Davey Water Products aquashield MAX User manual

Installation and

Operating Instructions

Aquashield®MAX

Packaged Ultra Violet

Water Treatment System

incorporating RainBank®and Torrium®Controllers,

Filterpure® Filters and Sterio® Disinfection

Please pass these instructions on to the operator of this equipment.

Maximum operating pressure for stainless steel UV chambers is 850kPa (125

psi). If this pressure can be exceeded or if operating close to this pressure t

a suitable pressure limiting valve in the supply to the UV chamber or mains

water line.

Minimum operating pressure is 0kPa. Installation on

a ooded suction is recommended. Installation under

vacuum is not advised, any damage to persons or

associated equipment will not be covered under this

guarantee.

WARNING: The pump, controller & UV Chamber operate under pressure.

Under no circumstances should they be disassembled unless the internal

pressure of the unit has been relieved. Failure to observe this warning will

expose persons to the possibility of personal injury and may result in damage

to the system or other property.

DO NOT DISASSEMBLE ANY COMPONENTS UNTIL YOU HAVE FULLY READ

THESE INSTRUCTIONS!

Ultra violet radiation is harmful to skin & eyes.

DO NOT LOOK AT UV LAMP WHILE LAMP IS OPERATING.

2

Table of Contents

INTRODUCTION Page 3

PREPARING YOUR SYSTEM Page 4

Choosing a Site Page 5

Power Connection Page 5

Pipe Connections Page 6

PUMP CONTROLLERS – Torrium Page 7

– RainBank Page 10

PRE-TREATMENT – (FILTRATION) Page 13

STERIFLO®– (DISINFECTION) Page 14

Lamp Installation Page 16

Operation Page 16

Maintenance Page 17

Water Quality Page 18

Lamp Fail Alarm Page 18

TROUBLE SHOOTING Page 19

3

INTRODUCTION

Congratulations on your purchase of a high quality, award winning

Aquashield MAX Ultra Violet water treatment system.

Aquashield MAX represents advances in safety and convenience of

rainwater harvesting technology for commercial and large scale rainwater

users. The range offers increased water treatment quality and safety

- producing water that is biologically safe to drink, without the use of

chemicals.

This all in one unit is pre tted with a correctly matched pump, Filterpure®

and Sterio®units and can come with either the Rainbank®Mk11 or the

Torrium®pump controller.

The huge advantage of the Aquashield MAX pre engineered pack is that

Davey do all the work and all thinking for you. Advantages like the pump

interlocking and lamp count down timer ensures only correctly disinfected

water is delivered.

Applications: Pressure boosting and disinfection of rainwater for:

• School shower and toilet blocks

• Commercial toilet ushing

• Large home potable water supply

• Industry process water treatment

• Guest house potable water supply

• Bacteria and algae growth control for aquaculture and water features

• Also suitable for bore and surface water treatment – *subject to a water

quality test

Features & Benets:

• Factory matched and tested package – ensures correct UV dosage and

high reliability

• Pump interlock detects lamp failure and locks pump out– ensures only

disinfected water is delivered

• Lamp count down timer with set limit of 9000 hours - ensures only

disinfected water is delivered

• Durable UV resistant cover – allows for exible, vandal resistant exterior

installation

• RainBank®MK II controller options – provides seamless automatic

mains water backup

• Torrium®controller options – intelligent automatic pump control

maximizes pump efciency by adjusting run on time and cut in pressures

• 2 x 20” Jumbo cartridge lter housings – for low friction losses and long

cleaning intervals

• 20 micron ltration – for long cleaning intervals and dirt, rust, sediment

and debris reduction

• 1 micron ltration – for parasitic cyst reduction and high UV dosage rates

4

PREPARING YOUR SYSTEM

Your new Aquashield MAX system incorporates a lamp failure system

design feature that enables you to be warned of a lamp failure by :-

1. A lamp failure LED

2. An audible alarm

3. Remote alarm contacts

4. Pump lock out feature

In addition when the alarm “beeps” on and off, the lamp is due to be

changed so effective treatment is maintained.

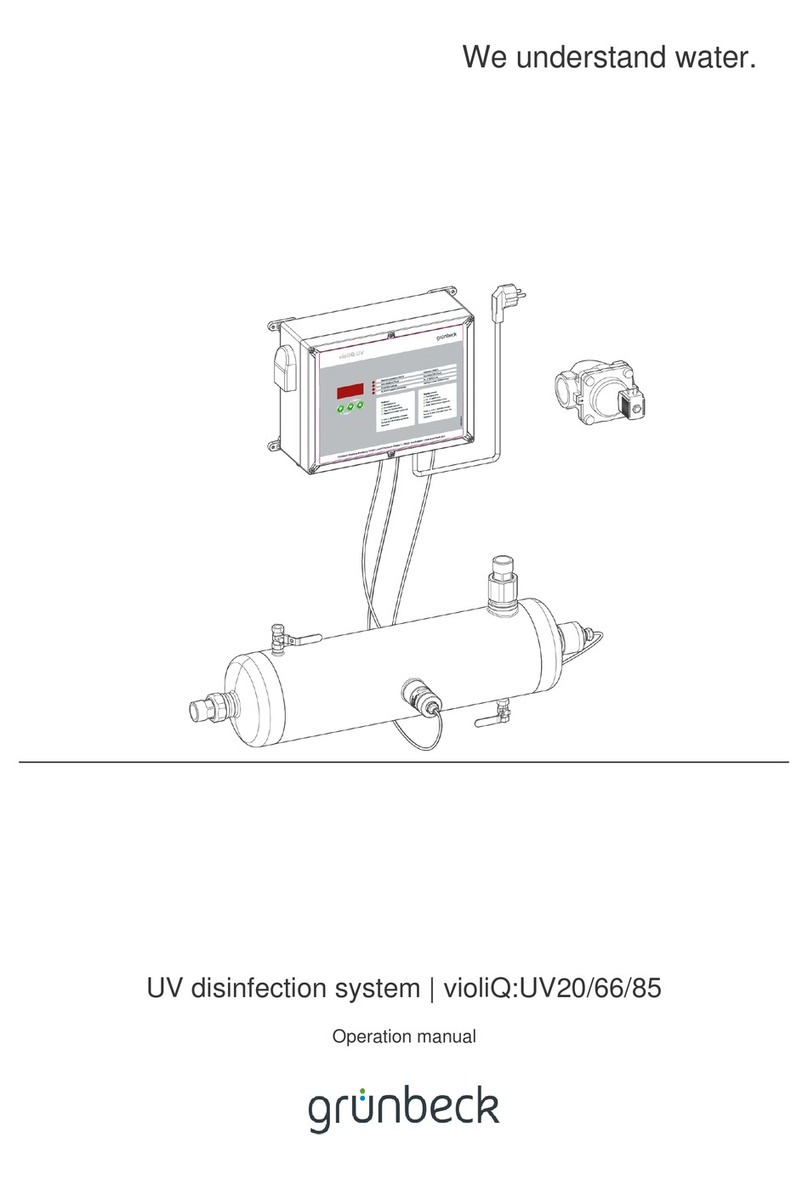

Aquashield MAX

with RainBank®

Aquashield MAX

with Torrium®

Before installing your new Aquashield MAX please read all instructions

carefully as failures caused by incorrect installation or operation are not

covered by the guarantee. Your Ultra Violet water treatment system is

designed to handle clean water. The system should not be used for any other

purpose without specic referral to Davey Water Products. The use of the

system with ammable, corrosive and other materials of a hazardous nature

is specically excluded.

DO NOT DISASSEMBLE ANY COMPONENTS UNTIL YOU HAVE FULLY READ

THESE INSTRUCTIONS!

Torrium®

Controller

HM or

HS Pump

Steriflo®

UV Lamp

Steriflo®Lamp

Controller &

Power Pack

RainBank®

Controller

HM or

HS Pump

Steriflo®

UV Lamp

Steriflo®Lamp

Controller &

Power Pack

5

Prior to using this system you must ensure that:

• The system is installed in a safe and dry environment

• The system enclosure has adequate drainage in the event of leakage

• Any transport plugs are removed

• The pipe-work is correctly sealed and supported

• The pump is primed correctly

• The power supply is correctly connected

• All steps have been taken for safe operation

CHOOSING A SITE

Choose a site with a rm mounting position. Allow room for removal of the

lamp and sleeve during servicing. Leave a chamber lengths space above

the lamp cover & connector end for lamp removal.

To protect your system from the weather, make sure the site is ood proof,

water proof, frost free and has adequate ventilation. Allow for drainage, to

avoid damage due to ooding etc., that over time may occur from leaking

pipe joints or seals.

POWER CONNECTION

Connect lead to power supply designated on control box label. Check that

the earth is connected to the stainless steel chambers using bolt provided

on the chamber.

WARNING: Some insects, such as small ants, nd electrical devices

attractive for various reasons. If your site or enclosure is susceptible to

insect infestation you should implement a suitable pest control plan.

WARNING: When servicing or attending your Aquashield MAX, always ensure

power is switched off and lead unplugged. Electrical connections should be

serviced only by qualied persons. If the electrical supply lead of this system

is damaged, it must only be replaced by a qualied service personnel.

The Sterio®control box has a red LED alarm indicator light mounted on

its front panel, adjacent to the amber “power on” LED. This light will be

illuminated whenever the Sterio®control box senses no lamp current. There

is also an audible alarm in the event of lamp failure. The LED and/or alarm

will only work when unit is connected to the correct electrical supply.

NOTE:

a) For protection, the Davey® pump motor is tted with an automatic

“over temperature” cut-out. Constant tripping of this overload device

indicates a problem e.g. low voltage at pump, excessive ambient

temperature (above 50°C) in pump enclosure.

b) The Torrium®control device may have to be reset after rectifying any of

the above operating troubles. This is done by pushing in the “prime”

button and releasing it after 2 seconds, or switching the power supply

off then on.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

6

PIPE CONNECTIONS

For best performance use P.V.C. or

polythene pipes at least the same

diameter as the pump’s inlet and

delivery outlet openings. Larger

diameter pipe may be used to

minimise resistance to ow when

pumping longer distances.

Use unions at pipe connections to enable easy

removal and servicing. Use sufcient tape to ensure

airtight seal and hand

tighten only. To prevent strain on pump threads

always support heavy inlet and outlet pipes. If

there is a likelihood the water supply may contain

solid particles such as pieces of plant or vegetable

matter, a lter should be installed before the pump to avoid blocking of

water ways. Lay suction pipe at a constant gradient to avoid air pockets

which may reduce pump efciency.

Use unions at pipe connections to enable easy removal and servicing.

Use sufcient tape to ensure airtight seal and do not over tighten. To

prevent strain on unit threads always support heavy inlet and outlet pipes.

NOTE: Suction leaks are the largest cause of poor pump performance and

are difcult to detect. Ensure all connections are completely sealed using

thread tape only.

Do not use pipe thread sealing compounds on any part of this pump. ONLY

use Teon sealing tape.

NOTE: Prior to installation remove the transport plugs from the inlet, outlet

and lamp end cap.

Do not use pipe thread sealing compounds (especially hemp) on any part

of this unit. ONLY use Teon sealing tape.

RainBank® controllers can only be connected to mains water, by a qualied

licensed plumber.

7

PUMP CONTROLLERS

TORRIUM®

Your new system incorporates ‘Torrium®’, electronic ow controller – a

Davey designed unit that enables the use of a highly efcient pump design

and offers the following benets:–

1. Enables the pump to deliver a constant ow of water particularly at

low ow rates – reducing the inconvenience of pressure variation in

showers etc.

2. Provides automatic “cut-out” protection should the pump run out of

water or overheat*, should the pump fail to start due to low voltage or a

blockage in the pump.

3. Provides warning indications for critical and noncritical system faults.

4. Has adaptive pressure cut-in which allows the pump to start at

approximately 80% of the maximum pressure at last shut-down. This

allows the controller to accommodate varying inlet pressures and pump

performance.

5. Automatic retry functions in the event of a critical system fault.

* Motor overload / overheat protection included. Motor has its own overload

/ overheat protection.

Status Indicator

The Torrium®has a status indicator light on the front panel. This light will

enable you to understand what your pump is doing.

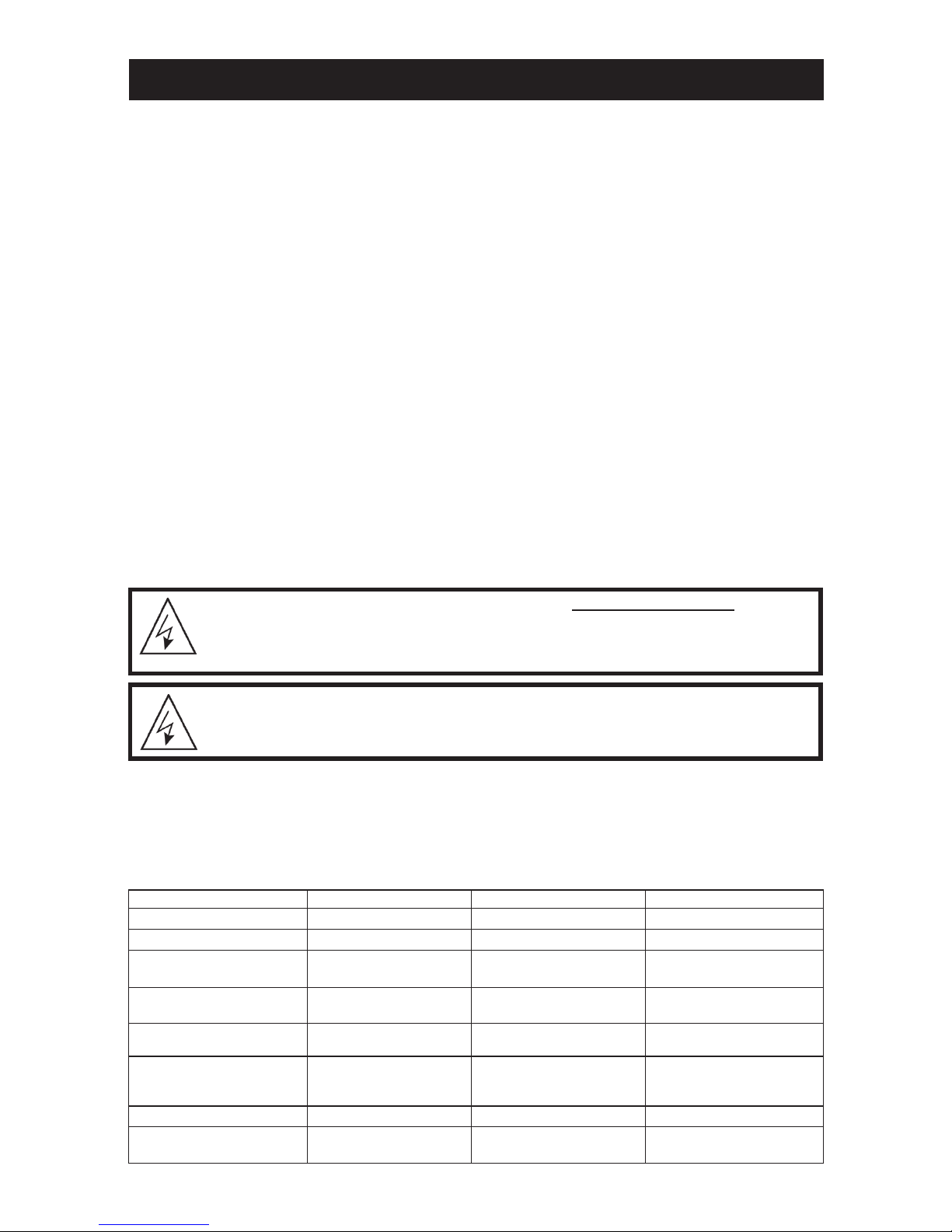

Condition Indicator readout Pump operation Restart / Reset Method

Standby mode Red light Standby Pressure drop

Running Green light Running N/A

Cistern ll Yellow/Amber light Running - 2 minutes Auto, push “Prime” button or

minimum run time cycle power off / on

Loss of Prime Red light single ash Stops, auto-retry & Push “Prime” button or cycle

“water return” activated power off / on

Locked rotor or ‘Prime’ Red light double ash Stops See Trouble shooting guide

button held in too long

Under voltage Red light double ash Normal operation Wait till voltage >180 volts or

push “Prime” button or cycle

power off / on

Water over temperature Red light triple ash Stops Wait till water temp < 60oC

Slow leak Red light triple ash Normal operation with Auto-reset or push “Prime”

reduced cut-in pressure button or cycle power off / on

The electrical connections and checks must be made by a qualied

electrician and comply with applicable local standards.

The Davey Torrium® tted to this pump has a status indicator light mounted

on its front panel. This light will be illuminated whenever the Torrium®

senses that there is electrical power available. The light will only work

when unit is connected to the correct electrical supply.

8

Both the Red & Green Indicators are shown in the same window. It is

possible for the pump to be running (ie. Green indicator) and for a Red ash

sequence to happen at the same time. In that case the Red ash will show

as a Yellow or Amber ash.

Cistern Fill Mode

When your new HP or HS pressure system is used to ll toilet cisterns or

troughs, a special feature of the Torrium®controller may be activated. This

special feature is activated when the controller detects three quick stop start

sequences in a short period. When activated the status indicator will glow

“Amber”, and the pump will run on for two minutes before shutting down.

This allows the cistern to be lled with the minimum number of pump cycles.

Electrical Power Surge Protection

An electrical power surge or spike can travel on the supply lines and cause

serious damage to your electrical equipment. The Sterio® control box has

a 2 Amp fuse to protect the circuit. The fuse is not a lightning arrestor and

may not protect the Sterio®if lightning or a very powerful surge hits the

unit.

If the installation is subject to electrical power surges or lightning we

strongly recommend the use of suitable additional surge protection devices

on ALL electrical equipment.

We recommend the use of an RCD or earth leakage circuit breaker on

the power supply to your unit.

Only one fault condition will be indicated at once.

DO NOT DISASSEMBLE ANY COMPONENTS UNTIL YOU HAVE FULLY READ

THESE INSTRUCTIONS!

Ultra violet radiation is harmful to skin & eyes.

DO NOT LOOK AT UV LAMP WHILE LAMP IS OPERATING.

9

Auto-retry and Water Return Modes

Should your Torrium®detect a loss of prime, after stopping the pump, it will

wait ve minutes before activating Auto-retry and Water Return modes.

Auto-retry automatically starts the pump to see if the pump is now primed.

It does this after 5 mins, 30 mins, 1 hr, 2 hrs, 8 hrs, 16 hrs and 32 hrs.

Water return mode will restart the pump automatically if the Torrium®detects

water ow through it.

Priming and Operation

The Torrium® module tted to your HM or HS system is provided with a

push button “Prime” button. This button is used during initial priming of the

pump and also acts as a reset button if the Torrium®switches out in pump

protection mode.

1. Remove priming plug and ll

casing and suction line (on

ooded suction, simply open

gate valve to pump). When

full, replace priming plug.

2. Ensure outlet nearest

to pump is open.

3. Ensure all valves in suction line

are open.

NOTE: If multiple errors are present, the highest priority error (least number

of ashes) is indicated. Any previous fault code is lost until it recurs.

4. Switch on power - The

status indicator light

will be illuminated

green and the pump

will run. A full ow

of water should be

discharged from the

open tap.

5. If the pump stops with the

tap open see troubleshooting

checklist.

6. Close the open outlet or tap and

the pump should stop after a

few seconds (the status indicator

light should be illuminated red

(constant). If not, consult the

troubleshooting checklist.

To Reset if Pump switches out in

Pump Protection Mode

1. Make sure pump is primed.

2. Open tap, push prime button.

3. Close tap and pump will stop.

10

RAINBANK®– HOW IT WORKS

1. When there is demand for water from your toilet, washing machine or

garden tap RainBank®senses this demand and checks the level of water

in the rainwater tank. Note: demand must be greater than 1.5 litres per

minute or mains water will be delivered.

2. If there is rainwater in the tank RainBank® switches on the pump. The

pressure of the pump is sufcient to overcome the pressure of the mains

water inside RainBank®and this closes a dual check valve and allows

the rainwater to ow. Note: mains water pressure is limited to 300kPa.

3. When there is no longer a demand for water, RainBank®detects that

water has ceased to move inside the pipes, switches off the pump and

waits for another water demand.

4. If RainBank® senses a water demand and detects insufcient water in

the rainwater tank it will automatically allow the mains water to ow.

5. If there is a power failure during a demand for water RainBank®will

automatically supply the mains water as backup.

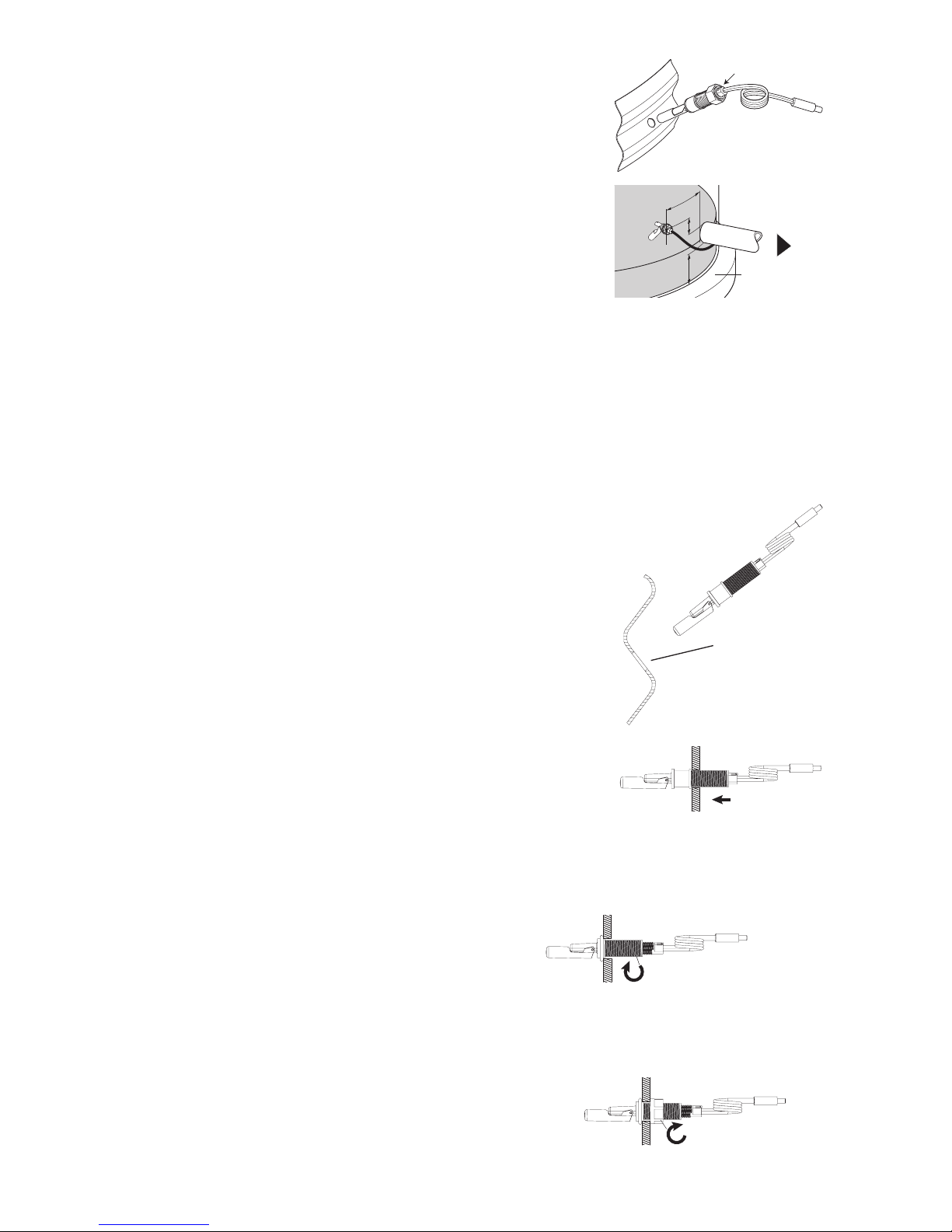

Fit oat switch to rainwater tank

IMPORTANT

• The level switch is suitable for installation in polyethylene and breglass

tanks. It can be tted in steel tanks but cutting through the zinc alum

or colourbond coating of the tank exposes bare steel and this can rust.

Check with the tank manufacturer before drilling.

• The oat switch is designed to be installed from the outside of the tank.

There is no need to get inside the tank.

• The sealing grommet of the oat switch is designed to work in a maximum

tank wall thickness of 25mm. It is not suitable for concrete or very thick

plastic walled tanks. There is an alternative oat switch that can be

lowered into the top of these types of tanks (Davey Part Number 13449).

Top

Bottom Sealing grommet

Level switch stem

Miniature audio D.C. power plug

Male plug Ø2.5mm

Sealing nut

Compression nut

11

Work out the correct position for the hole for the

oat switch. With a corrugated prole tank wall this

is on the upper at section of the prole as shown

below.

Work out the correct location of the oat switch

relative to the pump outlet.

The oat switch location should also be:

• At least 40mm above the pump inlet.

• Placed away from the rainwater entry into the tank so that the incoming

ow does not interfere with the operation of the switch.

Before cutting the hole check again that the 5m lead from the oat switch

will reach the RainBank®and plug comfortably into it.

1. Drill a 22mm hole in the side of the tank in the

correct position. A hole saw is the best tool for this

job. Ensure all swarf is removed from the hole.

If installing the switch in a corrugated tank you

should make sure that it is installed on the at

section between the radii as shown below.

2. Ensure the compression nut is loosened so that

the sealing grommet is not expanded. Remove

the sealing nut and insert the switch into the hole

as below.

3. The switch will not work properly if it is not

properly orientated. Make sure the word

“UP” is seen at the very end of the switch

body. Now tighten the compression nut to

expand the seal (as shown below).

4. Ensure that the switch is still correctly

orientated. With the word “UP” visible, screw

on and tighten the sealing nut to nish the

installation of the oat switch.

Centre hole on flat section of profile

Diameter of hole must be 22mm.

Note: Ensure level sensor is installed

with ‘UP’facing up

150

40

100

Slab

To

Pump

Tighten Sealing Nut

Tighten Compression Nut

Drill Hole

ø 22mm

Insert Float

12

Test the operation of RainBank®.

1. With the mains connected and the rainwater tank empty turn on one of

the taps in the laundry that feed the washing machine or ush the toilet.

Mains water should ow normally. The pump should not turn on. When

this is completed turn off tap.

2. Fill the rainwater tank with sufcient water to activate or cover the oat

switch.

3. Check that the pump is correctly primed and there are no air locks that

will interfere with its operation as per the Davey instructions. This is

essential for the proper operation of the unit. See the instructions on how

to do this for all types of Davey pump in the Priming section on page 26.

4. Turn on a tap or ush a toilet in the rainwater system. The pump should

run and deliver rainwater. Allow to run for several minutes to clear air

from pipes.

5. Remove the oat switch connection from the RainBank®– this should

stop the pump and conrms that the oat switch and power connections

have been made correctly - ret the oat switch connection. Press the

manual override button to operate the pump if needed.

6. Check for leaks around RainBank®, the pump, pipework and ttings.

IMPORTANT: To allow easy connection it is strongly recommended that you

have exible copper pipes that allow some movement so that they can line

up exactly with the mains water and rainwater outlet. These pipes must be

3 ⁄4 inch in diameter.

IMPORTANT: It is highly recommended that an isolation valve be tted to

where the mains water enters RainBank®and between the pump and the

rainwater tank. This facilitates easy removal of the unit if required without

turning off the household water or losing stored rainwater.

NOTE: Do not instal additional suction check valves on RainBank®systems

except where a foot valve is required (eg. suction lift installations). In the

case of suction lifts, to allow for the correct operation of your RainBank®

and for movement of the tank and pump which may occur over time, the

suction pipe must have a length of exible suction hose from pump to

top of tank. This hose can be braided hose, reinforced suction hose or

polythene pipe at least 1 metre in length.

13

PRE-TREATMENT (FILTRATION)

Preltration is usually required to ensure that particulate matter does not

shield micro-organisms from the UV light. Sand ltration or 20 micron

cartridge ltration is the usual minimum, this is provided in Stage 1 ltration.

In some cases, particularly with surface water, ner ltration may be

necessary, or if cysts like Giardia or Cryptosporidium may be present. In

this case 1 micron ltration is required, as provided in Stage 2 ltration.

Temperature Rating

Maximum 50oC - Minimum 8oC

Sediment Cartridge Filter Life

Once the housing is properly installed, a reduction in ow/pressure (to

such an extent as to cause inconvenience) will indicate when the cartridge

is becoming clogged and needs replacing/cleaning. Sediment cartridges

should be replaced/cleaned/sanitised when the water ow has been

noticeably reduced/or after 3-6 months - whichever comes rst (this is for

hygiene reasons).

Changing the Filter Cartridge

1. Turn off the valve to stop the ow of water.

2. Release the pressure by opening a tap downstream, or use the

pressure relief valve that is available in the lid of some lter housings.

3. Unscrew the bottom housing from the lid and pull out the used cartridge

and discard or wash. The inside of the lter housing and the lid should

be checked for cleanliness - they will usually need to be cleaned or

sanitised - use hot water and dishwashing liquid, thoroughly scrub all

surfaces and then rinse.

4. Check that the oring is in position in the top of the housing base,

lubricate with a coating of white petroleum jelly (Vaseline), place the

Caution: The housing must be protected against freezing. Failure to do so

may result in cracking of the housing and water leakage.

NOTE: Actual ltration/purication life of cartridge can vary with the

condition of incoming water.

NOTE: Clean lter Stage 1 once a pressure drop of 100 to 150kPa from

clean, or between Stages 1 and 2.

WARNING: CAREFULLY AND GENTLY TIGHTEN WITH HOUSING SPANNER

as the bowl should only be tightened enough to avoid water leaking

during operation.

WARNING: If the water system is not going to be used for extended

periods, the cartridge should be removed from the housing and replaced

with a new or cleaned cartridge when the system is used again.

14

IMPORTANT: When opening the lter housing to install or change the

cartridge (element) it is common for the oring seaI to lift out of the groove

and, at times, it may even stick to the cap.

CAUTION WHEN INSTALLING

1. This is a plastic product with a female thread. If you cross-thread a

male tting, and/or you over pack with sealing tape, you could do

permanent damage.

2. If you use a tapered thread male tting do not over tighten.

3. No warranty claims will be considered for damage due to incorrect

installation.

oring into the groove and with two ngers wipe the oring down into the

groove. Do not wipe the oring clean of lubricant after it has been properly

seated in the groove because the lubricant prevents “crawling” of the

oring during the tightening of the lid and thus prevents water leaks.

5. Screw the housing onto the lid and hand tighten. Open the tap

downstream of the lter and then open the inlet valve.

STERIFLO®

Your new Sterio®system incorporates a lamp failure system design

feature that enables you to be warned of a lamp failure by :-

1. A lamp failure LED

2. An audible alarm

3. Remote alarm contacts

In addition when the alarm “beeps” on and off, the lamp is due to be

changed so that effective treatment is maintained.

Lamp

Quartz Sleeve (pre-installed in chamber)

Drain plug

Lamp Lead

1 metre

OUTLET

or

INLET

INLET

or

OUTLET

Treatment Chamber

Power Lead

1.5 metre

Alarm LED (Red)

Alarm reset

On LED (Amber)

15

PREPARING YOUR SYSTEM

On removing your Sterio®system from its carton you should check all

components, especially the lamp, to ensure all are present and have not

been damaged in transportation. You should have:

1. Power supply control box with indicator light(s) and electrical ex.

2. UV lamp (or lamps).

3. Treatment chamber with mounting brackets.

Connect lead to power supply designated on control box label. Check that

the earth is connected to the stainless steel chambers using bolt provided

on the chamber.

Install the power supply enclosure above the treatment chamber so that in the

event of a leak, water cannot drip down the lamp lead into the enclosure.

CAUTION: The supply cord is necessary for lamp changing. The three pin

supply plug must remain accessible after installation. If installed to xed

wiring without the plug a two pole switch must be tted and its ON and OFF

positions shall be marked.

The appliance is not intended for use by young children or inrm persons

without supervision. Young children should be supervised to ensure they do

not play with the appliance

NOTE: The quartz sleeve has been factory tted, and there is no need to

remove these endcaps on rst installation. Before removing endcaps, please

read the Maintenance section of these instructions completely.

The Sterio®control box has a red LED alarm indicator light mounted on

its front panel, adjacent to the amber “power on” LED. This light will be

illuminated whenever the Sterio®control box senses no lamp current. There

is also an audible alarm in the event of lamp failure. The LED and/or alarm

will only work when unit is connected to the correct electrical supply.

16

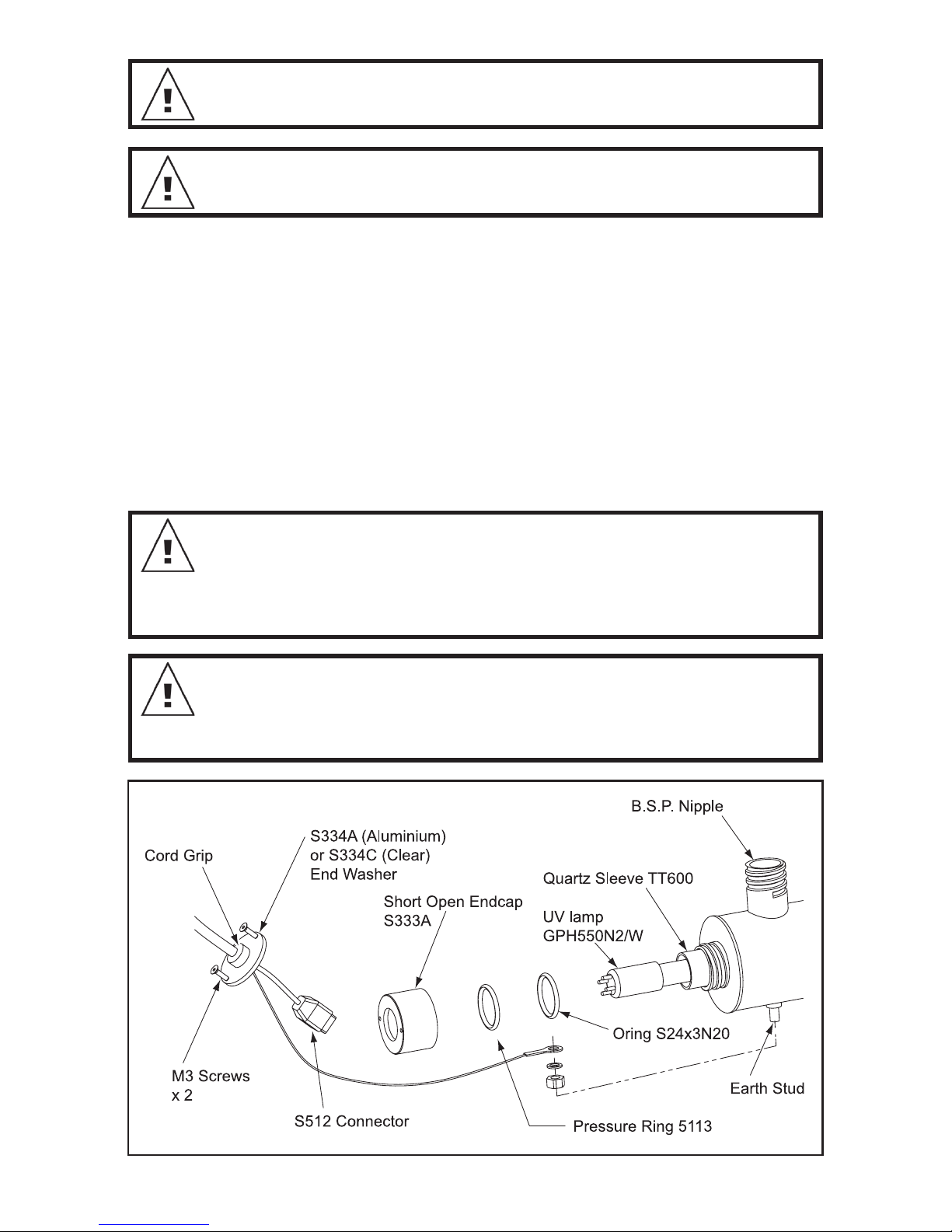

LAMP INSTALLATION

Once the Sterio®Treatment Chamber has been connected to the

pipework, the installation should be checked for water leaks.

Attach the “DO NOT LOOK AT LAMP” sticker in an obvious position on the

treatment chamber, check that the chamber is clean to ensure the sticker

will adhere correctly.

The Quartz Sleeve is pre-installed in the treatment chamber, and provided

the endcaps have not been disturbed or undone, is able to withstand well in

excess of the maximum operating pressures.

If the chamber test is successful, it is now time to insert the lamp. DO NOT

INSERT THREE PIN POWER PLUG TO POWER OUTLET YET!

Expose the connection end of the lamp from its transport tube and

protective wrapping. The lamp connection socket is “keyed” to ensure

correct alignment. Carefully remove the tube fully from its transport tube,

touching the lamp as little as possible. Handle the lamp by the ends where

possible. Wipe with clean cloth and methylated spirits if ngerprints or dirt

need removing.

Slide the lamp into the chamber, t lamp connection socket and then fasten

the end washer into the endcap, with the screws provided.

OPERATION

Once all leak testing and lamp tment has been completed, open valves

and allow water to ll the chamber. Connect three pin plug to outlet and

switch on. The “Mains On” Amber LED will be illuminated and the red alarm

light will ash slowly.

Allow two minutes for the UV lamp to reach full intensity before starting

water ow.

Full lamp performance for a new installation will be achieved in 24 hours.

On a new installation where no other form of sterilisation has been in

constant usage, we recommend ushing the pipework with a suitable

sanitiser such as Steritank HP at 100mg/L. This solution should be left in

the piping for at least an hour and preferably overnight.

The Steritank solution can be dosed to the water tank or if necessary added

as a shot dose to the bowl of any lter housing installed with the UV system

and slowly ushed into the piping.

If dosed to the water tank the Steritank HP will be left in the water as it is

tasteless and suitable for use in drinking water. If added as a shot dose it

should be rinsed out through a nearby tap.

Davey Water Products Limited can not accept responsibility for loss

or damage resulting from incorrect or unauthorised installations.

17

MAINTENANCE

Lamp changing (every year of operation) :

1. Shut valve(s) so that water cannot ow through steriliser.

2. Switch off steriliser by unplugging mains.

3. Undo end cover screws.

4. Unplug lamp connector.

5. Remove lamp.

Reverse procedure when replacing lamp, ensuring that lamp is centrally

located in the chamber. Handle only by the ends.

Quartz Sleeve Cleaning :

If dirt is allowed to build up on the quartz sleeve it will impair the UV output.

The quartz sleeve should be removed after one month and inspected for

deposits. Clean with calcium lime and rust remover (CLR). Apply some

CLR to a soft cloth and wipe the quartz sleeve. Once clean, wipe any

residual CLR off with a wet soft cloth. Handle the sleeve with tissue to keep

it clean. The sleeve should be cleaned every three months or as required.

Sleeve removal (use care-fragile) :

1. Remove lamp as described.

2. Remove drain port cap and empty water from chamber.

3. Undo nut at one end of the chamber and remove o-ring, repeat with nut

at other end and remove o-ring, withdraw sleeve carefully.

4. Inspect o-rings for damage, replace annually.

CAUTION: Handling lamp and quartz sleeve. Keep the quartz components

free of nger marks to avoid loss of output through dirt or grease shadows

- handle the lamps by their ends where possible. Wipe lamp and sleeve with

clean cloth or tissue if needed. The o-rings should be replaced annually or if

damaged – do not grease the o-rings.

NOTE: When withdrawing sleeve take care not to let the end drop into the

chamber as it could break - a clean dowel inserted right through the sleeve to

support it is useful.

18

MAINTENANCE CONTINUED...

Reverse procedure when replacing sleeve.

When replacing quartz sleeve after cleaning, the sleeve should stick out

about 1cm at each end. Place o-ring over closed nut end and t closed nut,

fastening it hand tight. Hold the other end of the sleeve in position during

the tightening with the other hand, then t open end o-ring and cap.

A tiny amount of silicon spray or CRC in the end of aluminium endcap

threads will aid easy tightening. Do not use excessive force when tightening

nuts. Do not re-use quartz sleeve or o-rings if damaged.

WATER QUALITY

Where the water being pumped contains unusually high levels of dissolved

solids (hard water), iron, manganese or biological organisms, a deposit

build up on the quartz sleeve may occur over time. This will compromise

the effectiveness of the UV system and the sleeve should be cleaned as

required to maintain it in a clean condition. Discoloured water will reduce

the effectiveness of the UV system and ltration should be installed.

LAMP ALARM SYSTEM

If the UV lamp is out due to a failure or bad connection the alarm buzzer

will sound and the red LED will light and the alarm will disconnect power

from the pump preventing untreated water from being delivered. The alarm

function can be checked by switching the unit off, disconnecting the lamp

and then switching the unit back on.

The lamp should be replaced after a year’s running time. The alarm will

beep intermittently after the internal clock has measured this time as a

reminder to change the lamp. Pressing the recessed ‘reset’ button with

a ballpoint pen will silence it for 24 hours at a time to allow time for a new

lamp to be obtained. Once a new lamp is installed press the reset button for

5 seconds to start another year’s timing. Do this whenever a new lamp is

installed. The alarm light ashes slowly during normal operation to show the

timer circuit is running.

If alarm sounds when new lamp is inserted, turn power off for ve minutes

to allow for internal reset of the power supply.

19

TROUBLESHOOTING

TORRIUM®

a) PUMP HAS STOPPED OR MOTOR RUNS FOR SHORT PERIOD

ONLY WHEN SWITCHED ON OR PRIME BUTTON PUSHED, BUT

DOES NOT PUMP - STATUS INDICATOR LIGHT ILLUMINATED RED

FLASHING ONCE PER SEQUENCE

1. Suction line and pump body not lled with water.

2. Air leaks in suction lines or suction pipe not under water.

3. Air trapped in suction lines (also possible with ooded suction due to

uneven rise in piping; eliminate humps and hollows).

4. No water at source or water level too low.

5. Valve on suction lines closed. Open valve & pump will restart

automatically or press “Prime” button.

b) PUMP SWITCHES ON AND OFF FREQUENTLY (CYCLING)

1. Cycling may occasionally be caused by oat valves lling tanks - see

“Cistern Fill Mode”.

2. Leaking taps, oat valves etc. check plumbing.

3. Leaking check valve/foot valve.

4. Discharge plumbing has been connected to the priming port.

c) MOTOR DOESN’T START WHEN SWITCHED ON - LOW PRESSURE

INDICATOR LIGHT NOT ILLUMINATED

1. Power not connected or no power available from supply outlet.

d) MOTOR STOPS - STATUS INDICATOR LIGHT IS ILLUMINATED RED,

FLASHING TWICE PER SEQUENCE

1. Motor ”over temperature” cut-out tripped. Consult Davey dealer.

2. Motor not free to turn - e.g. a jammed impeller. Consult Davey

dealer.

3. Prime button has been held in for too long. Release prime button

and switch off power for 1 minute to allow unit to reset.

e) PUMP WILL NOT STOP

1. Water leaks on discharge side of pump.

WARNING: Automatic reset thermal overloads may allow the pump to restart

without warning. Always disconnect the pump motor from the electrical supply

before maintenance or repairs.

WARNING: When servicing or attending pump and/or controllers, always

ensure power is switched off and lead unplugged. Electrical connections

should be serviced only by qualied persons.

20

f) PUMP WILL OPERATE NORMALLY INITIALLY BUT WILL NOT

RESTART ON WATER DEMAND - STATUS INDICATOR LIGHT NOT

ILLUMINATED

1. Power supply problem - see c) 1.

g) PUMP WILL OPERATE NORMALLY INITIALLY BUT WILL NOT

RESTART ON WATER DEMAND - STATUS INDICATOR LIGHT IS

ILLUMINATED RED CONSTANT

1. Suction air leak - pump has partially lost prime.

2. Blocked impellers or suction.

3. Discharge valve closed - open valve.

RAINBANK®

a) PUMP WILL NOT SWITCH OFF

1. Pump plugged directly into power outlet. Plug lead from pump into

base of RainBank®as per installation instructions.

2. Yellow ‘manual override’ button pushed in too far. Pry out the section

of the yellow button that has been pushed into the RainBank®

housing with a small at blade screwdriver.

3. Water is still being used. Check all taps, toilets and appliances

connected to RainBank®system to ensure they are turned off.

4. Water is leaking on discharge side of RainBank®system. Repair

leak.

5. Rock or debris caught inside RainBank®. Call your plumber to t a Y

strainer - RainBank®will need to be returned to Davey.

b) PUMP WILL NOT SWITCH ON

1. Pump not plugged in. Plug pump into base of RainBank®and

RainBank®into power supply.

2. No power supply to pump. Contact electrician and have power

restored.

b) PUMP WILL NOT SWITCH ON

3. Float switch not connected to RainBank®. Plug oat lead into base

of RainBank®. The connection port is located next to the power lead

coming from the RainBank®. To conrm the connection is correct,

depress yellow button, pump will start.

4. No water in tank. Check water level in tank.

5. Float switch located at water tank is installed incorrectly. Check to

see if the word “UP” is facing up on oat switch.

6. Mains water supply not connected to RainBank. RainBank®system

must have a pressurised water supply connected to inlet. Press

yellow “manual override” button to simulate mains water owing.

7. Mains supply to RainBank®turned off. Turn on mains water supply.

8. Pump is faulty. To conrm if the fault is within the pump, plug the

pump directly into power point and check to see if it starts. If the

Table of contents

Other Davey Water Products Water Filtration System manuals

Popular Water Filtration System manuals by other brands

SteriPEN

SteriPEN Adventurer user guide

amiad

amiad Filtomat MG112 Installation, operation and maintenance instructions

Lifesaver

Lifesaver bottle instruction manual

Cuckoo

Cuckoo CP-QN1401SW/WHCBMYCI user manual

Flexco

Flexco PLY 130 WB Safety and operation manual

Schaffner

Schaffner FN 3025 Installation guidelines