Bender CMD420 User manual

T M

Document NAE1038810 • 01.2013 • © Bender Inc. • Page 1/1 • Side 1/2Bender Inc. • USA: 800.356.4266 / 610.383.9200 / info@bender.org • Canada: 800.243.2438 / 905.602.9990 / [email protected] • www.bender.org

US

k1 l1

k2

L2

l2

k3

L3

l3

A1

11 12 14

K1

K2

21 22 24

A2

k1 l1 k2

k3 A1 A2l3

l2

CMD420 / CMD421

Installation Bulletin / Reference Guide

This document is intended as a reference guide for installing and using BENDER CMD420 and CMD421

three-phase AC current relays. This document includes installation, setup, and usage instructions. For

complete details, including installation, setup, settings, and troubleshooting, refer to the CMD420 /

CMD421 user manual, document number TGH1459en. This document is intended as a supplement

and not a replacement to the complete user manual.

Only qualied maintenance personnel shall operate or service this equipment. These instructions

should not be viewed as sucient for those who are not otherwise qualied to operate or service this

equipment. This document is intended to provide accurate information only. No responsibility is as-

sumed by BENDER for any consequences arising from use of this document.

Installation

Mounting

CMD420 / CMD421 series devices may be DIN rail mounted, or screw mounted using the black

clips located on the top and bottom of the device. Screw mounting requires an extra black clip

(article number B98060008, sold separately).

!DANGER

• Disconnect all power before servicing.

• Observe all local, state, and national

codes, standards, and regulations.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

Wiring - General

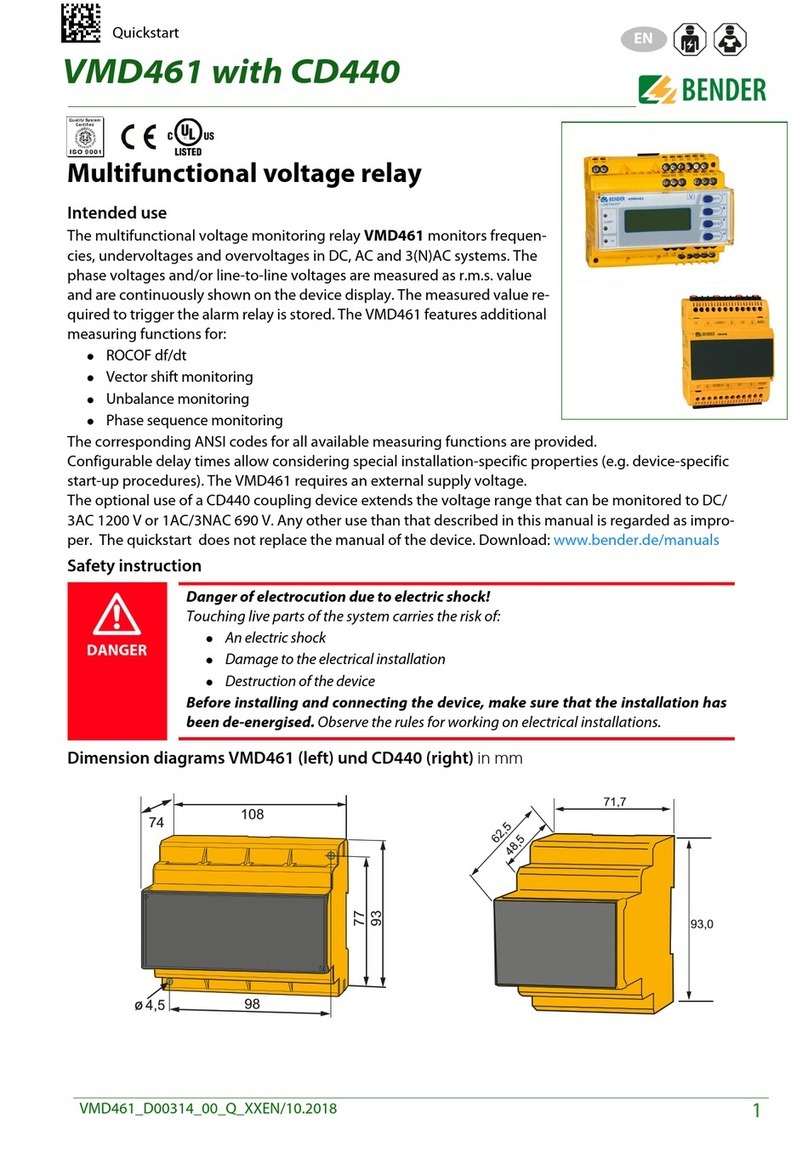

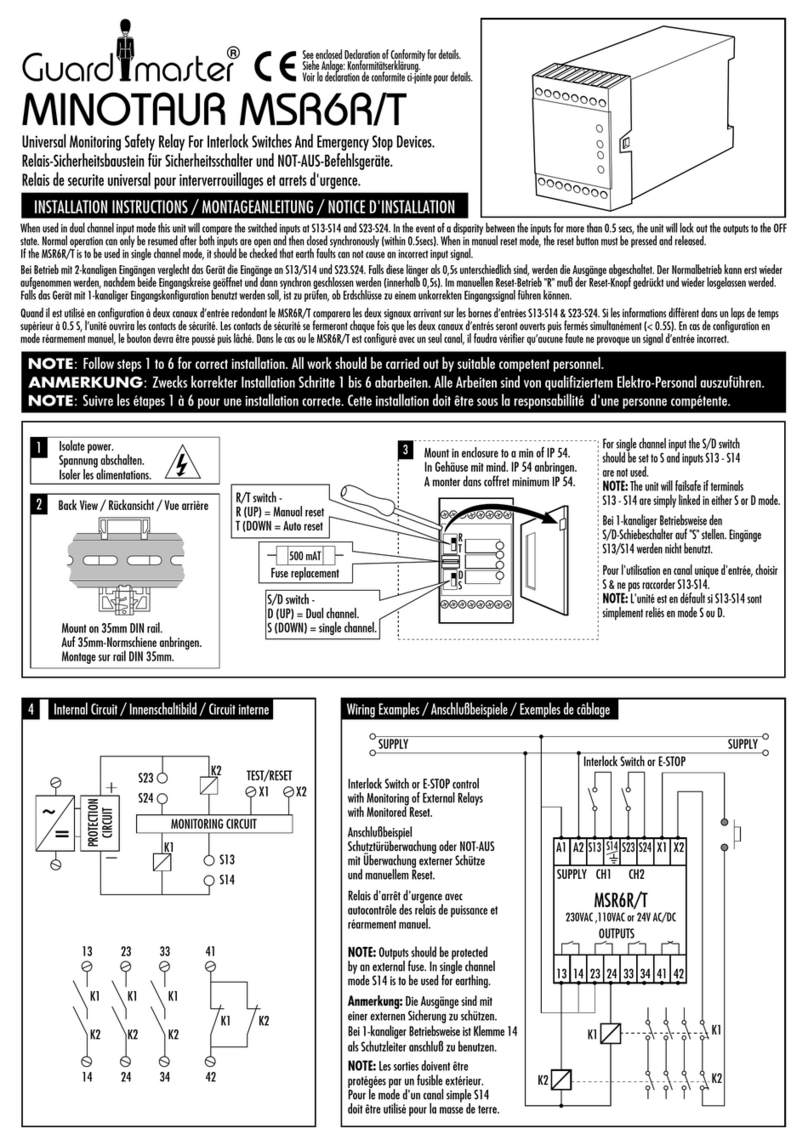

Refer to gure 1 for wiring the CMD420 or CMD421.

When using the CMD420, a current transformer with

1 A secondary (x/1 type) is required. For CMD421 de-

vices, a current transformer with a 5 A secondary (x/5

type) is required. Use minimum AWG 24, maximum

AWG 12 size wire. Refer to CMD420 / 421 series user

manual for complete technical details.

1. External supply voltage; 5A fuse

required for internal device pro-

tection

2. Connection to individual phase

conductors via current transform-

ers. Use x/1 type (1 A secondary)

for CMD420 and x/5 type (5 A sec-

ondary) for CMD421.

3. Alarm relay K1: SPDT contact

4. Alarm relay K2: SPDT contact

Figure 1 - Common wiring diagram for CMD420 and CMD421

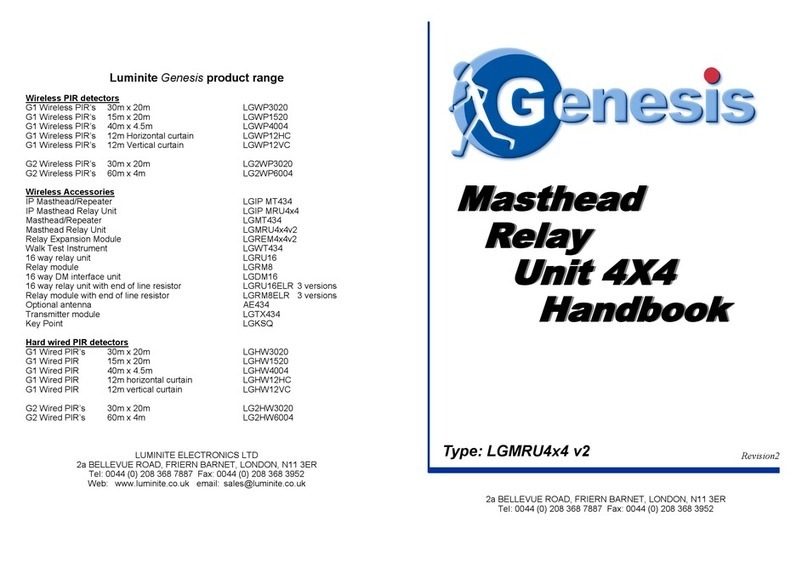

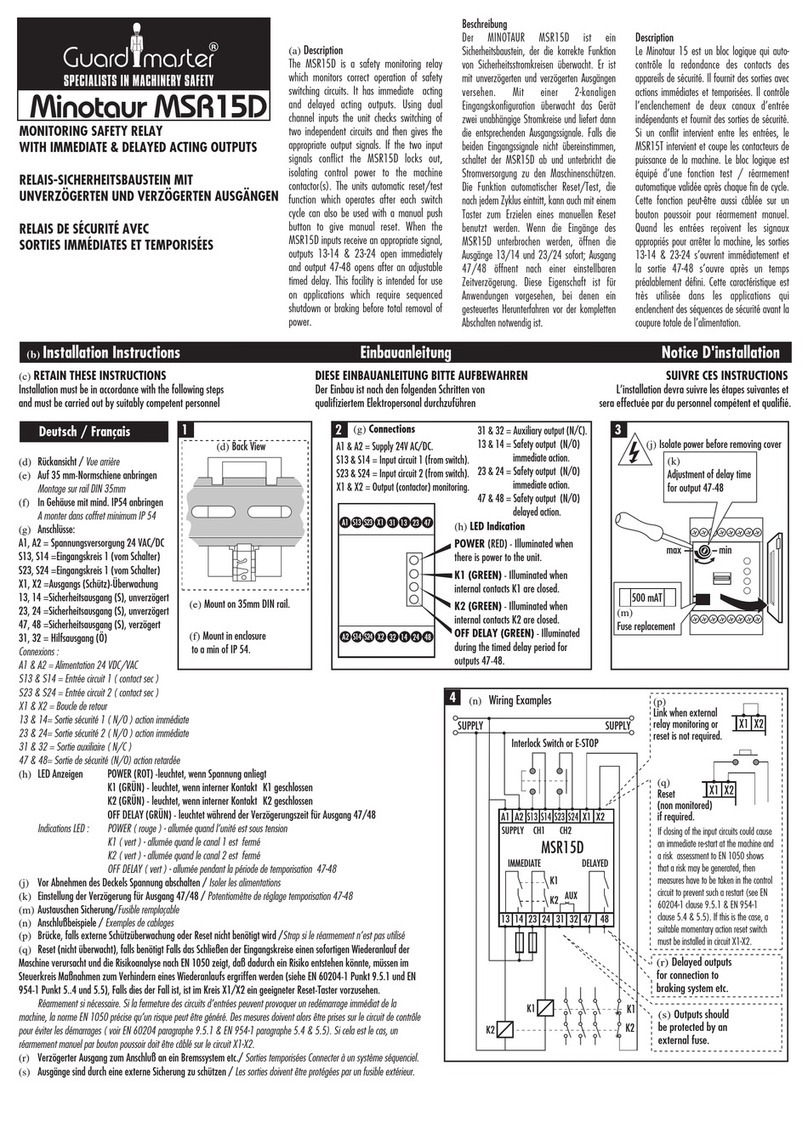

Front Panel Display

1. LED “ON” (green): Illuminates when

power is applied to the device. Flashes

when the CT connection alarm is active.

2. LED “AL1” (yellow): Illuminates when

the prealarm is activated. Flashes when

the CT connection alarm is active.

3. LED “AL2” (yellow): Illuminates when

the main alarm is activated. Flashes

when the CT connection alarm is active.

4. Backlit LCD display

5. TEST / UP button: Activates self-test /

scrolls up inside main menu.

6. RESET / DOWN button: Resets device /

scrolls down inside main menu.

7. MENU / ENTER button: Activates main

menu / Confirms (momuntary push) or

goes back a step (held > 1.5 s) inside

main menu.

1 2 3

4

5 6 7

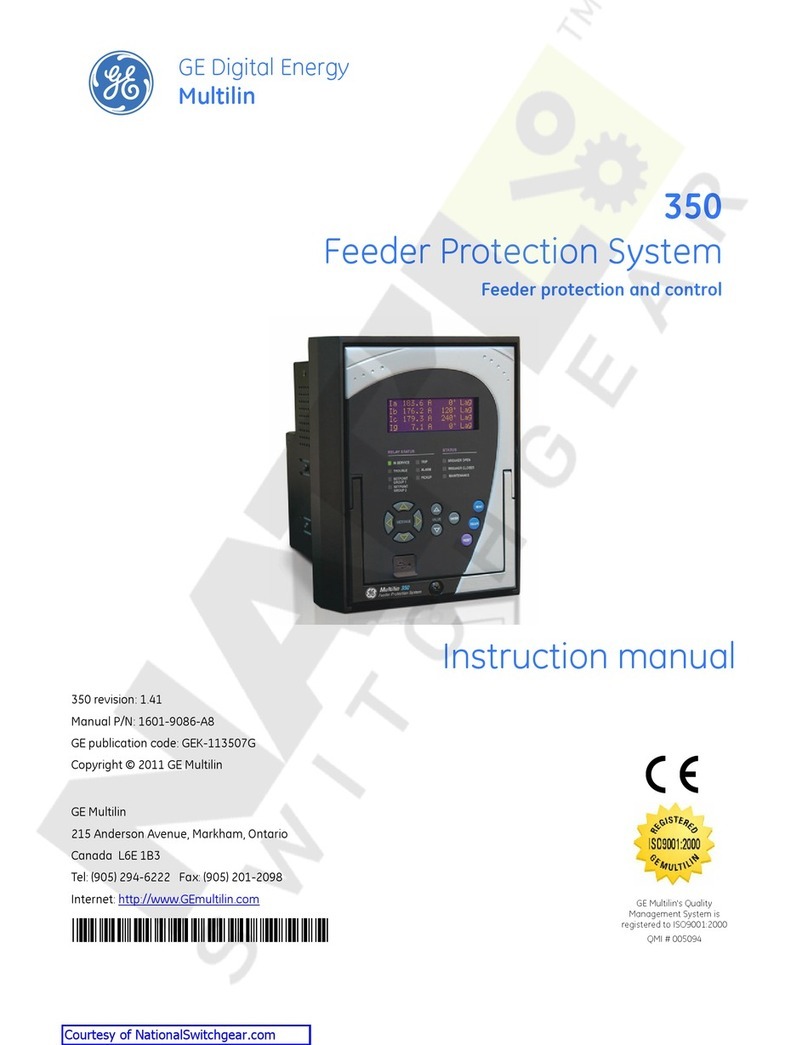

Dimensions

Dimensions listed in inches (mm).

Figure 2 - CMD420 / CMD421 front display

1.42” (36)

2.78”

(70.5)

1.87”

(47.5)

1.22” (31.1)

2.66” (67.5)

1.77” (45)

3.54” (90)

1

2

3

Menu Flow Chart for Common Settings

Figure 4 through gure 8 on the reverse side of this document contain ow charts for modify-

ing commonly used features and settings in the device’s main menu. Not all available features

are listed in this document. For more information, consult the CMD420 / CMD421 user manual.

R

T

Menu Legend

MENU / ENTER button

DOWN ARROW button

UP ARROW button

Momuntary button push

< 1.5 s

Hold button for at least 1.5 s,

then release

> 1.5 s

Normally energized mode (N/E)

Failsafe mode

“N/C”in device settings menu

Power ON, normal state (no alarms)

Power OFF

Power ON, alarm state

11-12 OPEN

11-14 CLOSED

11-12 CLOSED

11-14 OPEN

11-12 CLOSED

11-14 OPEN

21-22 OPEN

21-24 CLOSED

21-22 CLOSED

21-24 OPEN

21-22 CLOSED

21-24 OPEN

Normally deenergized mode (N/D)

Non-failsafe mode

“N/O”in device settings menu

Power ON, normal state (no alarms)

Power OFF

Power ON, alarm state

11-12 CLOSED

11-14 OPEN

11-12 CLOSED

11-14 OPEN

11-12 OPEN

11-14 CLOSED

21-22 CLOSED

21-24 OPEN

21-22 CLOSED

21-24 OPEN

21-22 OPEN

21-24 CLOSED

Relay Operation Setting Device Alarm State K1 STATE K2 STATE

Device Relay Conditions

Wiring - Contacts

Using a normally closed or normally open contact utilizes two factors: wiring out of the proper

terminal, and setting the respective contact to normally energized or deenergized operation.

Refer to the chart below for relay conditions. For changing the energized state of the contact,

refer to “Figure 7 - Contact operation” on the reverse side of this document.

The factory default is normally deenergized operation for relays K1 and K2.

4

T M

Document NAE1038810 • 01.2013 • © Bender Inc. • Page 1/1 • Side 2/2Bender Inc. • USA: 800.356.4266 / 610.383.9200 / info@bender.org • Canada: 800.243.2438 / 905.602.9990 / [email protected] • www.bender.org

CMD420 / CMD421

Installation Bulletin / Reference Guide

Figure 5 - Changing Time Delays

Four separate time delays are available:

• ton1 - Response delay, prewarning

• ton2 - Response delay, main alarm

• t - Startup delay

• toff - Delay on release

= Flashing Symbol

T R

ton1 Adjustment

0...10 seconds

> 1.5 sec

< 1.5 sec

< 1.5 sec

< 1.5 sec

R

Press:

1 x for ton2

2 x for t

0...10 sec

3 x for toff

0...99 sec

OR

R

Press Twice

> 1.5 sec

> 1.5 sec

Figure 6 - Latching behavior (fault memory)

= Flashing Symbol

T R

> 1.5 sec

Press Once

Fault Memory

ON/OFF Select

> 1.5 sec

> 1.5 sec

< 1.5 sec

< 1.5 sec

< 1.5 sec

R

= Flashing Symbol

T R

Failsafe

ON/OFF Select

> 1.5 sec

Press Once

R

Press Once

R

> 1.5 sec

> 1.5 sec

< 1.5 sec

< 1.5 sec

< 1.5 sec

Figure 7 - Contact operation

Use this option to change the behavior of the contacts between normally deenergized (non-

failsafe) mode and normally energized (failsafe) mode. The two SPDT contacts may be changed

individually. Note that the CMD420/CMD421 labels normally deenergized operation as “N/O”

and normally energized operation as “N/C”; utilzing a normally open or normally closed con-

tact only depends on which contact output is wired.

Figure 4 - Setting alarm type and CT ratio

The recommended rst step is to set the type of alarm that will be used. Set this option to “HI”

for undercurrent, “LO” for undercurrent, or “In” for both (window function).

Regardless whether the CMD420 or CMD421 is being used, the ratio of the current transformer

used must be entered into the device as an X/1 type. For example, if using a 50:1 ratio CT with

the CMD420, enter a value of “50” for the CT ratio. If using a 250:5 ratio CT with the CMD421,

enter a value of“50” for the CT ratio.

NOTE: See below for instructions on setting alarm values. Alarm values will still be entered into

the device based on the secondary side (0 - 1 A for the CMD420, 0-5 A for the CMD421). How-

ever, since the CT ratio has been entered into the device, values on the primary side of the CT

will be displayed in real-time on the device’s screen during operation.

= Flashing Symbol

> 1.5 sec

< 1.5 sec

< 1.5 sec

Press nothing for

overcurrent (HI)

otherwise:

R

1x for both (In)

2x for undercurrent (Lo)

T R

Ratio Adjustment

> 1.5 sec

To quit

R

OR

To set CT

ratio

x 2

Rx 3

< 1.5 sec

> 1.5 sec

> 1.5 sec

> 1.5 sec

> 1.5 sec

To quitx 2

Figure 5 - Setting Alarm Values

The CMD420/CMD421 has two alarm values that may be set. Use the following guidelines for

setting these numbers:

• Using only overcurrent OR undercurrent: Only one value is required. The value I2is the

explicit alarm value that is set. The value I1is an optional prewarning that may be acti-

vated, which is a percentage value based on the previously set trip value.

• Using both overcurrent AND undercurrent: Both values are required. The value I2is the

overcurrent value, entered as an explicit number. The value I1is the undercurrent value,

entered as a percentage of the previously entered overcurrent value. EXAMPLE: For an

overcurrent alarm of 2 A and an undercurrent alarm of 1 A, enter“2” for I2, and enter“50%”

for I1.

= Flashing Symbol

> 1.5 sec

T R

Setpoint

Adjustment

R

< 1.5 sec

< 1.5 sec

< 1.5 sec

< 1.5 sec

T R

Setpoint

Adjustment

< 1.5 sec

> 1.5 sec

> 1.5 sec

I 2

A

I 2

A

= Flashing Symbol

> 1.5 sec

T R

Setpoint

Adjustment

R

< 1.5 sec

< 1.5 sec

< 1.5 sec

< 1.5 sec

T R

Setpoint

Adjustment

< 1.5 sec

> 1.5 sec

> 1.5 sec

I 2

A

I 2

A

Changing this setting aects the latching be-

havior of the device:

• “OFF” will cause the device to automati-

cally reset if the alarm condition clears.

• “ON”will cause the device to latch in the

event of an alarm and require a manual

reset. If power is cycled to the device

and the alarm condition has cleared, the

device will reset.

• “CON” will cause the device to latch

in the event of an alarm and require a

manual reset. The device will remain

latched even if power is cycled to the

device.

Other manuals for CMD420

2

This manual suits for next models

1

Other Bender Relay manuals

Bender

Bender cme420 User manual

Bender

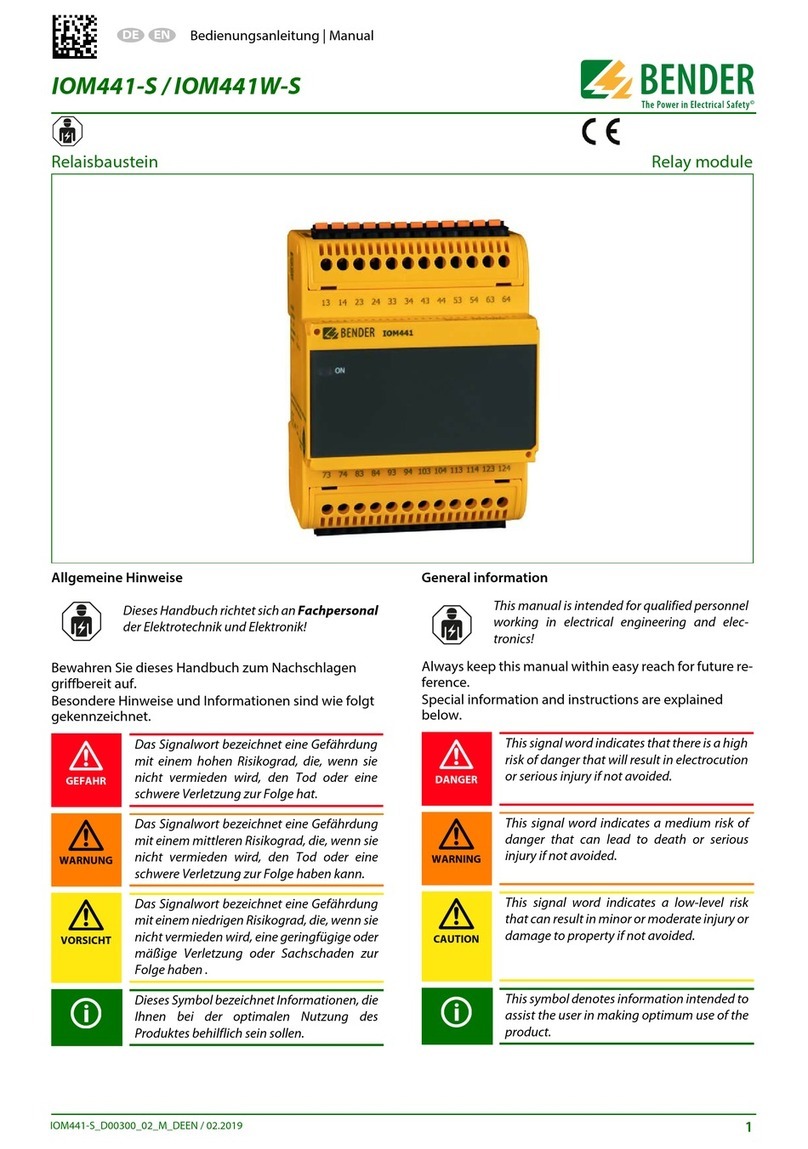

Bender IOM441-S User manual

Bender

Bender IOM441-S User manual

Bender

Bender IOM441-S User manual

Bender

Bender cme420 Manual

Bender

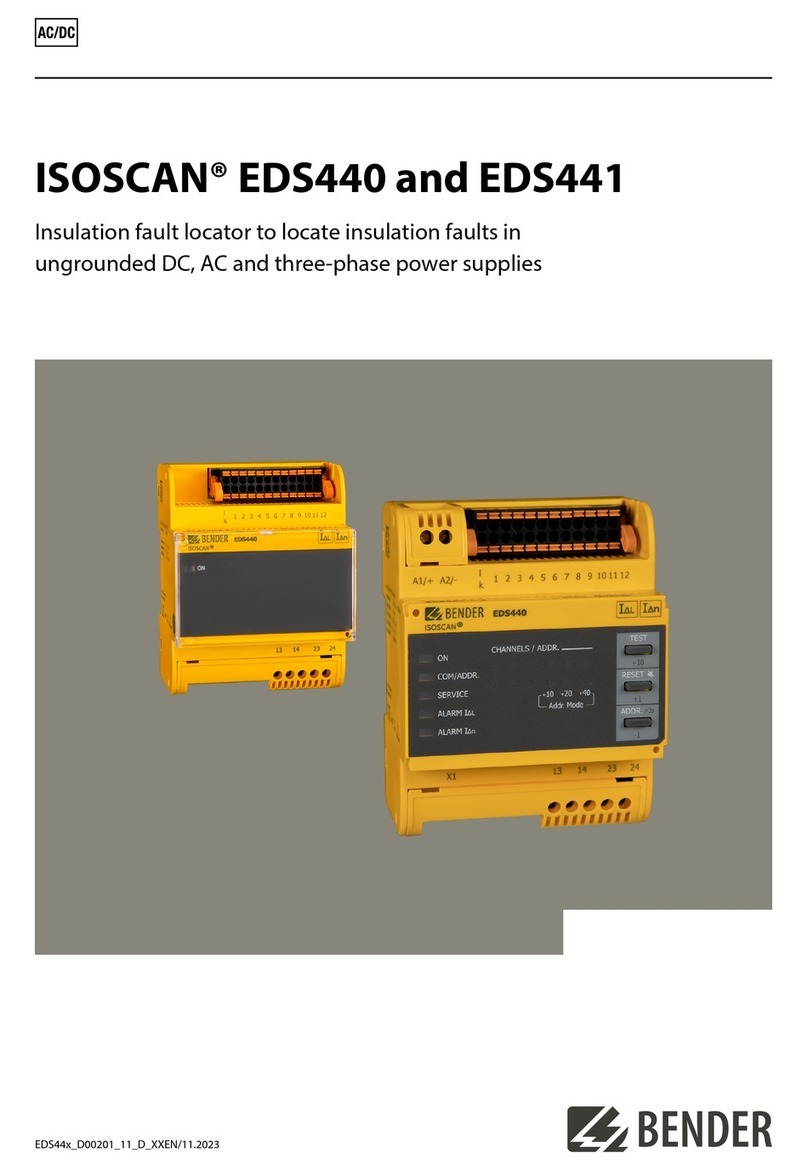

Bender EDS44 L-CN Series User manual

Bender

Bender EDS440 Instruction manual

Bender

Bender RCM470LY User manual

Bender

Bender VME421H User manual

Bender

Bender LINETRAXX VMD258 User manual