Datakom DPR-145 User manual

DPR-145 User Manual V-3.0 (14.09.2016)

-1-

DPR-145

TEMPERATURE

PROTECTION RELAY

▪PT100 INPUTS: 4

▪RELAY OUTPUTS: 4

▪RS-485 MODBUS PORT

▪UNIVERSAL SUPPLY

DPR-145 is a precision unit designed for the

temperature protection of dry type or resin filled

MV transformers. The unit offers a high degree of

protection against electromagnetic disturbances.

The unit has 4 temperature inputs of PT100 type.

Three of them are used for the transformer

protection. The fourth input may be used as core

temperature protection or ambient temperature

monitoring.

Alarm and trip levels of the unit are independently

adjustable for first 3 sensors and the fourth

sensor input.

Alarm levels are adjusted using the program

mode. If no operation is performed, then the unit

will exit program mode in 3 minutes.

The unit offers a cable compensation function in

order to prevent long cables from impairing the

measurement precision.

The unit has 4 dry contact relay outputs rated 6A.

FAN: provides cooler fan control

TRIP: high temperature failure relay

ALARM: pre-alarm relay

FAULT: sensor or internal failure indicator

The unit offers an automatic self test feature. The

self test consists on the verification of sensor

inputs and internal memory integrity.

The standard isolated RS-485 MODBUS RTU

communication port is not affected by ground

potential differences and allows safe transfer of

information to remote management and

automation systems.

The supply input is isolated from sensor

connections.

1 degrees C measurement precision

4 x PT100 analog inputs

Allows cable length compensation

Automatic detection of sensor failures

Automatic and manual self test

4 x relay outputs, 5A/250Vac

Fully isolated RS-485 serial port

MODBUS-RTU communication

Recording of maximum temperatures

Front panel programmable

2 alarm thresholds for channels 1-2-3

2 alarm thresholds for channel 4

Easy to read, 3 digit 14mm led display

Supply voltage range: 19-400VDC (85-305VAC)

Reduced panel depth, easy to install

Wide operating temperature range, -20 to +70°C

Sealed front panel (IP65 with gasket)

2 part connection system

DESCRIPTION

FEATURES

DPR-145 User Manual V-3.0 (14.09.2016)

-2-

•Electrical equipment should be installed only by qualified

specialist. No responsibility is assumed by the manufacturer or

any of its subsidiaries for any consequences resulting from the

non-compliance to these instructions.

•Check the unit for cracks and damages due to transportation. Do

not install damaged equipment.

•Do not open the unit. There is no serviceable parts inside.

Warranty voids if the unit is open.

•Fuse must be connected to the power supply input.

•Fuses must be of fast type with a maximum rating of 6A.

•Disconnect all power before working on equipment.

•When the unit is connected to the network do not touch

terminals.

•Any electrical parameter applied to the device must be in the

range specified in the user manual.

•Do not try to clean the device with solvent or the like. Only clean

with a dry cloth.

•Verify correct terminal connections before applying power.

•Only for front panel mounting.

SAFETY NOTICE

WARNING

Failure to follow below instructions may

result in death or serious injury.

DPR-145 User Manual V-3.0 (14.09.2016)

-3-

Section

1. INSTALLATION

1.1. FRONT / REAR PANELS

1.2. MECHANICAL INSTALLATION

1.3. ELECTRICAL INSTALLATION

2. PUSHBUTTON FUNCTIONS

3. DISPLAYS

3.1. MODES OF OPERATION

4. ALARMS

4.1. ALARM MENU

5. PROGRAMMING

5.1. ENTERING THE PROGRAM MODE

5.2. LAMP TEST

5.3. RELAY TEST

5.4. MODIFYING PROGRAM PARAMETERS

5.5. PROGRAM PARAMETER LIST

6. MODBUS COMMUNICATIONS

6.1. DESCRIPTION

6.2. PROGRAM PARAMETERS

6.3. COMMANDS

6.4. ALARM BITS

6.5. SENSOR DATA

7. TECHNICAL SPECIFICATIONS

TABLE OF CONTENTS

DPR-145 User Manual V-3.0 (14.09.2016)

-4-

Before installation:

•Read the user manual carefully, determine the correct connection diagram.

•Remove all connectors and mounting brackets from the unit, then pass the unit through

the mounting opening.

•Put mounting brackets and tighten. Do not tighten too much, this can brake the

enclosure. Spring type brackets do not require tightening.

•Make electrical connections with plugs removed from sockets, then place plugs to their

sockets. Otherwise sockets may get damaged.

•Make sure not overloading relay outputs. Use additional contactors if required.

Below conditions may damage the device:

•Incorrect connections.

•Incorrect power supply voltage.

•Voltage at measuring terminals beyond specified range.

•Current at measuring terminals beyond specified range.

•Overload or short circuit at relay outputs

Below conditions may cause abnormal operation:

•Power supply voltage below minimum acceptable level.

1. INSTALLATION

DPR-145 User Manual V-3.0 (14.09.2016)

-5-

Panel Cutout Required Panel Depth

1.1 FRONT / REAR PANELS

1.2 MECHANICAL INSTALLATION

DPR-145 User Manual V-3.0 (14.09.2016)

-6-

Although the unit is protected against electromagnetic disturbance, excessive disturbance

can affect the operation, measurement precision and data communication quality.

•ALWAYS remove plug connectors when inserting wires with a screwdriver.

•Fuse must be connected to the power supply input, in close proximity of the unit.

•Fuses must be of fast type with a maximum rating of 6A.

•Use cables of appropriate temperature range.

•Use adequate cable section, at least 0.75mm2 (AWG18).

•For the RS-485 connection, use appropriate shielded twisted wire cable.

Communication quality will depend highly on the cable used.

1.3 ELECTRICAL INSTALLATION

Do not install the unit close to high electromagnetic

noise emitting devices like contactors, high current

busbars, switchmode power supplies and the like.

DPR-145 User Manual V-3.0 (14.09.2016)

-7-

Programming and measuring screens are opened using 3 pushbuttons on the front panel.

PUSHBUTTON

FUNCTION

Switched between operating modes.

IF HELD PRESSED DURING 5 SEC:

Switches to the Alarm menu. (Trip, Fault and Alarm

messages displayed)

Switch to the previous channel or

increase related value (program mode)

Switch to the next channel or

decrease related value (program mode)

IF HELD PRESSED DURING 5 SEC:

“” will be displayed and all Trip, Fault and Alalrm

messages will be deleted.

IF HELD PRESSED DURING 5 SEC:

“” will be displayed and maximum temperature values

for each channel will be deleted.

IF HELD PRESSED TOGETHER DURING 5 SEC:

Enters/exits PROGRAM mode.

* NO KEY PRESSED DURING 3 MINUTES:

Resumes to last operating mode.

2. PUSHBUTTON FUNCTIONS

DPR-145 User Manual V-3.0 (14.09.2016)

-8-

SELECTED CHANNEL LEDS: indicates

the related channel to alarm or

information on display.

MOD LEDS: indicated the current mode

of operation.

ALARM LEDS: indicates the type of

alarm if any.

TEST LED: turns on during lamp test or

relay test.

PPROGRAM LED: turns on in program

mode.

The unit has 4 operating modes: SCAN, AUTO, MAN, MAX.

Every depression of the MODE button switches the unit to the next operating mode.

Related mode led will turn on. Channel leds on the right side (1,2,3,4) indicate the

related channel number.

•SCAN: Displays channel temperatures, switches to the next channel every 5

seconds.

•AUTO: Displays the temperature of the highest channel.

•MAN: Displays the temperature of the selected channel. Channels may be

scrolled with and pushbuttons.

•MAX: Displays the maximum recorded temperature of the selected channel.

Channels may be scrolled with and pushbuttons.

NOTE: If any of or pushbuttons is depressed in SCAN or AUTO modes, then

the unit will automatically switch to the MANUAL mode. If no pushbutton is depressed

during 30 minutes, it will resume previous mode.

3. DISPLAYS

3.1 MODES OF OPERATION

Selected

Channel Leds

Alarm Leds

Mod Leds

Test Led

Program Led

DPR-145 User Manual V-3.0 (14.09.2016)

-9-

The unit continuously monitors various abnormal conditions during operation.

Programmable alarm limits are provided for every measured value.

If any fault condition occurs, the related alarm led (TRIP, FAULT or ALARM) turns on,

alarm code is displayed, the alarm relay operates and the alarm code is added to the

alarm menu.

Even if the alarm goes off, the related alarm led will stay on but the relay output will be

deactivated. By depressing the MODE pushbutton, alarm display will turn off and normal

operating mode will be resumed.

ALARM CODE

DESCRIPTION

SHORT CIRCUIT ()

Indicates a short circuit on the related channel. The FAULT

led and the related channel led turns on. Cables should be

checked.

OPEN CIRCUIT ()

Indicates a missing connection in the related channel. The

FAULT led and the related channel led turns on. Sensor

connections should be checked.

HIGH TEMPERATURE ALARM ()

Occurs if the temperature goes over the adjusted Alarm limit.

The ALARM led and the related channel led turns on and the

alarm relay operates.

HIGH TEMPERATURE TRIP ()

Occurs if the temperature goes over the adjusted Trip limit.

The TRIP led and the related channel led turns on and the

trip relay operates.

4. ALARMS

DPR-145 User Manual V-3.0 (14.09.2016)

-10-

PUSHBUTTON

OPERATION

DISPLAY

In order to enter the Alarm menu, the

MODE pushbutton should be held

pressed during 5 seconds in SCAN,

AUTO, MAN or MAX modes.

The related channel led and the ALARM

led of the last occurres alarm will turn

on. The alarm code will be displayed.

Different alarm types (fault, trip, alarm)

may be scrolled with the MODE

pushbutton.

If the related type of alarm has not

occurred on any channel, then (---) wil

be displayed.

If the same alarm type occurred on more

than one channel, alarm messages may

be scrolled with up/down arrow

pushbuttons.

In order to exit alarm menu, hold

pressed the MODE button during 5

seconds. The previous operating mode

will be resumed.

4.1 ALARM MENU

DPR-145 User Manual V-3.0 (14.09.2016)

-11-

In order to provide the maximum flexibility of use, the unit features various

programmable parameters.

Parameters are recorded in a non-volatile memory and are not affected by power

failures.

Relay testing is also performed through program mode.

PUSHBUTTON

OPERATION

DISPLAY

In order to enter the PROGRAM

mode, hold pressed both up/down

arrow pushbuttons for 5 seconds.

PGM will be displayed.

Every depression to the MODE

button will switch to the next

parameter. Related parameter

name is displayed.

When the name of the parameter

to be modified is displayed, hold

pressed the MODE button for 5

seconds. The value of the

parameter will be displayed.

Modify and adjust the value with

up/down arrow pushbuttons.

PUSHBUTTON

OPERATION

DISPLAY

In order to exit program mode,

hold pressed both up/down arrow

pushbuttons during 5 seconds.

5. PROGRAMMING

5.1 ENTERING THE PROGRAM MODE

If no pushbutton is depressed during 3 minutes, the

PROGRAM mode will be automatically terminated.

DPR-145 User Manual V-3.0 (14.09.2016)

-12-

PUSHBUTTON

OPERATION

DISPLAY

The required relay to be tested is

selected with MODE button. Trip (),

Fault(), Alarm() or Fan() can

be selected.

When the relay name is on display, hold

MODE button pressed during 5

seconds. The test screen of this relat

will open. The initial value of “0” is

displayed.

Arrow up button activates the relay

output and displays “1” on the screen.

Arrow down button deactivates the relay

output and displays “0” on the screen.

Mode button will switch to next relay or

parameter display.

5.2 LAMP TEST

When exiting the PROGRAM mode, the unit makes a LAMP

TEST during 5 seconds.

During LAMP TEST all leds will turn on. At the end of 5

seconds or if MODE button is depressed the LAMP TEST is

terminated.

If no pushbutton is depressed during 3 minutes, the

PROGRAM mode will be automatically terminated.

In this case LAMP TEST is not performed.

5.3 RELAY TEST

Exiting the relay test display will cause the relay resume

normal operation.

DPR-145 User Manual V-3.0 (14.09.2016)

-13-

TUŞ

İŞLEM

EKRAN

The parameter to be modified is

selected with MODE button.

When the parameter name is on

display, hold the MENU button

pressed during 5 seconds. The

parameter value will be displayed.

Adjust the parameter using up/down

arrow buttons.

In order to increase/decrease faster

you can hold arrow buttons pressed.

When MODE button is pressed, the

parameter value is recorded and the

next parameter name is displayed.

DISPLAY

DESCRIPTION

MIN

MAX

PT100 CABLE SECTION ()

PT100 cable section in mm2.

The factory set value is 0.5mm2.

0.10

9.99

PT100 CABLE LENGTH ()

PT100 cable length in meters (m).

The factory set value is 0m.

0

999

TRIP RELAY TEST ()

Used to test the TRIP relay. The value of

“1” activates the relay. The value of “0”

deactivates it.

0

1

5.4 MODIFYING PROGRAM PARAMETERS

5.5 PROGRAM PARAMETER LIST

DPR-145 User Manual V-3.0 (14.09.2016)

-14-

DISPLAY

DESCRIPTION

MIN

MAX

FAULT RELAY TEST ()

Used to test the FAULT relay. The value

of “1” activates the relay. The value of

“0” deactivates it.

0

1

ALARM RELAY TEST ()

Used to test the ALARM relay. The value

of “1” activates the relay. The value of

“0” deactivates it.

0

1

FAN RELAYE TEST ()

Used to test the FAN relay. The value of

“1” activates the relay. The value of “0”

deactivates it.

0

1

ALARM PARAMETER ()

Adjusts High Temperature Alarm limit

values of each channel.

0

295

TRIP PARAMETER ()

Adjusts High Temperature Trip values of

channels.

5

300

FAN CHANNEL PARAMETER ()

This parameter defines from which

channels the fan will operate.

0

15

0: none

1: channel_1

2: channel_2

3: channel_1+2

4: channel_3

5: channel_1+3

6: channel_2+3

7: channel_1+2+3

8: channel_4

9: channel_1+4

10: channel_2+4

11: channel_1+2+4

12: channel_3+4

13: channel_1+3+4

14: channel_2+3+4

15: channel_1+2+3+4

FAN ON PARAMETER ()

Adjusts Fan Turn ON Temperature

5

300

DPR-145 User Manual V-3.0 (14.09.2016)

-15-

DISPLAY

DESCRIPTION

MIN

MAX

FAN OFF PARAMETER ()

Adjusts Fan Turn OFF Temperature.

0

295

ALARM ENABLE PARAMETER

()

0: No alarm is generated from this

channel

1: if the temperature read from this

channel is over Alx limit, then an alarm is

generated.

0

1

RS-485 DATA RATE: (bdr)

0: 2400 baud 5: 28800 baud

1: 4800 baud 6: 38400 baud

2: 9600 baud 7: 56000 baud

3: 14400 baud 8: 57600 baud

4: 19200 baud 9: 115200 baud

0

9

MODBUS NODE ADDRESS (nod)

This parameter defines the address of

the unit in a Modbus network. Each

device in the same network must have a

different address.

0

255

For any channel, the difference between Alarm and Trip

temperatures cannot be less than 5 degrees C and the Trip

temperature is always higher than Alarm temperature.

The same way, the difference between Fan Turn ON and Turn

OFF parameters cannot be less than 5 degrees C and Fan

Turn ON is always higher than Fan Turn OFF.

DPR-145 User Manual V-3.0 (14.09.2016)

-16-

The unit offers serial data communication port allowing it to be integrated in automation

systems.

The serial port is of RS-485 MODBUS-RTU standard. It is fully isolated from power

supply and measurement terminals for failure-free operation under harsh industrial

conditions.

The MODBUS properties of the unit are:

-Data transfer mode: RTU

-Serial data: 9600 bps, 8 bit data, no parity, 1 bit stop

-The answer to an incoming message is sent with a minimum of 4.3ms delay after

message reception.

Each register consists of 2 bytes (16 bits). Larger data structure contain multiple

registers.

Detailed description about the MODBUS protocol is found in the document “Modicon

Modbus Protocol Reference Guide”.This document may be downloaded at:

www.modbus.org/docs/PI_MBUS_300.pdf

Supported functions:

-Function 3 (Read multiple registers)

-Function 6 (Write single register)

-Function 16 (Write multiple registers)

Error codes

Only 3 error codes are used:

01: illegal function code

02: illegal address

10: write protection (attempt to write a read_only register)

Data types

Each register consists of 16 bits (2 bytes)

If the data type is a byte, only the low byte will contain valid data. High byte is don’t care.

For data type longer than 16 bits, consecutive registers are used. The least significant

register comes first.

6. MODBUS COMMUNICATION

6.1 DESCRIPTION

DPR-145 User Manual V-3.0 (14.09.2016)

-17-

12 parameters are available in total. Parameter values may be modified with Function 10

(Write Multiple Registers). All values should be sent at once.

ADDRESS

NAME

DESCRIPTION

LENGTH

R/W

TYPE

X

0

Alarm 1

Channel 1 Alarm temperature (°C)

16 BIT

R/W

unsigned

word

1

1

Alarm 2

Channel 2 Alarm temperature (°C)

16 BIT

R/W

unsigned

word

1

2

Alarm 3

Channel 3 Alarm temperature (°C)

16 BIT

R/W

unsigned

word

1

3

Alarm 4

Channel 4 Alarm temperature (°C)

16 BIT

R/W

unsigned

word

1

4

Trip 1

Channel 1 Trip temperature (°C)

16 BIT

R/W

unsigned

word

1

5

Trip 2

Channel 2 Trip temperature (°C)

16 BIT

R/W

unsigned

word

1

6

Trip 3

Channel 3 Trip temperature (°C)

16 BIT

R/W

unsigned

word

1

7

Trip 4

Channel 4 Trip temperature (°C)

16 BIT

R/W

unsigned

word

1

8

Fan

Channel

Fan relay channel selection

16 BIT

R/W

unsigned

word

1

9

Fan ON

Fan Turn On Temperature (°C)

16 BIT

R/W

unsigned

word

1

10

Fan OFF

Fan Turn Off Temperature (°C)

16 BIT

R/W

unsigned

word

1

11

Cable

Lenght

Cable Length (m)

16 BIT

R/W

unsigned

word

1

12

Cable

Section

Cable Section(mm2)

16 BIT

R/W

unsigned

word

0.01

13

Channel_1

Alarm

Alarm enable parameter of the

related channel

16 BIT

R/W

unsigned

word

1

14

Channel_2

Alarm

Alarm enable parameter of the

related channel

16 BIT

R/W

unsigned

word

1

15

Channel_3

Alarm

Alarm enable parameter of the

related channel

16 BIT

R/W

unsigned

word

1

16

Channel_4

Alarm

Alarm enable parameter of the

related channel

16 BIT

R/W

unsigned

word

1

17

Baud Rate

RS-485 data rate

16 BIT

R/W

unsigned

word

1

18

Modbus

Address

Modbus address of the device

16 BIT

R/W

unsigned

word

1

6.2 PROGRAM PARAMETERS

DPR-145 User Manual V-3.0 (14.09.2016)

-18-

Commands should be sent with Function 6 (Write Single Register).

ADDRESS

VALUE

R/W

DESCRIPTION

16384

1

W-O

Reset Maximum Temperatures

16385

1

W-O

Reset all Alarms

16386

-

W-O

Arrow Down pushbutton

16387

-

W-O

Arrow Up pushbutton

16388

-

W-O

MODE pushbutton

16389

-

W-O

Arrow Down pushbutton long press

16390

-

W-O

Arrow Up pushbutton long press

16391

-

W-O

MODE pushbutton long press

16392

-

W-O

PROGRAM pushbutton long press

MODBUS Warning Record are contains 20 bits in 3 registers.

ADDRESS

BIT

R/W

DESCRIPTION

20488

0

R-O

Alarm Relay Status

1

R-O

Trip Relay Status

2

R-O

Fan Relay Status

3

R-O

Fault Relay Status

4-15

R-O

Not used

20489

0

R-O

Channel 1 Alarm

1

R-O

Channel 2 Alarm

2

R-O

Channel 3 Alarm

3

R-O

Channel 4 Alarm

4

R-O

Channel 1 Trip

5

R-O

Channel 2 Trip

6

R-O

Channel 3 Trip

7

R-O

Channel 4 Trip

8-15

R-O

Not used

20490

0

R-O

Channel 1 Open Circuit Alarm

1

R-O

Channel 2 Open Circuit Alarm

2

R-O

Channel 3 Open Circuit Alarm

3

R-O

Channel 4 Open Circuit Alarm

4

R-O

Channel 1 Short Circuit Alarm

5

R-O

Channel 2 Short Circuit Alarm

6

R-O

Channel 3 Short Circuit Alarm

7

R-O

Channel 4 Short Circuit Alarm

8-15

R-O

Not used

6.3 COMMANDS

6.4 ALARM BITS

DPR-145 User Manual V-3.0 (14.09.2016)

-19-

ADDRESS

NAME

DESCRIPTION

LENGTH

R/W

TYPE

X

20480

Max Temp 1

Channel 1 Maximum Temp.

16 BIT

R-O

unsigned

word

1

20481

Max Temp 2

Channel 2 Maximum Temp.

16 BIT

R-O

unsigned

word

1

20482

Max Temp 3

Channel 3 Maximum Temp.

16 BIT

R-O

unsigned

word

1

20483

Max Temp 4

Channel 4 Maximum Temp.

16 BIT

R-O

unsigned

word

1

20484

Temp 1

Channel 1 Actual Temperature

16 BIT

R-O

unsigned

word

1

20485

Temp 2

Channel 2 Actual Temperature

16 BIT

R-O

unsigned

word

1

20486

Temp 3

Channel 3 Actual Temperature

16 BIT

R-O

unsigned

word

1

20487

Temp 4

Channel 4 Actual Temperature

16 BIT

R-O

unsigned

word

1

Supply Input:

19-400VDC (85-305VAC)

Measuring Inputs:

4 x PT100 (3 terminals)

Accuracy: 1% + 1 digit

Measurement Range: -40 to +250°C

Power Consumption: < 4 VA

Relay Outputs: 5A @ 250V AC

Serial Port:

Signal type: RS-485

Protocol: Modbus RTU

Data Rate: 2400-115200b, adjustable

Isolation: 1000V AC, 1 minute

Operating Temperature range:

-20°C to +70 °C (-4°F to 158°F)

Max Relative Humidity:

95% non condensing

Protection:

IP 65 (front panel, with gasket)

IP 30 (back panel)

Enclosure:

Flame retardant, ROHS compliant,

high temperature ABS/PC (UL94-V0)

Installation:

Panel mount, rear retaining plastic

brackets.

Dimensions:

102x102x53mm (WxHxD)

Panel Cut-out: 92x92mm

Weight: 200 gr (approx)

EU Directives:

2014/35/EC (LVD)

2014/30/EC (EMC)

Reference

Standards:

EN 61010 (safety)

EN 61326 (EMC)

DATAKOM Elektronics Inc.

6.5 SENSOR DATA

7. TECHNICAL SPECIFICATIONS

Table of contents

Other Datakom Relay manuals

Popular Relay manuals by other brands

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-3520 Instruction book

OEZ

OEZ MINIA MCR-MB-001-UNI Instructions for use

Intiel

Intiel EFR-01 user manual

Schweitzer Engineering Laboratories

Schweitzer Engineering Laboratories SEL-352-1 instruction manual

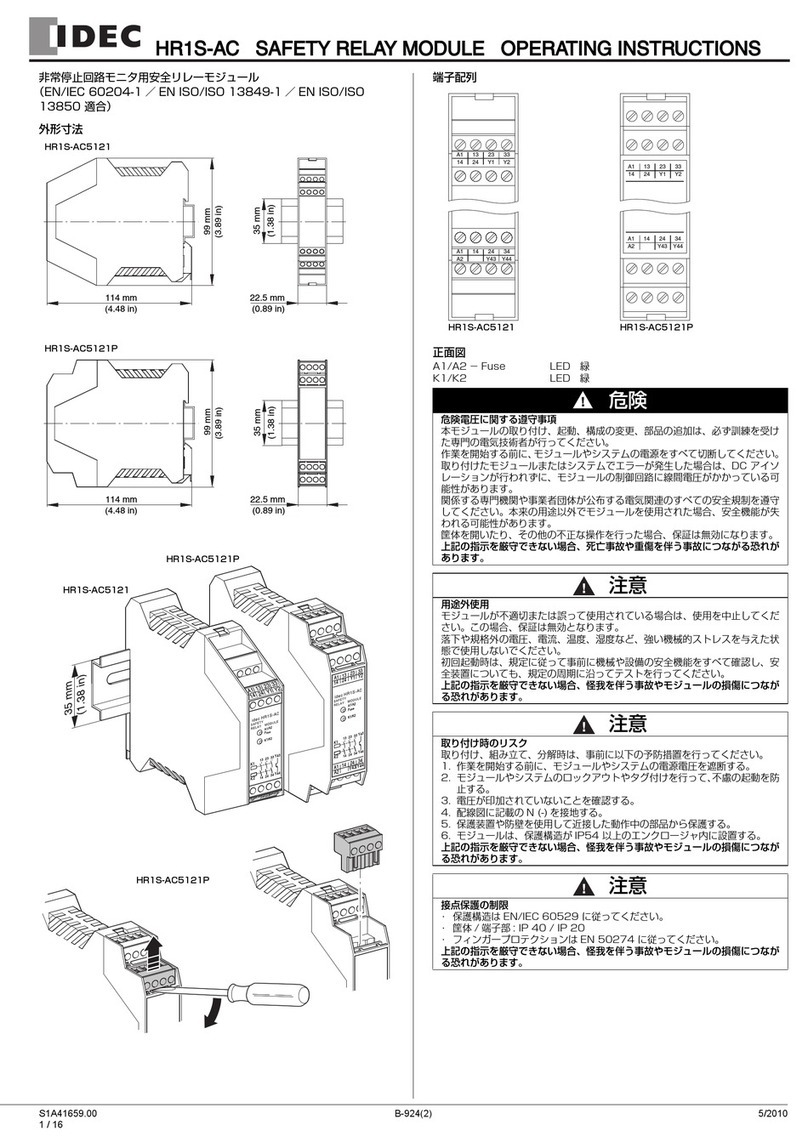

IDEC

IDEC HR1S-AC operating instructions

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-0236B Instruction book