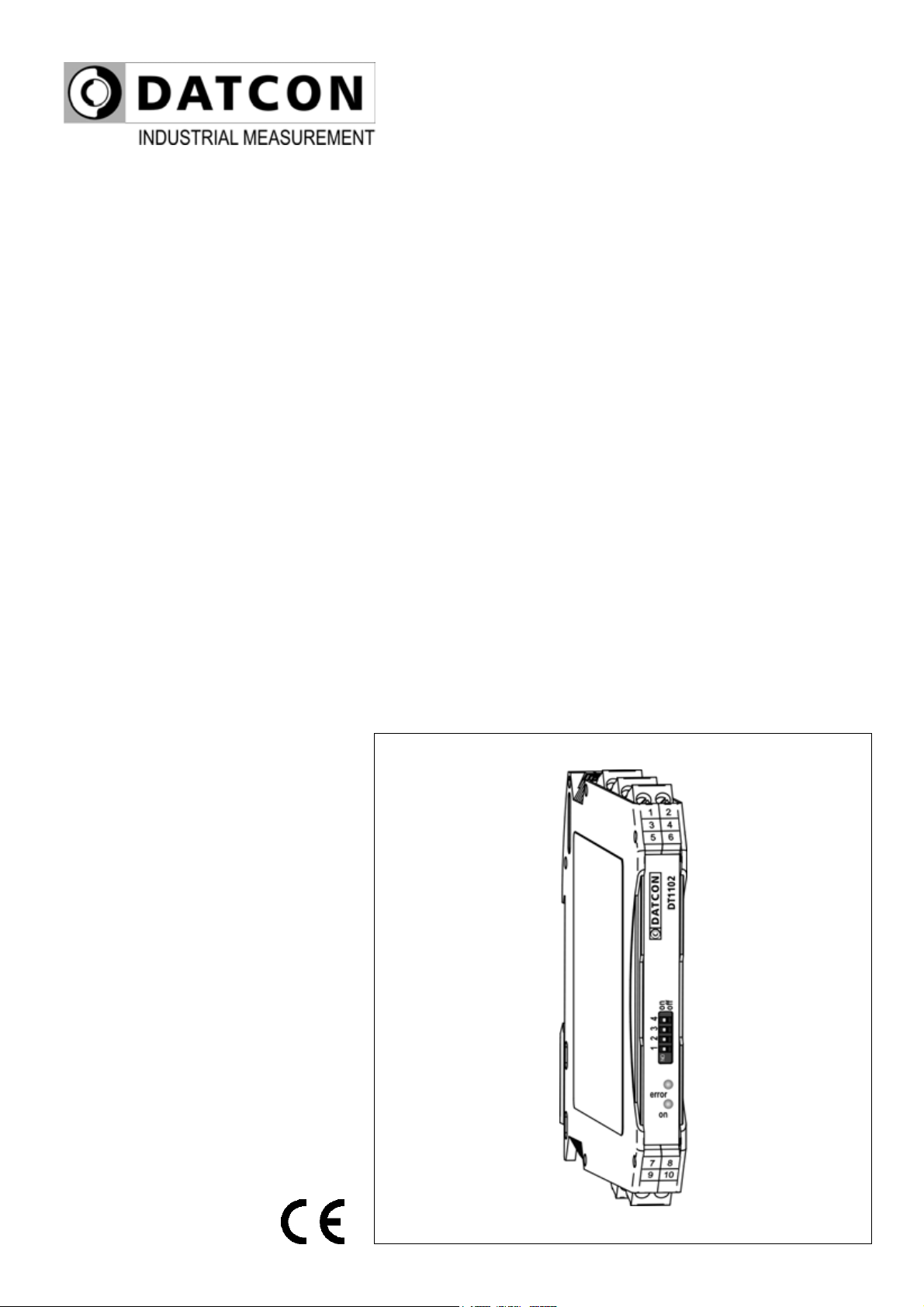

Datcon DT1102 (PS) User manual

DT1102 (PS)

Switch Configurable I/O Galvanic Isolator

Operating Instructions

DT1102 (PS)

220220202-V0

Contents

1. About this document..............................................................4

1.1. Function...............................................................................................4

1.2. Target group........................................................................................4

1.3. Symbolism used ..................................................................................4

2. For your safety........................................................................5

2.1. Authorized personnel...........................................................................5

2.2. Appropriate use ...................................................................................5

2.3. Warning about misuse.........................................................................5

2.4. General safety instructions ..................................................................5

2.5. CE conformity......................................................................................5

2.6. Environmental instructions...................................................................5

3. Product description................................................................6

3.1. Delivery configuration ..........................................................................6

3.2. Type designation .................................................................................6

3.3. Operating principle ..............................................................................7

3.4. Indicators, configuration switches ........................................................8

3.5. Input/output signal selection ................................................................9

3.6. Storage and transport........................................................................ 10

4. Mounting ...............................................................................11

4.1. General instructions........................................................................... 11

4.2. Main dimensions of the instrument .................................................... 11

4.3. Mounting procedure........................................................................... 12

5. Connecting............................................................................13

5.1. Preparing the connection................................................................... 13

5.2. Connecting active output current source to the input ......................... 14

5.3. Connecting 4-20 mA two wire (passive) transmitter to the input ........ 15

5.4. Connecting voltage source to the input.............................................. 16

5.5. Connecting current output to the signal processing unit .................... 17

5.6. Connecting voltage output to the signal processing unit .................... 18

5.7. Connecting instrument to the power supply ....................................... 19

DT1102 (PS)

20220202-V0 3

6. First „power on”, front panel indicators.............................20

6.1. First „power on” ................................................................................. 20

6.2. Front panel Indicators........................................................................ 20

7. Fault rectification..................................................................21

7.1. Fault finding....................................................................................... 21

7.2. Repearing.......................................................................................... 21

8. Dismounting..........................................................................22

8.1. Dismounting procedure...................................................................... 22

8.2. Disposal............................................................................................. 22

9. Appendix...............................................................................23

9.1. Technical specification ...................................................................... 23

9.2. Application example .......................................................................... 25

DT1102 (PS)

420220202-V0

start 1. About this document

1.1. Function

This operating instructions manual has all the information you need for

quick set-up and safe operation of DT1102 (PS)

Please read this manual before you start setup.

1.2. Target group

This operating instructions manual is directed to trained personnel.

The contents of this manual should be made available to these

personnel and put into practice by them.

1.3. Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution, warning, danger

This symbol informs you of a dangerous situation that could occur.

Ignoring this cautionary note can impair the person and/or the

instrument or it’s environ.

•List

The dot set in front indicates a list with no implied sequence.

→Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

DT1102 (PS)

20220202-V0 5

2. For your safety

2.1. Authorized personnel

All operations described in this operating instructions manual must be

carried out only by trained and authorized specialist personnel.

For safety and warranty reasons, any internal work on the instruments

must be carried out only by DATCON personnel.

2.2. Appropriate use

The DT1102 (PS) is an instrument for industrial use. Detailed

information on the application range is available in chapter 3. Product

description.

2.3. Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, or damage to system components

through incorrect installing or adjustment.

2.4. General safety instructions

Using the DT1102 (PS) requiring the strict observance of standards,

regulations and guidelines.

The user must take note of the safety instructions in this operating

instructions manual, the country-specific installation standards as well

as all prevailing safety regulations and accident prevention rules.

2.5. CE conformity

The DT1102 (PS) is in conformity with the provisions of the following

standards:

EN IEC 61326-1 (EMC)

EN 61010-1 (Safety)

EN 61558-1 (Safety)

2.6. Environmental instructions

Protection of the environment is one of our most important duties.

Please take note of the instructions written in the following chapters:

•Chapter 3.6. Storage and transport

•Chapter 8.2. Disposal

DT1102 (PS)

620220202-V0

3. Product description

3.1. Delivery configuration

Delivered items The scope of delivery encompasses:

•DT1102 (PS)

•tool for switch setting

(in case of shipping more instrument only one tool is enclosed)

•documentation:

this operating instructions manual

certification

warranty

3.2. Type designation

DT1102 24 VDC power supply

DT1102 PS 230 V AC/DC power supply

DT1102 (PS)

20220202-V0 7

3.3. Operating principle

Area of application The DT1102 (PS) Switch Configurable I/O Galvanic Isolator

provide signal transmission and conversion between transmitters and

signal processing units.

The instruments feature complete 3-way isolation: the input, the

output and the power supply are isolated from each other.

The instrument has two inputs:

1. 0(4)-20 mADC current or*

2. 0(2)-10 VDC voltage*

and two outputs:

1. 0(4)-20 mADC current or*

2. 0(2)-10 VDC voltage.

* only one input and one output are active together

The input/output ranges are switch selectable.

The DT1102 (PS) - providing a 20 VDC, 20 mA supply on the input –

for supplying 4-20 mA passive transmitters.

The front panel LED indicators provide information about the

operating status of the device. (power on state, error states)

Principle of operation

The input current flows through the measuring resistor or the input

voltage divides through the attenuator. This voltage drop is led to a

24 bit A/D converter. The digital output signal of the A/D converter is

processed by a microcontroller.

The microcontroller produces a pulse width modulated (PWM) output

signal. The pulse width is proportional to the processed, measuring

value. The output pulse is galvanic isolated by an optocoupler. After

filtering the pulse is converted into analogue current or voltage signal.

The input/output ranges are switch configurable.

The internal power supplies are generated by an isolated dual output

DC/DC converter, using planar transformer technology.

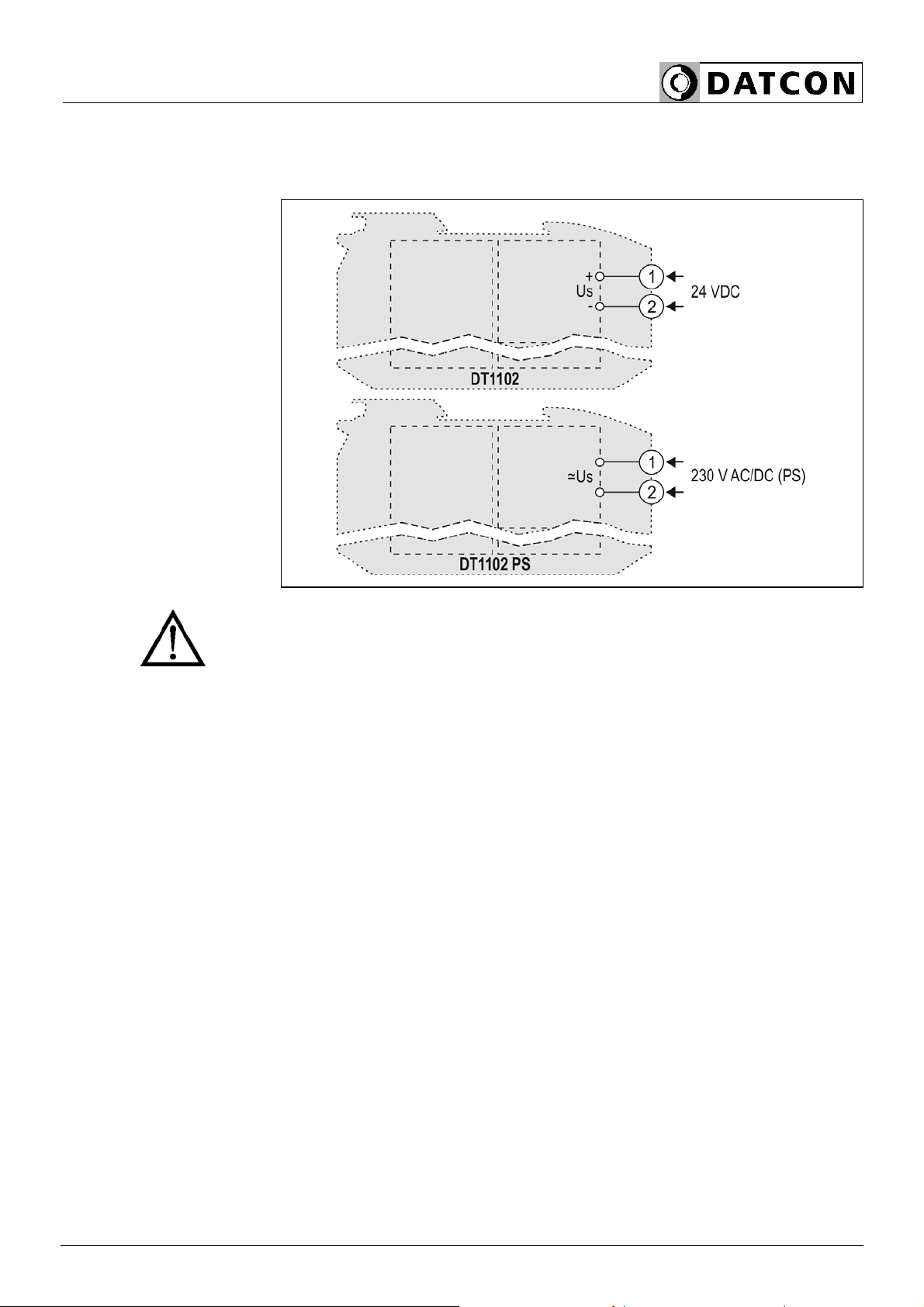

Power supply The instrument has two different power supply version:

DT1102:

Power supply: 24 VDC ±10%

DT1102 PS:

Power supply: 230 V AC/DC ±10%

DT1102 (PS)

820220202-V0

3.4. Indicators, configuration switches

The following figure shows the indicators and the configuration

switches on the DT1102 (PS) front panel.

(1) configuration switches for selection input/output ranges

(2) red „error” indicator shows the error states

(3) green „on” indicator shows the power on state

DT1102 (PS)

20220202-V0 9

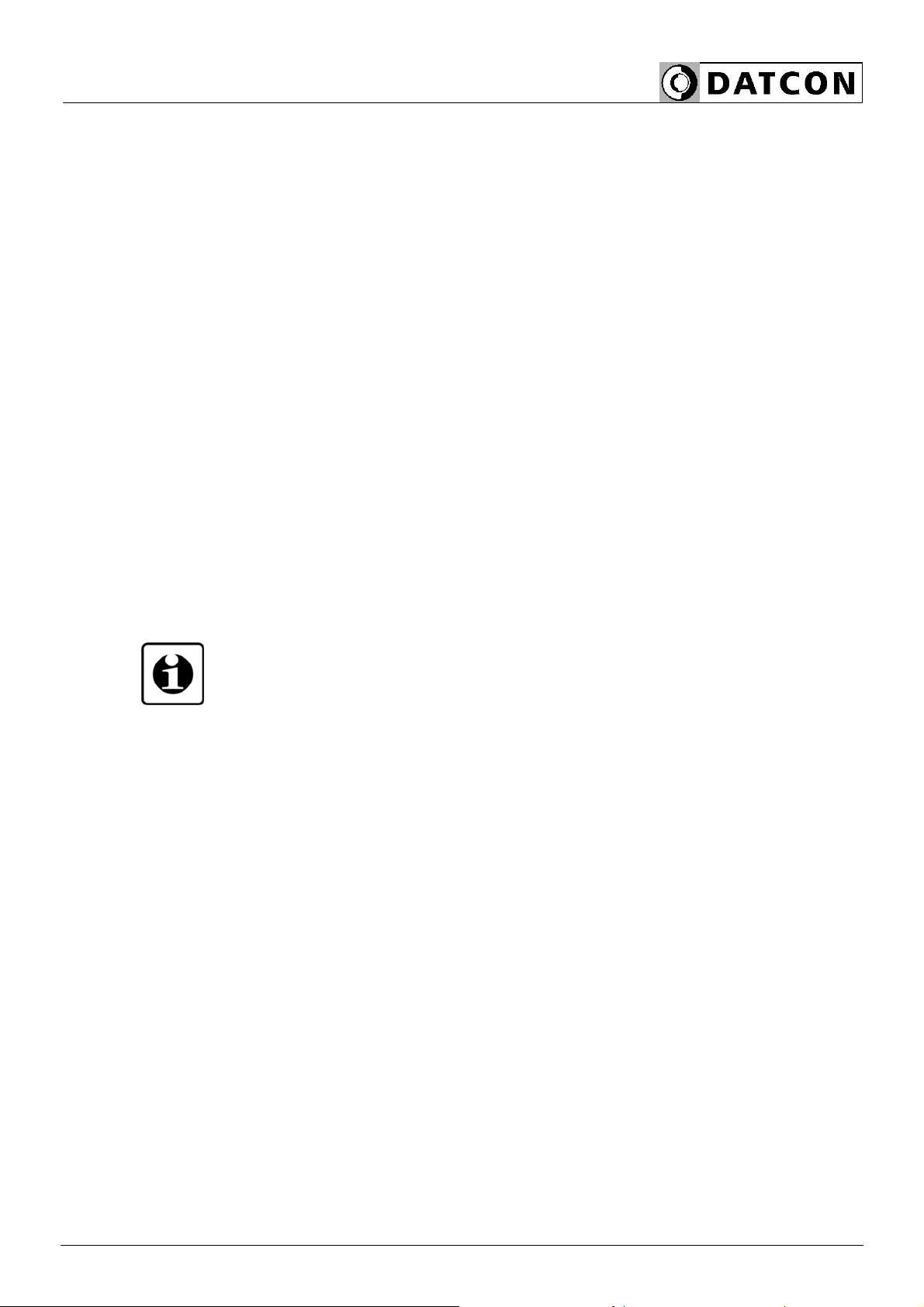

3.5. Input/output signal selection

Four different input/output signal range can be selected with the front

panel switches:

0-20 mA, 4-20 mA, 0-10 V, 2-10 V

Default setting: 0-20 mA input, 0-20 mA output

(all switches are in „off” state).

The following figure shows the input/output signal range selection

table:

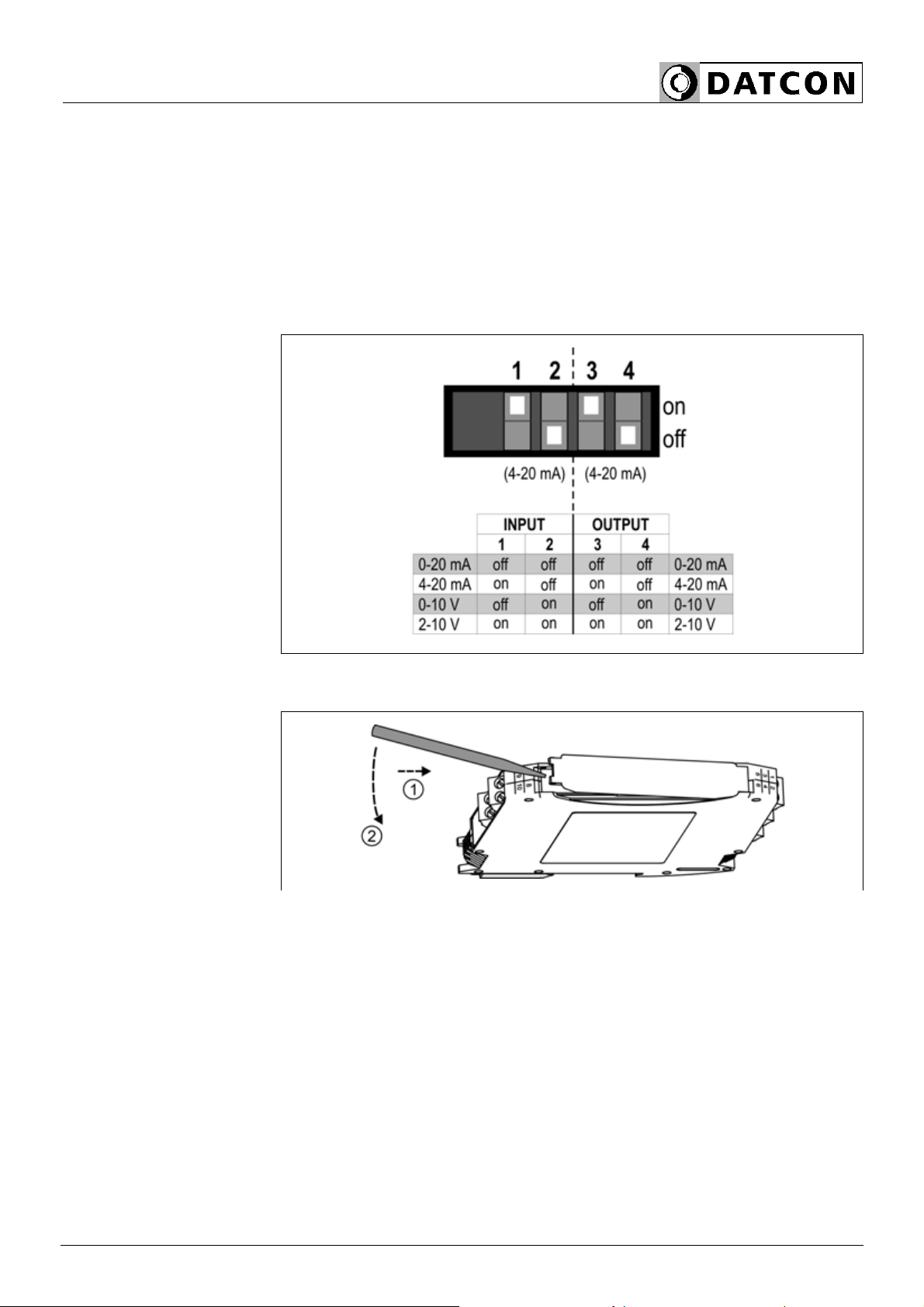

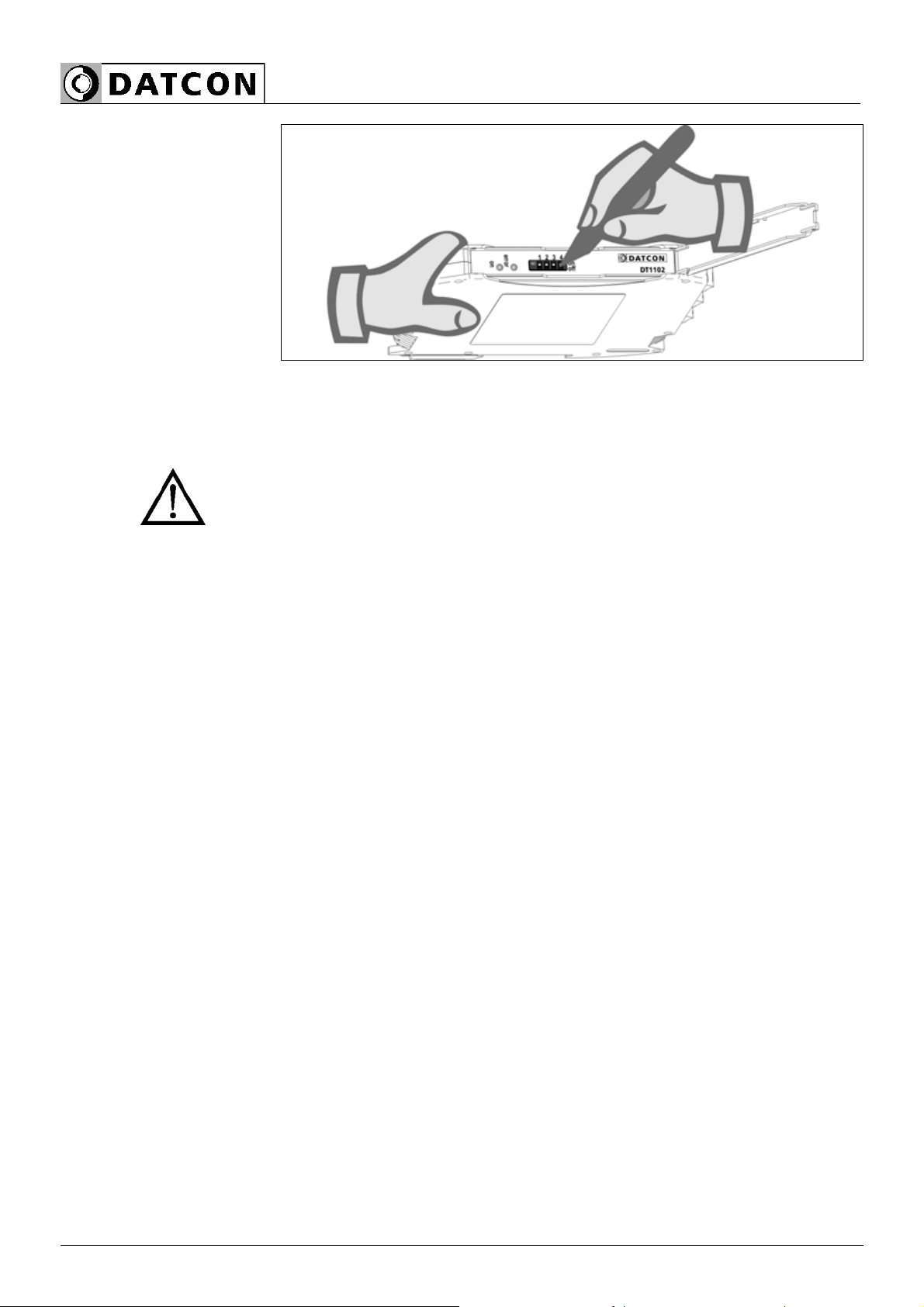

The following figure shows steps of setting:

1. Take the instrument in hand according to the figure

2. Open the front panel cover with the enclosed tool according to the

figure

DT1102 (PS)

10 20220202-V0

3. Set the configuration switches according to the signal range

selection table

4. Close the front panel cover

Do not use other tool than the enclosed one because you may cause

injury either to switches or to front panel!

3.6. Storage and transport

This instrument should be stored and transport in places whose

climatic conditions are in accordance with chapter 9.1. Technical

specification, as described under the title: Environmental conditions.

The packaging of DT1102 (PS) consist of environment-friendly,

recyclable cardboard is used to protect the instrument against the

impacts of normal stresses occurring during transportation.

The corrugated cardboard box is made from environment-friendly,

recyclable paper. The inner protective material is nylon, which should

be disposed of via specialized recycling companies.

DT1102 (PS)

20220202-V0 11

4. Mounting

4.1. General instructions

The instrument should be installed in a cabinet with sufficient IP

protection, where the operating conditions are in accordance with

chapter 9.1. Technical specification, as described under the title:

Operating conditions.

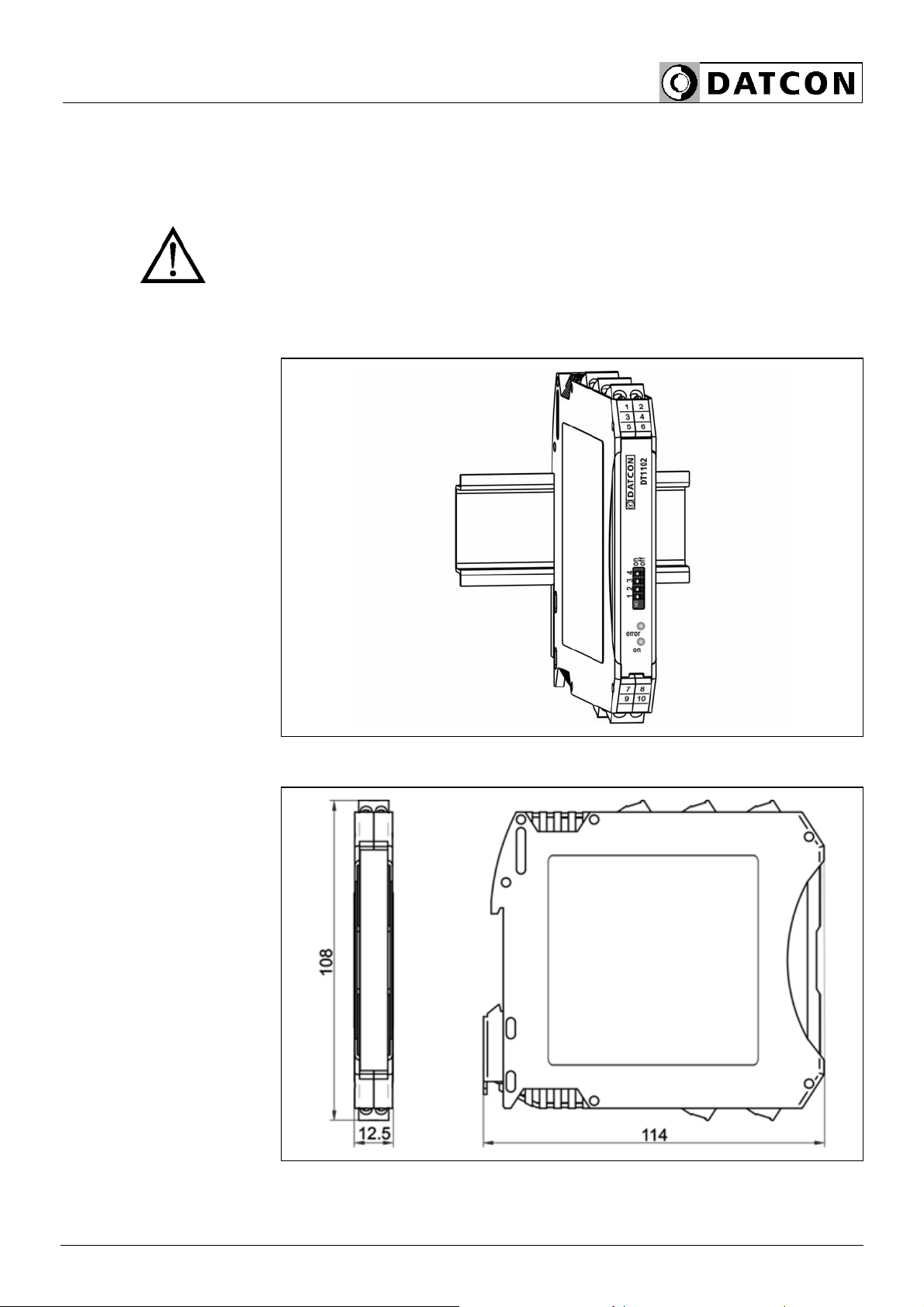

Mounting position The DT1102 (PS) is built in a plastic housing, for mounting on TS-35

rail. Suggested mounting position: vertical (horizontal rail position).

4.2. Main dimensions of the instrument

DT1102 (PS)

12 20220202-V0

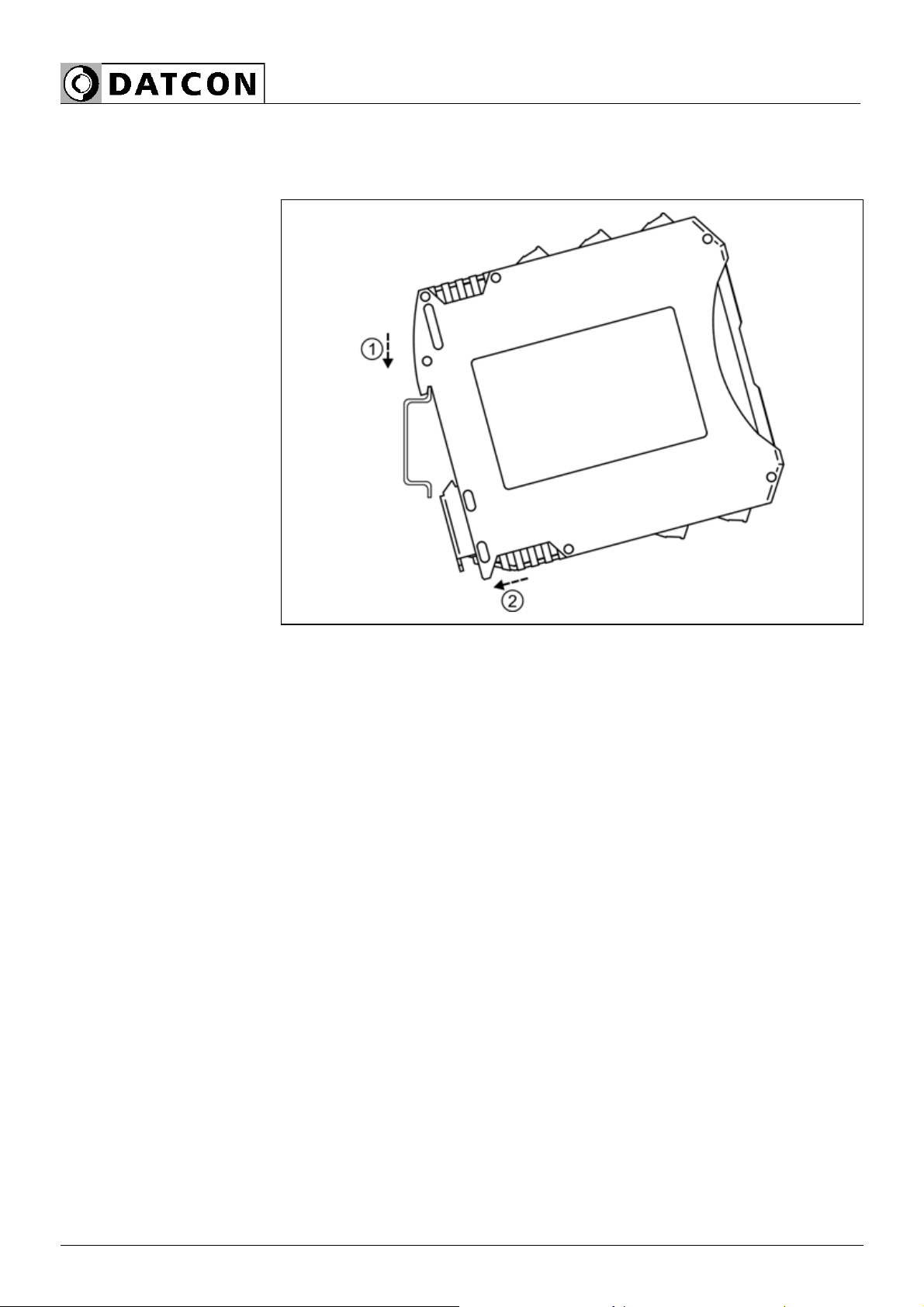

4.3. Mounting procedure

The following figure shows the mounting procedures (fixing on the

rail):

Mounting on the rail

The mounting doesn’t need any tool.

1. Tilt the instrument according to the figure; put the instrument’s

mounting hole onto the upper edge of the rail (figure step 1.).

2. Push the instrument’s bottom onto the bottom edge of the rail

(figure step 2.), you will hear the fixing assembly closing.

3. Check the hold of the fixing by moving the instrument firmly.

DT1102 (PS)

20220202-V0 13

5. Connecting

5.1. Preparing the connection

Select connection

cable

Preparing cables

Always observe the following safety instructions:

•The connection must be carried out by trained and authorized

personnel only!

•Connect or disconnect only in the complete absence of line voltage

•You should take note the data concerning on the overcurrent

protection in installation.

•Use only a screwdriver with appropriate head

Take note the suitability of the connecting cable

(wire cross-section, insulation, screening, etc.).

You may use either solid conductor or flexible conductor.

In case of using flexible conductor use crimped wire end.

The instrument can be connected with standard two-wire cable

without screen.

If electromagnetic interference is expected which is above the test

values of the correspondent standard for industrial areas (e.g. high

power frequency drives are working in the area) screened cable

should be used. Ground the cable shield on the cabinet side.

Always lead the signal cables on a separate path from the control and

power cables!

Prepare the cable for the connection. Strip approx. 8 mm insulation.

In case of using flexible conductor use crimped wire end.

DT1102 (PS)

14 20220202-V0

5.2. Connecting active output current source to the input

The following figure shows connecting active output current source to

the input:

Wiring plan, connecting

active output current

source

(see also “Application

example”)

Be careful the polarity of

the cables

1. Loosen terminal screws.

2. Insert the wire ends into the open terminals according to the wiring

plan.

3. Screw the terminal in.

4. Check the hold of the wires in terminals by pulling on

them firmly.

Terminal (8) and (10) are out of use!

Checking the

connections

Check if the cables are connected properly (have you connected all

the cables, have you connected to the right place, do not the cable-

ends touch each other).

DT1102 (PS)

20220202-V0 15

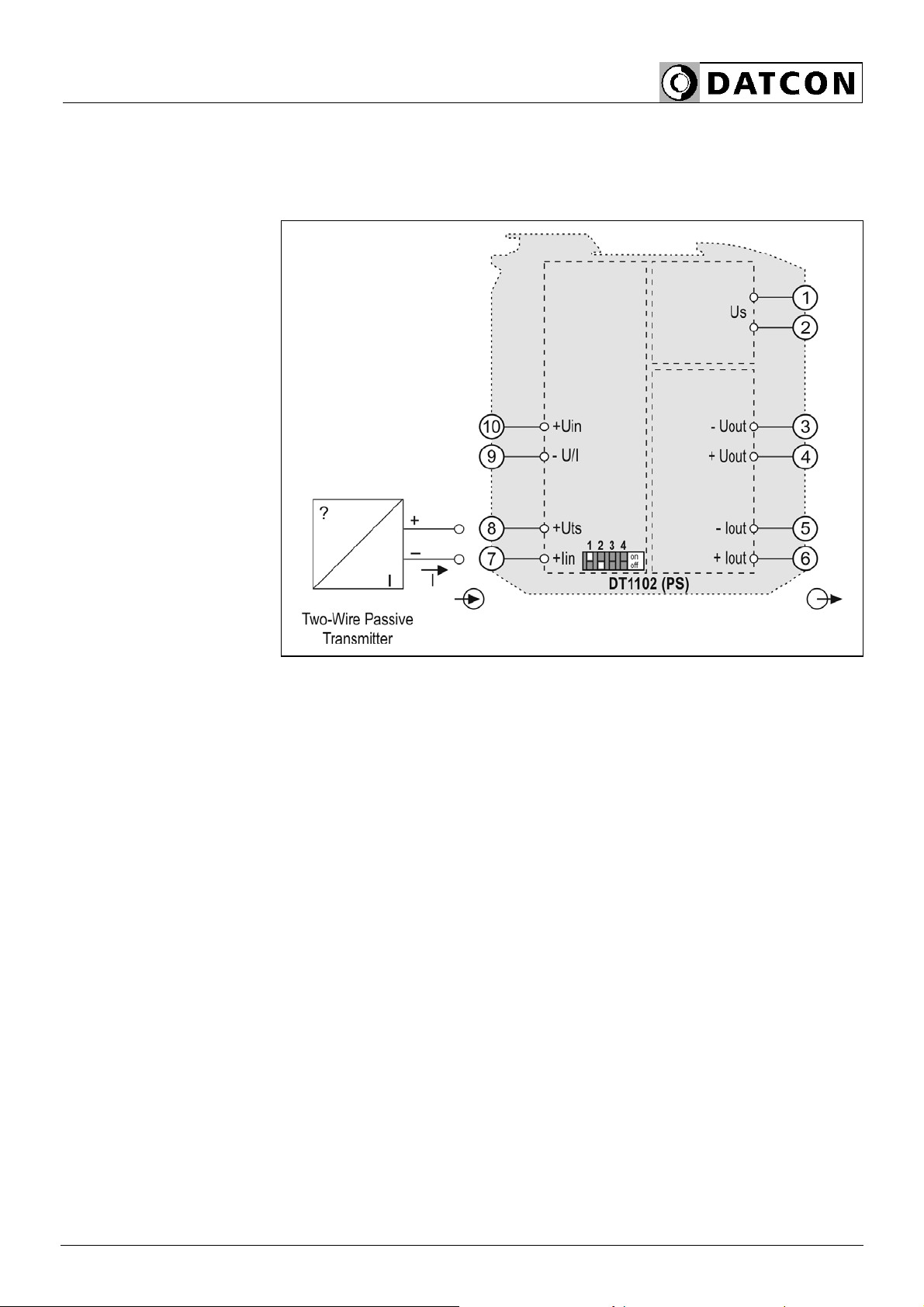

5.3. Connecting 4-20 mA two wire (passive) transmitter to the

input

The following figure shows connecting 4-20 mA two wire (passive)

transmitter to the input:

Wiring plan, connecting

4-20 mA two wire

transmitter (see also

“Application example”)

Be careful the polarity of

the cables

1. Loosen terminal screws.

2. Insert the wire ends into the open terminals according to the wiring

plan.

3. Screw the terminal in.

4. Check the hold of the wires in terminals by pulling on

them firmly.

Terminal (9) and (10) are out of use!

Checking the

connections

Check if the cables are connected properly (have you connected all

the cables, have you connected to the right place, do not the cable-

ends touch each other).

DT1102 (PS)

16 20220202-V0

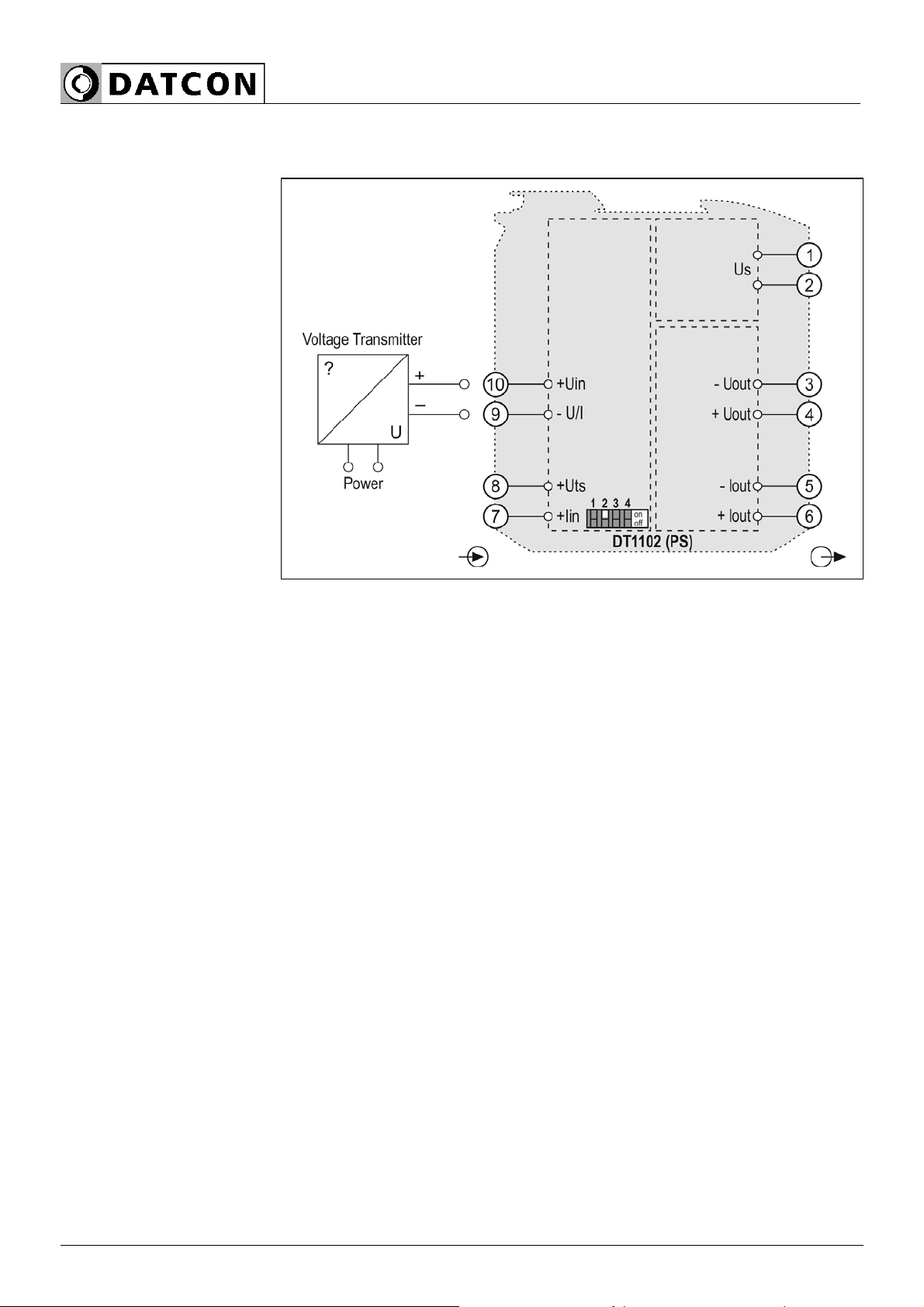

5.4. Connecting voltage source to the input

The following figure shows connecting voltage source to the input:

Wiring plan, connecting

voltage source

(see also “Application

example”)

Be careful the polarity of

the cables

1. Loosen terminal screws.

2. Insert the wire ends into the open terminals according to the wiring

plan.

3. Screw the terminal in.

4. Check the hold of the wires in terminals by pulling on

them firmly.

Terminal (8) and (7) are out of use!

Checking the

connections

Check if the cables are connected properly (have you connected all

the cables, have you connected to the right place, do not the cable-

ends touch each other).

DT1102 (PS)

20220202-V0 17

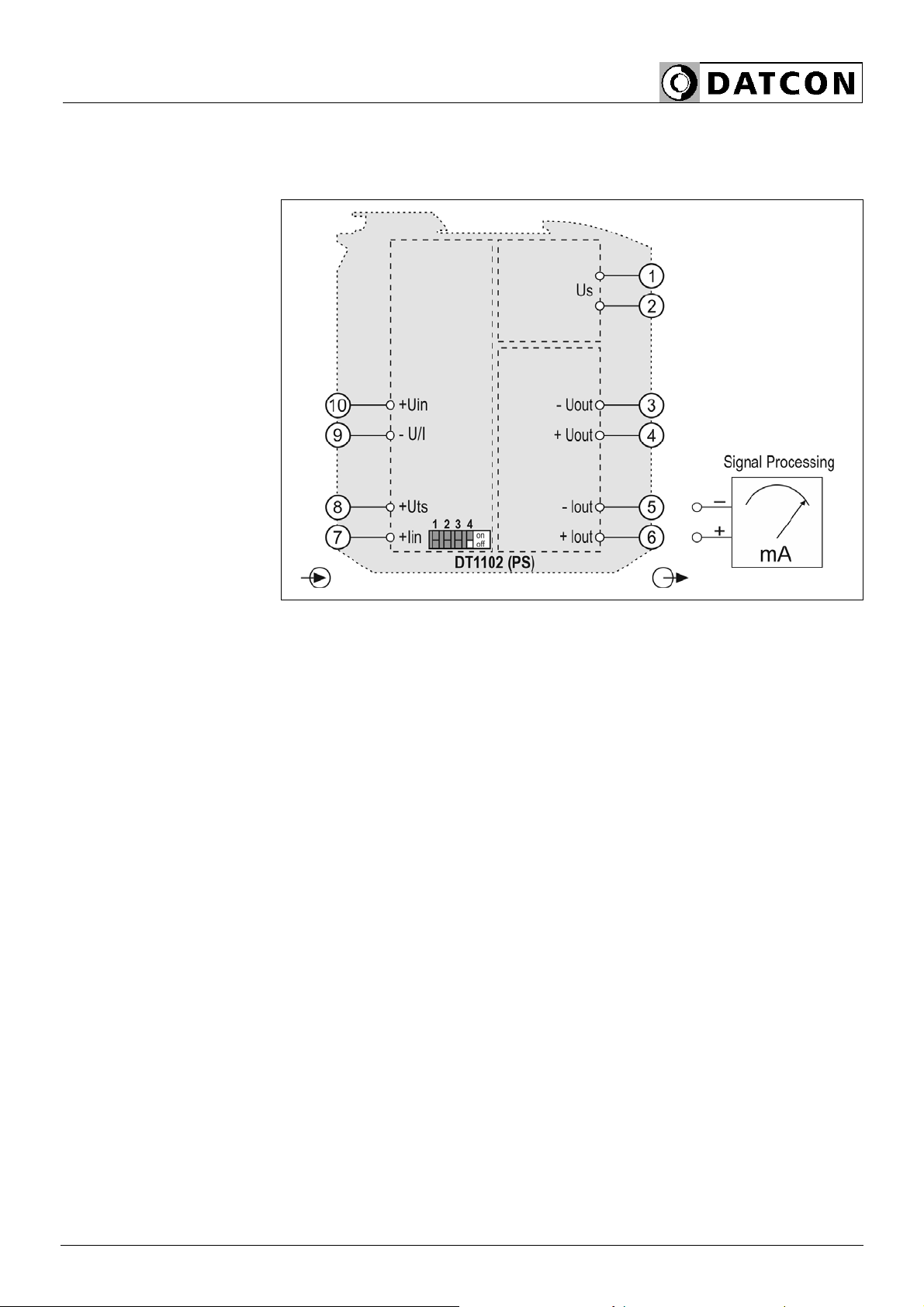

5.5. Connecting current output to the signal processing unit

The following figure shows connecting current output to the signal

processing unit:

Wiring plan, connecting

current output

(see also “Application

example”)

Be careful the polarity of

the cables

1. Loosen terminal screws.

2. Insert the wire ends into the open terminals according to the wiring

plan.

3. Screw the terminal in.

4. Check the hold of the wires in terminals by pulling on

them firmly.

Terminal (3) and (4) are out of use!

Checking the

connections

Check if the cables are connected properly (have you connected all

the cables, have you connected to the right place, do not the cable-

ends touch each other).

DT1102 (PS)

18 20220202-V0

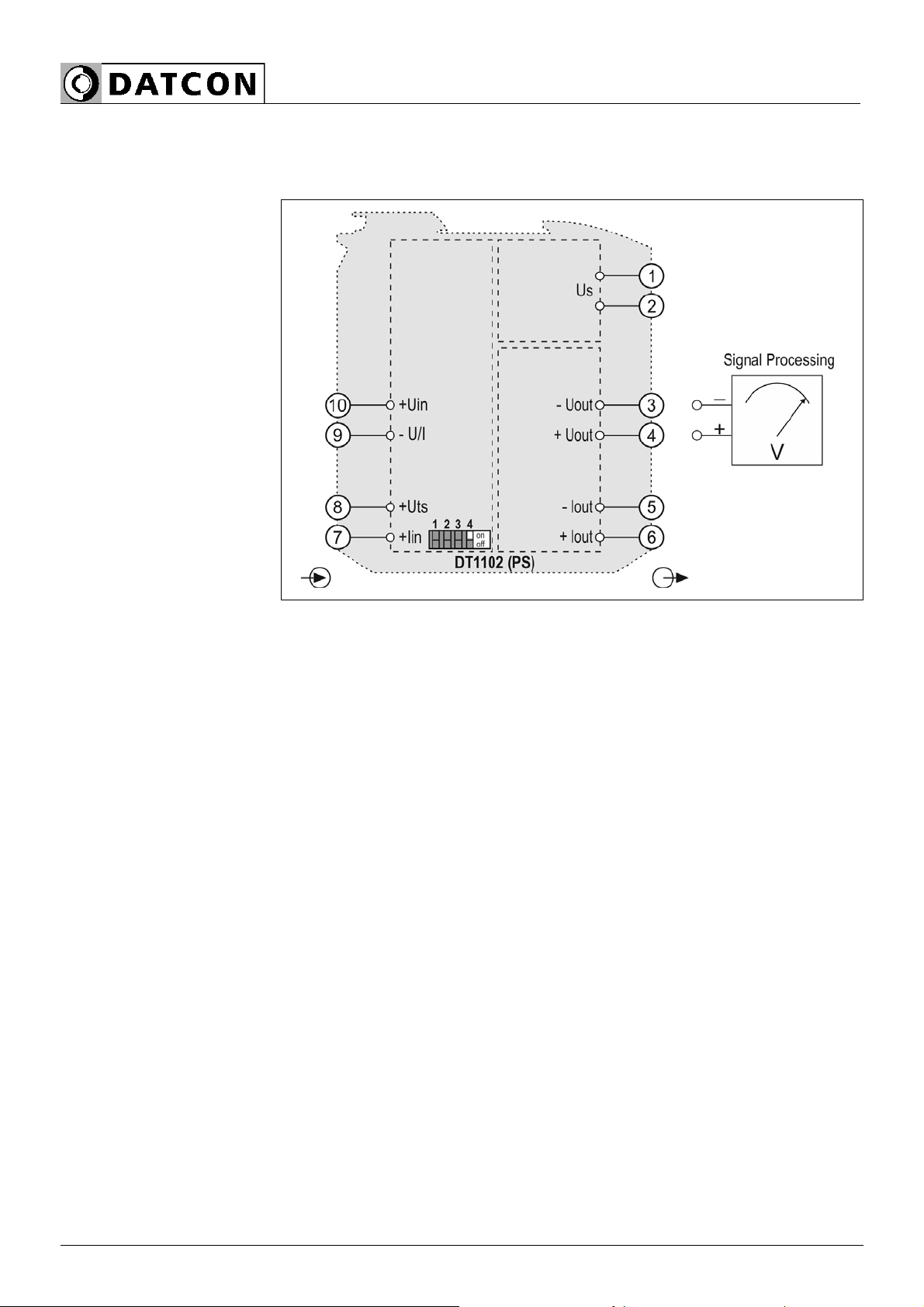

5.6. Connecting voltage output to the signal processing unit

The following figure shows connecting current output to the signal

processing unit:

Wiring plan, connecting

voltage output

(see also “Application

example”)

Be careful the polarity of

the cables

1. Loosen terminal screws.

2. Insert the wire ends into the open terminals according to the wiring

plan.

3. Screw the terminal in.

4. Check the hold of the wires in terminals by pulling on

them firmly.

Terminal (5) and (6) are out of use!

Checking the

connections

Check if the cables are connected properly (have you connected all

the cables, have you connected to the right place, do not the cable-

ends touch each other).

DT1102 (PS)

20220202-V0 19

5.7. Connecting instrument to the power supply

The following figure shows connecting the instrument to the power

supply:

Wiring plan, connecting

the power supply

(see also “Application

example”)

The polarity of the cables

is indifferent

1. Before connecting check that the supply voltage correspond with

the supply voltage written on the data label. When the instrument type

designation ends with „PS” then the power supply terminal coloured

black.

2. Connect only in the complete absence of line voltage

3. Loosen terminal screws.

4. Insert the wire ends into the open terminals according to the wiring

plan.

5. Screw the terminal in.

6. Check the hold of the wires in terminals by pulling on

them firmly.

Checking the

connections

Check if the cables are connected properly (have you connected all

the cables, have you connected to the right place, do not the cable-

ends touch each other).

DT1102 (PS)

20 20220202-V0

6. First „power on”, front panel indicators

6.1. First „power on”

After you have completed the connections, put the instrument under

supply voltage. If the connection is correct green “on” indicator lights,

red “error” indicator dark and you can measure the expected current

or voltage on the output.

Warning! Insufficient setting or connection may cause improper

working of the instrument or in certain situation may cause impairment

of the instrument!

6.2. Front panel Indicators

•In normal (working) mode:

Green „on” indicator lights, red „error” indicator dark.

•Under configuration (switch setting):

Green „on” indicator goes out 1, 2, 3, 4 times according to the number

of the switch which state was changed.

•In error state:

Green „on” indicator lights, red „error” indicator flashes periodically

according to the error type:

1 flash/sec + break: the instrument is defective

4 flash/sec + break: input out of range

5 flash/sec + break: output out of range

Table of contents

Other Datcon Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

TLV

TLV PowerTrap GP5C instruction manual

Eaton

Eaton Cutler-Hammer ATC-300 Instruction booklet

Parker

Parker Gemini GV6K Series Hardware installation guide

M.J. MALLIS GROUP

M.J. MALLIS GROUP SIAT SM 11-SP Instruction manual and spare parts list

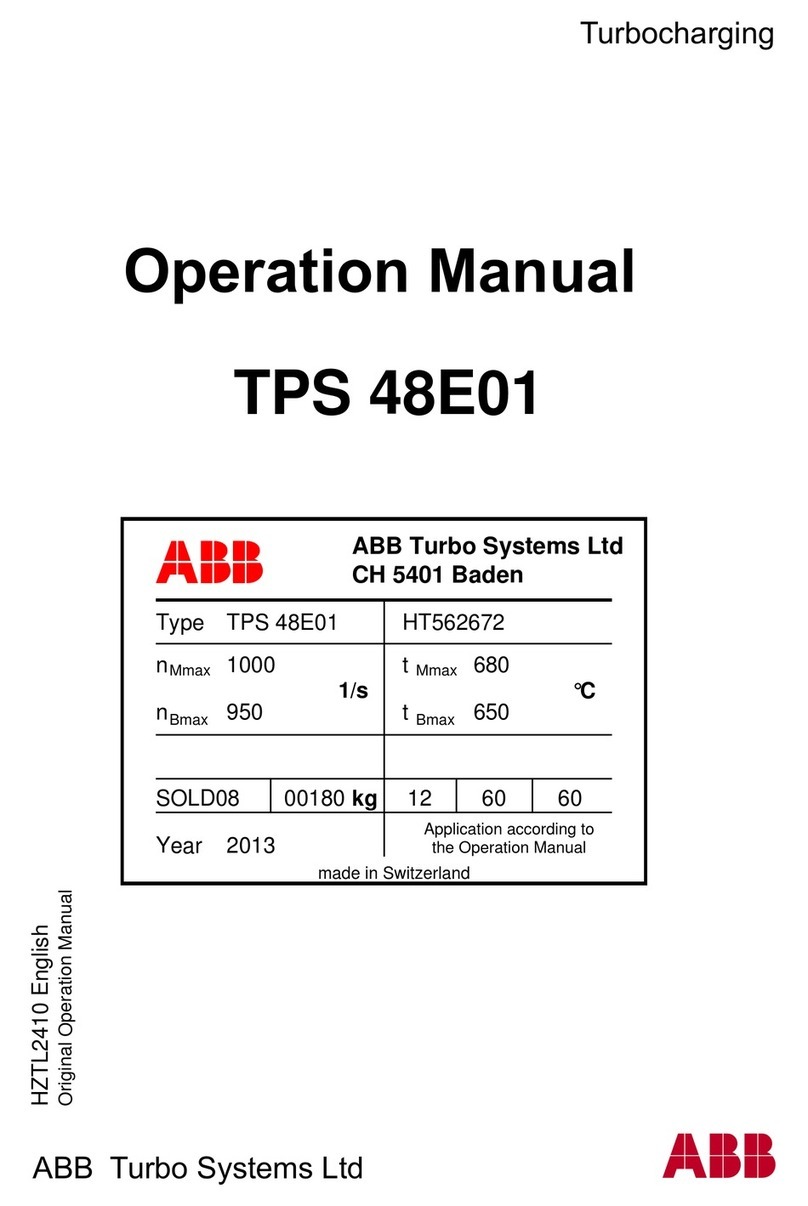

ABB

ABB HT562672 Operation manual

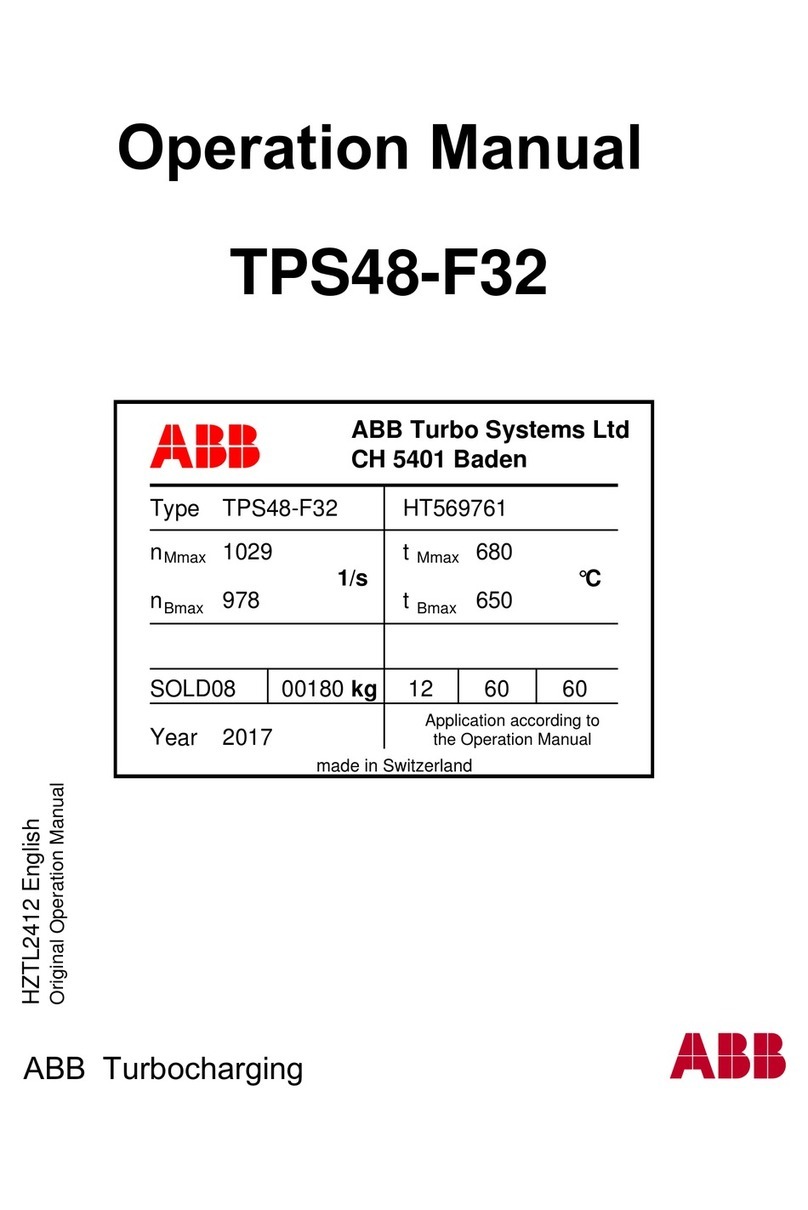

ABB

ABB HT569761 Operation manual