FOR ASSISTANCE CALL 1-800-275-6187 2.1

Section 2: Safety Information & Instructions

1. Read manual and warnings carefully.

2. Keep the door in good working

condition. Periodically lubricate all

moving parts of door.

3. If door has a sensing edge, check

operations monthly. Make any necessary

repairs to keep it functional.

4. AT LEAST twice a year, manually

operate door by disconnecting it from

the operator. The Door should open and

close freely. If it does not, the door must

be taken out of service and a trained

service representative must correct the

condition causing the malfunction.

5. The Operator Motor is protected against

overheating by an internal thermal

protector. If the operator ceases to

function because motor protector has

tripped, a trained service technician

may need to correct the condition which

caused the overheating. When motor has

cooled, thermal protector will

automatically reset and normal

operation can be resumed.

6. In case of power failure, the door can be

operated manually by pulling the release

cable to disconnect the operator drive

system.

7. Keep instructions in a prominent

location near the pushbutton.

WARNING

Overhead Doors are large, heavy objects that move with the help of springs under high tension and electric motors. Since

moving objects, springs under tension, and electric motors can cause injuries, your safety and the safety of others depend on

you reading the information in this manual. If you have any questions or do not understand the information presented, call

your nearest service representative. For the number of your local Overhead Door Dealer, call 800-929-3667, and for Overhead

Door Factory Technical Advice, call 800-275-6187.

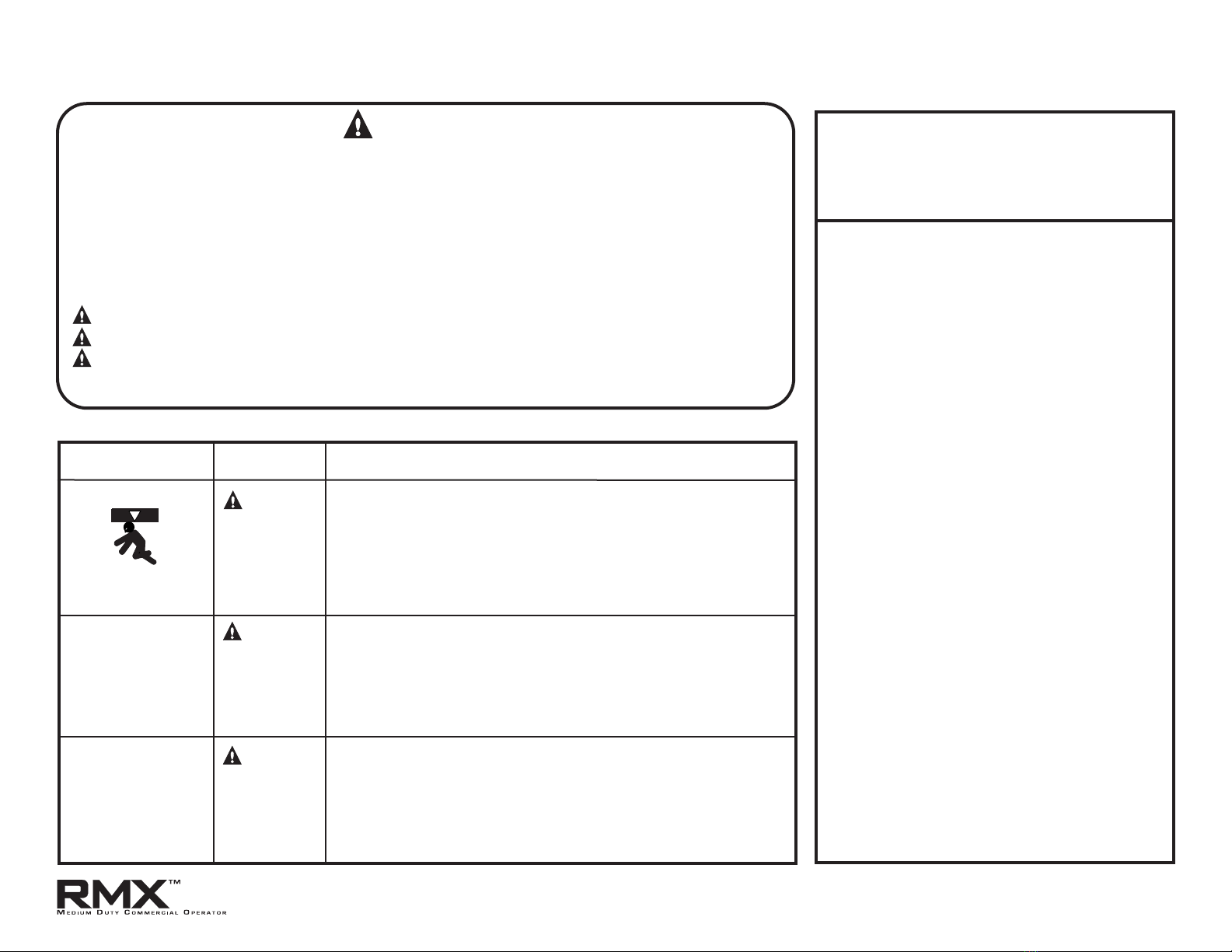

In this Section and those that follow, the words Danger, Warning, and Caution are used to stress important

safety information.The word:

:

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in injury or property damage.

The word NOTE is used to indicate important steps to be followed or important considerations.

POTENTIAL EFFECT PREVENTION

HAZARD

MOVING DOOR

Do Not operate unless the doorway is in sight and free of

obstructions. Keep people clear of opening while door is moving.

Do Not allow children to play with the door operator.

Do Not change operator control to momentary contact unless an

external reversing means is installed.

Do Not operate a door that jams or one that has a broken spring

Could result

in Serious

Injury

or Death

Turn off electrical power before removing operator cover.

When replacing the cover, make sure wires are not pinched or

near moving parts.

Operator must be electrically grounded.

ELECTRICAL

SHOCK

Do Not try to remove, repair or adjust springs or anything to

which door spring parts are fastened, such as, wood block,

steel bracket, cable or any other structure or like item.

Repairs and adjustments must be made by a trained service

representative using proper tools and instructions.

HIGH SPRING

TENSION

Could result

in Serious

Injury

or Death

Could result

in Serious

Injury

or Death

IMPORTANT

READ PRIOR TO ANY DOOR OPERATION

WARNING

WARNING

WARNING

07/30/09