Datcon DT9100 B User manual

DT9100 B

Intrinsically Safe Digital Clock

Operating Instructions

DT9100 B

Contents

1. About this document.....................................................4

1.1. Function.....................................................................................4

1.2. Target group..............................................................................4

1.3. Sy bolis used........................................................................4

2. For our safet ..............................................................5

2.1. Authorised personnel.................................................................5

2.2. Appropriate use.........................................................................5

2.3. Warning about isuse...............................................................5

2.4. General safety instructions........................................................5

2.5. EU confor ity............................................................................5

2.6. Safety infor ation for Ex areas.................................................6

2.7. Environ ental instructions........................................................6

3. Product description.......................................................7

3.1. Delivery configuration................................................................7

3.2. Principle of operation.................................................................8

3.3. Adjust ent.................................................................................9

3.4. Storage and transport................................................................9

4. Mounting......................................................................10

4.1. General instructions.................................................................10

4.2. Main di ensions of the instru ent..........................................11

4.3. Mounting as a wall-instru ent.................................................12

4.4. Mounting as a panel-instru ent..............................................15

5. Connecting...................................................................17

5.1. Preparing the connection.........................................................17

5.2. Connecting the synchronising input........................................20

5.3. Connecting the digital outputs.................................................21

5.4. Connecting the battery pack....................................................22

5.5. The replace ent of the battery pack.......................................23

6. Displa and manual controls......................................25

6.1. The first start-up.......................................................................25

6.2. Characters and ne onics appearing on the display............26

6.3. Manual controls.......................................................................28

220180905-V120180905-V1

DT9100 B

7. Setting up.....................................................................29

7.1. Type in the code (password)...................................................29

7.2. The enu.................................................................................30

7.3. Second clear (01. enu ite ).................................................31

7.4. Ti e-set (02. enu ite )........................................................32

7.5. User code (03. enu ite )......................................................33

7.6. Synchronisation ode (04. enu ite )..................................35

7.7. Synchronisation ti e (05. enu ite ).....................................36

7.8. Synchronisation gate ti e (06. enu ite ).............................37

7.9. Digital output 1 (07. enu ite )..............................................38

7.10. Digital output 2 (08. enu ite )............................................39

7.11. Changing the supervisor code (09. enu ite )....................40

7.12. Tests (10. enu ite )............................................................42

8. Fault rectification.........................................................44

8.1. Fault finding.............................................................................44

8.2. Repairing..................................................................................44

9. Dismounting................................................................44

9.1. Dis ounting procedure...........................................................44

9.2. Disposal...................................................................................44

10. Appendix....................................................................45

10.1. Technical specifications.........................................................45

10.2. Application exa ple..............................................................47

10.3. Error essages.....................................................................48

10.4. Messages of critical errors.....................................................49

10.5. Description of the enu ite s...............................................50

10.6. Messages and error essages during setting up.................53

10.7. Setting the ti e (exa ple)....................................................54

10.8. ATEX Certification.................................................................56

20180905-V1 3

DT9100 B

1. About this document

1.1. Function

This operating instructions has all the infor ation you need

for quick set-up and safe operation of DT9100 B.

Please read these instructions before you start setting up

the instru ent.

1.2. Target group

This operating instructions is directed to trained personnel.

The contents of these instructions should be ade

available to these personnel and put into practice by the .

1.3. S mbolism used

Information, tip, note

This sy bol indicates helpful additional infor ation.

Caution, warning, danger

This sy bol infor s you of a dangerous situation that could

occur. Ignoring this cautionary note can i pair the operator

and/or the instru ent.

Ex applications

This sy bol indicates special instructions for Ex

applications.

•

List

The dot set in front indicates a list with no i plied

sequence.

→

Action

This arrow indicates a single action.

1

Sequence

Nu bers set in front indicate successive steps in a

procedure.

420180905-V120180905-V1

DT9100 B

2. For our safet

2.1. Authorised personnel

All operations described in these operating instructions

ust be carried out only by trained and authorised

specialist personnel. For safety and warranty reasons, any

internal work on the instru ents ust be carried out only

by DATCON personnel.

2.2. Appropriate use

The DT9100 B is a battery-powered intrinsically safe digital

clock. Detailed infor ation on the application range of the

DT9100 B is available in chapter „Product description”.

2.3. Warning about misuse

Inappropriate or incorrect use of the instru ent can give

rise to application-specific hazards, or da age to syste

co ponents through incorrect ounting or adjust ent.

2.4. General safet instructions

The DT9100 B is a high-tech instru ent requiring the strict

observance of standard regulations and guidelines. The

user ust take note of the safety instructions in these

operating instructions, the country-specific installation

standard as well as all prevailing safety regulations and

accident prevention rules.

2.5. EU conformit

The DT9100 B is in confor ity with the provisions of the

following standards:

MSZ EN 60079-0:2013 (ATEX)

MSZ EN 60079-11:2012 (ATEX)

MSZ EN 61326-1:2013 (EMC)

20180905-V1 5

DT9100 B

2.6. Safet information for Ex areas

Please note the Ex-specific safety infor ation for

installation and operation in Ex areas. These safety

instructions are part of the operating instructions and co e

with the Ex-approved instru ents.

2.7. Environmental instructions

Protection of the environ ent is one of our ost i portant

duties.

Please take note of the instructions written in the following

chapters:

• Chapter 3.4. Storage and transport

• Chapter 9.2. Disposal

620180905-V120180905-V1

DT9100 B

3. Product description

3.1. Deliver configuration

Delivered items The scope of delivery enco passes:

• DT9100 B digital clock

• 1 pc. DT4V5BAT power supply

• 1 pc. M16x1.5 cable entry (accessory)

• 2 pcs. of screw cla ps (only for the panel- ounted

version)

• instru ent sealing (only for the panel- ounted version)

• docu entation:

this operating instructions

certification

warranty

The instru ent is built fro the following ain parts:

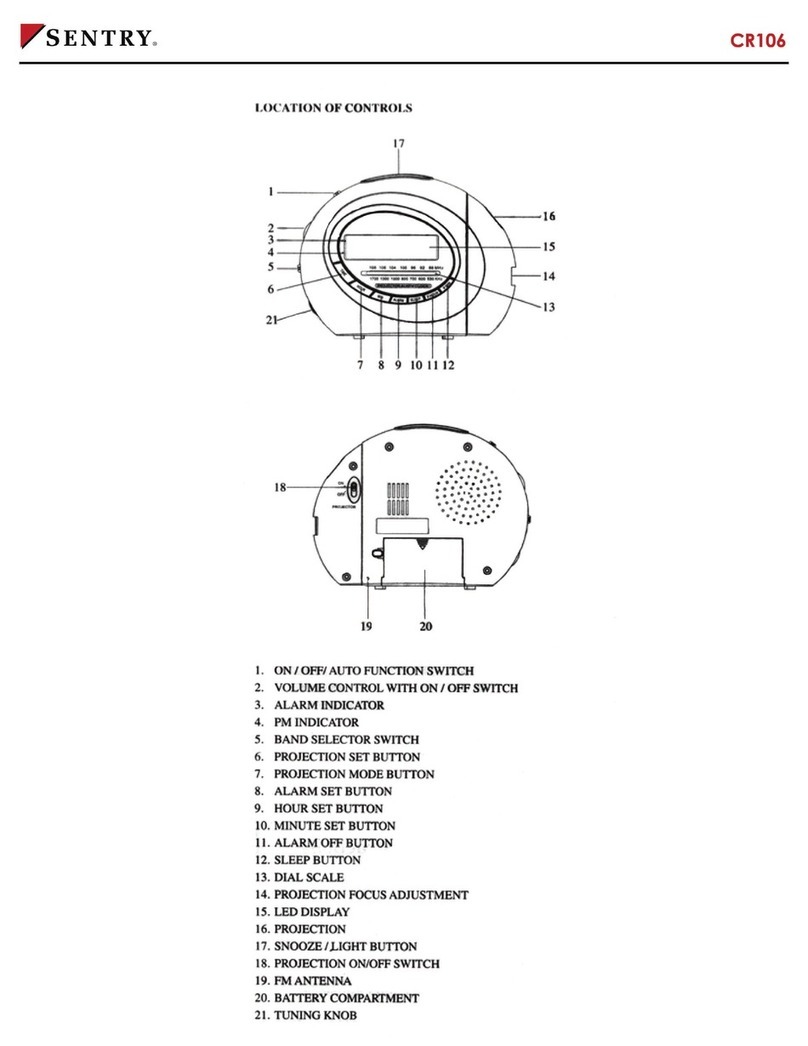

Main parts

1. instru ent case

2. front panel with 3 e brane push buttons

20180905-V1 7

DT9100 B

3.2. Principle of operation

Area of application DT9100 B is an intrinsically safe digital clock which enables

accurate ti e to be displayed in even the ost hazardous

plant areas: Zone 1 and 2 or in safe areas.

Synchronising function allows the clock to be synchronised

with a aster clock. Connecting synchronising ter inals

together will stop the clock. When the ter inals are

disconnected the clock will re-start fro a new ti e

selected in the progra e enu. This ay be the nearest

inute or the nearest hour of the original display or a

preset ti e entered during progra ing.

The DT9100 B has two isolated digital outputs, which can

be used for alar signalling or for synchronising other

clocks.

The clock is powered by a replaceable intrinsically safe

battery pack.

DT9100 B is housed in a oulded polycarbonate case in

co pliance with IP65 for installation in the field or on a

control panel.

Operating principle The clock incorporates a high accuracy te perature

co pensated ti e base, which is processed by a

icrocontroller. The icrocontroller produces real ti e in

24 hour HH:MM for at, drives a large 4 digit 25.4

height LCD display, processes the front panel keypad and

the synchronising inputs, and drives the digital outputs.

The settings and the actual ti e are stored in a e ory

which stores its content for ini u 15 inutes for

bridging the battery exchange ti e. The settings can be

done by tree front panel buttons.

The device is operational for at least 15 inutes even if the

power supply is re oved.

Power suppl The device does not need external power.

Power supply is DT4V5BAT type battery pack.

The battery pack provides the energy for ini u two

years.

Attention! The DT9100 B is powered by only DT4V5BAT

type intrinsically safe replaceable battery pack

( anufactured by Datcon Kft.)!

Do not recharge!

The battery replace ent can be acco plishes even in a

hazardous area.

820180905-V120180905-V1

DT9100 B

3.3. Adjustment

When supplied fro the anufacturer, the DT4V5BAT

power supply unit (included) is not connected to the device.

It ust be connected after installation!

First step after installation is set the ti e, or set the

synchronization para eters and synchronization ti e.

As long as you do not set the exact ti e or do not

synchronize the display shows .

The DT9100 B can be adjusted through the 3 front panel

e brane keypads. The instru ent doesn’t need any

internal adjust ent.

3.4. Storage and transport

This instru ent should be stored and transported in places

whose cli atic conditions are in accordance with the

conditions described under the title: Environ ental

conditions in Chapter 10.1. Technical specifications.

For the packaging of DT9100 B environ entally-friendly

recyclable cardboard is used to protect the instru ent

against the i pacts of nor al stresses occurring during

transportation. The corrugated cardboard box is ade fro

environ entally-friendly recyclable paper. The inner

protective aterial is polyurethane foa and nylon, which

should be disposed of via specialised recycling co panies.

The dry roo te perature and vibration free storing place

is beneficial the DT4V5BAT battery's lifeti e.

20180905-V1 9

DT9100 B

4. Mounting

4.1. General instructions

After the dis ount of front panel be careful that do not get

in foreign aterial to inside of device.

When ount of front panel be careful the seal, because if

you ount the seal in wrong position, the enclosure ay

get wet!

When ounting DT9100 B as panel instru ent, use the

enclosed seal to assure IP 65 protection between the

instru ent and the panel on the front side (only for the

panel- ounted version).

Electrostatic hazard! Clean only with a oist cloth and

detergent.

Mounting positions The device can be ounted any position.

Select a ounting position: where you can easily read the

display, which is accessible for ounting and connecting

the instru ent, and which ini ises the hazard of water,

dust or du p getting into the instru ent.

The reco ended ounting position is sa e like in

chapter 4.2. Main di ensions of the instru ent.

Mounting cable entries The instru ent is equipped with one M16x1.5 cable entry

and one additional hole equipped with sealing plug. One

M16x1.5 cable entry are accessories. If ore than one

cable entry is required (see chapter 5.), take out a sealing

plug by turning it in an anticlockwise direction. To put in a

cable entry, use a sealing ring and turn the cable entry in a

clockwise direction. Tighten the screws as uch as

necessary to ensure the desired sealing. Use only

appropriate tools.

10 20180905-V120180905-V1

DT9100 B

4.2. Main dimensions of the instrument

Wall- ounted instru ent

Panel- ounted instru ent

20180905-V1 11

DT9100 B

4.3. Mounting as a wall-instrument

Removing the front

cover

In order to re ove the front cover, first re ove the four

fixing screws as shown in the drawing. A screwdriver of

appropriate head-size should only be used. Using

screwdrivers with an inappropriate head-size ay cause

da age to the screws’ heads or to the instru ent front

panel.

Re ove the screws by turning the in an anticlockwise

direction as shown in the drawing Step (1). The screws are

secured against falling out. After this, you can si ply take

away the front cover fro the housing (2) and you can

open the housing by turning the cover downwards (3).

Plastic ties are used for fastening the front cover to the

housing in order to prevent it fro falling down.

12 20180905-V120180905-V1

DT9100 B

Preparator steps There are four through-holes, shown by arrows in the

following drawing, for the fastening of the housing. The

dia eters of the holes are ade for M3 screws.

Holes for mounting

1. Mark the places of the holes in accordance with the

drawing.

2. Make the holes ready for ounting.

3. Re ove any burrs fro the ready- ade holes.

Please observe the safety rules throughout the operation.

20180905-V1 13

DT9100 B

Mounting the instrument Four M3 threaded screws are needed for ounting the

instru ent (these are not accessories). The type of the

screws depends on the wall- aterial, while their

di ensions depend on the wall-thickness. The use of cross

recessed pan head screws is reco ended to ake the

ounting easier. The ini u screw-length should be the

wall-thickness + 10 .

During ounting, please observe all safety rules, and use

only appropriate tools.

Secure the screws against getting loose. For this purpose

you ay use spring lock or serrated lock washers.

Depending on the aterial of the wall, and in order to

ensure the ost practicable ounting ethod, it is not

andatory, of course, to use the above-described threaded

joints. Depending on the situation, special screw types for

wood or for etal sheets can also be used, or the joint can

be riveted too.

Mounting back the front

cover

1. Check if there are foreign objects left in the housing, like

s all tools, wire or etal pieces, plastic chips, etc. If there

are, re ove the .

2. Put back the front cover of the instru ent, taking care

that the sealing should get to its place. There should be no

gaps or cables left between the housing and the front

cover.

3. Tighten the front cover.

Turn the screws in clockwise direction. Tighten the screws

as uch as necessary to ensure the desired sealing.

14 20180905-V120180905-V1

DT9100 B

4.4. Mounting as a panel-instrument

Preparator steps 1. Cut a piece out of the panel according to the figure

shown below.

The cutting requires special tools; it ust be carried out by

trained specialist personnel.

Cut-out dimensions

20180905-V1 15

DT9100 B

Mounting with the

screw clamps

2. Put on the enclosed seal onto the instru ent case fro

the rear side and fit it to the instru ent holding fra e

(Figure step 2).

3. Put the instru ent into the prepared cut-out as uch as

possible and check the fitting of the seal between case and

ounting surface.

4. Put on the enclosed screw cla ps onto the sides of the

instru ent case (Figure step 4.1 and 4.2).

Fix the instru ent by turning the screws in clockwise

direction (Figure step 4.3).

Take care that pointed, sharp etal parts do not cause

accidents.

16 20180905-V120180905-V1

DT9100 B

5. Connecting

5.1. Preparing the connection

Always observe the following safety instructions:

• When you are going to install instru ents in a hazardous

area, or install instru ents which are connected to

instru ents working in a hazardous area, you should take

note of the appropriate regulations, and confor ity and

type approval certificates of the DT9100 B and the other

instru ents (e.g. isolator, Zener barrier).

• The connection ust be carried out by trained and

authorized personnel.

• In particular, ake sure that no potential equalization

current flows over the cable screen. Ground only one side

the cable screen.

• Use only a screwdriver with appropriate head.

• Do not touch the wire ends of the battery pack to each

other.

Select the connection

cable

Use two wire twisted pair screened cable.

The wire cross-section should be 0.25–1.5 2.

You ay use either solid conductor or flexible conductor.

In the case of using flexible conductor, use cri ped wire

end.

When select the cable, consider the Ex installation

regulations.

EMC considerations In installation ust be ensured, that no potential

equalization currents flows over the cable screen.

Ground only one side the cable screen (it’s reco ended

the trans itter side). If necessary of grounding on both

sides (for suppress very high level, high fequency

interference signals) this can be achieved by use separate

potential equalization or by use of a blocking capacitor (e.g.

cera ic capacitor 1 nF, 1500 V) or. The low frequency

potential equalization currents are thus suppressed, but the

protective effect against high frequency interference signals

re ains.

Choosing the value of the capacitor should take consider

the Ex installation regulations.

20180905-V1 17

DT9100 B

The DT9100 B has a very powerful EMC protection, so

grounding and practice on both sides are generally

unnecessary, but when a particularly high electrical

disturbance device (such as an inverter drive syste ) is

used nearby, it ay be necessary to use the above. An

i portant rule is that the signal cables, separate fro the

power cable.

Number of cables It is reco ended to trace the synchronizing contact with a

separate shielded cable and digital outputs on another

cable. To reduce electro agnetic disturbance to the

device, it is i perative to install the wiring shown on the

previous pages and to for the shields as shown in the

diagra .

A co on cable can only be used, if the insulation

strength between the wires is 500 V or higher!

Cables entries 1. Check the confor ity of the cables as described in the

Cables Selection section.

2. Prepare the cable for connection. The uninsulated wire

end length should be 8 .

3. Re ove the front cover of the device as described in

chapter 4.3.

4. Loosen the cla p nut on the cable gland so that the

cable can be easily inserted. (Do not wrap it down

co pletely, as it ay be lost and the sealing ring ay be

lost.)

5. Route the cable through the cable gland into the housing

so long that it can easily loosen the cable tie. (The excess

length can be retracted at the end of the operation.) Make

sure the cable does not da age the device.

18 20180905-V120180905-V1

DT9100 B

Connecting the cables

into the terminal

assemblies

Make sure before connection that the power supply is

switched off.

The push-in direct connector asse blies used allow a fast

connection of the cables.

Their proper usage is shown by the following figure:

1. Push the stripped cable-end until it possible into the

ter inal asse bly. In the case of flexible cable-ends, you

can facilitate opening the connection part by pushing down

the white button.

2. By pushing the wire in, the self-closing connection is

being established. Check it by pulling it outwards slightly.

(3. When you disasse ble the cable, push down the white

button by a screwdriver, and pull the cable-end out.)

There is no need to use great force for pushing the cable

in, neither for re oval. The button can be pushed down

easily. Please do not exercise forces higher than

necessary, as it ay cause da ages to the ter inal

asse bly.

20180905-V1 19

DT9100 B

5.2. Connecting the s nchronising input

A DT9100 B synchronising input is a digital input for driving

it either with a contact or with a solid state switch. You ay

connect an instru ent to the input if its output is in

confor ity with the following input para eters:

Uo < 30 V, Io < 200 A, Po < 0.75 W.

The following figure shows the connection:

Wiring plan, connecting

the s nchrinising input

(see also “Application

exa ple”)

Be careful with the polarity

of the cables

1. Push the cable end into the ter inal asse bly as far as

possible. By pushing the wire in, the self-closing connection

is being established.

2. Check it by pulling it outwards slightly.

20 20180905-V120180905-V1

Other manuals for DT9100 B

1

Table of contents

Other Datcon Clock manuals