Datawell BV Wave Unit User manual

Wave Unit

Reference Manual

April 15, 2019

Service & Sales

Voltastraat 3

1704 RP Heerhugowaard

The Netherlands

+31 72 534 5298

+31 72 572 6406

www.datawell.nl

2

3

4

Declaration of conformity

(According to EN ISO/IEC 17050-1:2004)

Document No.: Datawell_DoC_Wave_Unit_1_1

Manufacturer's name: Datawell B.V.

Manufacturer's address: Zomerluststraat 4

2012 LM Haarlem

The Netherlands

Declares under sole responsibility that the product:

Product name: Waverider

Trade name: Datawell

Model: Wave Unit

complies with the essential requirements of the following applicable European Directives,

and carries the CE marking accordingly:

EMC Directive (2004/108/EC)

RoHS Directive (2011/65/EU)

and conforms with the following product standards:

Standard Limit

EMC EN 300 220-1 V2.4.1 (2012-05) −54 dBm, 47-74, 87.5-118, 174-230, 470-862

MHz

EN 300 220-2 V2.4.1 (2012-05) −36 dBm, <1000 MHz, −30 dBm, >1000 MHz

EN 300 390-1 V1.2.1 (2000-09) −36 dBm, 30 MHz-1 GHz

EN 300 390-2 V1.1.1 (2000-09) −30 dBm, 1-4 GHz

EN 301 489-1 V1.9.2 (2011-09) / 3 V/m, 80-2700 MHz

EN 301 489-3 V1.4.1 (2011-09) 4 KV/8 KV contact/air

EN 55022: 2010 / 40 dB(μV/m), 30-230 MHz

EN 61000-6-3: 2007 47 dB(μV/m), 230-1000 MHz

EN 55024: 2010 / 3 V/m, 80-2700 MHz

EN 61000-6-1: 2005 4 KV/8 KV contact/air

Supplementary Information:

This DoC applies to above-listed products placed on the EU market after:

Jan 1, 2017 Eric Stoker

Date Quality Assurance Manager

5

Contents

1 Introduction ................................................................................................... 7

2 Maintenance................................................................................................... 9

2.1 Consumables ........................................................................................... 9

2.1.1 Bags of drying agent ......................................................................... 9

2.2 Inspection................................................................................................. 9

2.2.1 Damage ............................................................................................ 9

2.2.2 Opening the Wave Unit and sealing rings......................................... 9

2.3 Service ..................................................................................................... 9

2.3.1 The Wave Unit’s wave motion sensor............................................... 9

3 Trouble Shooting......................................................................................... 11

3.1 Wave Unit diagnosis .............................................................................. 11

3.2 The Wave Unit motion sensors .............................................................. 11

3.2.1 Stabilized platform and accelerometer............................................ 11

4 Repair ........................................................................................................... 13

4.1 Calibration .............................................................................................. 13

4.2 Contact................................................................................................... 13

4.3 Serial numbers ....................................................................................... 13

5 Reference ..................................................................................................... 15

5.1 Dangers and warnings ........................................................................... 15

5.1.1 Dangers .......................................................................................... 15

5.1.2 Warnings......................................................................................... 15

5.2 Measuring waves with the Wave Unit .................................................... 15

5.2.1 Measuring waves - Considerations ................................................. 15

5.2.2 Wave Unit parts .............................................................................. 16

5.2.3 Packing ........................................................................................... 16

5.2.4 Stainless steel housing ................................................................... 16

5.2.5 Lid Assembly................................................................................... 17

5.2.6 Lid ................................................................................................... 17

5.3 Wave motion sensors............................................................................. 18

5.3.1 Wave height, principle of measurement.......................................... 18

5.3.2 Wave direction, principle of measurement ...................................... 18

5.3.3 Wave Unit axes and references ...................................................... 19

5.3.4 Inspection of the fluid level.............................................................. 20

5.3.5 Sensor fluid and temperature.......................................................... 21

5.3.6 Calibration of the vertical accelerometer ......................................... 21

5.3.7 Platform offset and stability ............................................................. 21

5.3.8 Magnetic compass .......................................................................... 21

5.3.9 Pitch and roll ................................................................................... 22

5.3.10 Horizontal accelerometers ............................................................ 22

5.3.11 Filtering ......................................................................................... 22

5.4 Data processing ..................................................................................... 24

5.4.1 Wave height spectrum .................................................................... 24

5.4.2 Wave direction spectrum................................................................. 25

5.5 Data format ............................................................................................ 27

6

5.5.1 Wave Unit serial message format ................................................... 27

5.5.2 Datawell real-time format ................................................................ 28

5.6 Stainless steel housing and lid assembly............................................... 31

5.6.1 Installation....................................................................................... 31

5.6.2 Packing, weights and dimensions ................................................... 31

5.6.3 Wave Unit housing.......................................................................... 31

5.6.4 Handles........................................................................................... 31

5.6.5 Lid, serial number and FS direction ................................................ 31

5.6.6 Drying agent bags, plywood............................................................ 32

5.6.7 Lid and connections ........................................................................ 32

5.7 Power supply and consumption ............................................................. 34

5.8 Contacts and Questions......................................................................... 34

5.8.1 Addresses ....................................................................................... 34

5.8.2 Telephone and fax numbers ........................................................... 34

5.8.3 Email-addresses ............................................................................. 34

5.8.4 Website ........................................................................................... 35

5.8.5 FAQ ................................................................................................ 35

5.8.6 Datawell Bulletin ............................................................................. 35

5.9 Literature ................................................................................................ 35

7

1 Introduction

The Datawell Wave Unit is an OEM version of the well-known Directional Waverider Mk-III

for measuring wave motions in three directions. The unit gives out the real time heave, north

and west displacements as well as common wave parameters like Hs and Tz and spectral data.

The Wave Unit contains Datawell’s accurate and well-proven stabilized platform sensor,

enabling wave height measurements by a single accelerometer. For the wave direction, direct

pitch and roll measurements are performed needing no integration. This, in combination with

horizontal accelerometers and a compass, forms the complete sensor unit which is the heart of

the Wave Unit.

The Wave Unit is meant to be integrated as a complete sensor package in oceanographic and

meteorological buoys.

The Wave Unit is equipped with an RS-232 interface and a power converter. Both the power

converter and the RS-232 interface are galvanically isolated for easy integration and overall

robustness. The power converter is suitable to accept a wide input voltage range from 10V up to

30V DC. The data format of the Wave Unit is compatible with the format as sent out by a

DWR-MkIII and can be used with the Waves4 software package and/or libdatawell

library. Alternatively, the data can be received, interpreted and forwarded by an embedded

system.

The Wave Unit is a highly sophisticated piece of equipment which hardly requires any attention.

For continuous reliable operation some maintenance is required however at low frequency

intervals. Chapter 2 Maintenance covers this topic.

In Chapter 3 Trouble Shooting several suggestions are made to tackle possible problems or even

carry out some small repairs.

During the operational life of your equipment calibration drift, aging or incidents could make it

necessary to send (part of) the equipment back to Datawell Service department. To serve you

best it is important to know exactly which parts fail and need to be returned. Please contact our

Service department prior to returning the equipment, stating serial number and complaint.

Chapter 4 Repair tells you where to locate serial numbers, how to contact Datawell Service

department and where to send parts.

This manual describes the operation of the following configuration:

Wave Unit with stabilized platform accelerometer-based wave motion sensor

Supply: 10 - 30 V DC, power consumption 400 mW max; reverse polarity and ESD

protected

Stainless Steel housing

Size (approximately): diameter 410 mm, height 560 mm

Weight (approximately): 36 kg

Do not expose your Wave unit to sea water, install in a water tight compartment.

Also keep away any magnetic parts, since they will interfere with the magnetic compass

measurements and affect the measured wave direction

8

9

2 Maintenance

During the operational life of your Wave Unit it will require some maintenance even though it

may function without error. We recommend to inspect the Wave Unit on every possible

occasion in order to prevent possible malfunctioning.

This chapter indicates which parts need servicing and when. Rather than extensively describing

the full maintenance procedure, this chapter gives a short summary. Please refer to the

description of the respective part in Chapter 5 Reference for the actual maintenance procedure.

2.1 Consumables

2.1.1 Bags of drying agent

In a hermetically sealed Wave Unit the bags with drying agent will protect the Wave Unit’s

electronics from taking up any possible moisture. In case the drying agent gets saturated it needs

to be dried in an oven, see subsection 5.6.6. Bags are located near the electronics in the lid

assembly and near the sensor electronics.

2.2 Inspection

2.2.1 Damage

We advise to inspect the Wave Unit for damage upon delivery.

2.2.2 Opening the Wave Unit and sealing rings

For reasons of importance it is noted in the beginning of the paragraph that before the lid is

opened, it should be rinsed with fresh water to avoid migration of salt and dirt into screw holes,

sealing ring grooves or the Wave Unit interior.

Remove dirt from the circular grooves of the housing flange and inspect the rubber sealing rings

for cuts. Clean grooves and intact sealing rings are essential for water tightness.

To open the lid refer to subsection 5.2.6.

2.3 Service

2.3.1 The Wave Unit’s wave motion sensor

The stabilized platform vertical accelerometer consists of a fluid-filled sphere. Over the years

the fluid evaporates through the Perspex sphere. Check the fluid level at least once every three

years. Experience showed that a small refill is required every three years. Section 5.3 will

explain where to check and how to refill.

As long as the sphere is correctly filled, the motion sensor is a robust sensor with nearly

perfectly buoyant invulnerable mechanics in the fluid. However, with insufficient fluid inside

the sphere, the mechanics in the fluid will no longer remain perfectly suspended and ultimately

will collapse under its own load. For a long life of your wave motion sensor carefully maintain

the sensor fluid level.

When in doubt, several tests in section 5.3 describe how to roughly verify the correct

functioning of your motion sensors.

10

11

3 Trouble Shooting

This chapter will deal with minor problems that may occur and can be traced and solved by

yourself.

3.1 Wave Unit diagnosis

The Wave Unit has been provided with a processor board, which processes the digital signals to

the serial communication channel. This channel is available for host access. For the processor

board is a common part in most products of Datawell’s product range, it has some redundant

circuitry when using it in this Wave Unit application.

3.2 The Wave Unit motion sensors

The stabilized platform motion sensor is a very delicate instrument that can only be repaired by

skilled persons. In this section the symptoms of malfunction will be described, but faults are

almost impossible to repair for a layman.

3.2.1 Stabilized platform and accelerometer

The strength of the Datawell stabilized platform is that the heave is only determined by the

vertical accelerometer sensor. This implies that an erratic heave directly points at the vertical

accelerometer. Apart from the heave also the offset of the vertical accelerometer in the system

file, subsection 5.5.2.3, can be inspected. Possible causes are damaged suspension or internal

wires, moisture on the electronics, or low battery voltage.

Platform instability typically produces long period oscillations (20-25 s) of significant

amplitude (on the order of a meter) in the horizontal displacements. A faulty inclination angle

supports this. Likely causes are turbulence in the fluid or a sudden temperature change. Too fast

rotations may also cause turbulence. These disturbances will disappear within 24 hours. It

should be noted that pitch and roll errors can produce similar symptoms.

3.2.2 Magnetic compass

Inclination is the angle the local earth magnetic field makes with the local earth surface. A

measured inclination angle which matches the true local inclination within 1.5º indicates that (1)

the compass is functioning well, and (2) the offset angle of the platform is not too large. Local

inclination may be found on the web, e.g. visit www.ngdc.noaa.gov/seg/geomag/magfield.shtml.

Orientation is the angle between the reference axis of the Wave Unit and the magnetic north

direction. It does not depend on any tilt. The V-shaped groove indicates the reference axis.

Orientation may be easily verified with help of a hand held magnetic compass or the known

local north.

Furthermore, a plot of the inclination as function of the orientation can be made. The inclination

should remain constant for different orientation angles. A dependency of inclination on buoy

orientation can be caused by a platform offset angle or by an offset of the fluxgate compass.

12

13

4 Repair

Datawell recommends you send your Wave Unit for service and maintenance every 3 to 6 years

approximately. Also if your Wave Unit does not function correctly and, although you may have

tracked down the problem with help of the Trouble shooting chapter, you are not able to solve

the problem, the malfunctioning Wave Unit (part) should be sent to Datawell Service

department. This chapter will explain where to turn for help and what information must be

provided that Datawell may swiftly remedy your problems.

4.1 Calibration

Datawell advises to have your Wave Unit recalibrated every 3 to 6 years. Assistance and

training: Datawell offers you to hire a service and repair specialist to train your personnel. If

you just purchased a wave measuring system you are entitled to one day of assistance and

training for free. Ask our Sales department or Service department.

4.2 Contact

To contact Datawell Service department, you can use the following address or numbers. If you

ship Wave Units or Wave Unit parts please use the same address.

Datawell BV

Voltastraat 3

1704 RP Heerhugowaard

The Netherlands

Phone +31-(0)72-5718219

Fax +31-(0)72-5712950

Email servdept@datawell.nl

If you use airfreight please use following address:

DATAWELL BV

c/o DHL Global Forwarding B.V.

PRESTWICKWEG 1

1118LC SCHIPHOL-SE

AMSTERDAM AIRPORT

THE NETHERLANDS

Notify: DATAWELL BV

TEL: 023 5316053

4.3 Serial numbers

If you have any questions regarding your Wave Unit or if you encounter problems and you wish

to contact Datawell, it is important to have the serial number at hand as listed on the text plate

on top of the Wave Unit.

14

15

5 Reference

This is the largest chapter by far. All Wave Unit functions and parts will be discussed here. To

start with, the various components of the Wave Unit, their names and location will be

introduced. You will be guided through the lid assembly and the stainless steel housing

assembly, and packing, first in general, then in detail. After that all possible standard functions

will follow. The chapter concludes with references to other sources of information and useful

addresses and contacts.

5.1 Dangers and warnings

Below you find a summary of dangers and warnings related to the present product.

5.1.1 Dangers

While transporting the Wave Unit, tie it down firmly. A Wave Unit moving

uncontrolled can be dangerous.

5.1.2 Warnings

Do not expose your Wave unit to sea water, install in a water tight compartment

Do not spin your Wave Unit more than 10 turns at once or faster than 1 turn/10s. This

may damage the motion sensor inside.

Do not expose your Wave Unit to temperatures below −5 ºC for longer periods; the

fluid in the sensor could be permanently altered.

Do not insert magnetic materials in or in the environment of the Wave Unit as this

will affect the magnetic compass readings. Use original Datawell parts.

Close the lid whenever the Wave Unit is not in use. Otherwise the bags of drying agent

inside the buoy will take up moisture and become saturated. Particularly for a cold

Wave Unit placed in a humid environment saturation will set in very fast.

5.2 Measuring waves with the Wave Unit

Datawell is specialized in the production of complete wave measuring equipment generating

high quality wave data and wave parameters for marine coastal engineering and scientific

institutes. Mooring lines, hull size and shape, wave motion sensors, etc. of all products are

designed and integrated specifically to serve this purpose. This Wave Unit however only

consists of the heart of such measuring equipment assembled in an stainless steel housing. The

accuracy of obtained data is highly dependent on the way the Wave Unit has been built into a

major assembly and the way this major assembly is moored, its buoyancy, etc.

5.2.1 Measuring waves - Considerations

If built into larger platforms, the following topics need to be reconsidered:

Wave lengths shorter than twice the diameter of the platform will not be measured

anymore. This will result in some high frequency cut-off in the generated spectra.

The reduced freedom of movement will result in a restriction mainly in the horizontal

direction, not so much in vertical direction. The problems in the horizontal direction are

its sign asymmetry (complete freedom of motion towards the mooring point and

absolutely no motion from the mooring point beyond the mooring line length) and

direction asymmetry (perpendicular to the mooring line the motion is nearly

unrestricted). This will slightly affect the estimated wave heights but may yield

misleading wave directions, depending on wave-, wind- and current direction.

16

Another point to consider is that pitching and rolling of tall structures may introduce

non-wave motion away from the centre of rotation (pseudo-motion); horizontal motion

will be influenced most.

A final point of consideration: the response of the buoy or platform to the waves may

display resonant motion like immersion resonance or pitch/roll resonance at certain

frequencies.

5.2.2 Wave Unit parts

The Wave Unit is a hermetically closed stainless steel housing with the sensor, compass,

accelerometers and the analogue circuitry inside the stainless steel housing; the filter board, the

power supply with the serial communication circuitry and the power connection, the AD

converter and the processor board have been built onto the inside of the lid. On top of the Wave

Unit the connection box is available for making the connections to the host unit.

5.2.3 Packing

The Wave Unit is packed on a wooden plate, secured with 4 bolts and nuts.

5.2.4 Stainless steel housing

On the outside of the stainless steel housing you will find, from the bottom up: the mounting

flange, the cylindrical housing with in the upper flange, the forward shipping reference and the

groove for the rubber sealing ring; on top you will find the lid again with a matching forward

shipping reference, the handles and the connection box. The forward shipping reference is

formed by a V-shaped cutting.

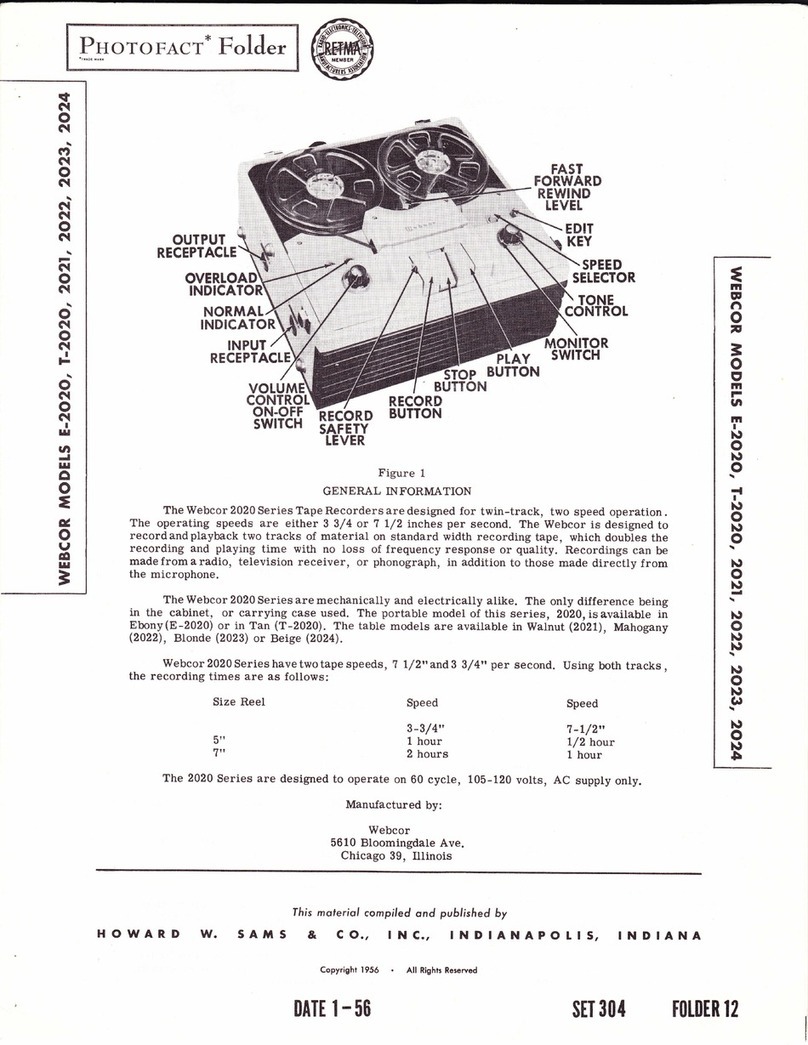

Figure 5.2.4.1 shows the contents of the Wave Unit; the motion sensor package consisting of

(analogue) electronics boards, a stabilized platform with vertical accelerometer, and pitch-roll

sensors, two horizontal accelerometers and a three-axial fluxgate compass. To the top one can

see the lid assembly with the filter board, the AD board, the processor board and the power

supply board with the serial communication channel.

Figure 5.2.4.1 Rendering of the stainless steel housing contents

17

To ensure proper functioning of all the electronics drying agent bags have been added at the

appropriate places.

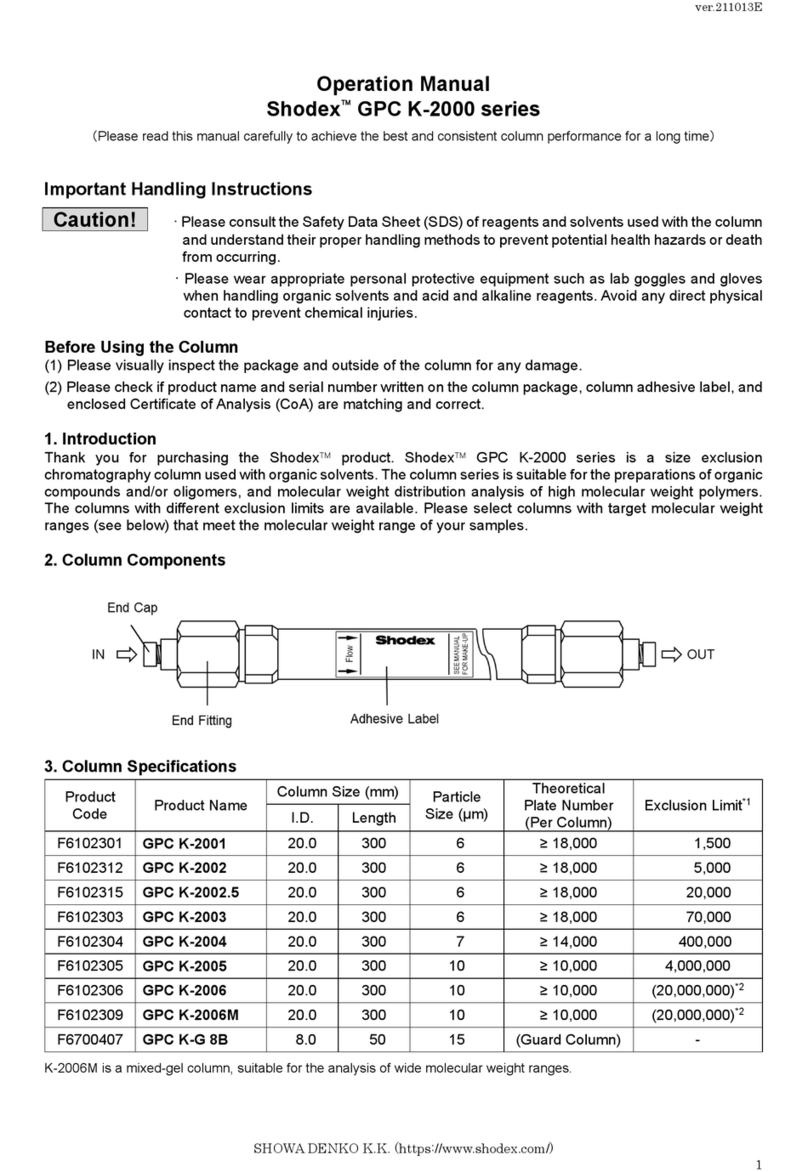

5.2.5 Lid Assembly

A whole range of printed circuit boards each with its own functionality and its own location has

been positioned onto the lid assembly. Figure 5.2.5.1 schematically shows the location of the

boards; the interconnecting ribbon cables and other cables are not shown.

At the heart of the lid assembly you find the microprocessor board. It manages all processes,

commands and controls actions, observes status and health, collects data, processes data and

redistributes processed data and handles various means of communication. All interconnecting

ribbon cables start or end here. Another central board is the power supply. This board adapts the

applied power at the terminal box at the top of the lid to voltages required to power the boards.

This board also contains the communication channel.

To perform the actual measurements, the analogue-to-digital converter board (ADC) samples

the buoy’s internal system temperature sensor which is present on the ADC board and all

motion sensors outputs and passes the readings on to the microprocessor. The data is processed

and made available at the serial communication terminal at the terminal box at the top of the lid.

Figure 5.2.5.1. Schematic drawing of the printed circuit boards on the lid assembly.

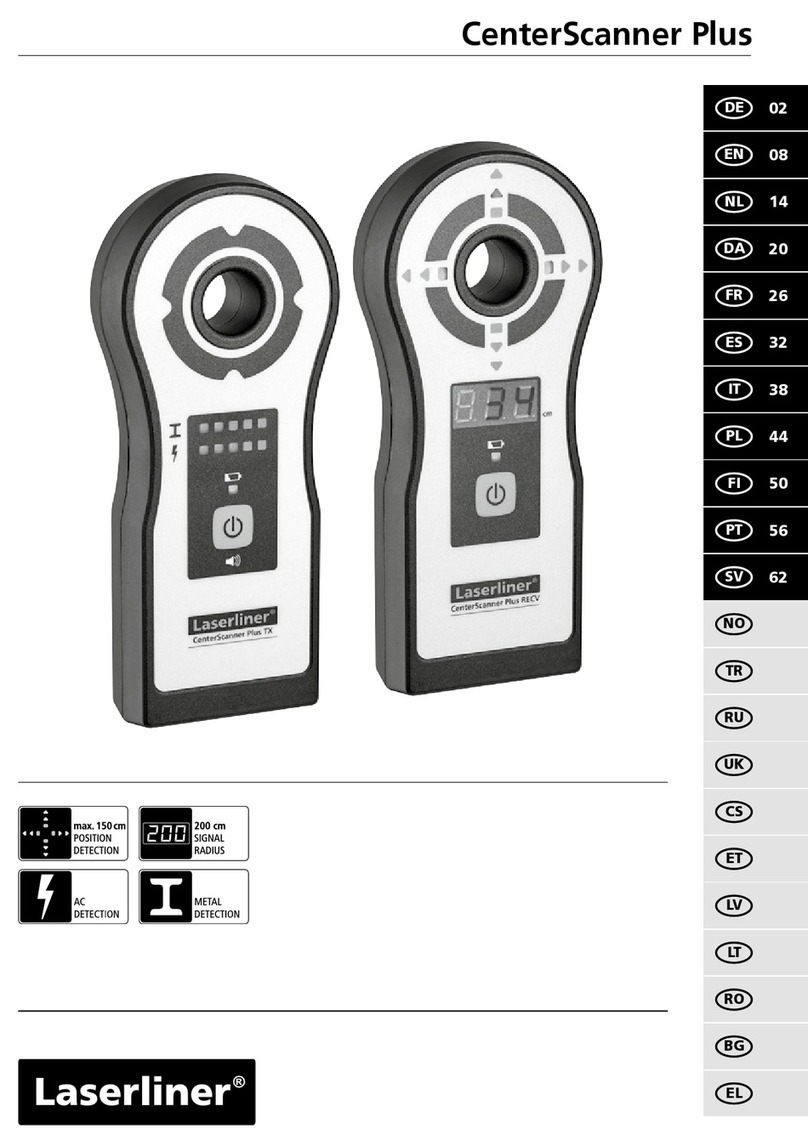

5.2.6 Lid

To close the lid 12 hexagon socket screws are used. One of these may be screwed in the 13th

lifting hole to overcome a possible partial vacuum when lifting the lid (Figure 5.2.6.1). The lid

can be lifted by using the treaded hole and one of the screws, in case of under pressure.

18

Figure 5.2.6.1. Opening the lid by using a screw in the lifting hole.

5.3 Wave motion sensors

5.3.1 Wave height, principle of measurement

The Wave Unit measures wave height by means of a single accelerometer. The sensitive axis of

this accelerometer points in the vertical direction. After filtering and double integration of the

acceleration signal the motion of the Wave Unit, hence the wave motion is obtained. The

strength of the Datawell principle is its gravity-stabilized platform. This patented principle is

unique and we will come to the advantages below. Essentially, the platform is formed by a

suspended disk in a fluid of equal density. By means of a very small metal weight the disk is

made gravity sensitive. The large mass of the fluid in combination with the small force of the

metal makes a pendulum with a natural period of 40 s, corresponding to a pendulum length of

400 m. This platform remains almost horizontal under any movement which can be expected at

sea. Mounting the accelerometer on this stabilized platform makes the measurement of wave

height through vertical acceleration straightforward.

5.3.2 Wave direction, principle of measurement

Wave direction is determined by measurement of the horizontal motion of the Wave Unit and

correlating this motion with the vertical motion. Two mutually perpendicular accelerometers are

mounted in the Wave Unit which measure the horizontal motion in case the Wave Unit is in the

upright position. In case of tilt, the pitch and roll angles are determined by coils around the

sensor sensing the electromagnetic coupling with a coil on the stabilized platform. With the help

of the pitch and roll sensors the measurements of the above mentioned acceleration sensors are

19

transferred to real horizontal acceleration. With the help of a fluxgate compass the acceleration

in Wave Unit coordinates is transferred to north-west-coordinates.

The beauty of the Datawell principle is that it has kept the vertical acceleration out of all the

transformations, thus ensuring that you get the best wave heights possible.

5.3.3 Wave Unit axes and references

The Wave Unit motion sensor package measures 8 observables: 3 accelerations Ax, Ay, Av, 3

magnetic field strengths Hx, HyHz, and pitch and roll. Figure 5.3.3.1 defines the directions of x,

y, z and vertical axes. All directions are referenced to the V-shaped groove (y) and normal (x),

the axis of rotation (z) fixed to the Wave Unit and the vertical axis (v) determined by the force

of gravity.

Suppose you were facing the V-shaped groove. Tilting the Wave Unit towards you would result

a positive pitch and a negative x-acceleration or Axoutput. Note that an accelerometer sensor

actually is a force sensor and that with a tilted Wave Unit the force of gravity will act as an

inertial force. If you add that the direction of acceleration is opposite to the direction of the

inertial force or gravity force, you will understand why Axis negative. Similarly, tilting the

Figure 5.3.3.1. Definition of the axes and signs of the motion sensors.

20

Wave Unit towards the left would result a positive roll and a positive y-acceleration or Ay

output. Considering an upright Wave Unit, if the positive Axdirection would point towards the

north then the positive Aydirection would point westward and the positive z-axis would be

directed upward. Double integration would yield north, west and vertical motion.

The signs of the compass outputs correspond to the positive x-, y-, but negative z-direction.

Directing the V-shaped groove towards the north will yield a positive Hx and zero orientation.

Looking from above a right angle clockwise rotation yields +90º orientation and a positive Hy.

Note that the Hz-axis is fixed to the housing whereas the Av-axis always points up and is fixed to

the stabilized platform.

For a tilted Wave Unit the orientation is the same as for an upright Wave Unit, which may be

verified by tilting the Wave Unit.

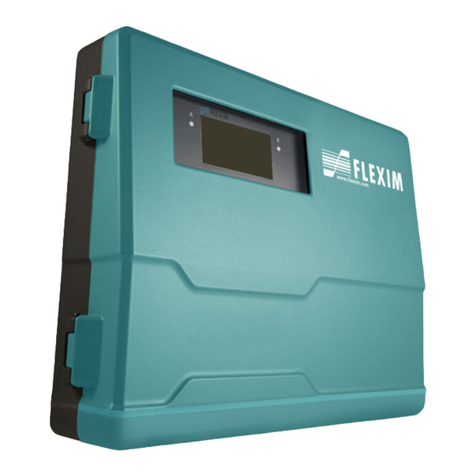

5.3.4 Inspection of the fluid level

As mentioned in Chapter 2 Maintenance it is important for the stabilized platform and vertical

accelerometer sensor to periodically check the fluid level within the plastic sphere. The fluid

level can be visually inspected through the Perspex lid on the sphere, see Figure 5.3.4-1. If the

centre of the rubber membrane is pointing upwards, Figure 5.3.4.1(b), the fluid level is

sufficient. In case the membrane touches the nylon screw, Figure 5.3.4.1(a), the fluid is too low

and fluid has to be added. Datawell advises to check the fluid level every 3 years. Based on

experience the sensor requires a small refill after 3 to 6 years.

Only fill up the sensor in a clean environment to avoid contamination of the fluid. Do not insert

anything but the original sensor fluid. Datawell will readily supply you with a small amount. To

avoid damage by spilled fluid wrap some tissue paper around the neck of the sensor. Take off

the plastic lid by unscrewing the 6 screw-bolts. Remove the rubber membrane and pour some

Figure 5.3.4.1. Examples of the fluid level of the stabilized platform and

vertical accelerometer sensor: (a) fluid level too low, (b) fluid level sufficient.

Table of contents

Popular Measuring Instrument manuals by other brands

Gill Instruments

Gill Instruments MetPak II user manual

PCB Piezotronics

PCB Piezotronics PCB-339A31 Installation and operating manual

Agilent Technologies

Agilent Technologies 8614 B Series user guide

Aqua-Scope

Aqua-Scope LoRaWAN AQSLWE01 User and installation manual

LaserLiner

LaserLiner CenterScanner Plus TX manual

Flexim

Flexim FLUXUS H721 Operating instruction