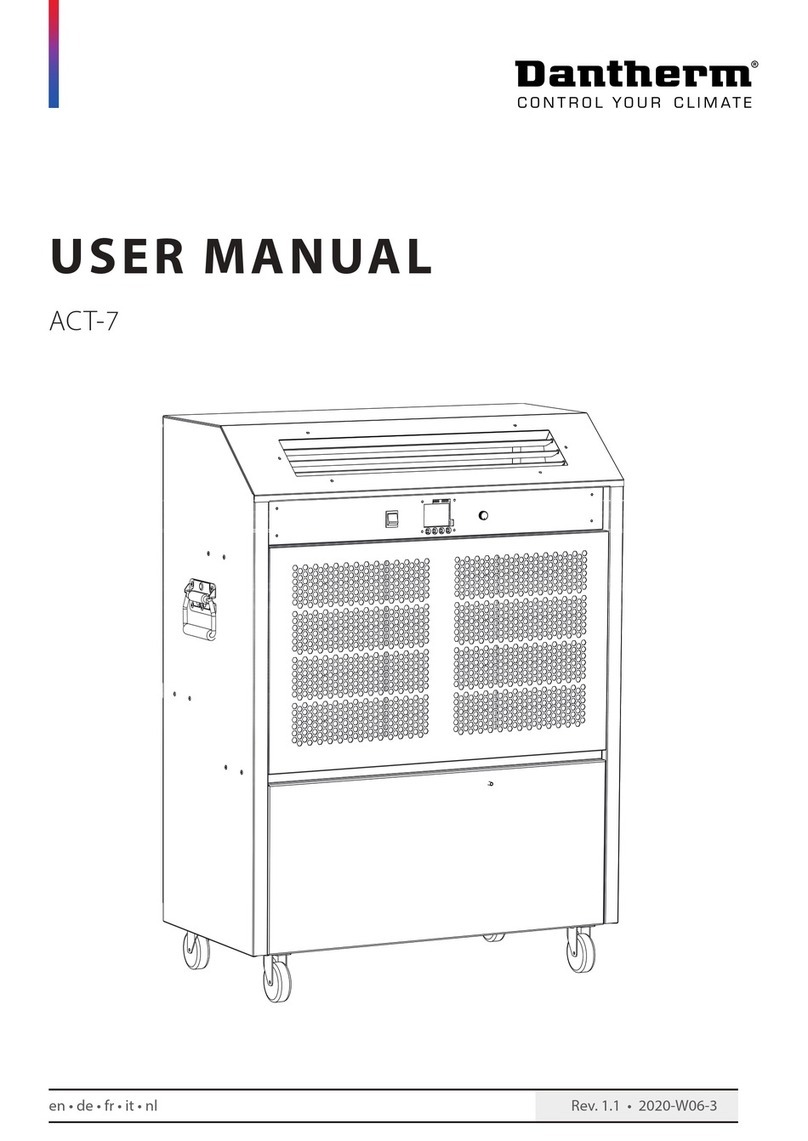

Dantherm 3000 User manual

Other Dantherm Air Conditioner manuals

Dantherm

Dantherm Combo Cooling 10000/1000 User manual

Dantherm

Dantherm Classic 20 CS020020A Dimensional drawing

Dantherm

Dantherm 4000 Series User manual

Dantherm

Dantherm CDT 90 MKII User manual

Dantherm

Dantherm iA/C T-A6000, iA/C T-B6000, iA/C T-B8000 Dimensional drawing

Dantherm

Dantherm CS030040A Dimensional drawing

Dantherm

Dantherm Flexibox 900 User manual

Dantherm

Dantherm Hex 6 A User manual

Dantherm

Dantherm iA/C T Series Quick setup guide

Dantherm

Dantherm DFC 350 User manual

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual