Datcon DT13 Series User manual

DOC. N°:. DT1361-1393-62 Eng

Manufacturer: DATCON Ipari Elektronikai Kft.

H-1148 Budapest, Fogarasi út 5. 27. ép.

Phone:+36-1-460-1000, Fax.: 460-1001

DT13xx

Intrinsically Safe NAMUR / Contact

Isolators

User Manual

for the types

DT1361, DT1362, DT1363, DT1364, DT1371,

DT1372, DT1373, DT1381, DT1382, DT1384, DT1393

Revision 4

14.10.2021

2

3

Contents

1. Function and Scope of Application.....................................................................................................4

. ...........................................................................................................................................................4

2. Accessories of the device...................................................................................................................4

. ...........................................................................................................................................................4

3. Technical specifications .....................................................................................................................4

. ...........................................................................................................................................................4

4. Information for placing the order ........................................................................................................6

. ...........................................................................................................................................................6

4.1. Type selection range:................................................................................................................................6

4.2. Inputs with 0,5 mA current ........................................................................................................................7

. ...........................................................................................................................................................7

5. Operating principle .............................................................................................................................7

. ...........................................................................................................................................................7

6. Preliminary Instructions ......................................................................................................................8

. ...........................................................................................................................................................8

7. Putting the device into operation; Operating Instructions...................................................................8

. ...........................................................................................................................................................8

7.1. Safety measures .......................................................................................................................................8

7.2. Addition to the contacts installed in the explosive area ............................................................................9

7.3. Connecting the device...............................................................................................................................9

7.4. Putting the device into operation; Preliminary settings ...........................................................................12

. .........................................................................................................................................................13

8. Design ..............................................................................................................................................13

. .........................................................................................................................................................13

9. Maintenance, repair..........................................................................................................................13

. .........................................................................................................................................................13

10. Appendix ........................................................................................................................................14

. .........................................................................................................................................................14

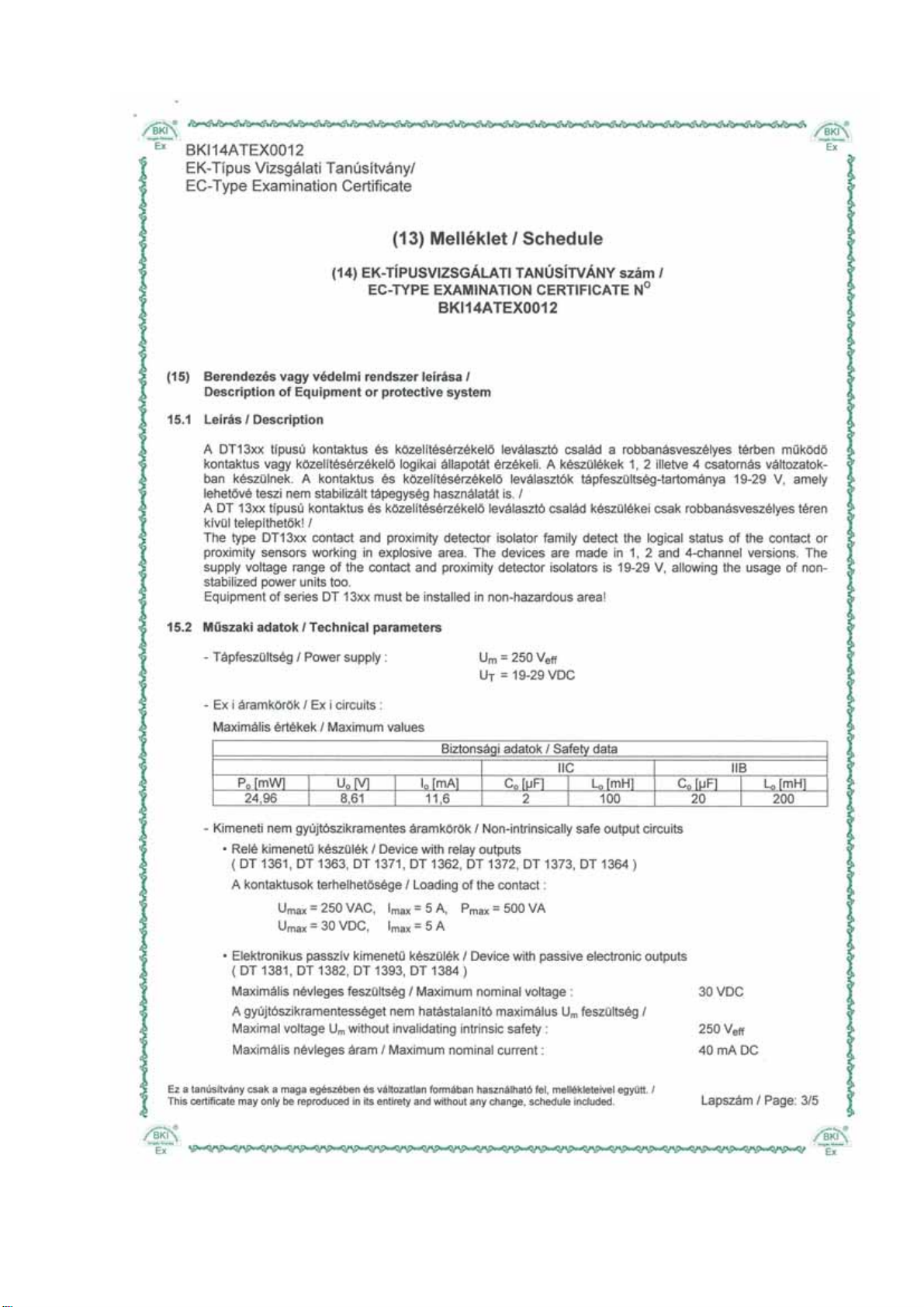

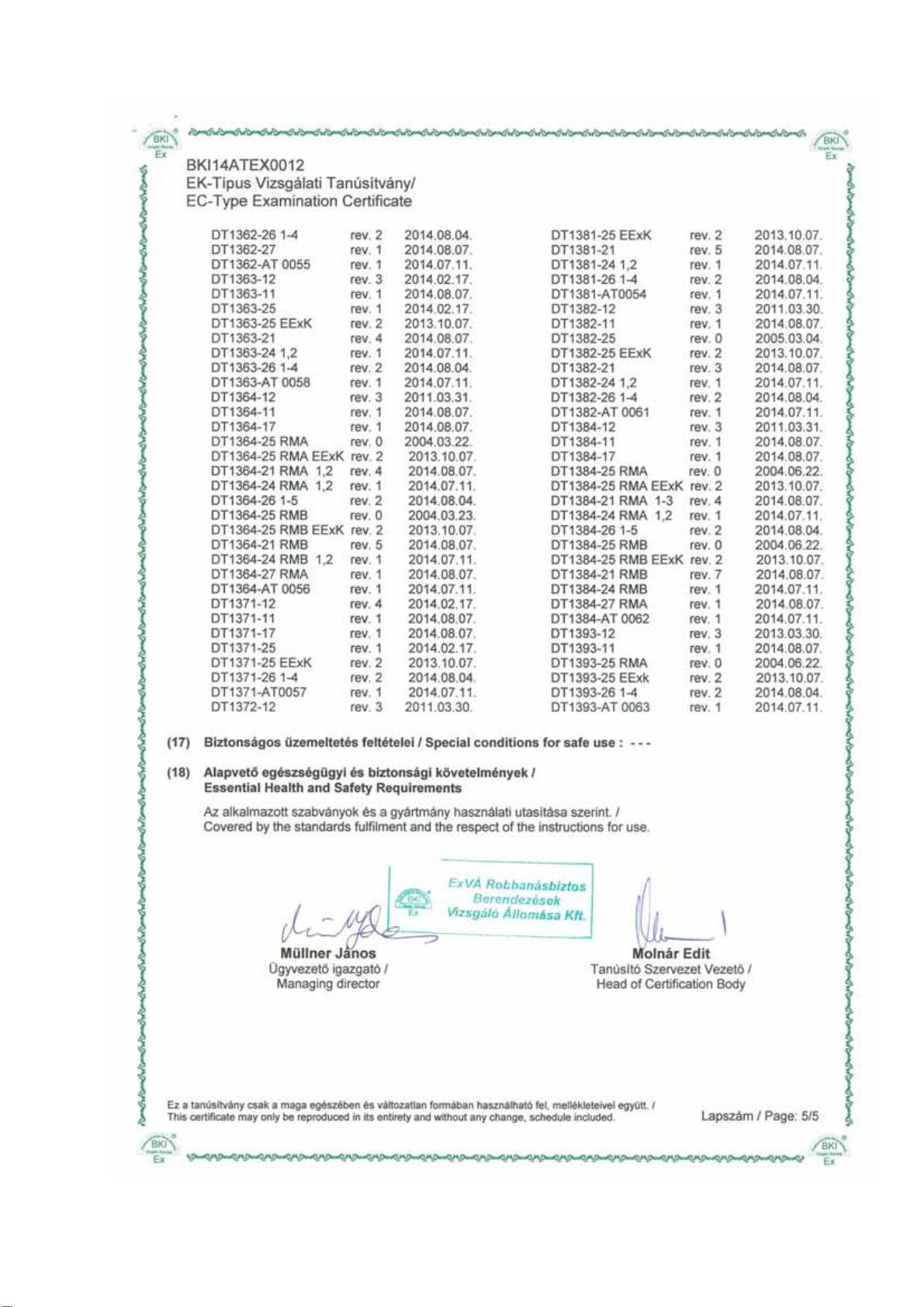

10.1. ATEX Certification.................................................................................................................................14

4

1. Function and Scope of Application

.

The contact- and proximity-detector isolator family belongs to the group of associated apparatus in terms of

intrinsical safety. These devices are classified as II (1)G Ex ia GaIIC/IIB (-20 C ≤Ta ≤50 C) and

II (1)D Ex ia DaIIIC (-20 C ≤Ta ≤50 C) device.

The members of this device-family detect the logical status (near-remote, or open-closed) of the proximity

sensors („NAMUR”), or of the contacts working in explosive area, through a connection cable of practically any

length.

The devices are made in 1-, 2-, and 4-channel versions.

The output of the isolators is either a semi-conductor, or a relay of switching-contact or closing-contact type. In

the case of semi-conductor output the maximum signal transmission frequency is 5 kHz, which makes it suitable

for an application as a fast interface.

The high-capacity contact of the devices with relay output (loadability: 5 A and 250 Veff) is suitable for directly

controlling the parts of automatic systems.

With the DIL switches mounted inside the device it is possible to check if the detector cables are short or

broken. If such failure is found, the output is set automatically to open (broken) status. The logical status of the

output may be switched to Direct or to Reverse connection with the output.

The supply voltage range of the contact- and proximity-detector isolators is 19-29 V, allowing the usage of non-

stabilized power supply units too.

2. Accessories of the device

.

User Manual

CE Declaration of Conformity

Quality certificate

3. Technical specifications

.

Safety parameters:

Marking of intrinsical safety: II (1)G Ex ia GaIIC/IIB

II (1)D Ex ia DaIIIC

(-20 C ≤Ta ≤50 C)

Uo: 8.61V

Io: 11.6mA

Um: 250 VAC

Ci IIC / IIB: 2 F / 20 F

Li IIC / IIB: 100 mH / 200 mH

Input parameters:

Input signal: In accordance with the standard

MSZ EN 60947-5-6 (NAMUR), and

it can be operated also as a contact switch.

Idle voltage: 8.2 V 5%

Short-circuit current: 8.2 mA 6%

Input resistance: 1000

Levels defining the logical status of the input:

switch on > 2.1 mA

switch off < 1.2 mA

Detection of cable break: < 0.15 mA

Detection of cable short: > 6.0mA

5

Output parameters:

Devices with relay output

Loadability of relay contacts: 250 VAC, 5 A or 30 VDC, 5 A

Relay contact types: closing or switch-over (morse)

Maximum switching frequency: 12 Hz

Devices with electronic output .

Operating mode of the switched output: passive

(works with external supply voltage)

Max. voltage in OFF status: 30 VDC

Max. leakage current: 10 A

Max.current in ON status: 40 mA

Max. residual voltage (at 8 mA): < 1.8 V

(at 40 mA): < 2.5 V

Max. operating frequency: 5 kHz

General parameters:

Power supply: 19-29 VDC

Operating temperature range: -20 C - +50 C

Indicators (supply voltage) green LED

(output ON): yellow LED

(fault of the line to the detector):red LED

Shock protection: extra-low voltage (SELV)

Applied standards: MSZ EN IEC 60079-0:2018 (ATEX)

MSZ EN 60079-11:2012 (ATEX)

MSZ EN IEC 61326-1:2021 (EMC)

MSZ EN 55011:2016 (EMC)

MSZ EN 55011:2016/A1:2017 (EMC)

MSZ EN 55011:2016/A2:2021 (EMC)

MSZ EN IEC 63000:2019 (RoHS 2)

DIN19234 (NAMUR)

Box dimensions: 114 x 99 mm

(the width varies with the types)

(TS-35 is mountable on busbars)

Ambient conditions for storing:

Temperature: -40 C – +70 C

Relative air humidity: max. 80%, non-condensing

6

4. Information for placing the order

.

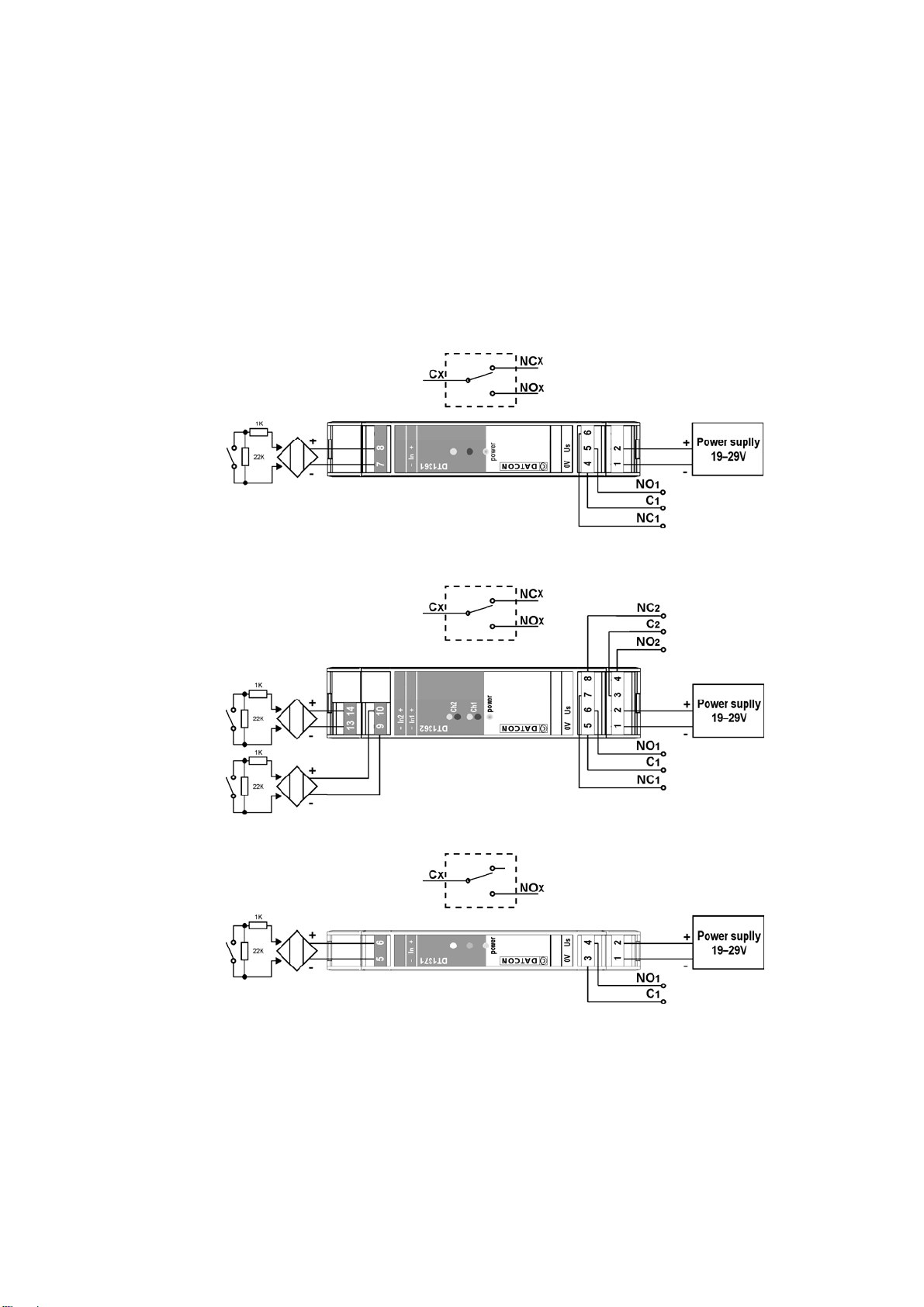

4.1. Type selection range:

Type

designation No. of

channels Output type Fault signal

output

Power

consumption

(W)

Box width

(mm)

DT1361 1 Relay switching contact - 0.6 17.5

DT1363 1 Relay closing contact 1 opening

contact 1.0 17.5

DT1371 1 Relay closing contact - 0.6 12.5

DT1381 1 Electronic passive - 0.6 12.5

DT1362 2 Relay switching contact - 1.0 22.5

DT1372 2 Relay closing contact - 1.0 17.5

DT1373 N 2 Relay closing contact * - 1.0 12.5

DT1373 P 2 Relay closing contact * - 1.0 12.5

DT1382 2 Electronic passive - 1.0 17.5

DT1393 N 2 Electronic passive * - 1.0 12.5

DT1393 P 2 Electronic passive * - 1.0 12.5

DT1364 4

Relay closing contact - 2.0 22.5

DT1384 N 4 Electronic passive - 1.6 22.5

DT1384 P 4 Electronic passive - 1.6 22.5

For each channel, one of the output pins with either 0 V or +24 V supply voltage

One of the output pins are commoned in each 2-2 channels

One of the output pins are commoned in each 2-2 channels or the negative or positive points

7

4.2. Inputs with 0,5 mA current

Inputs with 0.5 mA current are available optionally to satisfy specific customer needs.

Input parameters:

Short-circuit current: < 0.5 mA 6%

Input resistance: 18 k

.

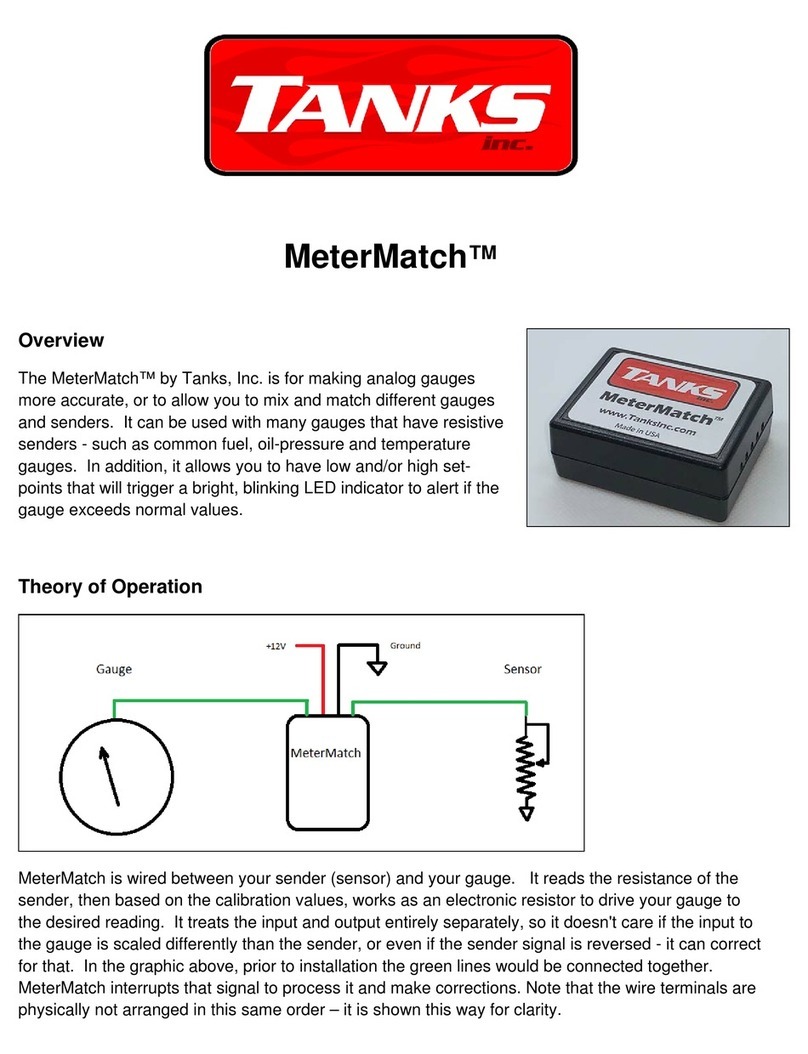

5. Operating principle

.

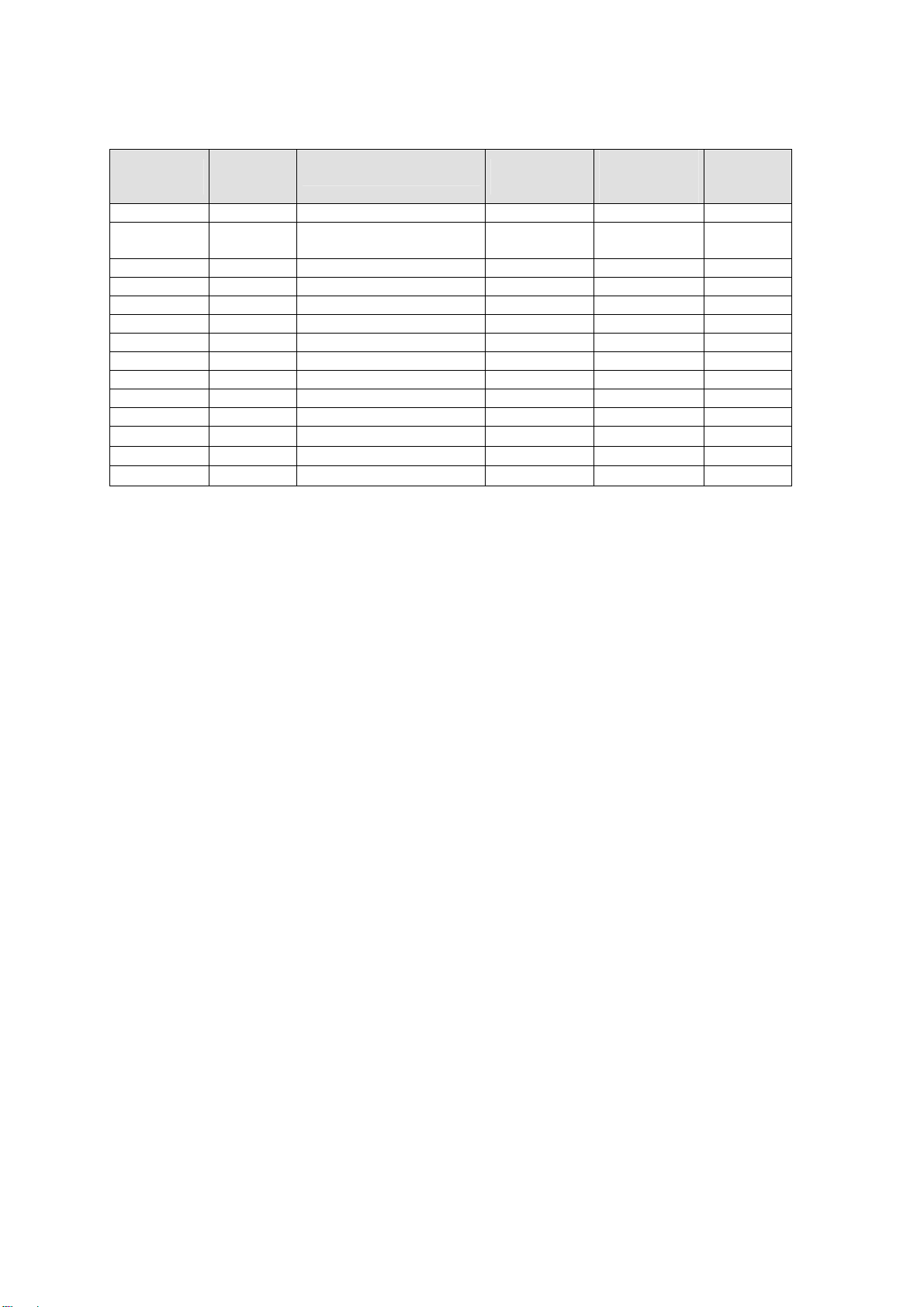

The operation of the device is shown in the block diagram of Figure 1.

Figure 1. The theoretical build-up of the device

The comparator unit detects the current flowing over the 1 kresistor connected serially with the +8.2 V voltage

generator. The threshold values in accordance with the NAMUR standard are as follows:

Direct switch position: > 2.1 mA

Reverse switch position: < 1.2 mA

Sensor line broken: < 0.15 mA

Sensor line short: > 6.0 mA

The following settings can be realized with the operating mode switch mounted inside the device (triple DIL-

switch):

S1, Direct – Reverse

S2, Detecting if the line is broken

S3, Detecting if the line is short

The function of detecting if the line is broken or short is applicable only when a NAMUR input detector is used!

In the case of operation with contact switch, the network in accordance with Figure 2 must be used for

establishing the connection to the contact switch ( S2 and S3 in ON position ).

8

Figure 2. Switch-positions of the device

The switching unit forwards the output signal of the comparators, depending on the setting of the operation

mode switch, to the isolator stage. In the case of relay-type output stage, it is the pulling coil of the relay, while

in the case of electronic output, it is the diode of an optical coupler.

The isolated output is either the contact of the relay or, in the case of electronic output stage, it is a PNP open

collector transistor, which gets its supply voltage from an external power supply unit.

A yellow LED indicates the ON status of the outputs. In the case of a line fault (broken or short) the red LED

gives light, and the output will be switched off.

The power supply for the two-stage (logical) intrinsically safe isolator is ensured by the DC/DC converter using

the 24 VDC, whose supply voltage may vary in a wide voltage range: 19-29 V. The supply voltage input is

protected against overvoltage.

6. Preliminary Instructions

.

The contact- and proximity-detector isolators and the User Manual are delivered in a packing that provide

appropriate protection. Special instructions for unpacking are not necessary.

Study the User Manual attentively before you put the device into operation, paying special attention to the

prescriptions ensuring an intrinsically safe operation, and to the safety measures.

7. Putting the device into operation; Operating Instructions.

.

7.1. Safety measures

In order to ensure the security of property and the safety of health and life of people, the following rules must be

met:

— Only properly qualified persons may put the device into operation.

— For making the connection of the screw-fixed type terminals, a cable with at least 0.5-2.5 mm2cross section

area must be used, whose insulation in radial direction is at least 0.2 mm

— The detector, or the contact, installed in the explosive area must be used concerning the cable that connects

the input of the isolators, it must be taken into consideration that intrinsical safety is ensured in that case only,

9

when the serial inductance and capacitance of the whole input circuit is not more than the values defined by the

Technical Specifications.

7.2. Addition to the contacts installed in the explosive area

If we want to apply a detection of the lines, the resistors necessary for the checking of the broken or short status

must be mounted to the switching contacts, and the DIL-switches mounted in the printed wiring within the device

must be set to the appropriate position.

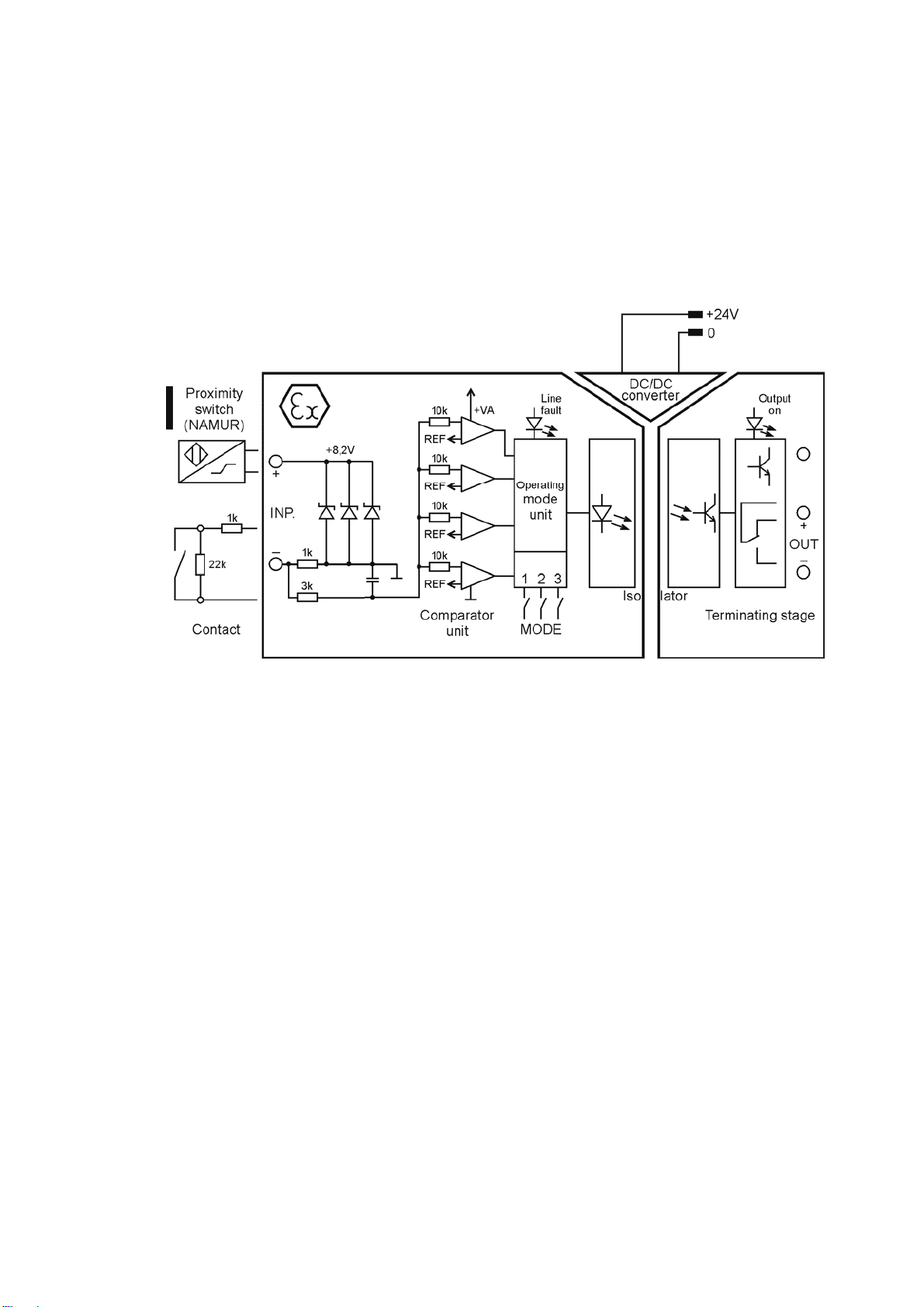

7.3. Connecting the device

The various types should be connected in accordance with the following instructions:

The types DT1361, DT1362, DT1371, DT1372, DT1381, and DT1382 have closing- and switching contacts, with

one or two channels. When these types are connected, the instructions under Clause 7.1 and Clause 7.2 must

be observed.

Connecting the output relay

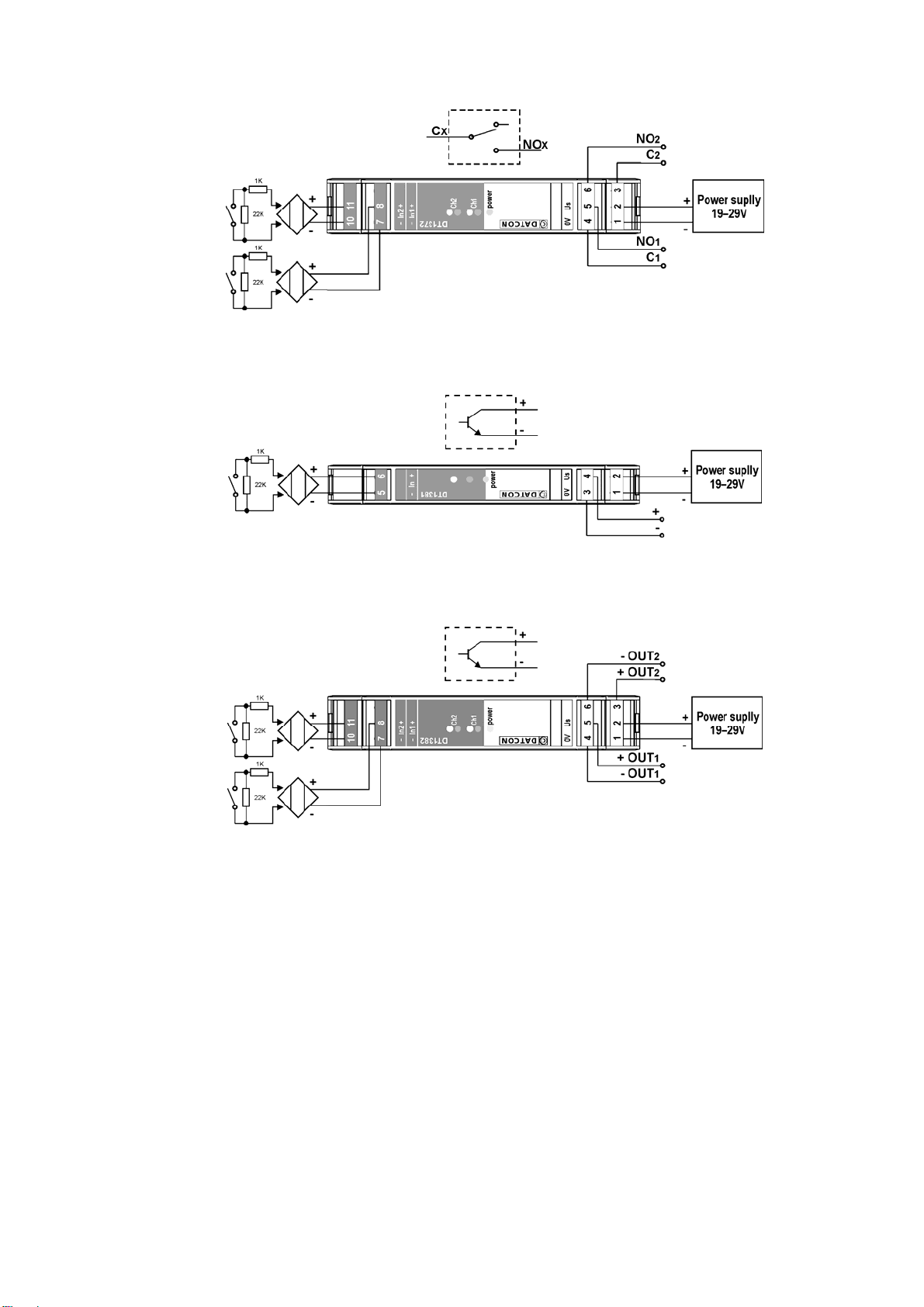

Figure 3a. Connection of DT1361

Connecting the output relays

Figure 3b. Connection of DT1362

Connecting the output relays

Figure 3c. Connection of DT1371

10

Connecting the output relays

Figure 3d. Connection of DT1372

Connecting the output semi-conductor

Figure 3e. Connection of DT1381

Connecting the output semi-conductors

Figure 3f. Connection of DT1382

11

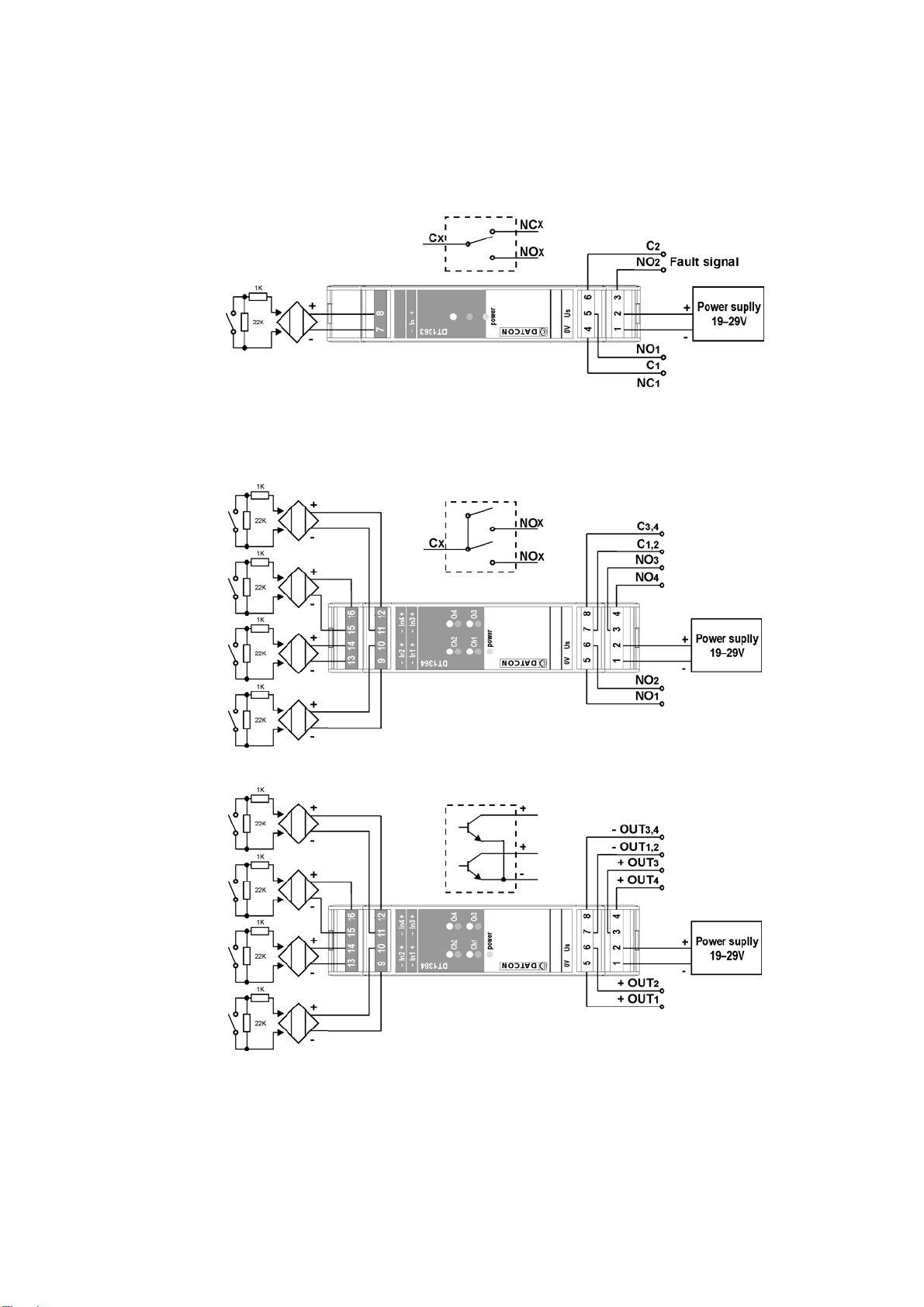

The type DT1363 is a single-channel device with closing contact, and with and additional fault-signal control

channel. At the output of the fault signal, a relay is found (whose type is identical with the one at the output of

the device). In the case of faultless operation its contact is in closed position. If some fault occurs (broken or

short line, no power supply), the fault signal relay will open the closing contact.

In order to ensure the proper operation of the fault signal relay, the fault signal detector switch, found inside the

device (S2 and S3) must be kept in ON status.

Connecting the output relays

Figure 3g. Connection of DT1363

The four-channel devices DT1364 and DT1384 include four independent channels. One of the terminations of

the outputs is commoned in each 2-2 channels.

Connecting the output relays

Figure 3h. Connection of DT1364

Connecting the output semi-conductors

Figure 3i. Connection of DT1384

12

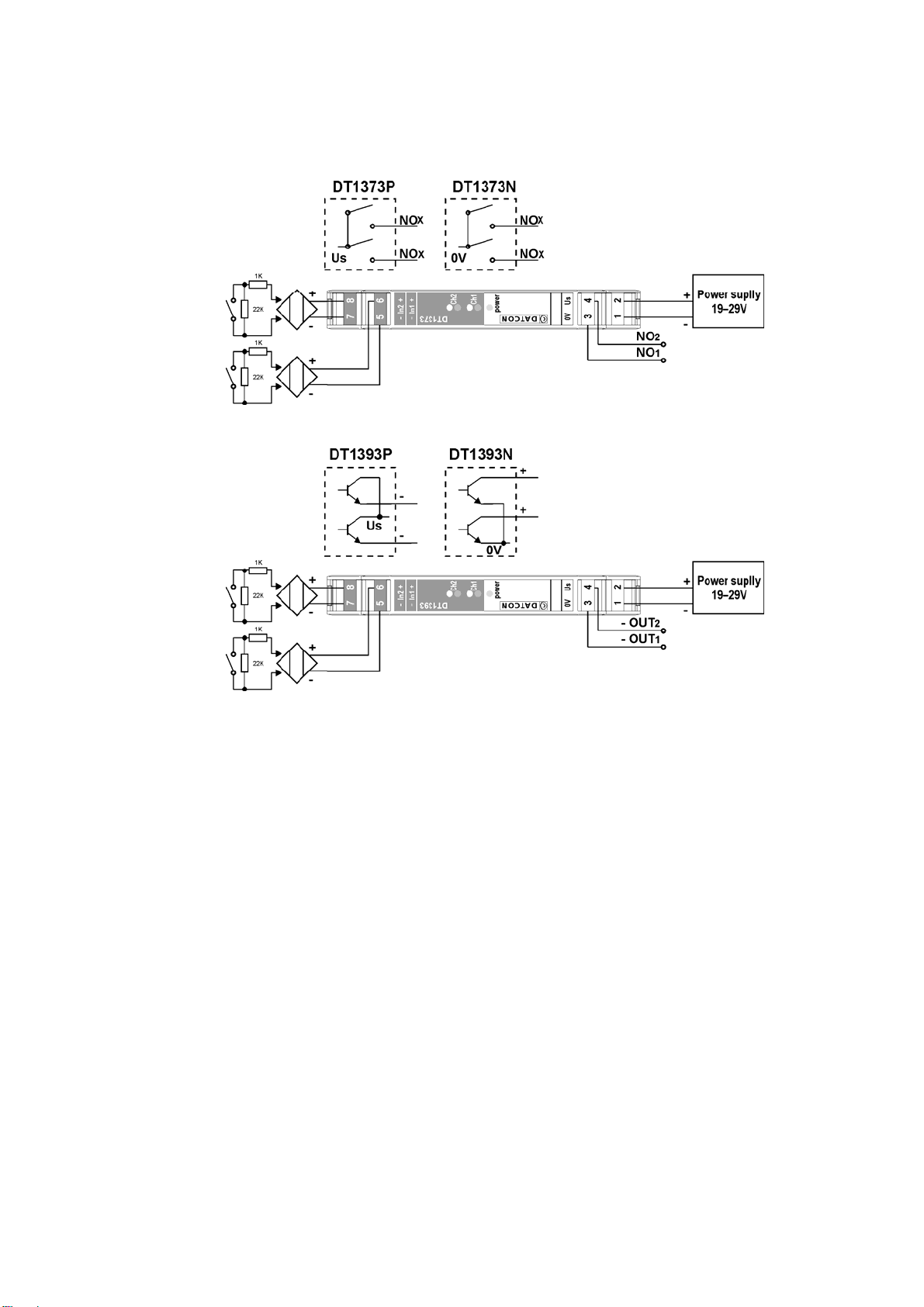

The types DT1373 and DT1393 are two-channel devices with relay closing contact or with semi-conductor

outputs. One of the terminals of the outputs are commoned with each-other and with one of the power supply

terminals (0 V or +24 V). In the lack of needs to the contrary, the devices as delivered by the Manufacturer are

commoned with the 0 V.

Connecting the output relays

Figure 3j. Connection of DT1373

Connecting the output semi-conductors

Figure 3k. Connection of DT1393

The types DT1381, DT1382, DT1384 and DT1393 have semi-conductor outputs, and passive operation (open-

collector output). By ensuring the right polarity, an external power supply unit should be connected to the output

through a resistor. The maximum voltage and current values of the external power supply unit are defined by

the Technical Specifications.

7.4. Putting the device into operation; Preliminary settings

After the MODE S1, S2, and S3 switches have been set previously (see Clause 5 and Figure 2), the

device should be put onto the busbar, and the connectors should be connected with the cables in

accordance with the above description.

13

.

8. Design

.

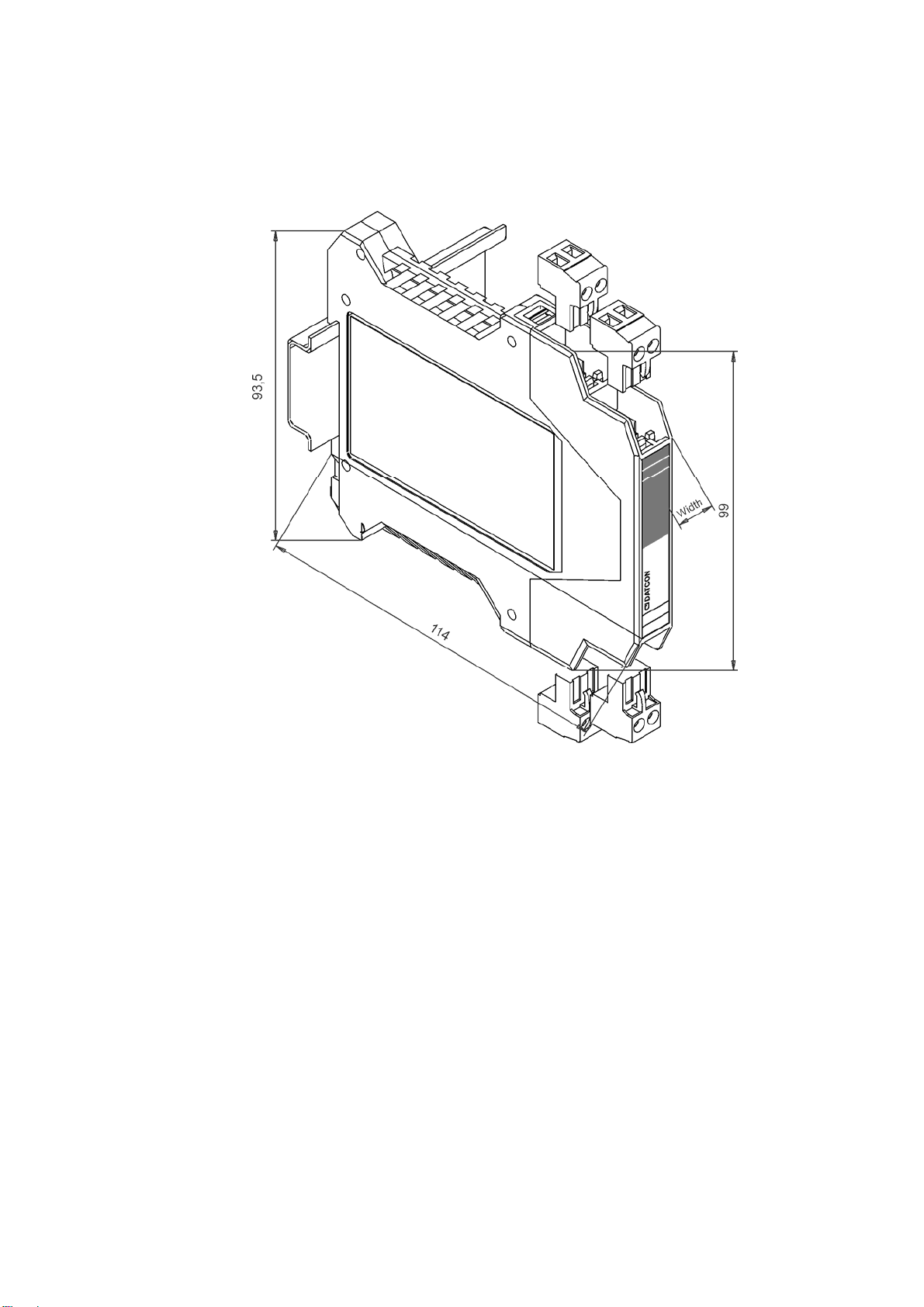

The isolators are built in a polyamide 6.6 box, that can be pushed on TS-35 type busbars, and ensure IP 20

protection. In terms of dimensions, only the width of the boxes vary, and it is shown under the point „Type

selection”. The drawing of the device’s housing (box) is presented by Figure 4.

Figure 4. Mounting of the device

9. Maintenance, repair

.

The isolators do not require maintenance.

Faulty units must be sent to the Manufacturer DATCON Kft for repair.

14

10. Appendix

.

10.1. ATEX Certification

15

16

17

18

19

20

This manual suits for next models

11

Table of contents

Other Datcon Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Habasit

Habasit Rossi IFIT Series operating instructions

MK

MK ZRF-P 2012 Technical documentation

Siemens

Siemens APACS+ Installation and service instruction

Energy Recovery

Energy Recovery PX G1300 Installation and operation manual

Saferoad

Saferoad MEGARAIL INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL

Spirax Sarco

Spirax Sarco CA44 Installation and maintenance instructions