NETWORK TYPE SELECTION

The network type depends on the application layout and installed

accessories.

Through the CBX500 several types of accessory Fieldbus Interface

Modules are available to connect to a Fieldbus as a Slave node.

The Net Type switch setting must match the Host Interface

accessory module being used.

For all CBX series connection boxes the Net Type selector switch

allows setting the ID-NET™ Slave type (Topology Role). This

setting must match the Master ID-NET™ Topology Role.

For CBX500 connection boxes the Net Type selector switch allows

setting the Fieldbus type.

Net Type Switch

0 = None (no network present)

1 = Ethernet IP

2 = Profibus

3 = DeviceNet

4 = Reserved

5 = Reserved

6 = Reserved

7 = Reserved

8 = ID-NET™ Slave Synchronized

9 = ID-NET™ Slave Multidata

Fieldbus Slave nodes (including Masters with an ID-NET™ sub-

network) should be set to the specific Fieldbus type (Ethernet,

Profibus, etc.).

ID-NET™ Masters communicating with the Host through the main

serial interface and all other non network applications should be

set to None.

If BM100s are used for ID-NET™ Slaves this switch should be set

to the Slave Synchronized or Slave Multidata position depending

on the ID-NET™ network Topology Role.

NETWORK ADDRESS SELECTION

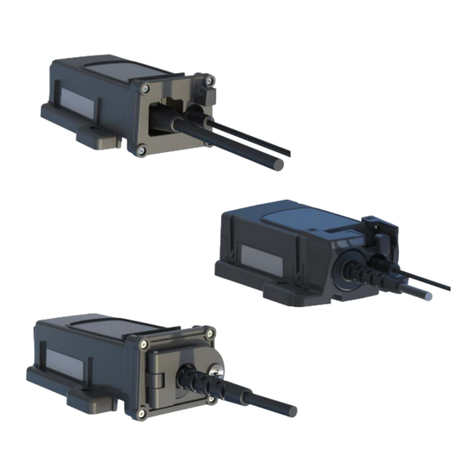

Figure 3 – Address Selection Switches

BM100 provides hardware network address selection for rapid

installation. These switch settings override software configuration

settings. Valid address selection depends on the network type:

Ethernet

The Ethernet address refers to the last three digits of the IP

address (i.e. 172.16.1.xxx). The valid selection range is from 000 to

255. Address selections outside of this range are not accepted by

the Fieldbus network.

Profibus

The valid selection range for the Profibus address is from 000 to

125. Address selections outside of this range are not accepted by

the Fieldbus network.

DeviceNet

The valid selection range for the DeviceNet address is from 00 to

63. Address selections outside of this range are not accepted by

the Fieldbus network. The x100 switch is ignored.

ID-NET™

The valid selection range for the ID-NET™ Slave addresses is

from 01 to 31. Address selections outside of this range are not

accepted by the ID-NET™ network. The x100 switch in this case

refers to the ID-NET™ baudrate.

BAUDRATE SELECTION

All the Fieldbus networks use the autobaudrate feature. This

means the reading devices automatically are set to use the

Fieldbus baudrate. The Fieldbus baudrate cannot be set

through the BM100 switches.

Figure 4 – ID-NET™ Baudrate Switch

When the BM100 is used for ID-NET™ network Slaves, the ID-

NET™ baudrate is selected through the baudrate switch and must

match the Master ID-NET™ baudrate. The settings are:

ID-NET™ Baudrate Switch

0 = 19200 Baud

1 = 38400 Baud

2 = 57600 Baud

3 = 125 kBaud

4 = 250 kBaud

5 = 500 kBaud

6 = 1 MBaud

7 = Reserved

8 = Reserved

9 = Reserved

WRITE PROTECTION LOCK

Figure 5 – Write Protection

A write protection switch is provided to protect configuration data

from being inadvertently overwritten. When this switch is in the lock

position, the Backup function is not available (data cannot be

written to the backup memory) and a diagnostic warning message

can be sent. The Restore function is available.

S/N LABEL

A duplicate Serial Number label is included in the BM100 package.

This label can be applied onto the outside of the CBX for quick

reference.

BM150 DISPLAY CONNECTOR

BM100 provides the flat cable connector for connection of the

BM150 Display and Keypad accessory for the CBX500.

When the BM150 accessory is used the Backup and Restore

functions are managed through the Display and Keypad and

therefore are disabled at the BM100 Backup/Restore button. The

BM150 has an extended menu which allows partial as well as

complete backup and restore functions.