Davco SHOP PRO ST User manual

Updated 09/08/2020

F1321 REV C

F1321 REV E

FOR UPDATED INFORMATION VISIT WWW.DAVCO.COM

SHOPPRO®ST

WITH 50/80 PSI REGULATOR

TECHNICAL MANUAL

F1321 REV E

TABLE OF CONTENTS

Applications and Features............................................... 1

ShopPro®ST Components .............................................. 2

EImportant Safety Precautions .........................................3

Set-up and Maintenance ................................................ 4

Hoses and Adapters .................................................... 5

Hose Connections Priming.............................................. 6

Priming the Fuel Module with Compucheck Fitting ....................... 7

Hose Connections for Priming at 50 PSI ................................. 8

Priming with Regulator settings of 50 PSI ...............................10

Fuel Tank Sweeping with Filtration......................................11

Fuel Transfer with Filtration ............................................12

Service Parts ..........................................................13

Service Parts - Adapters................................................14

Warranty Policy ........................................................15

Parts Return Policy ....................................................16

1

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

APPLICATIONS AND FEATURES

EProduct Warning: The ShopPro is only

approved for use with diesel fuel. It is

not approved for use with gasoline or

any other flammable liquids.

Applications

• Priming after Filter Service

- Eliminates the use of hand priming pumps after

performing maintenance

- Uses on-board fuel to prime engines and filters, avoids

the hassle of keeping reserve fuel on hand

- Eliminates cross contamination of fuel

• Fuel Transfer

- Filters and transfers fuel in one operation

- Transfers fuel when repairing tanks or crossover lines

- Transfers fuel for trucks being sold or taken out of

service

• Tank Cleaning

- Removes contaminated fuel, sediment and water from

fuel tanks of diesel powered equipment or from diesel

storage tanks

- Cleans fuel tanks during service — can be a value

added service or a new revenue stream

- Eliminates downtime due to fuel contamination

Specifications

• Height: 24" handle down, 38" handle up

• Width: 21"

• Depth: 24"

• Weight: 35 lbs

• Electric Motor: 12VDC, 3000 RPM, UL

®Listed

• Flow Rate: 12VDC: 91 GPH

ShopPro Filtration

• All-in-one fuel filter and water separator for diesel fuel

• Superior fuel/water separation

• Easy to access drain

• Lightweight aluminum construction

Features

• Cart

- Heavy-duty steel construction

- Portable and self-contained

• Electrical

- UL

®Listed, rear-facing receptacle

- Waterproof ON/OFF switch

- 12VDC connection

• Pump and Motor

- Electric motor/pump combination rated for continuous

operation

- UL

®Listed and CSA approved

• Adapters and hoses

- No-drip fittings

- Color-coded for function

• Regulator

- 50 psi (handle up, range of 45 psi to 50 psi) for use on

MaxxForce Engines

- 80 psi (handle down, range of 75 psi to 80 psi) for use

on other applications

2

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

SHOPPRO®ST COMPONENTS

Handle

Filtration

Unit

Dispensing

Wand

Pressure

Hose

Pick-up Wand

Drain

Suction Hose

Power Connection

On/Off Switch

Motor

Pump

3

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

General Safety Precautions

• The ShopPro is only approved for use with diesel fuel.

It is not approved for use with gasoline or any other

flammable liquids.

• Read all instructions before use to avoid injury.

• To avoid serious injury or death, follow the safety

information in this document.

• Keep this manual. If you need to replace the manual, call

customer service at 800-328-2611 or visit www.davco.

com for a replacement.

• Read all product safety labels.

• Refer to appropriate regulations for environmental and

workplace safety rules.

EWARNING: To prevent personal injury

- Recommended Personal Protection Equipment:

- Eye Protection

- Chemical resistant gloves

• Avoid Fuel Spillage: When disconnecting attachments

equipped with Quick connect fittings, wrap a shop rag

around the fitting to catch any residual fuel. Allow fuel to

drain back into hoses before closing ball valves to avoid

spillage when returning hoses to the Cart.

• Do not leave the ShopPro running unattended. Follow

engine manufacturer guidelines for proper priming

procedures. Always disconnect the power supply when

the ShopPro is not in use.

• Scalding hazard: When diesel fuel is circulated through

an operating engine, it can become very hot. Do not allow

fuel to come in contact with eyes or unprotected skin.

Allow the engine and fuel to cool to ambient temperature

before replacing the fuel filter or performing service

operations which could result in spillage of fuel from the

fuel system.

• Fire Prevention: Heated fuel can form combustible

vapor mixtures in the area around the fuel source. To

eliminate the potential for fire, keep open flames, sparks

or other potential ignition sources away from the work

area. Do not smoke during filter replacement or service

operations.

• Inhalation Precaution: Always perform engine or vehicle

fuel system maintenance in a well ventilated area that is

kept free of bystanders.

• The ignition key must be in the off position, unless

otherwise directed. To avoid unintentional engine startup,

use a lockout key and/or signage to alert personnel that

work is being performed.

Government Regulations

• Engine fluids (oil, fuel, and coolant) may be a hazard to

human health and the environment. Handle all fluids and

other contaminated materials (such as filters and rags)

in accordance with applicable regulations. Recycle or

dispose of engine fluids, filters, and other contaminated

materials according to applicable regulations.

FIMPORTANT SAFETY PRECAUTIONS

4

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

SETUP AND MAINTENANCE

Set-up and First Use

1. Unpack the ShopPro ST and remove cable ties from

hoses.

2. Remove the vent cap from the filtration unit.

3. Pour diesel fuel into the clear cover until it reaches the

black band on the filter element. (This fuel will be on

the “dirty” side of the filter, meaning that the fuel will be

filtered before flowing through the ShopPro ST to the

engine or tank.)

4. Reinstall the vent cap and tighten by hand until it clicks.

The ShopPro ST is now ready for use.

5. Connect the ShopPro to a power source. Install the

pick-up wand (green hose) and dispensing wand (red

hose). Put the wands in a five gallon (minimum) fuel

container or truck fuel tank. Turn the ShopPro power on

and circulate fuel until there are no bubbles in the sight

tube. Turn off the ShopPro. Close the ball valves on both

hoses. Remove the wands from the hoses and return

them to their storage area. Connect the hoses to the hose

retainers. (Refer to photo on page 2.)

Filtration Unit Maintenance

Drain Water

Water that has been separated from fuel will collect in the

bottom of the body of the filtration unit. Drain the water

periodically. The frequency will depend on how often the

ShopPro is used and the quality of the fuel it has filtered.

1. Open the vent cap slightly to break the vacuum. Place the

end of the drain hose in a suitable container and open the

drain valve.

2. When only fuel is coming out of the hose, shut the valve.

Hand tighten the vent cap until it clicks.

Filter Replacement

Replace the filter in the filtration unit when there is low flow/

pressure or when the filter is visibly contaminated. The filter

change will also include replacement of the seals on the vent

cap and on the collar.

1. Remove the vent cap and open the drain valve to drain

the fuel below the collar level. Close the drain valve.

2. Remove the collar (use the DAVCO wrench) then remove

the clear cover. Remove the filter. Remove the seals from

the cover and the vent cap. Dispose of the filter and the

seals properly.

3. Using a clean shop rag, clean the cover, vent cap, collar

and threads on the filtration unit body. Do not use any

acetone based cleaners on the clear cover.

4. Install the new filter and the seals (included with the

replacement filter).

Pro Tip: Write the date of the filter change with a permanent

marker on the filter wrap.

Pro Tip: Install the cover and collar on the filtration unit hous-

ing. Apply downward pressure on the top of the cover and

rotate the collar until contact. Use a DAVCO wrench to tighten

three additional ribs.

5. Pour clean fuel into the filtration unit.

6. Reinstall the vent cap and tighten by hand until it clicks.

Replacement filter part number:

Fleetguard: FS19624

Service Parts

See 13 for service parts. Call DAVCO customer service at

800-328-2611 to order.

5

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

HOSES AND ADAPTERS

HOSES

Hose Connection Description Photo

Red Quick connect Pressure Hose with check valve

Green Quick connect Suction Hose

ADAPTERS

Hose Connection Description Photo

Blue Compucheck Compucheck fitting for priming Fuel

Module

Red Voss Priming MaxxForce Engines using

regulator setting of 50 PSI

Green Voss Priming MaxxForce Engines using

regulator setting of 50 PSI

60" White tube Quick connect Pick-up Wand: Put in fuel tank or

container

20" White tube Quick connect Dispensing Wand: Tank sweeping or

fuel transfer

6

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

HOSE CONNECTIONS PRIMING

PRESSURE

HOSE

SUCTION

HOSE

QUICK

CONNECT

PRESSURE (RED)

SUCTION (GREEN)

PRESSURE (RED)

SUCTION (GREEN)

PRESSURE (RED) SUCTION (GREEN)

FUEL PRIMING

COMPUCHECK FITTING

COMPUCHECK

ADAPTER (BLUE)

Priming with Compucheck Adapter—Use 80 PSI Setting on Regulator

7

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

PRIMING THE FUEL MODULE WITH COMPUCHECK FITTING

Regulator Settings:

Use the 80 PSI Regulator setting to prime the fuel module.

1. Connect the ShopPro to a power source.

2. Attach the Pick-up (60") wand to the suction hose (green)

and insert it into the fuel tank.

3. Open the ball valve.

4. Attach the Compucheck Adapter (blue hose) to the

pressure hose (red) on the ShopPro.

5. Connect the Compucheck fitting to the priming port on

the fuel module.

6. Open the ball valve.

7. Turn the ShopPro FXP ON. Prime the fuel system for four

minutes.

8. While the ShopPro is still turned ON, start the engine.

Allow the engine to idle for one minute before revving the

engine. Turn off the engine.

9. Turn the ShopPro off. Close the ShopPro pressure hose

ball valve. Remove the Compucheck adapter from the fuel

module.

10. Remove the pick-up wand from the fuel tank. Allow the

fuel to drain back into the tank before closing the ball

valve.

11. Return the adapters and hoses to the ShopPro cart.

12. Restart the truck and check for leaks.

8

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

HOSE CONNECTIONS FOR PRIMING AT 50 PSI

Priming with Regulator Settings of 50 PSI

Use on engine applications that require 50 PSI for priming

PRESSURE

HOSE

SUCTION

HOSE

FUEL TANK

PRESSURE (RED)

SUCTION (GREEN)

PRESSURE (RED)

SUCTION (GREEN)

QUICK

CONNECT

QUICK

CONNECT

SUCTION (GREEN)PRESSURE (RED)

50

PSI

Green hose with 90°

Voss Fitting

Connect to Fuel

Outlet on Fuel Pro

Connect to Fuel

Supply Line

Green Suction Hose

Red Pressure Hose

Red hose with

straight Voss Fitting

9

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

PRIMING WITH REGULATOR SETTINGS OF 50 PSI

ECAUTION!: To prevent damage to fuel

system components, make sure pressure

regulator handle is in 50 PSI position

when servicing MaxxForce®11, 13 and 15

engines.

50

PSI

1. Connect the ShopPro to a power source.

2. Attach the green Voss adapter to the suction hose

(green).

3. Connect the red Voss adapter to the pressure hose (red).

4. Disconnect the fuel supply line from the FUEL OUT port.

5. Connect the green Voss adapter to the Fuel Pro inlet

fitting. (Item 3).

6. Connect the engine fuel supply line (Item 1) to the red

Voss adapter (Item 2).

ECAUTION: USE CARE WHEN CONNECTING VOSS

FITTINGS TO AVOID ACCIDENTAL BREAKAGE.

7. Open the ball valves (Items 1 and 2).

10

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

PRIMING WITH REGULATOR SETTINGS OF 50 PSI

8. Turn the ShopProON. Let the ShopPro run for a mini-

mum of two minutes after no bubbles are visible in sight

glass.

9. Start the engine and run the engine at 1200 rpm for a

minimum of two minutes. Turn off engine.

10. Turn the ShopPro OFF.

11. Close pressure and suction hose ball valves (Items 1 and

2).

12. Disconnect the adapters from the fuel line and FuelPro.

13. Reconnect the fuel supply line to FuelPro FUEL OUT

port.

14. Return the adapters to the cart. Return the hoses to the

cart. Connect the hoses to the hose retainers.

15. Restart the truck and check for leaks.

11

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

FUEL TANK SWEEPING WITH FILTRATION

Overview:

The suction hose (green) is connected to the pick-up wand

(60” white wand). The pressure hose (red) is connected to

the dispensing wand (20” white wand). The fuel is filtered

as it is drawn from the tank and returned to the same tank

(or auxiliary tank). By moving the wand along the sides

and bottom of the tank, water and contaminants that have

settled in the tank are removed. The sight tube aids in

determining the length of time needed to clean the tank.

Use the regulator setting of 80 PSI.

FUEL TANK

QUICK

CONNECT

PRESSURE

HOSE

SUCTION

HOSE

PRESSURE (RED)SUCTION (GREEN)

Pro Tip: Remove the anti-siphon fill cap from the fuel tank be-

fore sweeping.

Pro Tip: Elevate the end of the truck to allow water and con-

taminants to collect closest to the fuel fill point.

1. Connect the ShopPro to a power source.

2. Attach the 60" pick-up wand to the suction hose (green)

and insert it into the fuel tank.

3. Open the ball valve.

4. Attach the 20" dispensing wand to the pressure hose

(red).

5. Insert the dispensing wand into the fuel tank and open

the ball valve.

6. Turn the ShopPro ON.

7. With the pick up wand, slowly sweep the bottom and

sides of the fuel tank with a side-to-side motion. If the

tank being cleaned has excessive water (visible in the

clear cover) turn the ShopPro off and drain the filtration

unit.

8. When sweeping is complete, run for one additional min-

ute to flush residual water from the ShopPro to prevent

gear corrosion. Turn the ShopPro OFF.

9. Remove the wands from the fuel tank. Allow the fuel to

drain back into the tank before closing the ball valves.

10. Return the wands to the cart.

11. Return the hoses to the hose retainers.

12

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

FUEL TRANSFER WITH FILTRATION

Overview:

The suction hose (green) is connected to the pick-up wand

(60” white wand). The pressure hose (red) is connected to

the dispensing wand (20” white wand). The fuel is filtered

as it is drawn from the Tank A or storage container and

transfered to Tank B. Water and contaminants that have

settled in the tank are removed as the fuel is transferred

between the tanks.

Use the regulator setting of 80 PSI.

PRESSURE

HOSE

SUCTION

HOSE

FUEL TANK

SUCTION (GREEN)

PRESSURE (RED)

QUICK

CONNECT

QUICK

CONNECT

TANK A TANK B

1. Connect the ShopPro to a power source.

2. Attach the 60" pick-up wand to the suction hose (green)

and insert it into the fuel tank.

3. Open the ball valve. Attach the 20" dispensing wand to

the pressure hose (red). Insert the dispensing wand into

the fuel tank or container that the fuel is to be transferred

to.

4. Open the ball valve.

5. Turn the ShopPro ON. If the tank the fuel is being

transferred from has excessive water (visible in the clear

cover) turn the ShopPro off and drain the filtration unit.

6. When the fuel transfer is complete, run for one additional

minute to flush residual water from the ShopPro to

potential pump corrosion. Turn the ShopPro OFF.

7. Remove the wands from the fuel tank. Allow the fuel to

drain back into the tank before closing the ball valves.

8. Return the wands to the cart.

9. Return the hoses to the hose retainers.

13

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

CART

A Plugs (10) 1.5" x 1.5" Sq 772019S

B Clip w/ Screws (Sm) 772034S

C Clip w/ Screws (Lg) 772033S

D Motor Cover and (5) Screws 782126S-B

Motor Bracket and Fasteners (Not Shown) 782088S-B

E Handle Asm 772031S-B

Pump Bracket, Washers & Screws (Not Shown) 782214S-B

F Wheels, Axle and Bumpers 772029S

ELECTRICAL

G Coupler Asm 782098S

H Electrical Box 12V with Switch 782106S

I Electrical Switch 12V 782099S

Motor (Not Shown) 782078S

J Pump 782002S

K Cable, Wire w/Clips 782077S

FILTRATION

L Cover, Collar, Spring, Vent Cap and Vent Cap O-rings 243013SDAV

M Filtration Unit w/Fasteners regulated ShopPro ST 772030S

N Regulator Asm 772025S

O Wrench 232007DAV

P Fleetguard Brand 7 micron FS19624

HOSES

Description Purchased

before 09/06/16

Purchased

after 09/06/16

Q Pressure Hose (red) 17 ft. 782134S 782286S

R Suction Hose (green) 12 ft. 782117S 782287S

S Hose Asm, Pump to Reg 772040S

T Hose Asm, Reg to Filter 772039S

U Hose Asm, Pump to Filter 772038S

SERVICE PARTS

Purchase service parts directly from the

DAVCO on-line store. Scan this code with

your cell phone to go directly to the

ShopPro ST Service Parts page.

K

P

E

A

B

R

Q

U

T

L

M

E

K

D

JF

G

U

S

I

H

C

N

O

14

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

SERVICE PARTS ADAPTERS

ADAPTERS

Description Purchased before 09/06/16 Purchased after 09/06/16

Compucheck Adapter (Blue) 782236S 782294S

Pick-Up Wand (60" tube) 782114S 782289S

Dispensing Wand (20" tube) 782133S 782288S

NAVISTAR HOSE KITS

Description Purchased before 09/06/16 Purchased after 09/06/16

Voss Fitting Adapter (Red) 782207S 782293S

Angled Voss Adapter (Green) 782206S 782292S

Includes Voss Fitting Adapter

(Red) and Angled Voss Adapter

(Green) for Navistar Engines

782320S 782319S

FITTINGS

Description Purchased before 09/06/16 Purchased after 09/06/16

Quick Connect Fitting for

Pressure/Suction hoses

103119S

782284S

Compucheck Fitting for

782236S/782294S

782012S

15

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

Please review DAVCO’s Product Warranty terms and conditions carefully before installing and/or using a

DAVCO product.

DieselPro®243, DieselPro®245, Fuel Pro®382, Fuel Pro®482, Fuel Pro®483, Fuel Pro®485, Fuel Pro®487,

Industrial Pro®, Pro-Chek®, Sea Pro®

DAVCO Technology, LLC warrants these products to be free of defects in material and workmanship for five years, 500,000 miles

or 10,000 hours (whichever comes first) and electrical parts for two-years, 200,000 miles or 4,000 hours (whichever comes first)

from the purchase date*.

ShopPro®

DAVCO Technology, LLC warrants the ShopPro (except for the motor) to be free of defects in material and workmanship for two

years from the date of purchase. The ShopPro motor is warranted for one year from date of purchase.

REN Products, EyeMax®, and Fuel Pro®384

DAVCO Technology, LLC warrants these products to be free of defects in material and workmanship for two-years or 200,000

miles (whichever comes first) from the purchase date.

By installing and/or using the product, you agree to be bound by the following:

This Warranty does not apply to:

• Failure or inadequate performance due to improper installation, misuse, misapplication, faulty installation, alteration/

modification, poor maintenance, neglect, accident, or conditions resulting from actions outside DAVCO’s control, including

but not limited to the use of contaminated, corrosive, and unapproved fluids.

• Downtime, loss of use, loss of profits or income, loss of capital, cost of substitute equipment, living expenses, claims by

purchaser’s customers or other third parties, or other incidental, special or consequential damages.

• Attachments, accessory items, and parts not manufactured or distributed by DAVCO.

• Any aftermarket or OEM component not approved specifically to work with a DAVCO manufactured product

• Product that has been installed with aftermarket parts or altered or modified in any way.

• Normal wear and tear, abuse, vandalism, acts of God, improper storage or handling, disasters such as flood, fire, or war,

failure to operate, maintain or repair in accordance with instructions, or failure to repair the vehicle into which the product is

installed in accordance with the vehicle manufacturer’s instructions or common maintenance practices.

This warranty is the sole warranty made by DAVCO. DAVCO makes no other warranties, expressed or implied, of merchantability

or fitness for a particular purpose.

In the unlikely event of a defective product, DAVCO will either rework the defective product or replace it at DAVCO’s discretion.

If you feel you have a warrantable issue, contact DAVCO at 800-328-2611 for a Return Goods Authorization (RGA) number **. An

RGA number is required prior to the return of any product.

* Purchase Date: The date of the first retail purchase of a new vehicle or piece of equipment from the OEM dealer or factory. For

“Over the Counter” purchase: The date of sale to the first retail customer.

**Products submitted for Warranty consideration will be inspected by DAVCO personnel. Re-work or replacement will be based

on DAVCO’s Warranty procedure and/or the results of their evaluation. DAVCO’s Warranty Program does not in any way consti-

tute a product guarantee.

WARRANTY POLICY

16

DAVCO Technology, LLC www.davco.com800-328-26111600 Woodland Drive, Saline, MI 48176-1629 F1321 REV E

SHOP PRO®ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

Parts Return General Policy

A Return Goods Authorization (RGA) must be obtained from DAVCO prior to returning any products. Returns may be

accepted under the following circumstances:

• Order Shipping Error: A credit against the original invoice, including freight charges for both ways will be issued for returns

in which DAVCO inadvertently shipped incorrect quantity or product.

• Overstock: Returns for ordering more product(s) than required, or incorrect part(s), will be accepted within 60 days from

the date of purchase. Proof of purchase will be required, i.e.: original invoice/delivery receipt. These types of return(s) are

subject to a minimum restock fee of 40% or $40.00, whichever is higher. Additional restock fees may apply. Product(s) will

be inspected for “like new” condition and additional costs will be the responsibility of the customer. No obsolete parts may

be returned.

• Freight charges for return(s) will be the responsibility of the customer.

PARTS RETURN POLICY

Table of contents

Other Davco Water System manuals

Popular Water System manuals by other brands

Hydrolevel Company

Hydrolevel Company VXT-120 quick start guide

Nibe

Nibe SCA 41 Installer manual

Omnifilter

Omnifilter OT32 Series E installation instructions

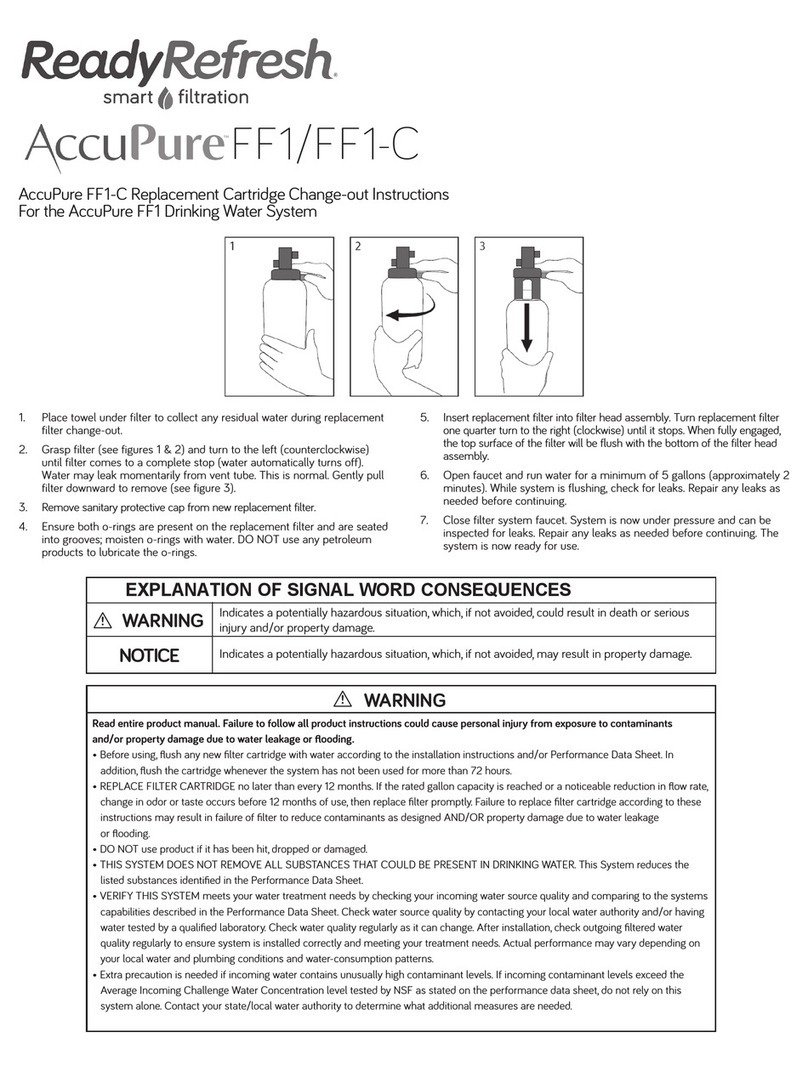

ReadyRefresh

ReadyRefresh AccuPure FF1 instructions

Evinox

Evinox ModuSat SP Cooling Unit installation manual

A.O. Smith

A.O. Smith waterclinic LOTUS 75 M user manual

Intewa

Intewa AQUALOOP greywater recycling Series Maintenance manual

Galletti

Galletti CSW T Installation, use and maintenance manual

Trane

Trane Axiom GEHB 006 Installation, operation and maintenance

Addie Water Systems

Addie Water Systems OXIDIZER PLUS owner's manual

ACO

ACO Self Europoint Flat installation instructions

J.E. Adams

J.E. Adams 9730 manual