DAVID HI-CAP 548 User manual

548

GRAIN

CLEANER

OWNERS

MANUAL

AND

.

PARTS

LIST

DAVID

MANUFACTURING COMPANY

Ma$on

City,

Iowa

50401

\

(RIGHT

SIDE)

MODEL

"548 HI-CAP GRAIN

CLEANER

,l~./

,

C;

''':'';' (

(LEfT SIDE)

0079

INTRODUCTION

Congratulations

I

You

made

a

very

wise

decision

in

purchasing

a

Model

548

Hi-Cap

Grain

Cleaner,

and

with

the

wide

range

of

screen

sizes

which

are

available,

it

will

take

care

of

all

your

screening

needs.

With

its

dual

screening

action,

it

not

only

removes

"fines",

chaff,

etc.,

but

also

the

large

trash

such

as

cob

particles,

straw

and

stalks.

If

equipped

with

an

eight

inch

feed-in

auger,

it

will

operate

in

a

full

half-circle

for

ease

unlopding

of

grain.

With

proper

maintenance,

your

new

Model

548

Hi-Cap

Grain

Cleaner

will

give

you

years

of

reliable

service.

SERVICE

Lubricate

all

grease

fittings

every

500

bushels,

or

at

least

once

every

year.

At

the

same

time,

check

belt

tensions

and

clean

any

accumulated

trash

out

of

the

pulley

grooves.

~~~~~~~~~~~~~~~

FOR

YOUR

PROTECTION

"..~'

~

~

KEEP

ALL

SAFETY

SHIELDS

IN

PLACE!

".

~

~

.~~~~~~~~~,.,~~

.~

As

with

all

moving

machinery,

DO

NOT

stand

close

to

the

Hi-Cap

Grain

Cleaner

while

it

is

operating,

and

always

stop

it

to

make

adjustments.

OPERATION

The

cleaning

drum

should

turn

21

revolutions

per

minute,

and

rotate

clockwise

when

viewed

from

the

feed-in

end.

The

cleaner

should

be

run

until

empty

before

stopping.

It

is

not

advisable

to

leave

grain

in

the

cleaner

or

start

the

cleaner

with

a

load

of

grain

in

it.

The

ADJUSTABLE BAFFLE

in

the

internal

screen

serves

two

purposes:

first,

to

force

the

grain

through

the

coarse

screen

close

to

the

feed-in

end,

to

insure

as

much

fine

screening

as

possible,

and

secondly

to

prevent

grain

from

working

to

the

far

end

and

out

through

the

large

particle

chute.

It

will

be

found

that

the

baffle

can

be

closer

to

the

feed-in

auger

for

dry

grain

than

for

wet.

Observation

of

operation

will

reveal

the

need

for

adjustment

to

give

most

efficient

cleaning.

If

the

grain

tends

to

build

up

in

the

internal

screen,

set

the

baffle

plate

farther

toward

the

large

particle

chute

end.

Otherwise,

keep

it

as

close

to

the

feed-in

end

as

possible.

The

ADJUSTABLE JACK-STAND

provides

two

functions:

1)

it

enables

you

to

hook

the

Model

548

up

to

your

prime

mover

very

easily,

and

2)

it

also

serves

as

the

leveling

jack

when

the

Hi-Cap

is

in

working

position.

A

decal

arrow

placed

near

the

leveling

jack

permits

you

to

adjust

the

slant

of

your

Model

548

to

fit

your

cleaning

needs.

(See

Photo

12).

The

grain

will

pass

through

the

cleaner

faster

with

a

steep

slant;

the

cleaning

action

,will

be

more

thorough

with

less

slan~.

U

t\-7

1-

DROP

PIN

The

8"

feed-in

augers

are

designed

to

hold

the

auger

from

swinging

in

trans-

port

position.

aowever,

to

swing

in-

to

operation

position,

lift

the

pin

and

rotate

a

quarter

turn.

This

will

lock

pin

up

for

easy

auger

movement.

2

SCREENS

A

variety

of

screens

can

be

obtained

to fit

your

needs.

When

viewing

the

grain

cleaner

from

the

grain

discharge

end,

the

outside

screens

should

be

put

on

so

that

the

lap

is as

shown

in

the

drawing:

Lap

If

screens

are

not

properly

placed

on

the

screener,

grain

can

get

in

behind

the

lap

and

cause

problems.

The

lap

should

also

be

over

the

tumbling

bars.

Ma ke

sure

that

a

II

of

the

slack

is

taken

out

of

the

screen

before

the

bands

are

attached.

This

can

be

done

quite

easily

with

the

help

of

a

couple

common

door

springs.

Hook

the

springs

on

to

the

screen,

making

sure

the

lap

is

on

the

proper

side,

then

tap

the

screen

Ii

~

Drum

Rotation

ghtly.

This will

remove

all

the

slack. Last,

the

outside

screen

straps

are

put

over

the

screen.

To

have

the

straps

positioned

correctly,

the

bolts

that

tighten

the

straps

should

come

directly

over

the

screen

lap. Eight

straps

are

required;

four

per

screen

section.

Screen

straps

positioned

over

drum

rings

need

to

be

tightened

very

securely.

Straps

that

encompass

drum

over

tumbling

b<HS

require

care in

tightening

so

that

the

tumbling

bars

are

not

compressed.

TIRE

PRESSURE

20

PSI

will

give

your

tires

maximum

tire life

and

yet

provide

floatation

for

your

Hi-Cap

while

being

towed

at

highway

speeds.

TOWING

SPEED

Towing

~peed

should

not

exceed

50

miles

per

hour. For

highway

use,

connect

safety

chain.

OPTIONAL EQUIPMENT:

8"

x

11"

auger

with

Hopper and Slide Gate

Collector

pan

Stationary model

1

Y2

HP

Auger

Motor

Screens

to match

your

operation

ALL

HI-CAP

MODEL

548

GRAIN

CLEANER

MOTORS

ARE

WIRED

230

VOLTS

3

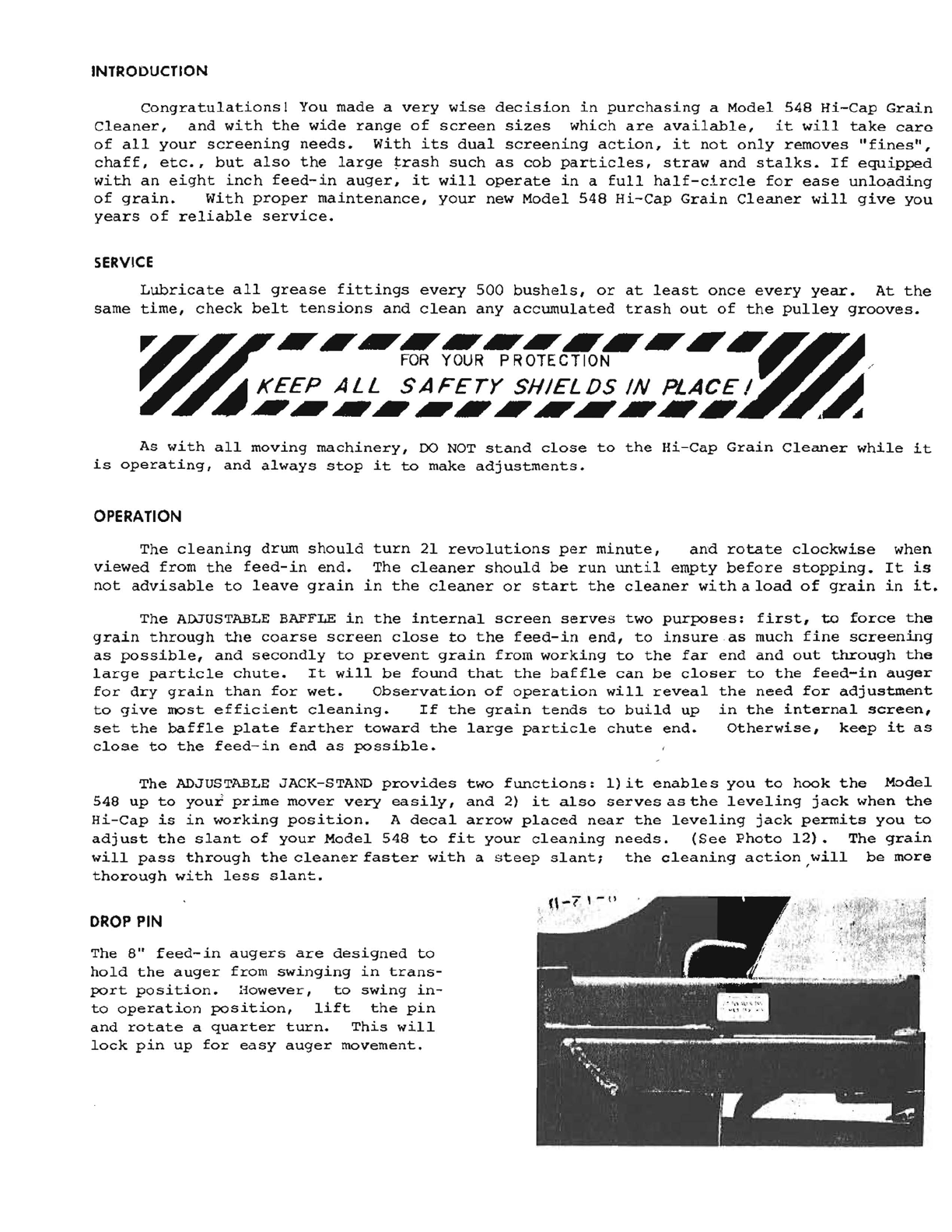

COLLEaOR

PAN

548

HI-CAP

548

HI-CAP

REF.

PART

DESCRIPTION

NO.

PART

NO.

14.

Set

Screw

-

Skt.

Hd. ,

5/16"

x

5/16"

1

2FH05l2

No.

Req.

15.

Bearing

Housing

1 PTQ413

l-

End

Panel

-

Pan

1

20400102

16.

Bearing,

7/8"

1 PT0206

2.

Side

Panel

-

Pan

(right)

1

20400103

17.

Hex

Bolt,

3/8"

x 1

1/4"

2 2FH0856

3.

Side

Panel

-

Pan

(left)

1

20400104

18.

Hex

Bolt,

3/8"

x

3/4"

4 2FH0853

4.

Auger

-

Discharge

5.

Pulley

-

Auger,

7/8"

)(

au

A

section

1

1

20400108

PT0660

19.

20•.

Machine

Screw-Pan

Hd.,

Hex

Bolt,

1/4"

x

3/4"

1/4"

x 1/2·" 23

8 2FH0747

2FH0803

6.

Bracket

-

Belt

Idler

1

20400110

21.

Flat

Washer,

1/4"

8 3FH0863

7.

Belt,

A-66

1 PTOS02

22.

Lock

Washer,

1/4"

med.

31

3FH0789

8.

Pulley

-

Bel

t

Idler,

1/2"

x 3

1/4"

1 PT0710

23.

Lock

Washer,

3/8"

med. 6 JFH0791

9.

Key -

Woodruff,

J/16"

H'

BQaring

-

Front,

7/8"

x

1"

(complete)

1

1 3FH0992

PT01l2

24.

25.

Hex

Nut,

Hex

Nut,

1/4"

3/8"

31

6 lFH0763

lFH0765

t3~

Bearing,

7/8"

Bear

ing

Housing

Bearing

-

Rear,

(complete)

7/8",

self-aligning

1

1

1

PT0207

PT0415

PT0104

26.

27.

2G.

29.

30.

Deflector

Shield

Carriage

Bolt,

1/2"

x 2

11

Flat

Washer,

5/8"

SkE

LOck

Washer,

1/2"

med.

Hex

Nut,

1/2"

1

1

I

1

1

20400109

2Ffl0676

Jf'H0952

3FH0793

IFIl0767

4

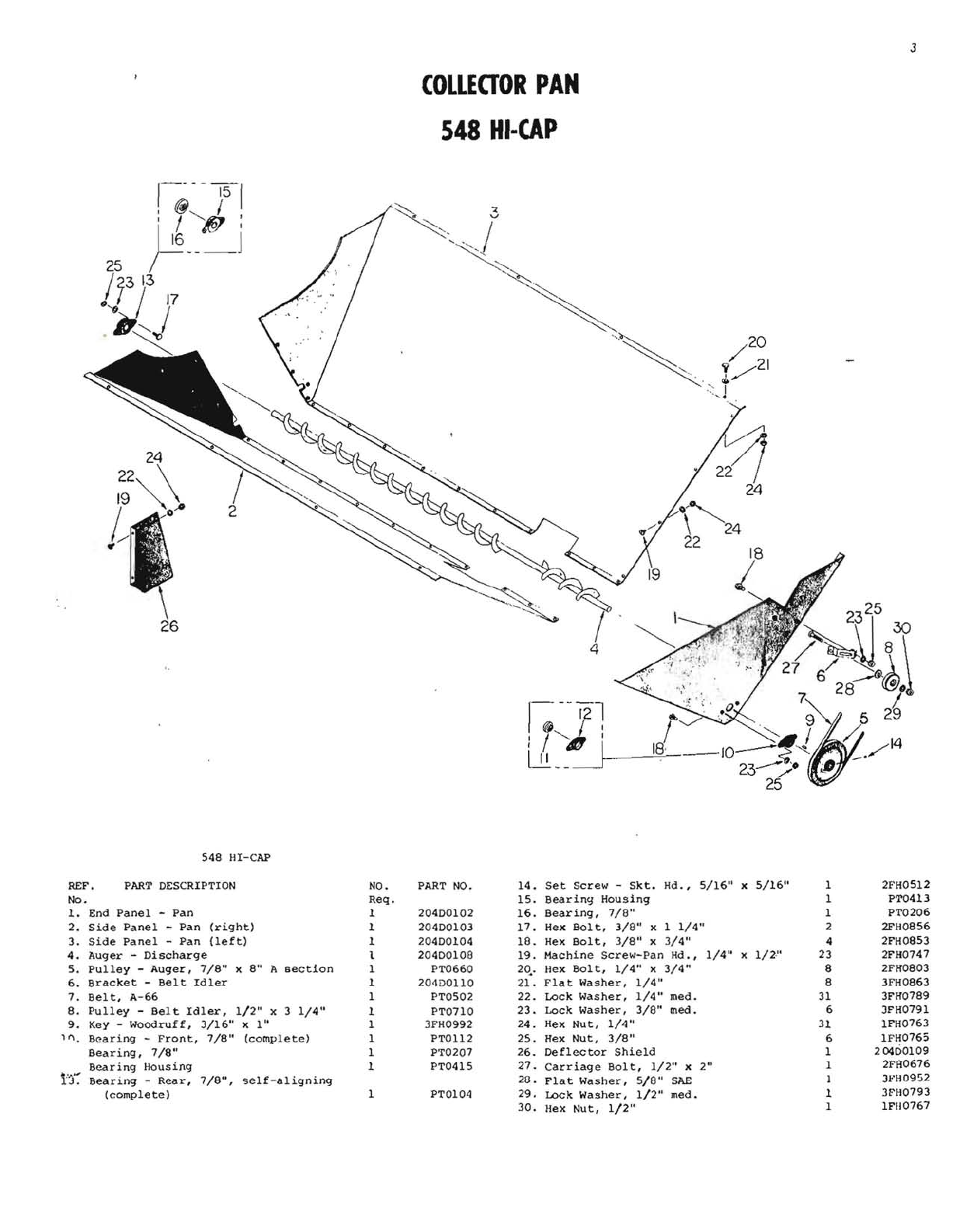

548

HI-CAP

CLEANER

TRANSPORT

MODEL

\\

17

18

548

HI-CAP

CLEANER

TRANSPORT

MODEL

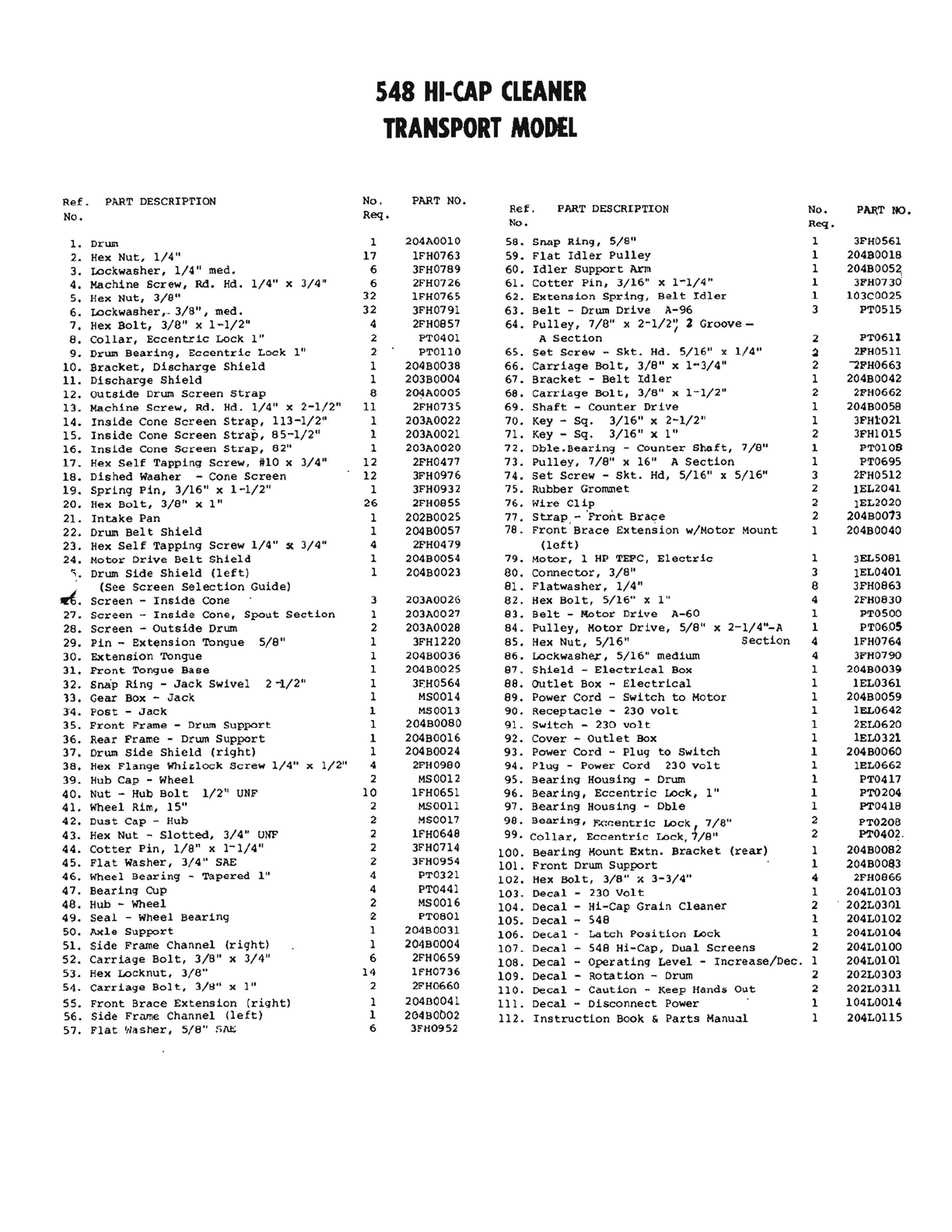

Ref.

PART

DESCRIPTION

No.

PART

NO.

Ref.

PART DESCRIPTION

No.

PAR,T

NO,

No.

Req.

No.

Req.

1.

Drum 1204AOOIO

58.

Snap

Ring,

5/8"

2.

Hex

Nut,

1/4"

17

IFH0763

59.

Flat

Idler

Pulley

3.

Lockwasher,

1/4"

med.

6

3FH0789

60.

Idler

Support

Arm

4.

Machine

Screw,

Rd.

Hd.

1/4"

x

3/4"

6

2FH0726

61.

Cotter

Pin,

3/16"

x

1-1/4"

5.

Hex

Nut,

3/8"

32

IFH0765

62.

Extension

Spring,

Belt

Idler

3FH0561

204B0018

1

1

1

1

1

204B005~

3FH0730

103C0025

6.

Lockwasher,.,

3/8",

med.

32

3FH0791

63.

Belt

-Drum

Drive

A-96

3

PTOSIS

7.

Hex

Bolt,

3/8"

x

1-1/2"

4

2FH0857

64.

Pulley,

7/8"

x

2-1/2';

2

Groove-

PT0401

A

Section

2

PT0611

PTOllO

65.

Set

Screw

-

Skt.

Hd.

5/16"

x

1/4"

~

21'H0511

8.

Collar,

Eccentric

Lock

1"

9.

Drum

Bearing,

Eccentric

Lock

1"

10.

Bracket,

Discharge

Shield

11.

Discharge

Shield

2

2

1

1

"""2FH0663

204B0042

2FH0662

204B0058

3FH3:021

3FHI015

2

1

2

1

1

2

204B0038

66.

Carriage

Bolt,

3/8"

x

1-3/4"

203B0004

67.

Bracket

-

Belt

Idler

Carriage

Bolt,

3/8"

x

1-1/2"

12.

Outside

Drum

Screen

Strap

8

204A0005

68.

13.

Machine

Screw,

Rd.

Hd.

1/4"

x

2-1/2"

11

2FH0735

69.

Shaft

-

Counter

Drive

203A0022

70.

Key

-

Sq.

3/16"

x

2-1/2"

203A0021

71.

Key

-

Sq.

3/16"

xl"

14.

Inside

Cone

Screen

Strap,

113-1/2"

15.

Inside

Cone

Screen

Strap,

85-1/2"

16.

Inside

Cone

Screen

Strap,

82"

1

1

1

203A0020

72.

Dble,Bearing

-

Counter

Shaft,

7/8"

PTOI08

PT0695

1

1

2FH0477

73.

Pulley,

7/8"

x

16"

A

Section

17.

Hex

Self

Tapping

Screw,

1110

x

3/4"

12

18.

Dished

Washer

-

Cone

Screen

12

3FH0976

74.

Set

Screw

-

Skt.

Hd,

5/16"

x

5/16"

3

2FH0512

2

lEL2041

3FH0932

75.

Rubber

Grommet

1

19.

Spring

Pin,

3/16"

x

1-1/2"

2FH0855

76.

Wire

Clip

lEL2020

204B0013

26

2

2

20.

Hex

Bolt,

3/8"

x

1"

202B0025

77.

Strap.

-

'Front

Brace

1

1

21.

Intake

Pan

22.

Drum

Belt

Shield

204B0057

78.

Front

Brace

Extension

w/Motor

Mount

204B0040

1

23.

Hex

Self

Tapping

Screw

1/4"

'C

3/4"

4

2FH0479

(left)

24.

Motor

Drive

Belt

Shield

'.

Drum

Side

Shield

(left)

1

1

204B0054

79.

Motor,

1

HP

TEFC,

Electric

1

3EL5081

204B0023

80.

Connector,

3/8"

3

lEL040l

(See

Screen

Selection

Guide)

8l.

Flatwasher,

1/4"

8

3FH0863

~.

Screen

Inside

Cone

3

203A0026

82.

Hex

Bolt,

5/16"

xl"

4

2FH0830

27.

Screen

-

Inside

Cone,

Spout

Section

1

203A0027

83.

Bel

t -

Rotor

Drive

A-60

1

PT0500

28.

Screen

-

Outside

Drum

29.

Pin

-

Extension

Tongue

5/8"

30.

Extension

Tongue

31.

Front

Tongue

Base

32.

Snap

Ring

-

Jack

Swivel

2

-1/2"

13.

Gear

Box

-

Jack

34.

Post

-

Jack

35.

Front

Frame

-

Drum

Support

36.

Rear

Frame

-Drum

Support

37.

Drum

Side

Shield

(right)

2

1

1

1

1

1

1

1

1

1

203A0028

84.

pulley,

Motor

Drive,

5/8"

x

2-1/4"-A

1 PT06.0S

3FHl220

85.

Hex

Nut,

5/16"

Section

4

lFH0764

204B0036

86.

Lockwasher,

5/16"

medium

4

3FH0790

204B0025

87.

Shield

-

Electrical

Box

1

204B0039

3FH0564

88.

OUtlet

Box -

Electrical

1

lEL0361

MS0014

89.

Power

Cord

-

Switch

to

Motor

1

204B0059

MS0013

90.

Receptacle

-

230

volt

1

lEL0642

204B0080

91.

Switch

-

230

volt

1

2EL0620

204B0016

92.

Cover

-

Outlet

Box

1

lEL0321

204B0024

93.

Power

Cord

-

Plug

to

Switch

1

204B0060

38.

Hex

Flange

Whizlock

Screw

1/4"

x

1/2"

4

2FH0980

94.

Plug

-

Power

Cord

230

volt

1

lEL0662

39.

Hub

Cap

-

Wheel

2 MS0012

95.

Bearing

Housing

-Drum 1

PT04l7

40.

Nut

-

Hub

Bolt

1/2"

UNF

10

IFH0651

96.

Bearing,

Eccentric

Lock,

1"

1

PT0204

41.

Wheel

Rim,

15"

2 MSOOll

97.

Bearing

Housing

-

Dble

1

PT0418

42.

Dust

Cap

-

Hub

2MS0017

98.

Bearing,

F.Gl":entric

Lock

7/8"

2

PT0208

43.

Hex

Nut

-

Slotted,

3/4"

UNF 2

IFH0648

99.

Collar,

Eccentric

Lock,1/8"

2

PT0402.

44.

Cotter

Pin,

1/8"

x

1-1/4"

2

3FH0714

100.

Bearing

Mount

Extn.

Bracket

(rear)

1

204B0082

45.

Flat

Washer,

3/4"

S1\E

2

3FH0954

101.

Front

Drum

Support

1 204BOO&3

46.

Wheel

Bearing

-

Tapered

1"

4

PT0321

102.

Hex

Bolt,

3/8"

J(

3-3/4"

4

2FH0866

PT0441

47.

Bearing

Cup

48.

Hub -

Wheel

49.

Seal

-

Wheel

Bearing

50.

Axle

Support

51.

Side

Frame

Channel

(right)

4

2

2

1

1

103.

Decal

-

230

Volt

1

204LOl03

MS0016

104.

Decal

-

Hi-Cap

Grain

Cleaner

2

202L03r:ll

PT0801

105.

Decal

-

548

1

204LOl02

204B0031

106.

Dec.a1 -

La

tch

Position

Lock

1

204LOl04

204B0004

107.

Decal

-

548

Hi-Cap,

Dual

Screens

2 204LOlOO

52.

Carriage

Bolt,

3/8"

x

3/4"

6

2FH0659

108.

Decal

-

Operating

Level

-

Increase/Dec.

1

204LOlOl

53.

Hex

Locknut,

3/8"

14

lFH0736

109.

Decal

-

Rotation

-Drum 2

202L0303

54.

Carriage

Bolt,

3/11" x

1"

2

2FH0660

110.

Decal

-

Caution

-

Keep

Hands

Out

2

202L0311

20400041

111.

Decal

-

Disconnect

Power

1

104L0014

55.

Front

Brace

Extension

(right)

56.

Side

Frame

Channel

(left)

1

1

204BOb02

112.

Instruction

Book

&

Parts

Manual

1

204L01l5

57.

Flat

'tla

sher,

5/8"

f,1\.E

6

3FH0952

6

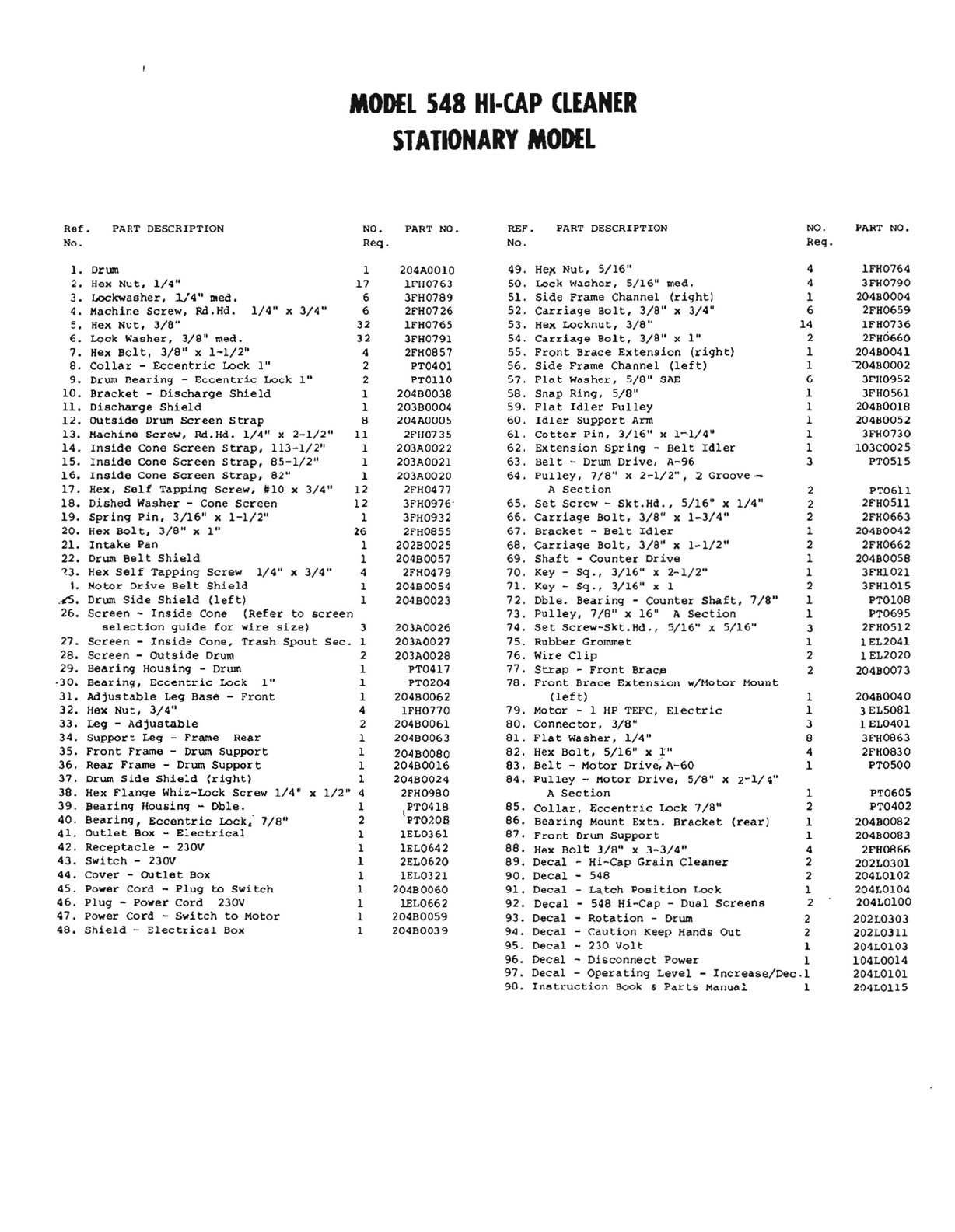

MODEL

548

HI-CAP

CLEANER

STATIONARY

MODEL

\

\ \

16

17

18

~

-

27-.

]I

26

2 .-."'-.

_-00

• - \

_0-

-

~

____

.,'='.-1_

0

,.

--"r-

I

,----->

/3

14

--'-i-,------'

15

88

MODEL

548

HI-CAP

CLEANER

STATIONARY

MODEL

Ref.

PART

DESCRIPTION

NO.

No.

Req.

1.

Drum 1

2.

Hex

Nut,

1/4"

17

3.

Lockwasher,

J.!4" DIed. 6

4.

Machine

Screw,

M.Hd.

1/4"

x

3/4"

6

5.

Hex

Nut,

3/8"

32

6.

Lock

Washer,

3/8"

med.

32

7.

Hex

Bolt,

3/8"

x

1-1/2"

4

8.

Collar

-

Eccentric

Lock

1"

2

9.

Drum

nearing

-

Eccentric

Lock

1"

2

10.

Bracket

-

Discharge

Shield

1

11.

Discharge

Shield

1

12.

OUtside

Drum

Screen

Strap

8

13.

Machine

Screw,

Rd.Hd.

1/4"

x

2-1/2"

11

14.

Inside

Cone

Screen

Strap,

113-1/2"

1

15.

Inside

Cone

Screen

Strap,

85-1/2"

1

16.

Inside

Cone

Screen

Strap,

82"

1

17.

Hex,

Self

Tapping

Screw,

1110

x

3/4"

12

18.

Dished

Washer

-Cone

Screen

12

19.

Spring

Pin,

3/16"

x

1-1/2"

1

20.

Hex

Bolt,

3/8"

x

1"

26

21.

Intake

Pan

1

22.

Drum

Belt

Shield

1

~3.

Hex

Self

Tapping

Screw

1/4"

x

3/4"

4

I.

Motor

Drive

Belt

Shield

1

.-6.

Drum

Side

Shield

(left)

1

26.

Screen

-

Inside

Cone

(Refer

to

screen

selection

guide

for

wire

si~e)

3

27.

Screen

-

Inside

Cone,

Trash

Spout

Sec.

1

28.

Screen

-

OUtside

Drum 2

29.

Bearing

Housing

-Drum 1

·30.

Bearing,

Eccentric

Lock

1"

1

31.

Adjustable

Leg

Base

-

Front

1

32.

Hex

Nut,

3/4"

4

33.

Leg -

Adjustable

2

34.

Support

Leg -

Frame

Rear

1

35.

Front

Frame

-Drwn

Support

1

36.

Rear

Frame

-Drum

Support

1

37.

Drum

Side

Shield

(right)

1

38.

Hex

Flange

Whi~-Lock

Screw

1/4"

x

1/2"

4

39.

Bearing

lIousing

-

Db1e.

1

40.

Bearing,

Eccentric

Lock,

7/8"

2

41.

Outlet

Box -

Elec

trical

1

42.

Receptacle

-230V 1

43.

Switch

-230V 1

44.

Cover

-

OUtlet

Box 1

45.

Power

Cord

-

Plug

to

Swi

tch

1

46.

Plug

-

Power

Cord

230V 1

47.

Power

Cord

-

Switch

to

Motor

1

48.

Shield

-

Electrical

Box 1

PART

NO.

2Q4A0010

1FH0763

3FH0789

2FH0726

1FH0765

3FH0791

2FH0857

PT0401

PTOllO

20480038

203B0004

204AO005

2Ffl0735

203A0022

203A0021

203A0020

2FH0477

3FH0976'

3FH0932

2FH0855

202B0025

204B0057

2FH0479

204B0054

204B0023

203A0026

203A0027

203A0028

PT0417

PT0204

204B0062

IFH0770

204B0061

204B0063

204B0080

204B0016

204B0024

2FH0980

PT0418

IpTO?oa

lEL0361

lEL0642

2EL0620

lEL0321

204B0060

lEL0662

204B0059

204B0039

REF'.

PART

DESCRIPTION

NO.

No.

Req.

49.

Heit

Nut,

5/16"

4

50.

Lock

Washer,

5/16"

med.

4

51.

Side

Frame

Channel

(right)

1

52.

Carriage

Bolt,

3/8"

x

3/4"

6

53.

Hex

Locknut,

3/8"

14

54.

Carriage

Bolt,

3/8"

x

1"

2

55.

Front

Brace

Extension

(right)

1

56.

Side

Frame

Channel

(left)

1

57.

Flat

Washer,

5/8"

SAE

6

58.

Snap

Ring,

5/8"

1

59.

Flat

Idler

Pulley

1

60.

Idler

Support

Arm

1

61.

Cotter

Pin,

3/16"

x

1~1/4"

1

62.

Extension

Spring

-

Belt

Idler

1

63.

Belt

-Drum

Drive,

A-96

3

64.

Pulley,

7/8"

x

2~1/2",

2

Groove-

A

Section

2

65.

Set

Screw

-

Skt.Hd.,

5/16"

x

1/4"

2

66.

Carriage

Bolt,

3/8"

x

1-3/4"

2

67.

Bracket

-

Belt

Idler

1

68.

Carriage

Bolt,

3/8"

x

1-1/2"

2

69.

Shaft

-

Counter

Drive

1

70.

Key -

sq.,

3/16"

x

2-1/2"

1

71.

Key -

sq.,

3/16"

x 1 2

72.

Dble.

Bearing

-

Counter

Shaft,

7/8"

1

73.

PUlley,

7/B"

x

16"

A

Section

1

74.

Set

screw-Skt.Hd.,

5/16"

x

5/16"

3

75.

Rubber

Grommet 1

76.

Wire

Clip

2

77.

Strap

-

Front

Brac~

2

78.

Front

Brace

Extension

w/Motor

Mount

(left)

1

79.

Motor

- 1

HP

TEFC,

Electric

1

80.

Connector,

3/8"

3

81.

Flat

washer,

1/4"

8

82.

Hex

Bolt,

5/16"

x

I"

4

83.

Belt

-

Motor

Drive;

A-60

1

84.

Pulley

-.

Motor

Drive,

5/8"

x

2-1/4"

A

Section

1

85.

Collar.

Eccentric

Lock

7/8"

2

86.

Bearing

Mo~nt

Ext~.

Bracket

(rear)

1

87.

Front

Drum

Support

1

88.

Hex

Bolt

3/8"

x

3-3/4"

4

89.

Decal

-

Hi-Cap

Grain

Cleaner

2

90.

Decal

-

548

2

91.

Decal

-

Latch

position

Lock

1

92.

Decal

-

548

Hi-Cap

-

Dual

Screens

2

93.

Deca

1 -

Rota

tion

-Drum 2

94.

Decal

-

Caution

Keep

Hands

Out

2

95.

Decal

-

230

Volt

1

96.

Decal

-

Disconnect

Power

1

97.

Decal

-

Operating

Level

-

Increase/Dec.1

98.

Instruction

Book "

Parts

Manua::' 1

PART

NO.

1FH0764

3FH0790

204B0004

2FH0659

IFH0736

2FH0660

204B0041

"'204B0002

3FH0952

3FH0561

204B0018

204B0052

3FH0730

103C0025

PTOSIS

PT06),1

2FH05ll

2FH0663

204B0042

2FH0662

204B0058

3FHl021

3FHI015

PTOI08

PT0695

2FH0512

1EL2041

1 EL2020

204B0073

20480040

3 EL5081

1 EL0401

3FH0863

2FIl0830

PT0500

PT0605

PT0402

20480082

204B0083

2FHMfifi

202L0301

204L0102

204LOI04

204L0100

202L0303

202L0311

204LOI03

104L0014

204LOIOl

204L01l5

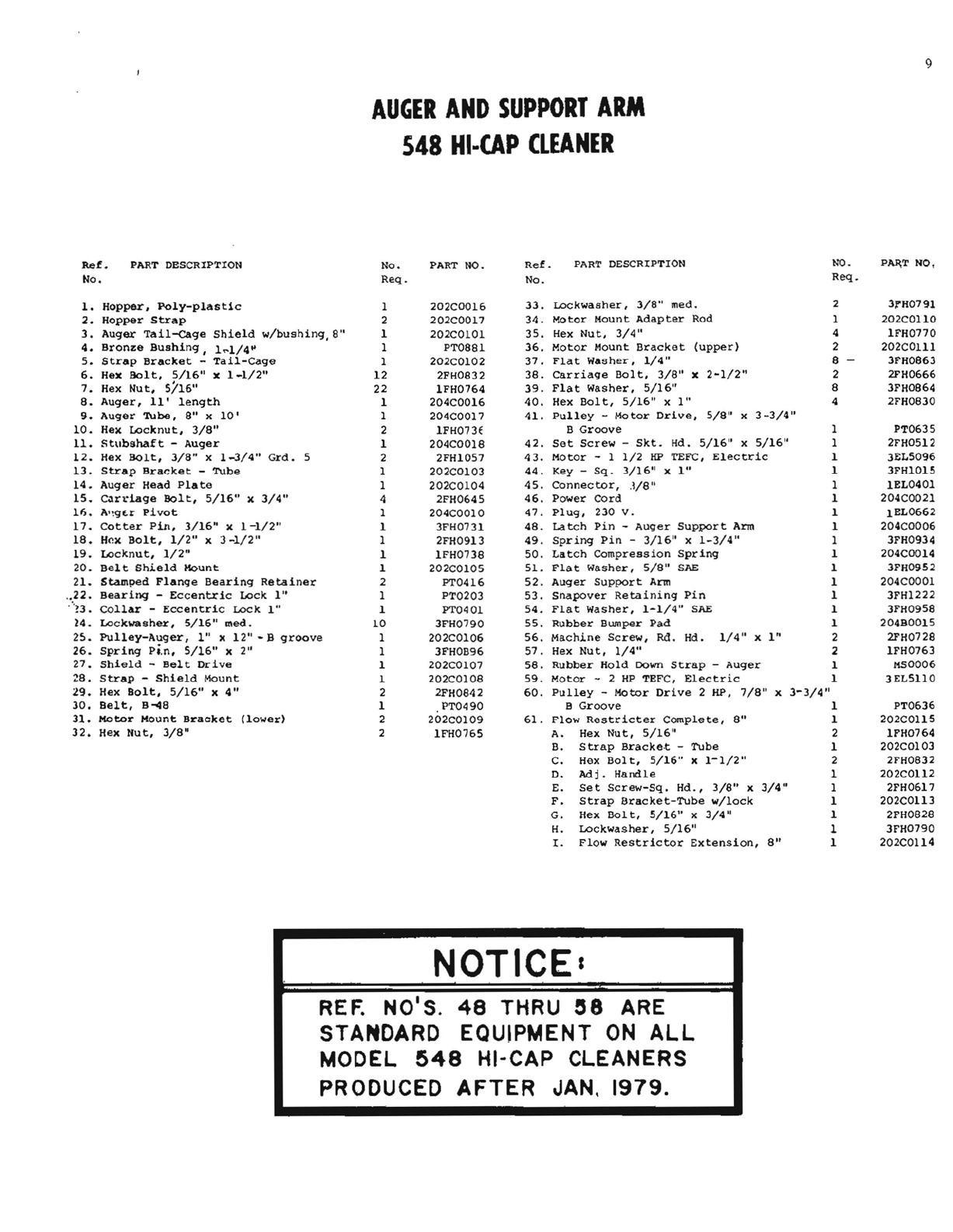

AUGER

AND

SUPPORT

ARM

548

HI

..

CAP

CLEANER

27--~

__

i

I

I

[§iJ

9

AUGER

AND

SUPPORT

ARM

548

HI-CAP

CLEANER

Ref.

PART DESCRIPTION

No.

PART NO.

Ref.

PART

DESCRIPTION

NO.

P~T

NO.

No.

Req.

No.

Req.

33.

Lockwasher,

3/8"

med.

2 3""H0791

1.

Hopper,

Poly-plastic

2.

Hopper

Strap

3.

Auger

Tail-<:age

Shield

w/bushing,8"

4.

Bronze

Bushing,

1~1/4~

5.

Strap

Bracket

-

Tail-Cage

1

2

1

1

1

202C0016

34.

Motor

Mount

Adapter

Rod 1

202COI10

202C0017

35.

Hex

Nut,

3/4"

4

1FH0770

202COIOl

PT0881

36.

Motor

Mount

Bracket

(upper)

2

202COll1

202C0102

37.

Flat

Washer,

1/4"

8

3FH0863

6.

Hex

Bolt,

5/16"

x

1-1/2"

12

2FH0832

38.

Carriage

Bol

t,

3/8"

x

2-1/2"

2

2FH0666

7.

Hex

Nut,

5/16"

22

1FH0764

39.

Flat

Washer,

5/16"

8

3FH0864

8.

Auger,

11'

length

9.

Auger

Tube,

8"

x

10'

10.

Hex

Locknut,

3/8"

11.

Stuhshaft

-

Auger

12.

Hex

Bolt,

3/8"

x

1-3/4"

Grd.

5

13.

Strap

Bracket

-

Tube

14.

Auger

Head

Plate

1

1

2

1

2

1

1

204C0016

40.

Hex

Bolt,

5/16"

xl"

4

2FH0830

204C0017

41.

pulley

-

Motor

Drive,

5/8"

x

3-3/4"

B

Groove

1

PT0635

42.

Set

Screw

-

Skt.

Hd.

5/16"

x

5/16"

1

2FH0512

43.

Motor

- 1

1/2

HP

TEFC,

Electric

1

3EL5096

1FH073E

204C0018

2FHI057

202C0103

44.

Key

-

Sq.

3/16"

x

1"

1

3FHI015

202COI04

45.

Connector,

.lI8"

1

1EL0401

15.

C.1n·iage

Bolt,

5/16"

x

3/4"

4

2FH0645

46.

Power

Cord

1

204C0021

11;.

A'~gE.r

pivot

17.

Cotter

Pin,

3/16"

x

1-1/2"

18.

Hl'lx

Bolt,

1/2"

x

3-1/2"

19.

Locknut,

1/2"

20.

Belt

Shield

Mount

21.

Stamped

Flange

Bearing

Retainer

..

22.

Bearing

-

Eccentric

Lock

1"

···?3.

Collar

-

Eccentric

Lock

1"

1

1

1

1

1

2

1

1

204COOI0

47.

Plug,

230

V.

1

lEL0662

3FH0731

48.

Latch

Pin

-

Auger

Support

Arm 1

204C0006

2FH0913

49.

Spring

Pin

-

3/16"

x

1-3/4"

1

3FH0934

1FH0738

50.

Latch

Compression

Spring

1 204COO14

202C0105

51.

Flat

washer,

5/8"

SAE 1

3FH0952

PT0416

52.

Auger

Support

Arm 1 204COOOl

PT0203

53.

snapover

Retaining

Pin

1

3FH1222

PT0401

54.

Flat

Washer,

1-1/4"

SAE 1

3FH0958

24.

Lockwasher,

5/16"

med.

10

3FH0790

55.

Rubber

Bumper

Pad

1

204B0015

25.

Pulley-Auger,

I"

x

12"-S

groove

26.

Spring

pi.n,

5/16"

x

2"

27.

Shield

-

Belt

Drive

Z8.

Strap

-

Shield

Mount

:l9.

Hex

Bolt,

5/16"

x

4"

30.

Belt,

B-.48

31.

!'IOtor

Mount

Bracket

(lower)

1

1

1

1

2

1

2

202COI06

56.

Machine

Screw,

Rd.

Hd.

1/4"

x

1"

2

2FH0728

3FHOB96

57.

Hex

Nut,

1/4"

2

1FH0763

202COI07

58.

Rubber

Hold

DOwn

Strap

-

Auger

1

MS0006

202COI08

59.

Motor

- 2

HP

TEFC,

Electric

1

3EL5110

2FH0842

60.

Pulley

-

Motor

Drive

2 HP,

7/8"

x

3-3/4"

PT0490

B

Groove

1

PT0636

202COI09

61.

Flow

Restricter

Complete,

8"

1

202C01l5

32.

Hex

Nut,

3/8"

2

IFH0765

A.

Hex

Nut,

5/16"

2

1FH0764

B.

Strap

Bracke·t

-

Tube

1

202COI03

C.

Hex

Bolt,

5/16"

x

1-1/2"

2

2FH0832

D.

Adj.

Handle

1

202C01l2

E.

Set

Screw-sq.

Hd.,

3/8"

x

3/4"

1

2FH0617

F.

Strap

Bracket-Tube

w/10ck

1

202C01l3

G.

Hex

Bolt,

5/16"

x

3/4"

1

2FH0828

H.

Lockwasher,

5/16"

1

3FH0790

1.

Flow

Restrictor

Extension,

8"

1

202C01l4

NOTICEs

REF:

NO'S.

48

THRU ee

ARE

STANDARD EQUIPMENT

ON

ALL

MODEL

548

HI-CAP CLEANERS

PRODUCED

AFTER

JAN,

1979.

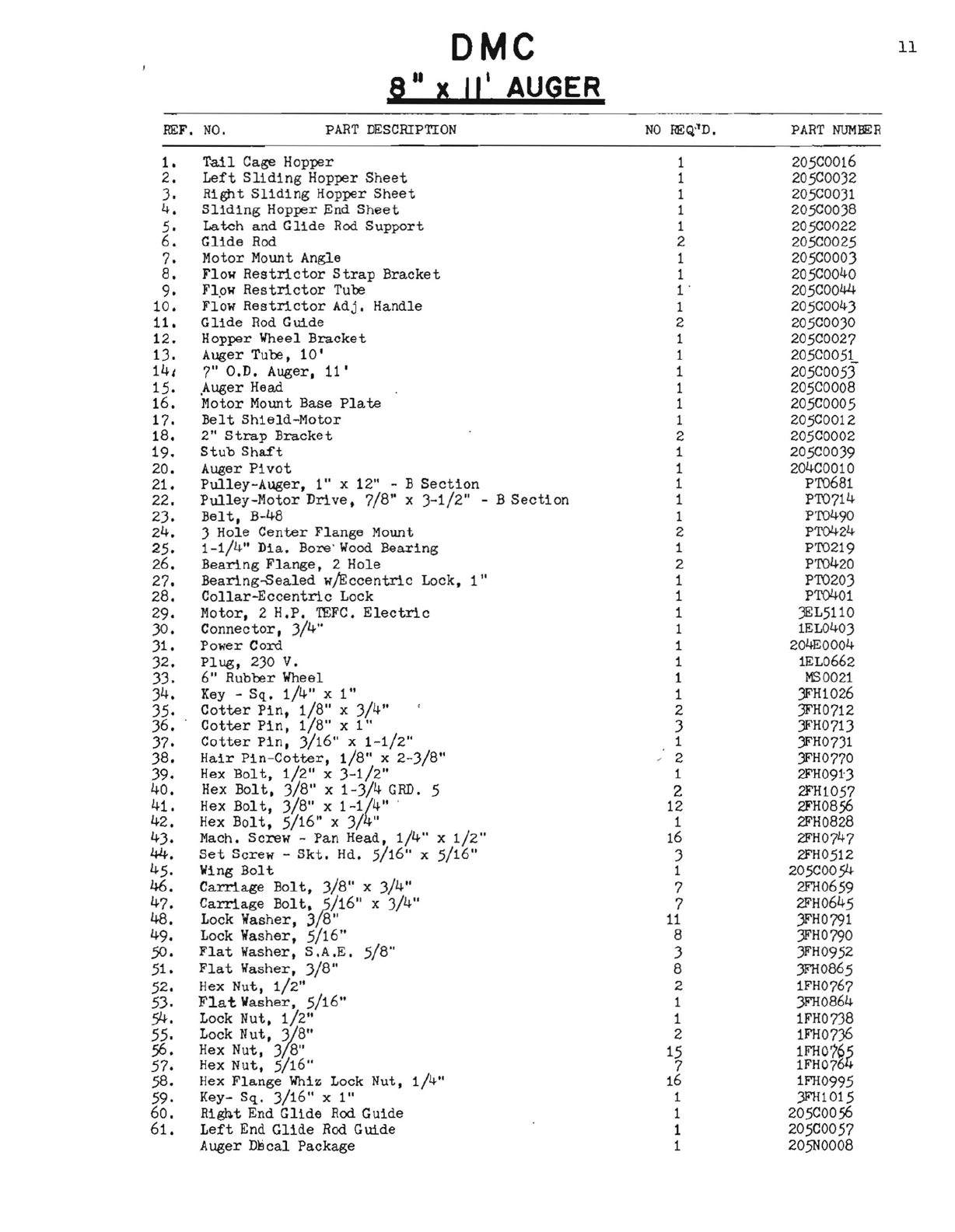

10

DMC

8

II

X

II'

AUGER

:0.

37

9

~

11

ER

REF.

NO.

PART

DESCRIPTION

NO

REQ"D.

PART

NUMIER

1.

Tail

Cage

Hopper

1

205COO16

2.

Left

Sliding

Hopper

Sheet

1 205COO)2

3.

Right

Sliding

Hopper

Sheet

1 205C00)1

4.

Sliding

Hopper

End

Sheet

1 205C0038

5.

Latch

and

Glide

Rod

Support

1

205COO22

6.

Glide

Rod 2 205C0025

7.

Motor

Mount

Angle

1

205COO03

8.

Flow

Restrictor

Strap

Bracket

1 205C0040

9.

Flpw

Restrictor

Tube

l'

205COO44

10.

Flow

Restrictor

Adj.

Handle

1 205C0043

11.

Glide

Rod

Guide

2 205C0030

12.

Hopper

Wheel

Bracket

1 205C0027

1).

Auger

Tube,

10'

1 205C0051

14,

7"

a.D.

Auger.

11'

1 205C0053

15.

,Auger Head 1

205COOOS

16.

Motor

Mount

Base

Plate

1

205COO05

17.

Belt

Shield-Motor

1

205COO12

18.

2"

Strap

Bracket

2

205COO02

19.

Stub

Shaft

1 205C0039

20.

Auger

Pivot

1 204C0010

21.

Pulley-Auger,

1"

x

12"

- B

Section

1 PT06S1

22.

Pulley-Motor

Drive,

7/S"

x

)-1/2"

- B

Section

1 PT0714

23.

Belt,

B-48

1 PT0490

24.

3

Hole

Center

Flange

Mount 2 PTQ424

25.

1-1/4"

Dia.

Bore'

Wood

Bearing

1 PT0219

26.

Bearing

Flange,

2

Hole

2 PT0420

27.

Bearing-Sealed

w/Eccentric

Lock,

1"

1 PT0203

28.

Collar-Eccentric

Lock

1 PTQ401

29.

Motor,

2

H.P.

!EFC.

Electric

1 JEL5110

30.

Connector,

3/4"

1 1EL0403

31.

Power

Cord

1 204EOO04

32.

Plug,

230

V.

1 lEL0662

33.

6"

Rubber

Wheel 1

MS0021

34.

Key -

Sq.

1/4"

x

1"

1 )FH1026

35.

Cotter

Pin,

1/8"

x

3/4"

2 3FH0712

36.

Cotter

Pin,

1/8"

xl"

3 )FH0713

37.

Cotter

Pin,

3/16"

x

1-1/2"

1 )FH0731

38.

Hair

Pin-Cotter,

1/8"

x

2-3/S"

, 2 )FH0770

39.

Hex

Bolt.

1/2"

x

3-1/2"

1 2FH091J

40.

Hex

Bolt.

3/8"

x

1-3/4

GRD.

5 2 2FH1057

41.

Hex

Bolt,

3/8"

x

1-1{4"

'

12

2FH0856

42.

Hex

Bolt,

5/16"

x

3/

" 1

2FHOS28

43.

Mach.

Screw

-

Pan

Head.

1/4"

x

1/2"

16 2FH0747

44.

Set

Screw

-

Skt.

Hd.

5/16"

x

5/16"

3 2FH0512

45.

Wing

Bolt

1 205COO54

46.

Carriage

Bolt,

3/S" x

3/4"

7 2FH0659

47.

48.

Carriage

BOlt,/s/16"

x

3/

4"

Lock

Washer,

3

8"

7

11

2FH0645

)FH0791

49.

Lock

Washer.

5/16"

S 3FH0790

50.

Flat

Washer,

S.A.E.

5/8"

3 3FH0952

51.

Flat

Washer,

3/S"

S )FH0865

52.

Hex

Nut.

1/2"

2 lFH0767

53.

Flat

Washer.

5/16"

1

3FHOS64

54.

Lock

Nut.

1/2"

1 lFH073S

55.

Lock

Nut.

%8"

2 lFH0736

56.

57.

Hex

Nut,

3

8"

Hex

Nut,

5/16"

15

7

lFH076,

lFH076

58.

Hex

Flange

Whiz

Lock

Nut.

1/4"

16 lFH0995

59.

Key-

Sq.

3/16"

xl"

1 JFH1015

60.

Righ.t End

Glide

Rod

Guide

1

205COO56

61.

Left

End

Glide

Rod

Guide

1 205C0057

Auger

DBcal

Package

1 205N000S

12

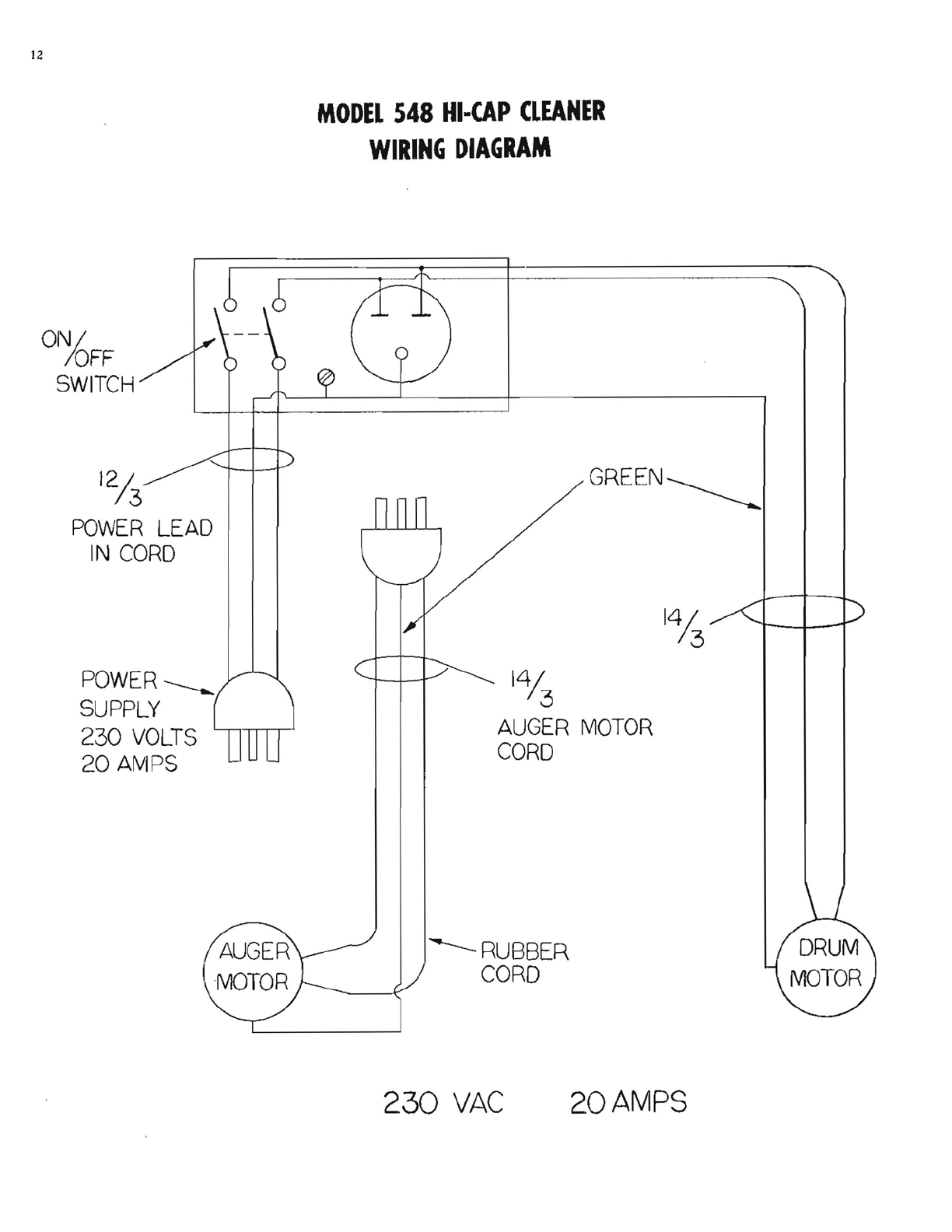

MODEL

548

HI-CAP

CLEANER

WIRING

DIAGRAM

GR.EEN~

ONI

IOFF

SWITCH

12/

3

POWER

LEAD

IN

CORD

POWER

----...

SUPPLY

230

VOLTS

20

AMPS

141

3

AUGER

MOTOR

CORD

---RUBBER

CORD

230

VAC

20

AMPS

19

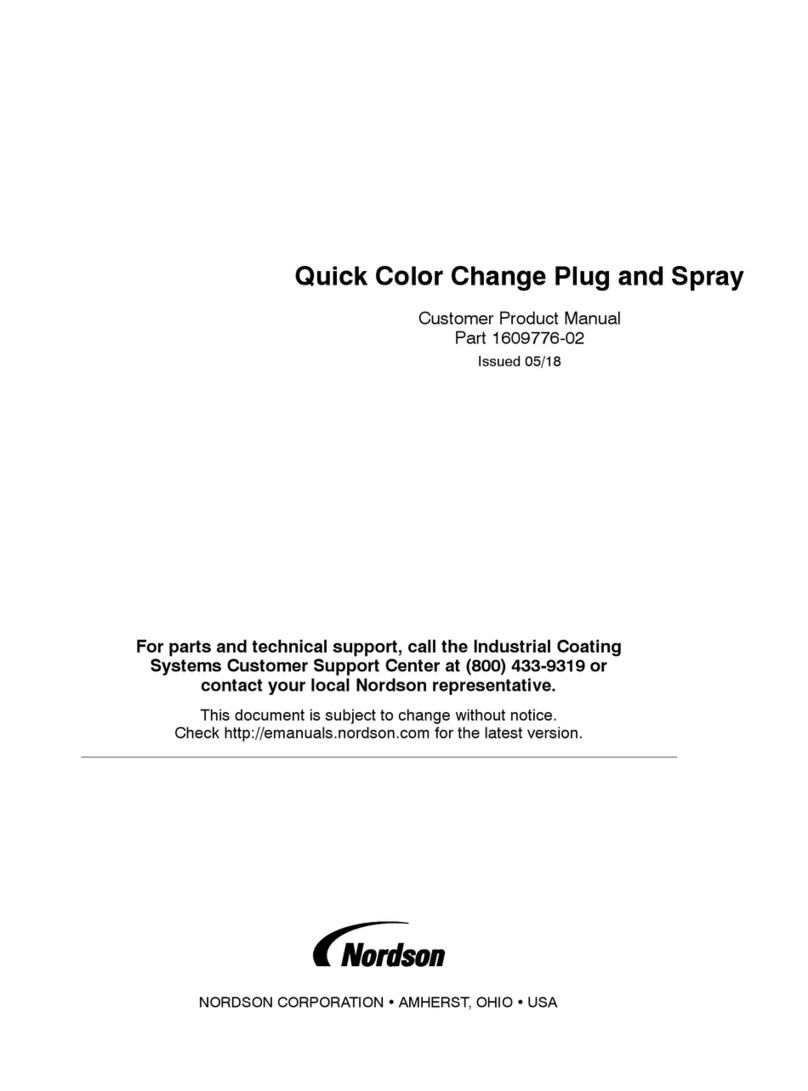

MODEL

548

CLEANER

OVERALL

DIMENSIONS

62/

1

/I

82

1/

"

72

104

RETRACTED

HOPPER

.....---:-;-;;:~~~~==---=~=-=-=----r.-----

'10

II

---~

112

1/2"

EXTENDED

HOPPER

20

WARRANTY

The Hi-Cap

Grain

Cleaner

is

guaranteed

for. a

period

of

one

year,

to

be

free

of

defects

in

material

or

workmanship,

when

properly

installed

and

operated

i"n

accordance

':"'ith

the

instructions.

Warranted

parts

will

be

exchanged

FOB,

Mason

City,

Iowa

without

charge

to

the

user.

Damage

resulting

from

n€.gligence

voids

the

warranty.

Warranty

DOES NOT

INCLUDE

LABOR, INSTALLATION OR

DELIVERY

OF REPLACEMENT PARTS.

Electric

motors

are

covered

by

the

warranties

of

the

respective

manufacturers.

Electric

service

centers

are

located

in all

regions.

Consult

your

dealer.

The Hi-Cap

Warranty,

and

the

liability

of

David

Manufacturing

Company,

its

distributors,

dealers,

and

agents

is

limited

to

replacement,

without

charge

of

defective

parts,

as

outlined

above.

No

other

warranties,

express

or

implied,

shall

apply,

in

any

circumstances.

The

manufacturer

reserves

the

right

to

make

changes

in

specifications

or

prices

without

incurring

obligation

on

previously-produced

merchandise.

Important

Data!

SERIAL

NUMBER

YEAR

PURCHASED---------

_

DEALER--------

Addressli-- _

Phone

#----------------

DMOl3

CroProcessing

Equipment

Table of contents

Popular Industrial Equipment manuals by other brands

Daktronics

Daktronics M Series Operation manual

Siemens

Siemens RM400 C Series operating manual

Tronair

Tronair 06-4035-3600 Operation & service manual

schmersal

schmersal PSC1 Series installation manual

Rapid Packaging

Rapid Packaging Eastey Value Series user guide

Cargo Floor

Cargo Floor CF500 SL-2 Replacement instructions