DAS 008641 User manual

Manual

Sectional Door Drive

1

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

TABLE OF CONTENT

General information 2

Safety standards 2

Installation rules 2

General danger warnings and preventive safety 4

Assembly instruction / Fixing the mechanism 4

Emergency manual releases 5

Limit switch setting 6

Star/Delta voltage connection 7

Annual check 7

Technical specifications 8

Technical dimensions 9

Declaration of conformity 9

Manual

Sectional Door Drive

2

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

GENERAL INFORMATION

The gearmotors to which this instruction booklet refers are designed for operating sectional doors

balanced with springs or weights. If these products are to be used for different applications, it is

recommended to first discuss them with the Manufacturer.

The declaration loses its validity if the gearmotor is modified (e.g. wiring reversal).

SAFETY STANDARDS

• This manual contains important instructions and warnings regarding safety. Incorrect installation

may cause serious injury. Before commencing work, all sections of the manual

must be read carefully. If in any doubt, suspend installation and call the DAS Support Service for

clarification.

• This manual contains important instructions. Keep it for future maintenance work and disposal of

the product.

• Under the latest European legislation, automatic door and gate installations must be compliant

with the standards specified in Directive 2006/42/EC (formerly 98/37/EC) (the Machinery Directive)

and the standards EN 12445, EN 12453, EN 12635 and EN 13241-1 in particular, which enable

conformity of the automated functionality to be de cleared. In the light of the above, all work

involving installation, connection, testing and maintenance of the product must be carried out

exclusively by qualified and competent technicians!

INSTALLATION RULES

• Before commencing the installation, check if the product is suitable for the de sired type of use. If it

is not suitable, do not continue with the installation.

• The contents of this manual refer to a standard system.

• All installation and maintenance work must be carried out with the control unit disconnected from

the electricity supply. If the power disconnection device cannot be seen from where the control unit

is positioned, then before starting work a notice must be attached to the disconnection device

bearing the words “CAUTION! MAINTENANCE IN PROGRESS”.

• The Control unit must be connected to an electricity supply line equipped with protective earthing.

• Handle the product with care during installation, taking care to avoid crushing, denting or dropping

it, or contact with liquids of any kind. Keep the product away from sources of heat and naked flames.

Failure to observe the above can damage the product and increase the risk of danger or malfunction.

Should this occur, suspend installation work immediately and contact the DAS Support Service.

Manual

Sectional Door Drive

3

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

• The electrical power line must be fitted with a device that enables complete disconnection of the

automation from the mains. The disconnection device must have a gap between contacts that

ensures complete disconnection in the conditions of overvoltage category III, in compliance with

installation regulations.

• Do not modify any part of the product. Prohibited modifications can only lead to malfunctions. The

manufacturer declines all responsibility for damage resulting from unauthorized changes made to the

product.

• If the gate or door being automated has a pedestrian gate, then the system must include a control

device that will inhibit the operation of the motor when the pedestrian gate is open.

• The product’s packaging material must be disposed of in full compliance with local regulations.

Warnings for use:

• The product is not intended for use by persons, including children, with limited physical, sensory or

mental capacities, or who lack experience or knowledge, unless supervised or trained in the use of

the product by a person responsible for their safety.

• Any children near the automation system must be kept under supervision to ensure that they do

not play with it.

• Do not allow children to play with the fixed control devices. Keep remote control devices out of the

reach of children. The instructions shall contain at least the following information:

• the business name and full address of the manufacturer and, where applicable, his authorized

representative.

• model or type reference of the appliance as marked on the appliance itself, except for the serial

number.

• the designation of the appliance together with its explanation in case it is given by a combination of

letters and/or numbers.

• the general description of the appliance, when needed due to the complexity of the appliance.

• specific precautions if required during installation, operation, adjusting, user maintenance,

cleaning, repairing or moving.

• when needed drawings, diagrams, descriptions and explanations necessary for the safe use and

user maintenance of the appliance.

• the possible reasonably foreseeable misuse and, whenever relevant, a warning against the effects it

may have on the safe use of the appliance.

Manual

Sectional Door Drive

4

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

The words “Original instructions” shall appear on the language version(s) verified by the

manufacturer or by the authorized representative. When a translation of the original instructions has

been provided by a person introducing the appliance on the market; the meaning of the sentence

“Translation of the original instructions” must appear in the relevant instructions delivered with the

appliance. The instructions for maintenance/service to be done by specialized personnel, mandated

by the manufacturer or the authorized representative may be supplied in only one Community

language which the specialized personnel understand.

The instructions shall indicate the type and frequency of inspections and maintenance required for

safe operation including the preventive maintenance measures.

GENERAL DANGER WARNINGS AND PREVENTIVE SAFETY

According to the VDE 0113 booklet, the emergency stop devices must also be perfectly efficient

regardless of the gearmotor operation mode. Any release of the emergency stop device must not

cause an uncontrolled or undefined restarting.

OVERTURNING MOMENT: The fall of the balanced door wings by weights can be avoided if the

gearmotor is still able to support the wing weight even if the spring breaks.

This provision is based on the regulations of the National Insurance Institute for Industrial Accidents

BGR 232. The static overturning moment is the maximum load allowed for the mechanism at the

time the spring breaks. The Mstat static overturning moment is calculated with the following

formula:

Mstat [Nm] = Wing weight [N] × cable winder drum radius [m] Considering that two balancing springs

can yield at the same time, the Commission of experts about building devices recommends sizing the

gearmotor so that it is able to support

- the total weight of the wing when there are one or two springs

- 2/3 of the weight of the wing when there are three springs

- 1/2 of the weight of the wing when there are four springs.

Pursuant to the directives mentioned above, the considerably greater gearmotor breaking load is not

to be contemplated in defining the gearmotor sizing. In the case of cable winder drums of the scalar

type, the greater winding diameter is to be considered.

Consider the allowed forces of the cables!

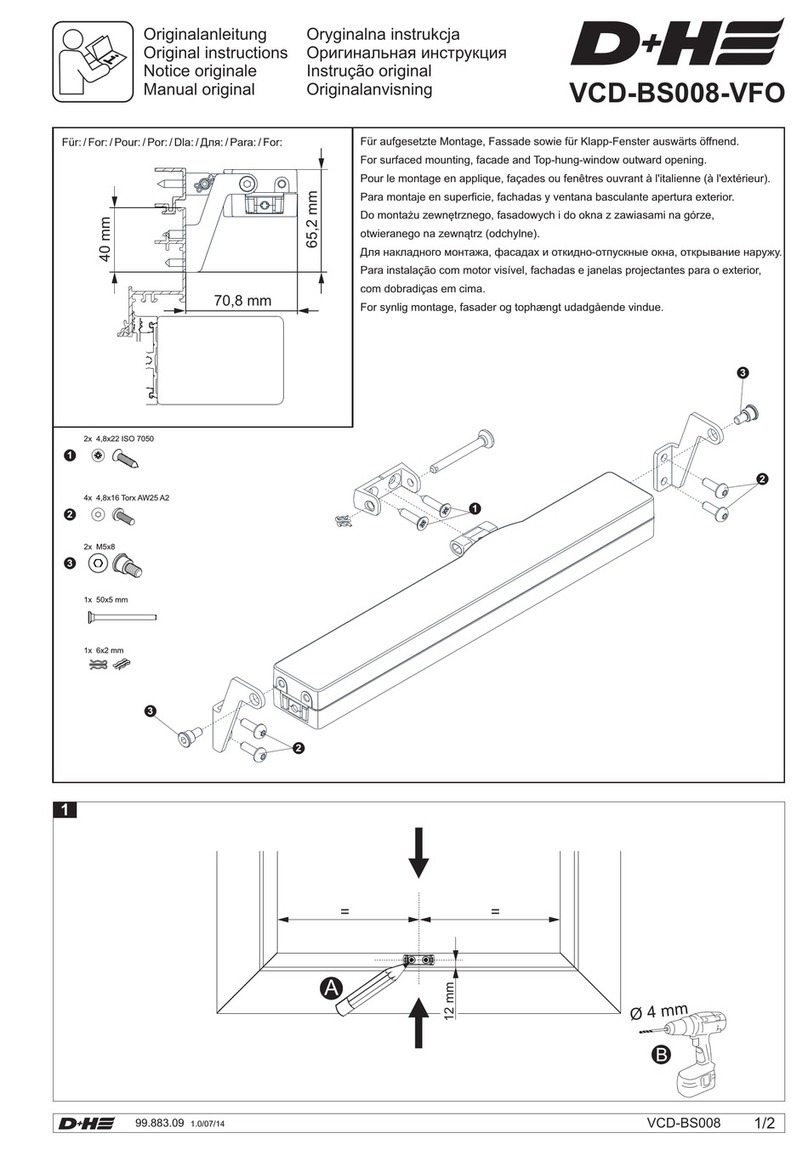

ASSEMBLY INSTRUCTIONS / FIXING THE MECHANISM

Clutch gearmotor

The gearmotor is to be pushed not too forcefully on the relevant part of the previously greased

flexible shaft.

The key (tab) is to be blocked on the through seat of the shaft with 1 screw (or, as an alternative,

with a fixing ring) to prevent accidental movement (Fig. 1).

There are fixing holes (on the bracket) o secure the support (bracket) to the reduction unit flange.

Precise fixing of the support (bracket) is specified in the instructions of the main door (Fig. 2).

Fixing must be performed using 4 M 8x12 screws and the washers supplied. Tightening torque must

be 20 Nm. The support is to be secured on the building side with 2 8/M10 screws.

Manual

Sectional Door Drive

5

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

EMERGENCY MANUAL RELEASES

The manual emergency release is envisaged for opening and closing the door in case of power

failure, so it is to be used only in emergency situations.

- Avoid regular use!!

Warning! Danger of injury in the case of incorrect use!

- Deactivate the main switch before using the manual emergency release.

- The manual emergency release is to be executed only with the motor stopped.

- The manual emergency release maneuver is to be executed from a safe place.

- With a gearmotor equipped with brake (pressure), the main door must be opened and closed with

the brake open (released).

- On doors not balanced with weights, the brake is to be released only for checking purposes with the

door in the low position for safety reasons.

- An undesirable brake release must be prevented with an adequate check (measurement) on site.

The manual emergency release must not move the door beyond the final positions because in this

case the main switch would activate.

Therefore, operation of the door in electrical mode is no longer possible. Handle-operated manual

emergency release (fig. 3)

- Insert the handle exerting moderate pressure, then turn it up to when it clicks in position. In this

way the control voltage is interrupted and the door can no longer be activated electrically.

- Open and/or close the door turning the handle

- The control voltage is reset and the door can again be activated electrically by removing the handle.

Manual chain-operated emergency release (fig. 4 and 9)

- Movement to the right or left activates a microswitch that will cut out the voltage going to the

reduction unit, afterwards the main door can be opened or closed by pulling the chain.

- After releasing the chain, the voltage will be restored and the reduction unit will once again be

operational. Average duration: 200 cycles! Manual chain-operated emergency release 2 (fig. 5a-d)

- Grasp the red handle / manual control (1) and softly pull until stopping to interrupt the control

voltage, and therefore prevent activation of the door in electric mode.

- Open and/or close the door with the emergency release chain (2)

- Grasp the green handle /motor control (3) and softly pull until stopping to restore the control

voltage, and therefore once again consent operation of the door in electric mode.

Average duration: 350 cycles! Interlocking release (fig. 6)

- Pull the red cable to release the gearmotor.

- Manually move the door upwards or downwards.

- Pull the green cable to once again lock the gearmotor.

Modification of the length of the emergency release chain (fig. 7)

- The emergency release chain opens in the connection point and therefore can be extended or

shortened by adding or removing links.

- The links must be carefully bent.

- When the emergency release chain length is modified, it is necessary to pay attention

WARNING: Max. chain length: 14 meters - max. assembly height 8 m!!!

NOTE: with chains having lengths min. 15 meters it is necessary to use the “2” chain release.

Manual

Sectional Door Drive

6

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

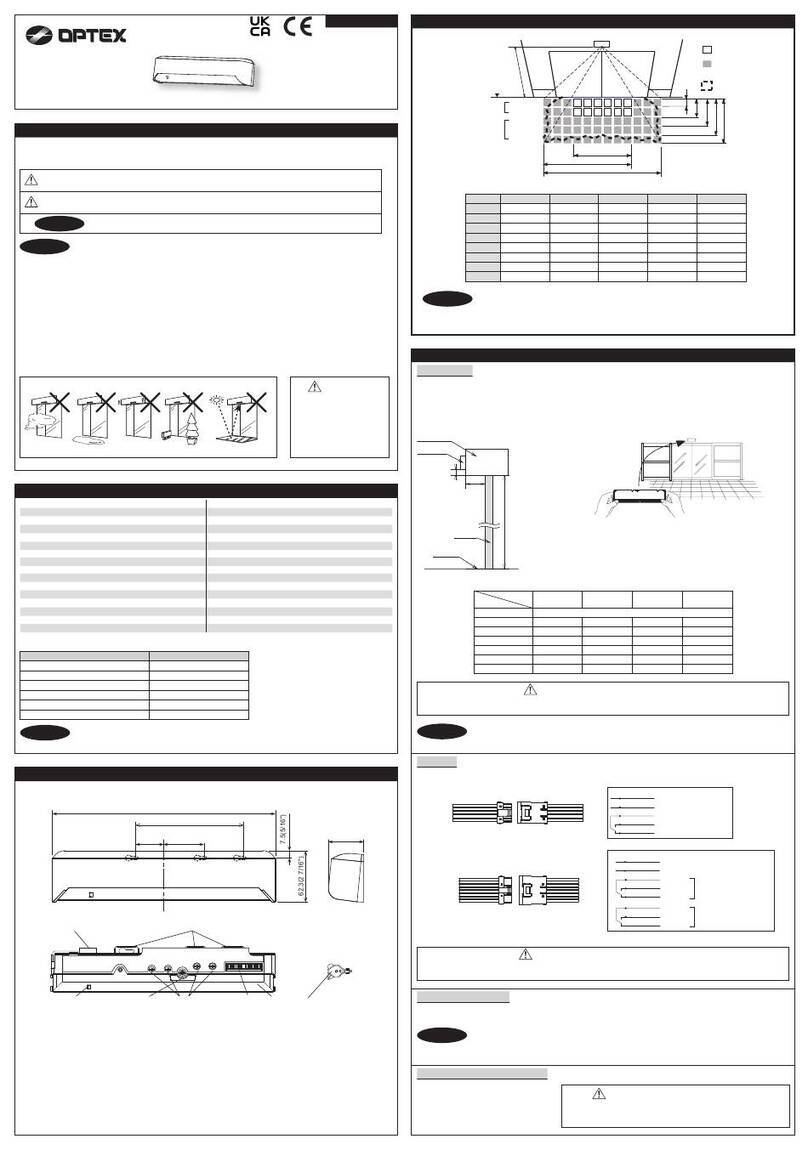

LIMIT SWITCH SETTING

The door must be balanced in all positions when assembling and balancing with the weights

according to the procedures prescribed by the standards. Correct balancing is ascertained by

manually opening and closing the door with identical activation force in both directions.

The Evotronix magnetic limit switch is a positioning switch with absolute value for rolling shutters,

doors and main doors. The assessment, or setting, of the final positions is carried out with

gearmotors for doors.

During assembly simply insert the six-pole plug. Mechanical settings and positionings are not needed.

The terminals for the safety chain (safety switch) are respectively located on the Evotronix magnetic

limit switch. See following picture:

Manual

Sectional Door Drive

7

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

STAR/DELTA VOLTAGE CONNECTION

Warning! Danger of death due to electric shock.

Before starting the assembly operations, exclude the voltage from the conductors and check that

they are equal to zero.

The commutability of the motor voltage makes it possible to use the gearmotor on both a 3 x 400 V

and 3 x 230 V power grid.

The motor is wired in the factory with star connection for a 3 x 400 V power grid.

For connection to a 230 V power grid, switch the motor onto a delta connection.

To commute the voltage onto the motor, wire the ends of the windings as illustrated in fig. 13-16.

When fixing the motor cables, pay attention that the cables are long enough to consent solid fixing,

to create a connection able to remain secure over time.

Pull the conductors to check if the connection is secure.

When switching over the motor for connection to a 3 x 230 V power grid, it is necessary to also adjust

the gearmotor.

3x 230V 3x 400V (default)

ANNUAL CHECK

BGR 232 directive “Windows, doors and main doors with mechanical operation” is applied. It can be

obtained from the National Insurance Institute for Industrial Accidents of your trade association or

from us on request.

Maintenance interventions on windows, doors and main doors with mechanical operation must be

performed only by personnel authorized by the company, having the necessary experience and

skills (BGR 232).

Manual

Sectional Door Drive

8

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

Information for whoever carries out the checks

Gearmotor:

The mechanism is maintenance free and it is provided with permanent lubrication. Absolutely no rust

must form on the output shaft.

Fixings:

Make sure that the fixing screws are all in the correct position and in perfect condition.

Balancing by weights (e.g. in the sectional main doors):

The door must be balanced in all the positions (see the door assembly instructions) when balancing is

done with weights according to the procedures prescribed by the standards.

Brake (if present):

During the annual check perfect brake operation is to be ascertained.

In the case of heavy wear of the brake pads, it is necessary to replace the complete brake. Before

replacement, disconnect the cables connected to the electric card.

TECHNICAL SPECIFICATIONS

NOTE: all the technical characteristics indicated refer to a temperature falling between -5°C and

+40°C. • DAS reserves the right to change all the modifications to the product it deems necessary at

any time but keeping the functions and intended use unaltered.

We recommend using 20 rpm gearmotors for doors with vertical movement with conical cable

winder drum.

For non-balanced sectional doors, we recommend using RDF series gearmotors with parachute

device.

When assembling gearmotors with 31.75 mm diameter shaft from the left, the tab is to be blocked

only with a shoulder collar because fixing with a screw could break the shaft.

Manual

Sectional Door Drive

9

DAS –Deutsche Antriebs und Steuerungstechnik GmbH

Otto-Hahn-Str. 3 •48301 Nottuln •Germany

info@das-automation.com

TECHNICAL DIMENSIONS

Table of contents

Popular Door Opening System manuals by other brands

DITEC

DITEC DAS107PLUS user manual

Assa Abloy

Assa Abloy Corbin Russwin DC6210 Series installation instructions

Assa Abloy

Assa Abloy Norton 6300 Series Installation and instruction manual

Eurospec

Eurospec XDB5760SV quick guide

Overhead door

Overhead door RMX DRAWBAR manual

DSC

DSC PG8949 installation instructions