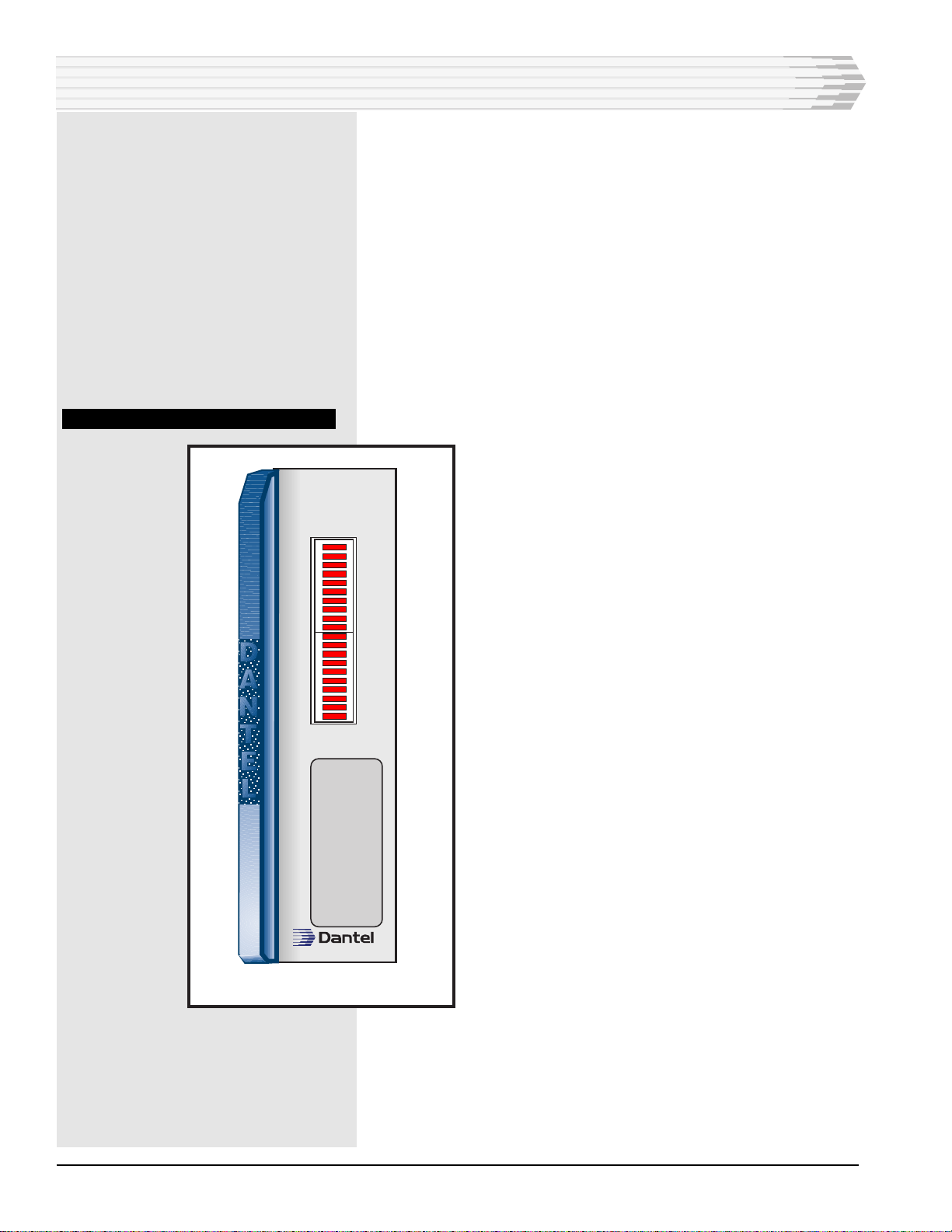

OPERATION

Operation of the 46034 Hubbing Module consists of observing

the 20 front panel LEDs that indicate the activity of all 9

ports. Refer to Fig. 9.

The first eight LEDs, labeled RX1 to RX8 respectively, indicate

receive (RX) activity for data ports one through eight.

The next eight LEDs, labeled TX1 to TX8 respectively, indicate

transmit (TX) activity for data ports one through eight.

The next two LEDs are not labeled and do not function.

The last two LEDs, labeled RXD and TXD, indicate data trans-

mit (TXD) and data receive (RXD) activity for the communica-

tions subassembly (port nine).

FIG. 9 - 46034 FRONT PANEL VIEW

46034-00 REV__

46034-00

HUBBING

MODULE

RX 1

RX 2

RX 3

RX 4

RX 5

RX 6

RX 7

RX 8

TX 1

TX 2

TX 3

TX 4

TX 5

TX 6

TX 7

TX 8

RXD

TXD

46034-0997<90-00030> PAGE 17

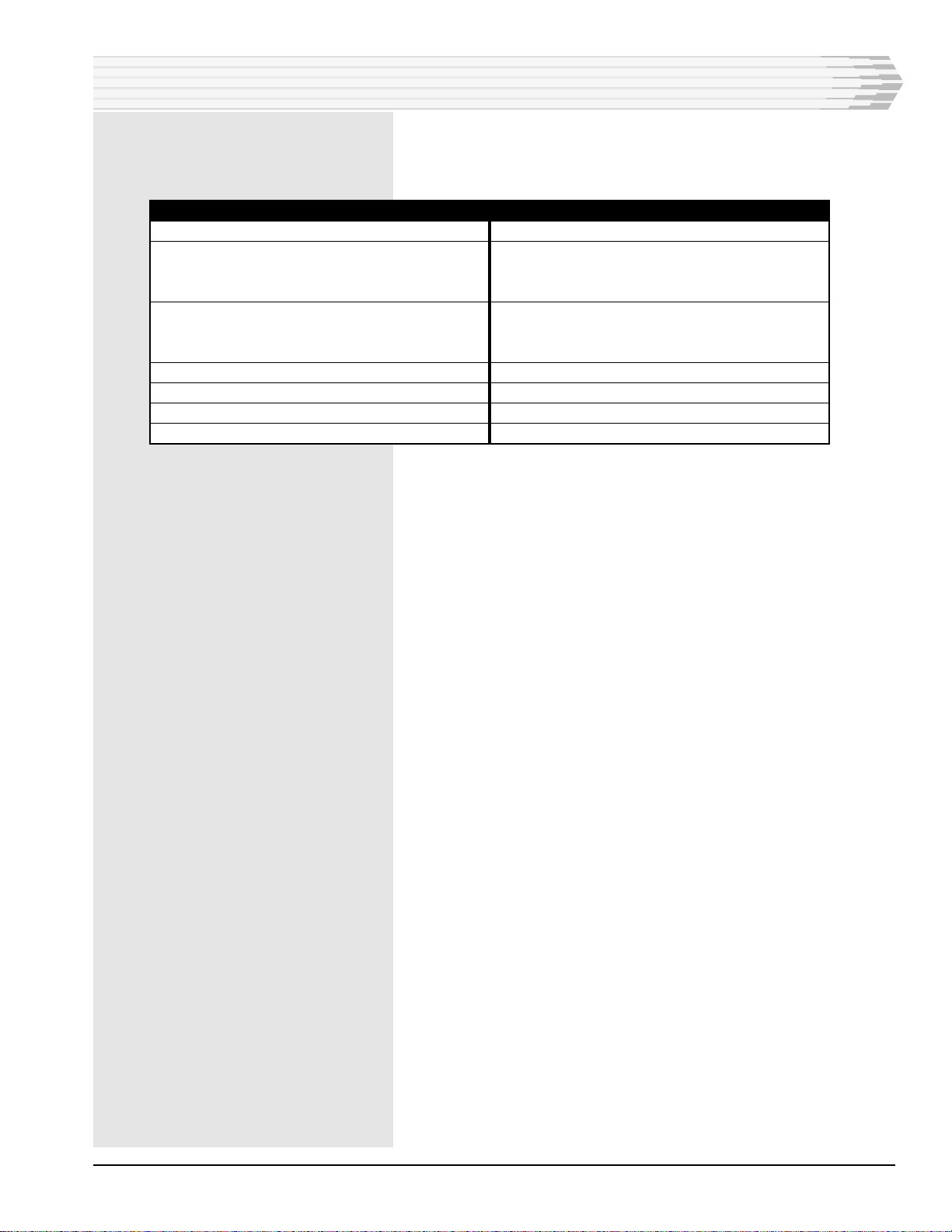

TECHNICAL SPECIFICATIONS

DESCRIPTION

Input Voltage

Input Power (full load; no subassembly)

@ -24 VDC

@ -48 VDC

Heat Dissipation (full load; no subassembly)

@ -24 VDC

@ -48 VDC

Physical Dimensions

Weight

Operating Temperature Range

Data Inputs and Outputs

VALUE

-21 to -56 VDC

64.0 mA

80.0 mA

5.2 BTU/Hr

13.1 BTU/Hr

1.4" x 6.0" x 5.6"

10 ounces

0° to 60° C.

EIA Standards for RS-232 and RS-422

PAGE 18

18 PAGES 46034-0997<90-00030>

LIMITED WARRANTY

The Seller warrants that the standard hardware products sold will be free from defects in material and

workmanship and perform to the Sellers applicable published specifications for a period of 18 months for

hardware, and 3 months for software, from the date of the original invoice. The liability of the Seller hereunder

shall be limited to replacing or repairing, at its option, any defective products which are returned F.O.B. to the

Sellers plant, (or, at the Sellers option, refunding the purchase price of such products). In no case are products

to be returned without first obtaining permission and a customer return authorization number from the Seller.

In no event shall the Seller be liable for any consequential or incidental damages.

Equipment or parts which have been subject to abuse, misuse, accident, alteration, neglect, unauthorized

repair or installation are not covered by warranty. The Seller shall make the final determination as to the

existence and cause of any alleged defect. No warranty is made with respect to custom equipment or products

produced to the Buyers specifications except as specifically stated in writing by the Seller in the contract for

such custom equipment.

This warranty is the only warranty made by the Seller with respect to the goods delivered hereunder, and may

be modified or amended only by a written instrument signed by a duly authorized officer of the Seller and

accepted by the Buyer.

Warranty and remedies on products not manufactured by the Seller are in accordance with warranty of the

respective manufacturer. THE SELLER MAKES NO OTHER WARRANTY OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED; AND ALL IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PUR-

POSE WHICH EXCEEDS THE AFORESAID OBLIGATIONS IS HEREBY DISCLAIMED BY THE SELLER.

INCASE OF DIFFICULTY

If you experience difficulty with this equipment, check the following, as appropriate:

1. Switch settings

2. Signal levels

3. Software configuration

4. Connections between Dantel’s equipment and your equipment.

If there is still a problem, substitute equipment that is known to be good. For additional assistance, call

Dantels Technical Field Service Department weekdays, 6 A.M. to 5 P.M. pacific time:

1-800-4DANTEL (1-800-432-6835).

If a thorough checkout shows a piece of equipment has malfunctioned, you may return it to the factory. For

repairs and emergency replacements, obtain a Return Material Authorization (RMA) number from the Cus-

tomer Service Representative at 1-800-4DANTEL (1-800-432-6835).

To ensure expedient processing of your order, provide a purchase order number and shipping and billing

information when requesting an RMA number. Also, when the units are returned to Dantel, include a descrip-

tion of the failure symptoms for each unit returned. Send defective equipment to:

Dantel, Inc. • 2991 North Argyle Avenue • Fresno, California 93727-1388

P.O. Box 55013 • Fresno, CA 93747-5013 Phone (209) 292-1111 Fax (209) 292-9355 http://www.dantel.com

WARRANTY

This manual suits for next models

1

Table of contents