Data Flow Systems TCU800 User manual

T C U 8 0 0

Quick Start Guide

Data Flow Systems, Inc.

NOTICE

Data Flow Systems, Inc. assumes no responsibility for any errors that may appear in this document, nor

does it make any commitment to update the information contained herein. However, questions regarding

the information contained in this document are welcomed.

Data Flow Systems, Inc. also reserves the right to make changes to the specifications of the Telemetry

Control Unit and to the information contained in this document at any time without notice.

© Data Flow Systems, Inc.

605 N. John Rodes Blvd., Melbourne, FL 32934

Phone 321-259-5009

Fax 321-259-4006

www.dataflowsys.com

DFS-00540-011-01

This document last updated October 29, 2020.

2

This document provides a brief overview of the TCU’s features and sufficient information to get the unit

mounted and powered in pump controller mode. Throughout this manual, the name “TCU” will refer to

specifically the TCU800 and NOT its predecessor the TCU001.

Detailed information on wiring the I/O, and configuring and using the TCU800 can be found in the TCU800

Installation and Operation Manual (see DFS website for the PDF version of this manual).

This quick start guide and other manuals can be found on Data Flow Systems’ web site at

www.dataflowsys.com.

This information is provided for qualified personnel only.

Improper installation, service, or maintenance can cause property damage, injury, or death.

Read the installation and operating instructions thoroughly before installing or servicing

this equipment.

Precautionary measures must be observed when installing, operating, and servicing the

TCU in order to prevent shock from voltages present.

If the TCU is to be installed into an existing control panel, make sure that all breakers are

shut off before starting the installation.

All wiring must conform to federal, state, and local electrical codes.

3

Description

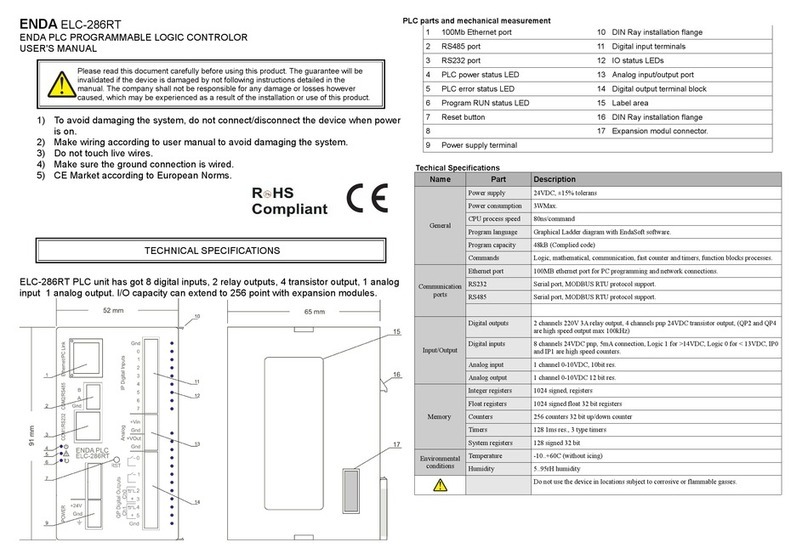

The Telemetry Control Unit (TCU) Model TCU800 is a highly-integrated pump controller running an

embedded Linux operating system. It is designed to be completely backward compatible with its

predecessor (TCU001) while also including additional feature enhancements to expand its operability.

There are several options for using the TCU's multiple input and output points.

• They can be used as non-intelligent I/O by setting the number of pumps to 0.

• They can be used in a pump control application.

• They can be manipulated logically with custom software (much like a PLC).

Additionally, the TCU:

• Can communicate with and manipulate the I/O of up to 15 remote modules via a radio or network

link.

• Can be incorporated into a Remote Terminal Unit (RTU) by using a Bus Extender Module

(BEM).

The installed pump control application program enables the TCU800 to be easily implemented in lift station

or storage tank applications. For a pump control application, the TCU800 contains all the hardware and

software needed to control up to three motor starters.

Placing custom software on the TCU800 enables it to perform a variety of automated tasks when interfaced

with other telemetry equipment (DFS equipment, or RS-485 or RS-232 Modbus compatible devices). When

used as a programmable device, the TCU800 can control up to 6 digital output devices, and monitor up to

18 digital and 4 analog input devices. It also features an expansion card slot on the top side which can be

used to add additional I/O for specialized applications.

The TCU's dual functionality (its ability to use the built-in pump control process or a custom program)

helps reduce overhead by enabling one unit to be used in either a pump control or programmable

application.

Parts List

• TCU800 with integrated radio

• Installation kit

Receipt of Equipment

When the equipment is received, examine the outside of the carton for any damage incurred during

shipment. Remove the packing list and the equipment from the shipping carton. Carefully inspect the

equipment for damage. Resolve any damage with the local carrier. Report damages to Data Flow Systems

via phone at 321-259-5009. Include the serial number of the unit and the extent of damage in your report.

Technical Specifications

• Box Dimensions: 5.75” X 8.75” X 5.45”

• Supply Voltage: 120VAC +/-10%, 60 Hz

• Supply Current: 0.5-1.5A

• Processor Core: AM335x SoC with an ARM Cortex A8 (1GHz) + dual PRU (200MHz); 512MB

DDR3 and 4 GB onboard flash

4

• Internal Phase Monitor: 240 VAC @ 60Hz single- or three-phase; 480 VAC @ 60Hz three-phase

using external resistors

• Battery Backup: 12-volt, sealed, lead-acid battery

• Analog Inputs: (3) 4-20mA @ 250Ω/ 0-5VDC or 0-10VDC @ 120KΩ, 15-bit

4-20mA @ 250Ω, 15-bit precision

• Digital Inputs: (17) 10-30V @ 6KΩ/ 30-300V with external resistors

10-30VDC / pulse input <1000 PPS

• Digital Outputs: (4) Solid State Relays, 120-240VAC @ 60Hz, 1A, Pilot Duty

• Alarm Relays: (2) Electromechanical Relays, 120VAC @ 60Hz, 0.5A / 0-24VDC, 1.0A; NO

(Alarm Horn), NC (Alarm Light)

• Integrated Radio: 2W @ 200 MHz or 5W @ synthesized 400 MHz

• RS-232 Interface: 9600-115200 baud serial interface for Modbus ASCII devices (RTU protocol

option available)

• RS-485 Interface: 9600-115200 baud serial interface for Modbus ASCII/RTU devices

• Ethernet Interface: 10/100base-T

• USB 2.0 (Full Speed): 2 ports external, 1 port internal

• Isolated 24VDC Bias: 300 mA current limited and regulated

• Input Protection: MOV (Metal Oxide Varistor), TVS (Transient Voltage Suppressor), and on-chip

transformer isolation

• 5” TFT LCD w/ capacitive touchscreen and overlay push-button

• H-O-A Switches: 3 x 3-position switches for Hand-Off-Auto operation

• Environmental Conditions:

• Ambient Operating Temperature Range: -10°C to 60°C (14°F to 140°F). The upper

temperature limit is 50°C (122°F) when using the recommended backup battery.

• Relative Humidity: 0-100%

• Atmospheric Pressure: 75-106 KPa

• Overvoltage Category II

• Pollution Degree 2

• Safety Approval: UL listed for Process Control Equipment (UL1092)

Features

• Backward compatibility with Data Flow Systems’ TAC Pack TCU001

• Integrated 10/100 network adapter to allow remote access via SSH client over a local area

network

• Eighteen (18) isolated digital inputs for monitoring level (float switches) or contact closures

• Four (4) 15-bit isolated analog inputs offer enhanced accuracy, range, and increased resolution

• Six (6) digital outputs: Three motor start outputs, one auxiliary output, and two for controlling an

alarm horn/light

• Integrated digital radio (2W, 200 MHz or 5W, 400MHz) is on-site programmable and can run in

legacy (Manchester) or high-speed mode

• ARM based core running Linux Debian allows easy programming and configuration via terminal

• True RMS AC phase monitor produces accurate voltage readings for single- and three-phase

power

5

• RS-485 Modbus fieldbus half-duplex serial interface enables communication with industry

standard devices and VFD motor controllers

• Configurable, auxiliary digital input can be used with pulse-type flow meters and rain gauges

• Standard RS-232 Modbus radio interface acts as an interface to external industry standard radios

• TX/RX/Status LEDs and LCD Touchscreen indicate operating I/O state

• Three fail-safe Hand-Off-Auto (HOA) switches

• Four connectorized wire terminals and USB configuration stick allow servicing or replacement of

the unit without rewiring the control panel

• 5” LCD provides a large area for displaying data, and the LCD's brightness can be changed via

settings and allows for a day- or night-mode display of screens to enhance visibility in either

direct sunlight or at night

• Home button/soft-power switch offers ease of use when powering up/down the TCU

• Self-monitoring capabilities include an ON state self-test and monitoring of radio current and unit

temperature

• For each pump, elapsed run time and average run time meters are provided

• HyperTAC 4 telemetry interface enables operators to remotely monitor off-site conditions and

control equipment from a central location

• Mounting options allow the TCU to be mounted to a front panel, or mounted flush against or

stood off from the back plate of a control panel

• Integrated switching power supply

• Surge protection (non-destructive) and on-board voltage regulation

• Battery backup with external battery (12V, 2.6Ah or 12V, 7.0Ah)

• Can be programmed using ladder logic via DFS’ Virtual Logic Builder

Pin Name / Wiring Definitions

The tables below and on the next several pages provide pin names and descriptions for a TCU using the

built-in pump controller application.

Pin Outs for Pump Controller Application

Top Front Connector: P1 (Pump Controller Mode)

PIN#

Name

Description

Electrical Rating

P1-1

PHASE_C

Phase C of the three-phase power monitor

120-240VAC, 60HZ,

10mA, 3-phase

P1-2

PHASE_B

Phase B of the three-phase power monitor

120-240VAC, 60HZ,

10mA, 3-phase

P1-3

PHASE_A /

PHASE_N

Phase A of the three-phase power monitor in

3-Wire (delta)

Neutral of the three- phase power monitor in

4-Wire (wye)

120-240VAC, 60HZ,

10mA, 3-phase

P1-4

PHASE A

Phase A of the three- phase power monitor in

4-Wire (wye) only.

120-240VAC, 60HZ,

10mA, 3-phase

P1-5

AC_PWR

AC power

120VAC, 60HZ, 0.5-1.5A

P1-6

AC_NEUT

AC neutral

120VAC, 60HZ, 0.5-1.5A

P1-7

TGND

Safety ground (Earth)

Ground

6

P1-8

BAT+

Backup battery positive terminal

<24V / Not Rated

P1-9

BAT-

Backup battery negative terminal

<24V / Not Rated

P1-10

BEMGND

Isolated ground (wire to BEM001, pin 12)

<24V / Not Rated

P1-11

BEM_PWR

Isolated power (wire to BEM001, pin 10)

<24V / Not Rated

P1-12

BEM_CTS

Isolated clear to send (wire to BEM001, pin 6)

<24V / Not Rated

P1-13

BEM_RXD

Isolated receive data (wire to BEM001, pin 4)

<24V / Not Rated

P1-14

BEM_TXD

Isolated transmit data (wire to BEM001, pin 2)

<24V / Not Rated

P1-15

BEM_RTS

Isolated request to send (wire to BEM001, pin

8)

<24V / Not Rated

P1-16

ALM_HORN

Load side of alarm horn relay (NO)

120VAC, 60HZ, 1A,

0-24VDC, 1A

P1-17

ALM_LITE

Load side of alarm light relay (NC)

120VAC, 60HZ, 1A,

0-24VDC, 1A

P1-18

ALM_PWR

Line side of alarm relays

120VAC, 60HZ, 2A,

0-24VDC, 2A

P1-19

AUX_OUT

Load side of auxiliary relay

120-240VAC, 60HZ, 1A,

Pilot Duty

P1-20

AUX_PWR

Line side of auxiliary relay

120-240VAC, 60HZ, 1A

P1-21

MTR3_STR

Load side of motor starter 3 relay

120-240VAC, 60HZ, 1A,

Pilot Duty

P1-22

MTR2_STR

Load side of motor starter 2 relay

120-240VAC, 60HZ, 1A,

Pilot Duty

P1-23

MTR1_STR

Load side of motor starter 1 relay

120-240VAC, 60HZ, 1A,

Pilot Duty

P1-24

STRT_PWR

Line side of motor starter relays

120-240VAC, 60HZ, 3A

Top Rear Connector: P3 (Pump Controller Mode)

PIN#

Name

Description

Electrical Rating

P3-1

C_CT+

C-phase current transformer positive connection

<24V / Not Rated

P3-2

C_CT-

C-phase current transformer negative connection

<24V / Not Rated

P3-3

B_CT+

B-phase current transformer positive connection

<24V / Not Rated

P3-4

B_CT-

B-phase current transformer negative connection

<24V / Not Rated

P3-5

A_CT+

A-phase current transformer positive connection

(wye setup only)

<24V / Not Rated

P3-6

A_CT-

A-phase current transformer negative connection

(wye setup only)

<24V / Not Rated

P3-7

ANALOG3+

0-5VDC or 0-10VDC or 4-20mA signal from

transducer; return signal at P3-8; jump

P3-9 to P3-8 to use as a

4-20mA input

<24V / Not Rated

P3-8

ANALOG3-

- return signal for ANALOG3+ (P3-7)

<24V / Not Rated

P3-9

SHUNT

250Ωshunt resistor; jump to P3-8 to use a

4-20mA signal for ANALOG3+ (P3-7)

<24V / Not Rated

P3-10

ANALOG4+

0-5VDC or 0-10VDC or 4-20mA signal from

transducer; return signal at P3-11; jump P3-12 to P3-

11 to use as a 4-20mA input

<24V / Not Rated

P3-11

ANALOG4-

- return signal for ANALOG4+ (P3-10)

<24V / Not Rated

P3-12

SHUNT

250Ωshunt resistor; jump to P3-11 to use a 4-20mA

signal for ANALOG4+ (P3-10)

<24V / Not Rated

7

P3-13

SHIELD

Internally connected to EARTH; cable shield for

analog monitor signals

Ground

P3-14

IN_COM_3

Common return for thermal and seal failure digital

inputs

10-30VAC/DC,

100mA RTN

P3-15

MTR3_THERM

Motor 3 temperature monitor input

10-30VAC/DC,

10mA

P3-16

MTR2_THERM

Motor 2 temperature monitor input

10-30VAC/DC,

10mA

P3-17

MTR1_THERM

Motor 1 temperature monitor input

10-30VAC/DC,

10mA

P3-18

MTR3_SEAL

Motor 3 moisture seal monitor input

10-30VAC/DC,

10mA

P3-19

MTR2_SEAL

Motor 2 moisture seal monitor input

10-30VAC/DC,

10mA

P3-20

MTR1_SEAL

Motor 1 moisture seal monitor input

10-30VAC/DC,

10mA

Bottom Front Connector: P2 (Pump Controller Mode)

PIN#

Name

Description

Electrical Rating

P2-1

MTR1_RUN

Motor 1 run digital monitor input

10-30VAC/DC,

10mA

P2-2

MTR2_RUN

Motor 2 run digital monitor input

10-30VAC/DC,

10mA

P2-3

MTR3_RUN

Motor 3 run digital monitor input

10-30VAC/DC,

10mA

P2-4

EXT_PM

External phase monitor digital input

10-30VAC/DC,

10mA

P2-5

IN_COM_1

Common return for motor run and external phase

monitor input

10-30VAC/DC,

100mA RTN

P2-6

LOW_LVL

Low Level digital monitor input

10-30VAC/DC,

10mA

P2-7

OFF_LVL

Off Level digital monitor input

10-30VAC/DC,

10mA

P2-8

LEAD_LVL

Lead Level digital monitor input

10-30VAC/DC,

10mA

P2-9

LAG1_LVL

Lag1 Level digital monitor input

10-30VAC/DC,

10mA

P2-10

LAG2_LVL

Lag2 Level digital monitor input

10-30VAC/DC,

10mA

P2-11

HIGH_LVL

High Level digital monitor input

10-30VAC/DC,

10mA

P2-12

AUX_IN

Auxiliary digital monitor input; supports pulse counting

10-30VDC, 10mA

P2-13

ALM_SIL

Alarm Silence Switch digital monitor input

10-30VAC/DC,

10mA

P2-14

IN_COM_2

Common return for input level, aux inputs, and alarm

silence switch

10-30VAC/DC,

100mA RTN

P2-15

ISOGND

Internally supplied 24VDC bias source return (isolated)

<24V / Not Rated

P2-16

ISO+24V

Internally supplied 24VDC bias source voltage

(isolated)

<24V / Not Rated

8

P2-17

TXD_232

RS-232 transmit data to external device

<24V / Not Rated

P2-18

RXD_232

RS-232 receive data from external device

<24V / Not Rated

P2-19

GND

RS-232 ground

<24V / Not Rated

P2-20

SHIELD

Internally connected to EARTH; cable shield for analog

monitor signals

Ground

P2-21

ANALOG2+

4-20mA signal from transducer; - signal at pin P2-23;

internal 250Ωshunt permanently connected

<24V / Not Rated

P2-22

ANALOG1+

0-5VDC or 0-10VDC or 4-20mA signal from

transducer; - signal at pin P2-23; jump pin P2-24 to P2-

23 to use as a 4-20mA input

<24V / Not Rated

P2-23

ANALOG-

- signal return for both ANALOG1+ at P2-22 and

ANALOG2+ at P2-21

<24V / Not Rated

P2-24

SHUNT

250Ωshunt resistor; jump to P2-23 to use a 4-20mA

signal for ANALOG1+ at P2-22

<24V / Not Rated

Bottom Rear Connector: P4 (Pump Controller Mode)

PIN#

Name

Description

Electrical Rating

P4-1

Unused

Reserved for future use; do not connect

Not Connected

P4-2

RS485_GND

RS-485 serial ground reference

<24V / Not Rated

P4-3

RS485_B

RS-485 serial interface B

<24V / Not Rated

P4-4

RS485_A

RS-485 serial interface A

<24V / Not Rated

P4-5

SHIELD

Internally connected to EARTH; Cable shield for

RS-485 or RS-232

Ground

P4-6

EX_GND_RAD

RS-232 signal ground

<24V / Not Rated

P4-7

RTS_RAD

RS-232 Request to send

<24V / Not Rated

P4-8

EX_TXD_RAD

RS-232 transmit data to external device

<24V / Not Rated

P4-9

EX_RXD_RAD

RS-232 receive data from external device

<24V / Not Rated

P4-10

CTS_RAD

RS-232 clear to send

<24V / Not Rated

P4-11

SDI12_GND

SDI-12 return/ground

<24V / Not Rated

P4-12

SDI12_DATA

SDI-12 data

<24V / Not Rated

P4-13

SDI12_PWR

12VDC power supply for SDI-12 bus devices

<24V / Not Rated

P4-14

Unused

Reserved for future use; do not connect

Not Connected

Safety Precautions

Review the following statements before installing, servicing, or replacing the Telemetry Control Unit or

any of its components.

General Precautions

• Only trained and qualified personnel should install, service, or replace this equipment.

• Carefully read the installation and wiring instructions before connecting the TCU to its power

source.

• Do not work on the TCU, or connect or disconnect any of its cables, during periods of lightning

activity.

• To prevent overheating the TCU, do not operate it in an area that exceeds the maximum

recommended temperature of -10°C to 60°C (14°F to 140°F). The upper temperature limit is

50°C (122°F) when using the recommended backup battery.

9

• Ensure that the unit is connected to earth ground during normal use.

• Precautionary measures must be observed when installing, operating, and servicing the TCU in

order to prevent shock from voltages present.

• If the TCU is to be installed into an existing control panel, make sure that all breakers are shut off

before starting the installation.

• All wiring should conform to federal, state, and local electrical codes.

• Read and follow all precautionary procedures that are displayed on TCU’s side-mounted labels.

Working with the TCU

Before working with the TCU, specifically when removal of the unit is necessary, perform the following

steps in the sequence indicated:

1. Power down the unit.

2. Turn off all circuit breakers to the TCU.

3. Ensure that any cables connected to the TCU will not become entangled in or caught on anything in

the surrounding area.

When disconnecting a cable, pull on its connector or on its strain-relief loop, not on the cable itself. Some

cables have a connector with locking tabs; when disconnecting this type of cable, press in on the locking

tabs before disconnecting the cable. When pulling connectors apart, keep them evenly aligned to avoid

bending any connector pins. Also, before connecting a cable, make sure both connectors are correctly

oriented and aligned.

Protecting Against Electrostatic Discharge

Static electricity can harm delicate components inside the TCU. To prevent static damage, put on an

electrostatic discharge wrist strap before touching any of the TCU’s electronic components.

In addition to the preceding precautions, the following steps can be taken to prevent damage from

electrostatic discharge (ESD):

• When unpacking a static-sensitive component from its shipping carton, do not remove the

component's antistatic packing material until ready to install the component in the TCU. Be sure

to put on an electrostatic discharge wrist strap before unwrapping the antistatic packaging.

• When transporting a sensitive component, first place it in an antistatic container or packaging.

• Handle all sensitive components in a static-safe area. Place the equipment on a grounded surface.

If possible, use antistatic floor pads and workbench pads.

Note: Contact DFS if electrostatic discharge packaging is needed for return shipments. See Return

Authorization (RA) Procedure on page 29 for more information on returning equipment.

Using the TCU

When using the TCU, observe the following safety guidelines:

• To help prevent electric shock, wire the TCU and peripheral power cables into properly grounded

power sources.

• Be sure nothing rests on the TCU’s cables and that the cables are not located where they can be

stepped on or tripped over.

If the TCU’s LCD Screen or Status LED is not lit, you should assume that the TCU is still powered. This

indicates that the TCU is in the off state, not that AC power has been removed. To remove power, you

must turn off the external circuit breaker.

10

Installation

Site Selection

When selecting a site for the TCU, keep the following in mind:

• The TCU requires a 120 VAC power supply.

• The TCU is designed to operate at a recommended temperature range of -10°C to 60°C (14°F to

140°F). The upper temperature limit is 50°C (122°F) when using the recommended backup

battery.

• The TCU is intended to be permanently installed in a NEMA 12 or higher rated panel that

prevents access to live parts without a tool.

• Attention should be given to the location of the TCU to provide accessibility for wiring and

servicing. Leave enough space around the TCU to access the TCU’s fuse and to remove the

connectorized terminal strips. Install the TCU in the panel at a position where the LCD display

can be read comfortably. The LCD is best viewed at slightly below eye level.

Pre-Installation Modification

Use snips, pliers, or a razor to remove the retention

clips from P-connectors.

Once the retention clip is removed, the P-connector

will be able to be used with the TCU800.

11

Mounting Instructions

The TCU is intended to be permanently installed in a NEMA 12 or higher rated panel that prevents access

to live parts without a tool. The TCU can be mounted in a control panel in several different ways. The unit

can be mounted flush to the back plate of the panel, stood off the back plate, or mounted to a front panel.

Mounting brackets are provided with the TCU that can be used to mount it in any of these positions.

Optional connectors to facilitate the various types of mountings are available as shown on page 21,

“Attaching Connectors” and may be specified as described in the TCU800 Installation and Operation

Manual.

Place the TCU800 in the enclosure in the same manner as a TCU001. Do not insert the address strap into

the new TCU800. Station address configuration is done internal to the TCU800. Find a location inside the

TCU enclosure to secure the Configuration USB. This Configuration USB acts in place of the TCU

Configuration Connector, and also houses all station statistics and settings. This allows a TCU800 to be

switched out in a station, but retain all station configurations and run data upon powering on the replacement

TCU800.

Applying power to the TCU800 will turn it on. To safely turn off the TCU800, hold down the Home button

for 5 seconds. To turn the TCU800 on after a safe shutdown, press the Home button once. To force a reset

of the TCU800, hold the Home button for 11 seconds.

TAC Pack Adapter

This mounting option is available when a TCU is replacing a rear-panel mounted PCU. It uses the

preinstalled PCU mounting bracket and brings the TCU to the same level as the PCU it is replacing.

This option uses the Retro installation kit (Basic Install Kit or Full Install Kit).

Snap-In (Back Panel) Mount

The snap-in mount is available for new installations (i.e., TCU is not replacing a PCU). The mounting

bracket is attached to the back of the control panel, and the TCU is snapped into place. With this mounting

option, the TCU can be installed and removed quickly and easily. This option uses the Snap-In Installation

Kit (Basic Install Kit or Full Install Kit).

PCU Front Panel Mount

This mounting option uses a PCU-type mounting bracket that is attached to the front of a control panel.

With this mounting option, the TCU is attached to the mounting bracket with screws instead of being

snapped into place. This option uses the Front Mount installation kit (Basic Install Kit or Full Install Kit).

This dimensional drawing is provided to aid in installation. If a panel cutout is required, the TCU can be

installed with or without edge molding around the front-panel opening. The panel cutout is different for

each mounting configuration. See "Control panel installation with TCU mounted to dead front" and

"Control panel installation with TCU mounted to front panel,” on the next page.

A qualified technician should install the TCU800.

Precautionary measures must be observed when installing, operating, and servicing the TCU800 in order

to percent shock from voltages present.

If the TCU800 is to be installed into an existing control panel, make sure that all breakers are shut off

before starting the installation.

12

Attaching Connectors

The graphic to the right depicts how each of the TCU's three optional connector types can be attached to

the unit. The first option uses the Spring-Clamp Connector Tool, which can be ordered from DFS. See the

TCU800 Installation and Operation Manual for information on ordering connectors and the connector tool.

Control panel installation with

TCU mounted to dead front

Control panel installation with

TCU mounted to front panel

13

Wiring AC Power

The maximum wire size to TCU connectors is 12 AWG.

Use stranded copper conductors only with a minimum rating of 75°C.

The recommended circuit breaker is 10 Amp maximum.

When using connectors with screw-type terminals, tighten screw terminals to a maximum

7 in-lb (.79 Nm).

All AC source power wired to the TCU should be from the same leg of the three-phase

system. (Diagrams in this section show Phase C (L3) being used.)

The LCD screen and Status LED do not indicate that AC power has been removed. Even if

these indicators are not lit, you should assume that the TCU is still powered. To remove

power, you must turn off the external circuit breaker.

The TCU operates from 120 VAC. Verify the input voltage on the TCU’s connector label before wiring.

Three terminals are provided for wiring power:

• P1-5, AC_PWR (AC power)

• P1-6, AC_NEUT (AC neutral)

• P1-7, TGND (earth ground)

Terminal P1-7 is designated Earth or Safety ground. The TCU’s enclosure is also connected to the TGND

terminal. Wire in accordance with Federal, State, and Local Electrical Codes.

The transformer must provide AC neutral. When wiring to a typical three-phase, 4-wire, 240 Volt

transformer that provides AC neutral, refer to “Typical 240 Volt, 4-Wire Transformer” (next page). Refer

to “Typical 480 Volt, 3-Wire Transformer" (next page) when connecting to a typical three-phase, 3-wire

480 Volt transformer with no neutral provided. Note that these diagrams are for typical installations. If

your installation deviates from that shown here, refer to the National Electrical Code® (NEC®)

Handbook.

14

Powering TCU with Typical 240 Volt, 4-Wire Transformer

Powering TCU with Typical 480 Volt, 3-Wire Transformer

General Operating Instructions

This section provides an overview of the TCU’s user interface. For detailed descriptions and instructions

on use, refer to the TCU800 Installation and Operation Manual, which can be found on the DFS website

(www.dataflowsys.com).

Home Button and Power Indicator

Press and hold the TCU’s home button to turn the unit on or enter a “soft off” state. The LCD screen

indicates the state (on or off) of the TCU800. When turning the unit on, there will be a delay while the LCD

screen is activated: the unit is considered ON when all of the front-panel LEDs are illuminated for a power-

on lamp test.

15

The LCD Screen and Status LED do not indicate that AC power has been removed. Even

if these indicators are not lit, you should assume that the TCU is still powered. To remove

power, you must turn off the external circuit breaker.

Connectorized Terminals

The TCU800’s four connectorized wire terminals (P1, P2, P3, and P4) allow the unit to be serviced or

replaced without rewiring the control panel. No user configuration straps or jumpers are required.

H-O-A Switches and LEDs

Three Hand-Off-Auto (H-O-A) switches on the TCU's front panel are provided to manually override the

TCU's automated control. They can be used to control the pumps connected to the unit. The H-O-A switches

are fail-safe, meaning they remain operational even if the TCU fails or loses power.

The home display screen indicates the status of each pump. Under normal operation, the display indicates

if the corresponding pump is on or off. The pump indicator flashes when a starter circuit fault is detected.

LCD Display and Touchscreen

The 5” TFT LCD touchscreen panel provides the interface for configuring the TCU, viewing and resetting

alarms, and analyzing status information.

Navigate through the TCU800 interface by swiping across the touchscreen either left or right. After swiping,

the screen will turn black and display the new screen in a moment. In order to configure the TCU800, tap

on the text and numbers in order to adjust their values. When you tap on a button in the interface it will

highlight that button.

Status LED

The STAT or Status LED indicates the current state of the unit. A slowly flashing STAT led means that the

unit is on and the pump logic is running without fault.

The Alarm LED is cleared when the alarm screen is exited and there are no active alarms. The Silence key

is used to silence the TCU’s own alarm horn and an external alarm horn if one has been connected.

Receive (RX Data) and Transmit (TX Data) LEDs

The RX and TX Data LEDs are part of the telemetry and service port interface and are provided to verify

the communications function. The RX Data LED strobes each time the TCU receives data; the TX Data

LED strobes each time the TCU transmits data.

USB Ports and Configuration

The TCU's front panel features two USB type-A ports that can be used for diagnostics and configuration

storage, and updating. A USB flash drive correctly formatted and loaded with the appropriate files will

allow easy transfer of pump configuration parameters from one TCU to another.

The TAC Pack TCU Configuration Connector or address card is NOT used with the TCU800. Instead, the

USB configuration stick will replace this method of setting the TCU’s station address.

16

Service Port

The USB ports can be used to serially connect to the TCU’s core through a USB-to-Ethernet adapter as

shown below. This will allow the user to SSH into the unit at the IP address registered to the adapter and

access the logs on the unit. If the TCU is already connected to the internet (via internal Ethernet) then the

USB-to-Ethernet adapter is not necessary.

Telemetry Configuration

Setting up the TCU as a component of the telemetry system enables you to remotely monitor conditions at

the site and control equipment from a central location via the HyperTAC IV (HT4) SCADA software. For

example, you can determine if a pump is currently running and manually turn it on if necessary.

In order for the TCU to interface with the central site and the HT4 server, it must have access to radio or

network communications and be properly configured in HT4’s Configuration Editor.

There are several options for connecting the TCU to the telemetry system. A TCU can be installed with a

DFS RTU station, or it can interface with industry standard radios using the TCU's RS-232 Modbus radio

interface. Alternately, the TCU can operate as a stand-alone unit and communicate with the central

computer or server via its integrated radio or network interface.

Using the TCU in conjunction with a radio-based telemetry system requires that you obtain an FCC-licensed

radio frequency if you do not already have a licensed frequency that can be used. Even when adding a site

to an existing frequency, the FCC requires that a complete application be submitted. DFS can assist you in

obtaining a new licensed frequency or adding a site to an existing frequency.

Setup

Configuring the TCU800 is done from the Settings screen. First ensure the H-O-A switches are all in the

HAND or OFF position. Then navigate to the Settings screen by tapping the screen, opening the left

Navigation Menu by tapping , scroll down using an upward swipe, and tap to select Settings. When

making a numerical configuration change, first delete the existing value before entering the desired value.

After making changes, select the to exit the Settings screen. A confirmation window will appear

summarizing the changes made and offer three options to continue: Discard (exit without saving), Save

(save and implement changes), or Edit (return to Settings Screen to further make changes before applying).

If the Save option is selected, a window will appear confirming the TCU800 and the Configuration USB

have been updated successfully.

TCU800 Service Adapter

17

Configuration Settings

Grouped configurations are found on the Settings screen. The following is a table with the locations of each

configuration. For further explanation of a configuration, refer to the TCU001 manual unless otherwise

indicated.

Settings

Analog

Main Settings

TCU Settings

Radio

High

Number of Pumps

IP Address

Station

Lag 2 On Level

Pump Mode

Subnet

Data Invert

Lag 2 Off Level

Transducer Type

DNS

Data Swap

Lag 1 On Level

Alternator Type

Gateway

Tx Invert

Lag 1 Off Level

Minimum Run Time

Home Screen

Rx Invert

Lead On Level

Minimum Off Time

Display Touch Gestures

Async Baud

Lead Off Level

Start Fault Alarm

Debug Logging

Dash Number

Flow EQ

Stop Fault Alarm

GBL MOD DLY

Low Level

Auto Retry

GBL FIX DLY

XDCR 2 Low Cal Point

BEM Modules

GBL STA DLY

XDCR 2 High Cal Point

Trend Rate

Rad PGM

XDCR 1 Low Cal Point

XDCR 1 High Cal Point

Fault Mode

XDCR Low Level

Fault

Auxiliary

Alarm Outputs

Phase Monitor

Floats

Aux Output Turns

Alarm Horn

Range

High Float

Delay After

Alarm Light

Low Alarm

Low Float

Aux Input Turns

High Alarm

XDCR High Float Fault

Aux Input Alarm

High Float Override

Aux Alarm

Moving the H-O-A switches to Auto at any point while in the Settings or Advanced Settings screen will

terminate the session and return to the last viewed screen without saving any changes.

18

Modbus

Derived Flow

Pump Monitoring

Protocol

Well Volume

THERM Function

Baud

Flow Units

THERM Alarm On

H Address

SEAL Function

H Length

SEAL Alarm On

I Address

Analog 3 Type

I Length

Analog 4 Type

J Address

J Length

K Address

K Length

L Address

L Length

M Address

M Length

N Address

N Length

O Address

O Length

* This setting is used in

development and should not

be changed.

Auto-Configuring

At this time, using a TCU001 PLC configuration will cause an error in the TCU800. To avoid this, first

transfer the existing configuration of the TCU800 using HT4 PLC editor. Then save the .plc file, create an

auto-config file, and upload it to the appropriate station you want to auto-config.

Remote Configuration Changes

Changing configuration values using the PLC editor is supported but requires that the settings be transferred

initially from the TCU800 (once). If taking this step, disregard the configuration values listed in the

Autodialer section of the editor as the TCU800 does not support Autodialer and the settings have been

repurposed for other use. This workaround is temporary. If only changing a few configuration values, this

step can be bypassed as only the changed values need to be selected and sent.

Advanced Settings

Auto-config

Request station configuration from HSS. Must have a

TCU800 auto-config file uploaded to server using

HT3/HT4 for the correct station address.

Factory Reset

Returns TCU800 to the factory default configuration.

19

Radio Test Mode

Allows for test messages to be sent during installation to

test antenna signal. Allows for keying of radio, and

viewing network traffic.

Reset Pump Statistics

Reset all pump statistics at once.

Calibrate PMA

Fine tune PMA chip. This should not have to be done

once installed.

Time

Manually configure internal clock.

Device Manager

Currently supports writing all station statistics and

configurations to the Configuration USB. If a USB device

is connected and has not been formatted as a

Configuration USB, it will ignore it.

For detailed instructions for integrating the TCU with your telemetry system, see the TCU800 Installation

and Operation Manual.

Touchscreen-invoked Functions

Detailed information on these functions can be found in the TCU800 Installation and Operation Manual.

View process ID and version level

Swipe to the Settings page. Select About > Software. This tab

contains the operating system version, serial number, PLC

version, and package version.

View serial number, station address,

radio configuration, and firmware

version

Swipe to the Settings page. Select About > Station. This tab

contains the station address and the radio configuration

Place TCU in radio test mode

Swipe to the Settings page. Select Advanced Options > Radio

Test Mode.

Key radio and measure antenna

reflective power

Place the TCU in radio test mode (see box above). Select the

KEY button to force a radio transmission.

Auto download TCU configuration

Swipe to the Settings page. Select Advanced Options > Auto

Configuration.

Other manuals for TCU800

1

Table of contents