4

Introduction to the Versa Sea Pak 200

Originally developed for ocean voyaging yachts, the Versa Sea Pak 200 Portable Water sys-

tems is both a desalinator and a water purifier developed specifically for the U.S. Military. It is

capable of producing High Quality, Good Tasting drinking water from a variety of water sources

including sea water, river water, lake water, or water from a brackish or contaminated well. It

will effectively separate out salts, organic chemicals, insecticides and pesticides, parasites and

their cysts, bacteria, and viruses from the product water. It does not remove non-ionized

heavy metals.

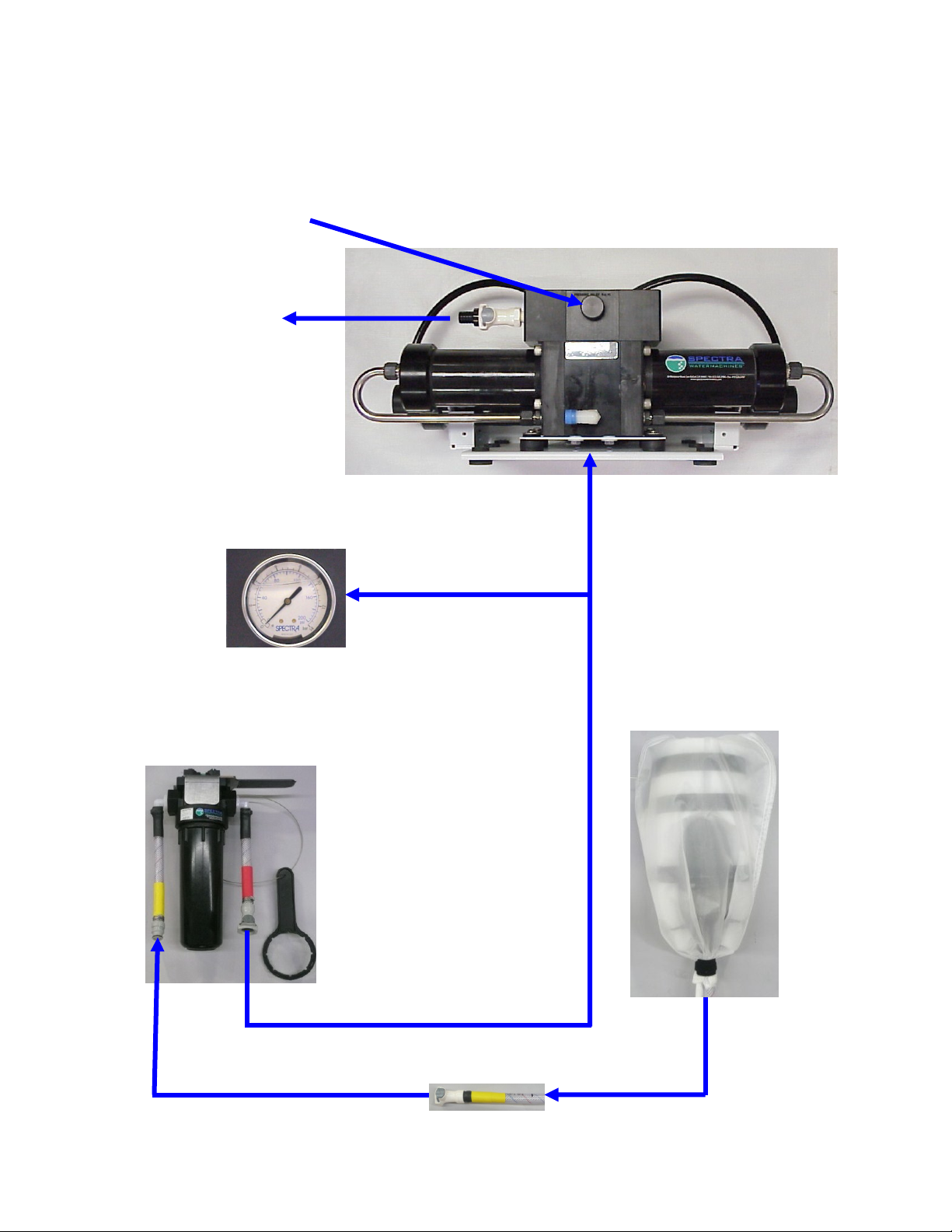

The system pumps approximately 1.5 gallons (6 liters) of feed water per minute to the Re-

verse Osmosis membrane, 10% of this water passes through the membrane as purified prod-

uct water and the remaining 90% is returned to the feed water source as concentrated brine.

The brine contains whatever was separated from the product water by the membrane and

nothing is retained inside the machine.

Feed water is filtered using a two stage process; a bag filter is provided to protect the feed

pump from sand and debris and then the water passes through a 5 micron pre-filter to protect

the hydraulic intensifier and membrane from silt, algae and abrasive particles.

The unit may equipped with a battery and a battery charger or configured to run directly from

AC or DC power sources. If the battery is fresh and fully charged the system can be operated

directly from the battery for two or more hours without an external power source. For longer

run times, an AC extension cord can be connected from any 110 volt power source to charge

the battery while the system is in operation.

In order to prevent damage to the system, the feed water should never contain Chlorine,

Bleach, or any other strong oxidizer, which will damage the membrane. Oil in the feed water

will also damage the membrane.

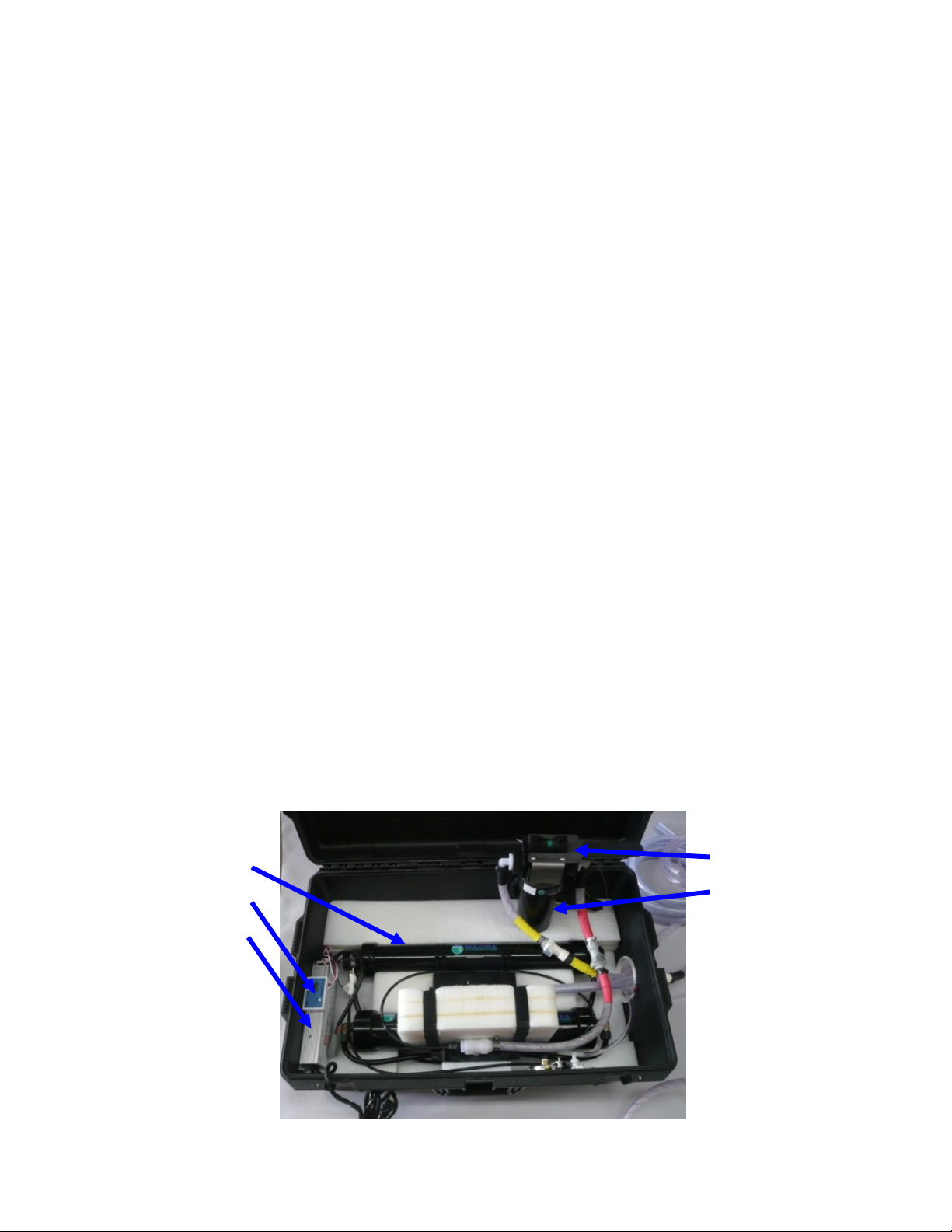

Filter indicator

Pre-Filter

Membrane Housing

Salinity Monitor

AC Power supply