Gary Machinery 3354 User manual

SINGLE WHEEL

SLITTER

METAL PROCESSING EQUIPMENT

www.GaryMachinery.net

MODEL 3354

INSTRUCTION MANUAL

G

A

R

Y

M

A

C

H

I

N

E

R

Y

G

A

R

Y

M

A

C

H

I

N

E

R

Y

LL

C

LL

C

1931 EastMainStreet

Griffith, IN46319

Phone:219/980-5700

F

A

X

:

2

1

9

/

9

8

0

-

0

4

0

5

OPERATOR SAFETY GUIDELINES

1. All operators and maintenance people must familiarize themselves with the

location of the power shut-off.

2. Be sure you know the machine –capacity, controls, operating mode and

safeguarding.

3. Never place any part of your body at the point of operation when the machine is

running.

4. Never operate, service repair or adjust the machine without proper instruction

from your supervisor and without reading and understanding the operators

manual.

5. Never operate the machine without guards or barriers.

6. If the machine requires cleaning, service, adjustment, or should become jammed,

do not insert hand in point of operation to remove assist, release, service or

adjust unless the following is done.

?Shut off machine

?Pull plug –remove power source

?Make sure supervisor is present

7. Make certain all personnel are away from the equipment before operating.

8. Keep alert –keep your mind on your job.

9. When leaving your machine, turn the power OFF –controls inoperative.

10. Keep your work area clean.

11. Wear snug fitting clothes.

FAILURE TO FOLLOW SAFE OPERATING PROCEDURES MAY RESULT IN SERIOUS

INJURY –TO YOU OR ANOTHER EMPLOYEE

1. Removal of guards punishable by law.

2. Become familiar with power shut-offs before operating this machine.

3. If machine requires service, adjustment or should become jammed, do not insert hand in point

of operation to remove, assist, release, service, or adjust, unless the following is done:

oShut off machine;

oPull plug -remove power source;

oMake sure supervisor is present;

4. Any malfunctions of this machine should be brought to the attention of foreman or

supervisor.

5. Instructions should be available for operation and he should be reviewed on this information

before being permitted to operate this machine.

6. It is suggested that after the equipment has been installed barrier guards be erected where

needed to prevent personnel entry into potential hazard areas.

Gary Machinery LLC “Single Wheel Slitter”

Operating & Instruction Manual

Introduction:

The Gary Machinery Single Wheel Slitter is thoroughly inspected before leaving our plant. This

includes running material through the unit to be sure that all components are operating properly

and that a satisfactory cut can be made.

To simplify the machine set up and to maintain proper operating, the following recommended

set-up steps have been outlined. Please read these carefully, and if any questions arise, call us

at any time.

Opening the Carton:

The Single Wheel Slitters are shipped in a heavy carton. The machine weight is just under 300

lbs. so whatever handling means are employed, care must be exercised to avoid personal strain

or equipment overload. Once the slitter is removed, the unit should be checked for damages

that may have occurred during transit.

If a means of overhead lifting is available, machine may be removed from the shipping container

using the eyebolt provided. A slight rearward tilt is normal.

If overhead liftingis not available, carton may be cut away and machine handled using extended

rods at each end as carrying handles.

NOTE:The plywood base to which themachine is attached for shipping may be removed as

desired. However, if optional support stand has been ordered, the board will serve as a top for

the stand and should be retained.

1 to 2 inches

Cut around base of carton

Remov

e these three bolts

Leave this bolt in place

Slide blocks even

With each other to

position shown –

Do NOT tighten hand knobs

This hole fits over the bolt head in LS block

Setting Up the Machine:

The squaring arm (gauge) is shipped loose and must be bolted in place before use. Procedure

is as follows:

a) Loosen hand knobs and move sliding mount blocks to the center of machine.

b) Remove both bolts from RS sliding block and the back bolt from L.S. sliding block using the

Allen wrench provided in accessory package.

c) Position gauge as shown in illustration and slide through opening in main housing.

d) Position gauge over remaining bolt on L.S. block.

e) Install bolts removed in step D finger tight.

f) Slide entire assembly up against stop collars at rear of machine and tighten all bolts being

careful not to move blocks away from stops. NOTE: Bolt on LS block will not tighten

against gauge bar; it is used only as a retainer to prevent bar from lifting off block.

Gauge Mounting

g) Gripping top of gauge bar with hands positioned to each side of the mount blocks and

applying even force the gauge should now slide easily throughout its width range.

Gauge Squaring

Position bolt head

Bump these blocks up

against stop collars

Retainer bolt; should

not fully tighten

against gauge bar.

Tighten these bolts

NOTE: Gauge Squareness

The stop collars used to position the slide blocks are factory set so that each time the gauge is

removed and re-installed the square between the gauge and cutter will be correct. If gauge is

not square, tapered strips will result. If stop collars should ever come loose or sheet metal

portion of gauge be replaced, it will be necessary to re—set squareness by the method used at

the factory. See Illustration below.

Once squareness is correct & bolts tightened, slide assembly to maximum width cut & re-set

stop collars.

Operation:

When ready to operate, remove the rust protective spray that was applied at the factory. You

are now ready to plug the machine in. Make sure that operating toggle switch is in the “off”

position. These machines are 110 Volts as a standard and will have a standard plugto be

plugged into a standard 110v outlet with grounded outlet.

Loosen locking knobs on gauge assembly and slide to position for cut size desired. The size of

cut may be directly read from the scale on the side of the machine. The scale pointer is factory

calibrated to the position of the cutters and should require no adjustment.

Tighten locking knobs, after positioning gauge.

Position blade of

square on this edge

Combination Square

or

Try Square

Loosen these bolts and

square sheet metal gauge to

main housing. (Check both

entry & exit sides.)

Use of the Sheet Guide:

The sheet guide supplied is used to

hold material to the gauge. As

material is fed into the unit, locate the

sheet guide on the operator side of

the sheet. Only exert sufficient

pressure to keep the material to the

gauge. This will insure dimensional

control and safe operation.

Turn machine “on” and note rotation of cutters. The upper cutter should be rotating in a

clockwise direction. The machine is designed to be fed from the right-hand side with slit

material exiting on the left as the operator stands facing the cutters.

Position edge of sheet to be cut into slot in thegauge

assembly. Hold the opposite edge of the sheet with the

sheet guide provided (Part#100011).

TOP VIEW

Cutter Knives

90

°

The locking knobs are located

on the sliding blocks on each

side of the machine

Shee

t

Side Guide

Feed Direction

Keep hands and clothing clear of opening in the side of the machine and rotating shaft on the

exit side.

NOTE:It is advisable upon initial operation of machine to check width and squareness

accuracy by running some test strips (2” –3”wide). If width is not as set using gauge pointer,

pointer may be bent or repositioned to correct. If parts are tapered, gauge squareness may not

be correct (refer to set-up procedure for gauge squareness).

Operating Hints and Cautions

Introduction:

To utilize the sheet slitter to its maximum capacity requires familiarization with the machine.

The operator of the slitter will gain most of this during actual machine running. The following list

contains some of the techniques we have found to maintain a maximum output with a minimum

set up time. It also includes an outline of the way to set the unit up for the best slitting results

and a trouble-shooting guide has been provided covering the most common problems and their

solutions.

Trouble Shooting Guide:

Material is not cut through

•Material thickness or tensile strength exceeded capacity of machine. 16 Ga. (.060”) is the

maximum thickness & 50,000 psi is the maximum shear strength.

•Knives penetration gap is not deep enough

Factory set at

.040” (±.005”)

(View is exaggerated to show clarity)

•Knives side clearance is too great

•Knives are extremely dull

•Clamp collars are loose

•An arbor may be loose at bearing or the bearing pins removed from the housing.

Burred Edge

•Knife side clearance is too great

•Chipped knife (burr will be random along edge and occur at approx. 12½”intervals)

•Dull knife

•Soft material

•Buildup on knife edge

Rolled Edge

•Dull knives

•Excessive penetration of cutters (Note, penetration & side clearance of cutters is factory

set to attain satisfactory results. Cutting material ranging from 30 ga. to 16 ga. a certain

amount of rolled edge must be expected when slitting light gauge material)

Tapered Stripped

•Gauge positioning out of square (refer to setup instructions)

•Material not being held into gauge with side guide. (refer to operating instructions under

sheet guide

•Build up on gauge

Material "hang-Up" in Machine

•Ragged edge on material getting trapped in gauge

•Gauge excessively worn. Replace gauge.

Machine Stalling

•Capacity exceeded.

•Motor defective

HORIZONTAL SIDE CLEARANCE

10% of stock thickness.020” -.060”

.00075” to .001”.010” -.018”

.0005” to .00075”.006” -.010”

.006 AND UNDER

NO CLEARANCE

STOCK THICKNES CLEARANCE

To obtain satisfactory results with any

slitting machine it is vital that the

horizontal clearances be properly set.

Final clearance adjustments are best

determined by making test runs with the

actual material to be slit. However these

setting have proven to be fairly accurate.

Allowance should be made for deflection

of the arbors, which occurs due to the

thickness and type of material being cut.

Note: Softer materials may need less

side clearance and harder materials may

need more side clearance.

Factory set at

.001” (±.0005”)

This allows for

slitting a wide range

of product, but many

not be optimum for

exclusive use on

heavy gauge

materials.

A

A

90

Excessive Drive Train Noise

•Chain loose. Adjust tension with take-up assembly; remove link from chain if take-up does

not provide enough adjustment

•Gears worn in motor gearhead (refer to manufacturer’s instructions).

•Defective idler bearing on chain wrap.

•Defective shaft bearing.

•NOTE:Gearhead motors are normally somewhat noisy. If motor is quiet when slitting

material, the motor is probably ok.

Lubricating & Maintenance Instructions

To maintain the Gary Machinery Slitter in its best operating condition and to avoid downtime, the

following items should be checked on a regular schedule.

1. The gear reducer should be checked when received to be sure the oil is at the proper level.

It should then be checked at regular intervals, with visual inspection of oil seals for possible

leaks. If oil is required, Browning GL32HT (or equivalent) is recommended. The oil can be

added through the plug at the top of the reducer. Caution must be taken not to overfill the

unit.

2. The arbors, knives, gauge bar, guide rods and skid table should be wiped down and

lubricated with a light oil such as WD-40. This will help prevent rust and remove debris from

the slitter. They should be re-lubricated on a regular basis. This re-lube period should be

more often if the slitter is operated in extremely dusty atmospheres.

3. The guard on the drive side of the slitter incorporates the main arbor bearings and provides

access to the chain and gears. Use a heavy-duty chain lube to lubricate chain and gears

before replacing the guard. Aerosol form is most convenient and effective. Keep drive

chain clean and well lubricated and check chain tension regularly.

4. Keep all fasteners tight and check that all guards are in place.

5. Lightly lubricate gauge rods periodically to maintain smooth movement as well as keep

clean.

6. Keep all unpainted surfaces lightly oiled to prevent rust.

Slitter Knife Sharpening Procedure:

1. The knife sharpening must be done by grinding the side

faces. DO NOT GRIND OUTSIDE DIAMETER.

2. Squareness of bore to side face must be maintained

(90°)

Instructions for the Removing or Replacing of Knives

to Model No. 3354

Gary Single Wheel Slitter

STEP #1 -Remove top and bottom cutter guards.

STEP #2 -Jog machine around so that screws in retainer rings and knives are accessible with

an Allen-wrench as shown on sketch. Unplug machine. Loosen locking screws in

retainer rings and setscrews in knives.

STEP #3 -Remove outside retainer rings and upper stripper ring. Slide inside retainers and

lower stripper ring back against housing.

STEP #4 -Rotate knives to position shown below and remove.

STEP #5 -Resharpen knives per enclosed instructions being careful to maintain the cutting face

at 90° to the bore.(ref to knife sharpening instructions or send back to factory for re-

sharpening)

STEP #6 -Re-assemble unit by reversing above procedures.

STEP #7 -Without bringing knife faces into contact with each other, tighten and loosen the knife

setscrews two or three times to “seat” on the keys.

STEP #8 -Set gauge pointer to some arbitrary length (3” or so) and tighten locking knobs to hold

in place. Using a small scale to measure from the inside of the gauge slot to the

cutting face of the knife, set the lower knife to the distance indicated by thegauge

pointer. Tighten setscrew tight (use rotational force only, do not pull Allen wrench to

side while tightening or knife may cock.

TOP

BOTTOM

Outside Retainer Ring

Inside Retainer Ring

Stripper Ring

Knife

STEP #9 -Insert 0.003’ feeler gauge between upper and lower knife faces and gently slide

upper knife into place (do not force or knife may cock) . Using slow gradual torte,

partially tighten the setscrew in the upper knife being careful not to exert any side to

aide force on the wrench——do not fully tighten screw. aemcve wrench and feeler

gauge.

STEP #10-Plug machine in and turn on. Watch clearance between knives as they rotate. If

knives are running true, the gap will remain the same. If gap opens and closes (knife

appears to wobble) then one or both of the knives are cocked and will have to be

reset —if gap ~s okay then fully tighten upper knife setscrew and double check to

make sure knives are still running true. If okay, jog machine around so that

setscrews are accessible and unplug machine.

STEP #11-push upper and lower stripper rings and retainers up against the sides of the knives

and rotate so tbat locking>c crews are accessible. hold retainers against knives and

stripper rings. (Tooling setup should now appear as shown in figure 11.)

STEP #12 -Re—install upper and lower guards.

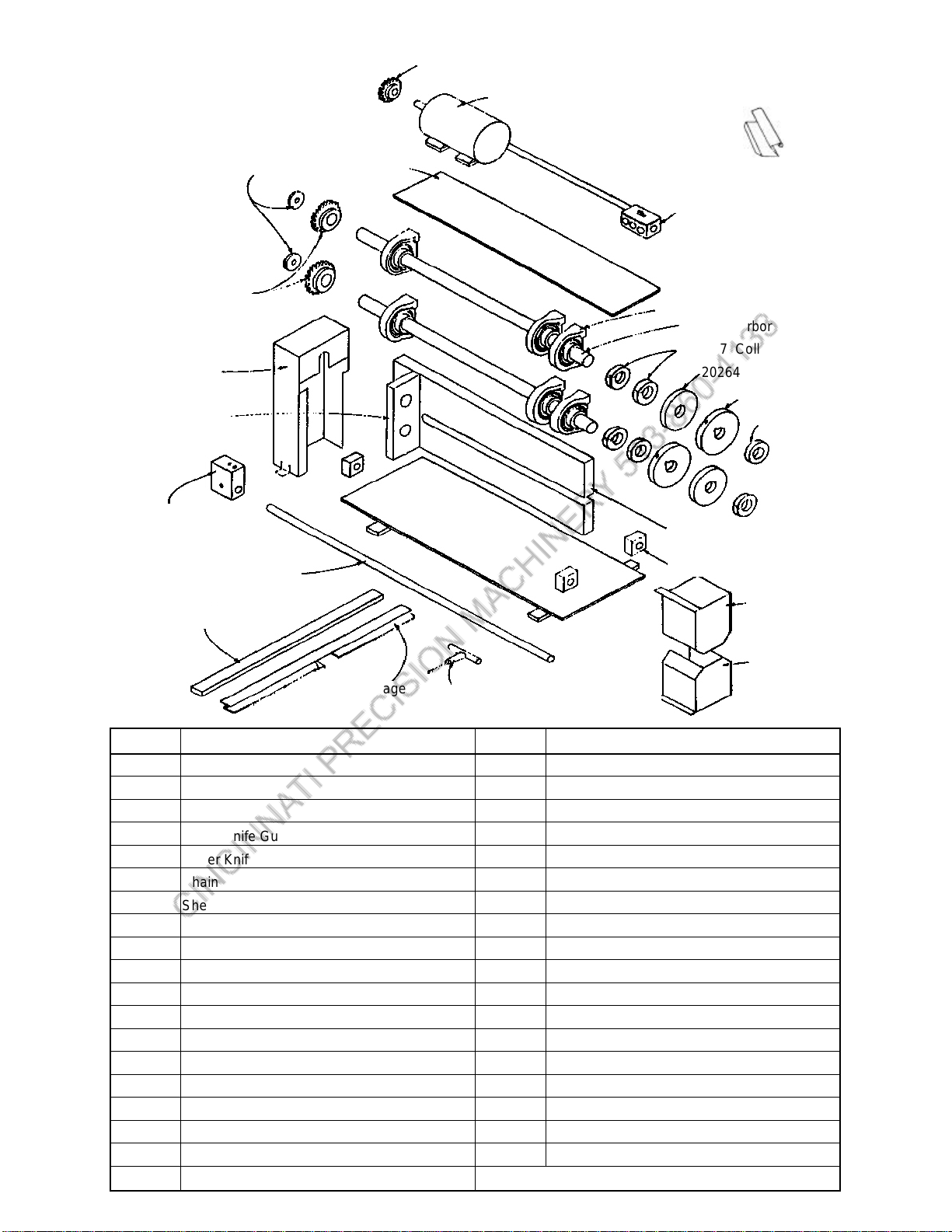

Part No.

Description Part No.

Description

100011 Sheet Guide 202450 Foot Mount

103533 Gage Pointer 202451 Arbor

105254 SM Gage *N.S.

202453 Gage Rod Block

105256 Upper Knife Guard 202454 Gage Slide

105257 Lower Knife Guard 202455 Gage Bar

105258 Chain Guard 202462 Brewer SS Chain Tensioner *N.S.

105345 Sheet Skid *N.S.

202483 Thrust Cap

200003 1/2" Chain Idler Bearing 202646 Knives

200004 40BS10 Motor Sprocket 202647 1" Collar

200007 Gearmotor 2Z848 202648 Stripper Ring

200008 Electric Cord w/plug *N.S.

202649 5/32”T Handle

200011 5/16”T Handle (optional for collars) 202678 Guide Rod

201261 40B14 Sprocket 202682 Reid DK-28 Knob

202409 Browning Bearing 285048 #40 Chain

202431 Measuring Stix *N.S.

285155 2x4 Handy Box

202440 Top Plate 285159 Toggle Plate Cover

202446 Side Plate 285160 SPST Switch

202447 End Plate 285908 3/8”-16 x 2 1/4 Eye Bolt *N.S.

202448 Base Plate *N.S.–Not Shown

100011

Sheet Guide

200004 Motor Sprocket

200007 Gearmotor

202483

Thrust Caps 20244

0

Top Plate

201261 Arbor Sprockets

202447 End Plate

202446 Main Side Plate

105258 Chain Guard

285155 Handy Box

285159 Toggle Plate Cover

285160 SPST Switch

202451 Arbor

105254 Gage

202455 Gage Bar

202678 Guide Rod

202454

Gauge Slide Block

202409 Bearing

202647 Collar

202648 Stripper Ring

202646 Knife

202647 Collar

105257 Lower Knife Guard

105256 Upper Knife Guard

202453 Gage Rod Block

202448

Base Plate

200011 5/16” T-handle Wrench

(for use on knife)

202649 5/32” T-handle Wrench

MODEL 335

4

SINGLE WHEEL SLITTER

Overall Depth

(Carring handles) 41”

Maximum cut width 24”

Gauge Lenght 36”

Arbor diameter 1”

Knife dimensions 4” O.D. x ¾”

Motor HP ? HP

Feed speed (FPM) 40 FPM

Voltage 110V –1 Ph.

Weight 300 Lbs.

Proudly

Made In

America

By

www.GaryMachinery.net

Specifications

G

A

R

Y

M

A

C

H

I

N

E

R

Y

G

A

R

Y

M

A

C

H

I

N

E

R

Y

LL

C

LL

C

1931 EastMainStreet

Griffith, IN46319

Phone:219/980-5700

F

A

X

:

2

1

9

/

9

8

0

-

0

4

0

5

Table of contents