DAYCO D105DC User manual

2Page

WARNING - SAFETY NOTE

IMPORTANT-DONOTOPERATETHISEQUIPMENTUNTILYOUREADANDFULLY

UNDERSTANDTHISMANUAL ANDITSASSEMBLYINSTRUCTIONS

ALWAYSWEAREYEPROTECTION

WARNING!!

!!

!USE ONLY THOSE HOSE AND COUPLING COMBINATIONS AND

CRIMPING EQUIPMENT SPECIFIED IN DAYCO HYDRAULIC PUBLISHED

LITERATURE. DAYCO RECOMMENDATIONSARE BASED ON TESTING,

AND USE OF HOSEAND COUPLING COMBINATIONS OTHER THAN

THOSE RECOMMENDED BY DAYCO CAN RESULT IN SERIOUS INJURY,

DEATH OR SUBSTANTIAL PROPERTY DAMAGE. DAYCO DISCLAIMSALL

LIABILITY FORANY HOSEAND COUPLINGASSEMBLY THAT IS NOT MADE

ACCORDING TO DAYCO RECOMMENDATIONS. CONSULT YOUR LOCAL

DAYCO REPRESENTATIVE OR DAYCO DISTRIBUTOR IF YOU HAVEANY

QUESTIONS.

file: D105DC/D100D-DC MarkIV Manual(Rev 4/23/2008).pmd

3Page

TABLE OFCONTENTS

PartsIdentification-----------------------------------------------------------------4

D105DC Quick Start Guide------------------------------------------------------5

D105s-DC Quick Start Guide---------------------------------------------------6

HosePreparation-------------------------------------------------------------------7

HoseCrimping-StandardDies---------------------------------------------------8

Hose Crimping-DoubleAngle Dies-------------------------------------------11

Calibration--------------------------------------------------------------------------12

Troubleshooting -------------------------------------------------------------------13

Kwikrimp®Concept--------------------------------------------------------------14

PartsBreakdown------------------------------------------------------------------15

4Page

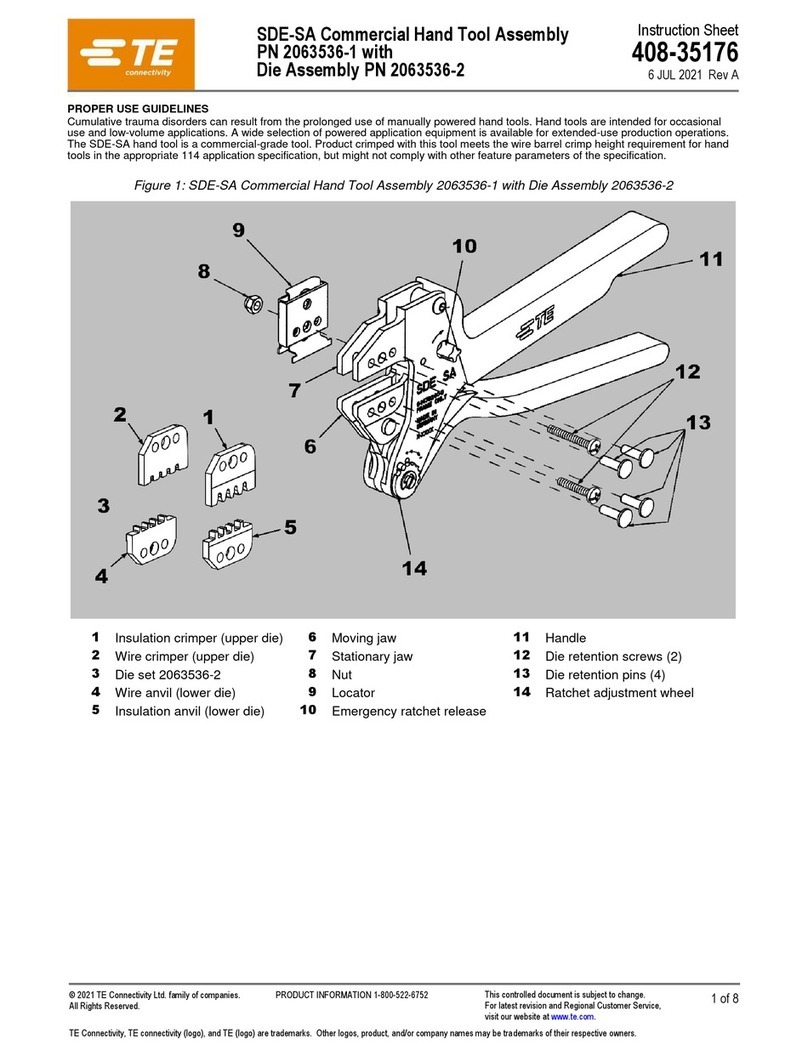

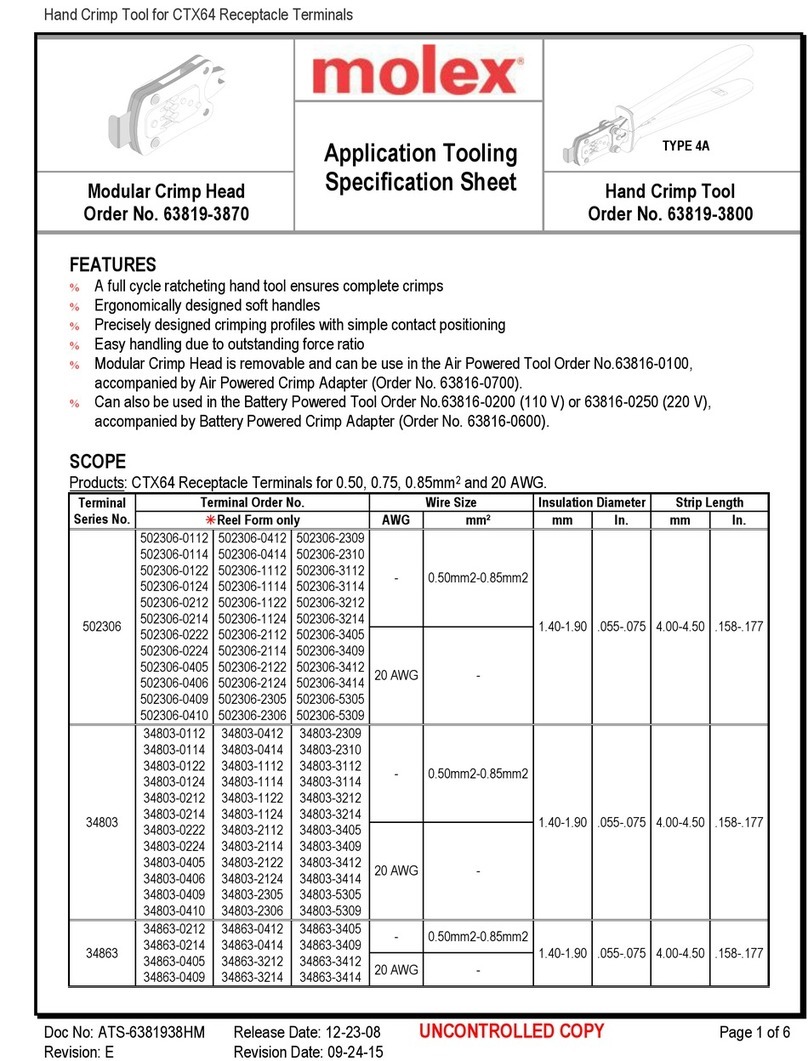

D105DC/D100S-DCPARTSIDENTIFICATION

10,000PSI PUMP

1HP, 110V-15AMPMOTOR

35TONHYDRAULIC

CYLINDER OILFILLAND

VENTPLUG

ADJUSTABLERAM

RETRACTIONSTOP

MICRO-CRIMP

ADJUSTER

CALIBRATION

ADJUSTMENT

SCREW

MANUALPNEUMATIC

START-STOPSWITCH

AUTOMATICSTOP

SWITCH

DOUBLEANGLETOP

COMPRESSION

RING

DOUBLE

ANGLEDIESET

DOUBLEANGLE

BASE RING

STANDARD DIE

SET

STANDARD

PRESSUREPLATE

POWERON/OFF

CIRCUITBREAKER

SWITCH

STANDARD

COMPPRESSION

RING

5Page

D105DC QUICK STARTGUIDE

CALIBRATION CHECK FOR THE D105DC

(See the following page for D100S-DC Calibration)

PLUG THE CRIMPER DIRECTLY INTO A 110 VOLT 20

AMP SINGLE PHASE WALL OUTLET.

DO NOT USE AN EXTENSION CORD OR RUN FROM

PORTABLE POWER SOURCES AS LOW VOLTAGE CAN

DAMAGE THE MOTOR.

THE OIL LEVEL IN THE PUMP SHOULD BE APPROX.

1 1/2 INCHES BELOW THE FILLER/VENT PLUG.

PLACE THE STANDARD PRESSURE

PLATE, ANY STANDARD DIE SET AND THE

STANDARD COMPRESSION RING IN THE

BASE OF THE CRIMPER IN THE ORDER

SHOWN.

SLIDE THE PUSHER ONTO THE

STUD OF THE HYDRAULIC RAM.

SET THE MICRO-CRIMP ADJUSTER

AT “95” FOR THE D105DC

PRESS AND HOLD THE START SWITCH.

IF THE RAM EXTENDS AND SHUTS OFF THE MOTOR

IN APPROXIMATELY ONE SECOND AFTER THE PUMP

STARTS TO BUILD PRESSURE, (THE SOUND OF THE PUMP

WILL CHANGE) AND THE DIE SET IS FULLY CLOSED, THE

CRIMPER IS CORRECTLY CALIBRATED.

IF THE TIME TO SHUT OFF IS NOT APPROXIMATELY

1 SECOND, THE CRIMPER MUST BE RECALIBRATED. SEE

INSTRUCTIONS.

FOLLOW THESE STEPS BEFORE YOU USE YOUR

CRIMPER FOR THE FIRST TIME

CALIBRATION CHECK PROCEEDURE

6Page

D100S-DC QUICK START GUIDE

CALIBRATION CHECK PROCEEDURE

FOLLOW THESE STEPS BEFORE YOU USE YOUR

D100S-DC CRIMPER FOR THE FIRST TIME

CALIBRATION CHECK FOR THE D100S-DC

A HYDRAULIC POWER SOURCE CAPABLE OF

GENERATING 10,000 PSI MUST BE ATTACHED TO THE D100S-

DC CRIMPER.

PLACE THE STANDARD PRESSURE PLATE, ANY

STANDARD DIE SET AND THE STANDARD COMPRESSION

RING IN THE BASE OF THE CRIMPER IN THE ORDER

SHOWN.

SLIDE THE PUSHER ONTO THE

STUD OF THE HYDRAULIC RAM.

SET THE MICRO-CRIMP

ADJUSTER AT “95” FOR THE D100S-DC

APPLY ENOUGH PRESSURE TO

THE RAM TO BRING THE DIE SET TO

THE FULLY CLOSED POSITION AND

FULLY SEAT ALL COMPONENTS.

WHEN THE DIE SET IS FULLY CLOSED AND ALL OF

THE COMPONENTS FIRMLY SEATED, THE WHITE LINE OF

THE MICRO-SITE ADJUSTER SHOULD BE JUST VISIBLE AS

SHOWN.

IF THE WHITE LINE DOES NOT APPEAR AS SHOWN

AT THE RIGHT, LENGTHEN OR SHORTEN THEADJUSTMENT

SCREW AS REQUIRED.

7Page

HOSE PREPARATION

Daycorecommendsthatall users familiarizethemselveswith Dayco’swarning

statements,SAEJ1273,and theKwikrimp®concept,foundin thisoperator’smanual.

Select the Dayco hose and coupling to be assembled.

Determinethecorrectcrimp

settingfromthecrimp specifications

sheet.

Determinehose cutlength

bysubtractingthecutofffactor for

eachcouplingfromthe overall

length of the assembly. For these

cutoff factors, see Dayco’s

publishedcatalogdata.

Cutthe hosesquareand to theproperlengthwith asuitable saw.

Coatthe coupling stemwith Dayco hoseassembly lubricant(HAL16) to easehose

insertion. Insertthe hoseuntilit “bottoms”in thecoupling shell.

To insurethatthe hoseis bottomedin thecollar,mark theinsertiondepth onthe hose

beforeinserting itintothe coupling(see figure below).

Usinga clockwisetwistingmotion orfixing thehexon thecoupling ina vise mayhelp when

tolerancesare tight.

8Page

D100 SERIES HOSE CRIMPING

CRIMPING WITH STANDARD DIES

InserttheStandardPressurePlateinthebottomflangemaking

certainthatthePressure Plate isseatedsquarelyinthe bottomflange.

Make certain that the seating area of the bottom flange is clean and

allows the Pressure Plate to seat squarely in the bottom flange

Selectthecorrectdiesetforthecombinationofhoseandfitting

beingcrimped.

Thenumber etchedon the die ring representsthe fullyclosed diameter

of the die set in either inches or millimeters depending upon the die

set.

Lubricate the contact surfaces of the die fingers and the

CompressionRing withthedielubricantfurnishedwiththecrimper.

Failure to lubricate the contact surfaces with the correct lubricant

can cause the dies to seize in the compression ring.

Alignthehose andfittingin thedie set. If thefitting has knurl

marks, align as shown. If there are no knurl marks on the fitting,

obtainthecorrectcrimplengthfromthecrimpspecificationchartand

markthefittingatthe properpoint.

CAUTION: The notches on the die set must be

completelycoveredbythe CompressionRingprior

to starting the crimp. If the notches are visible,

you must go to a larger die set. Crimping with

an incorrect die size could result in personal

injury

9Page

D100 SERIES HOSE CRIMPING

Positionthedies inthecrimper asshownmaking certainthat

the die rings set squarely on the pressure plate and that the die ring

halves do not overlap each other.

Align the hose and fitting in the die set and place the

Compression Ring loosely over the die set. Manually depress the

compressionring untilthe fittingis heldloosely inthe dieset.

Selectthe propercrimp setting from the CrimpSpecification

chartandset theMicroCrimp adjusteratthe settingrecommended.

Note: Each die set has a limited range of diameters for which a

satisfactory crimp can be obtained. As a “rule of thumb” a standard

die set can crimp 3 mm (.120 inches) above the closed diameter etched

on the die ring. Always consult the hose and fitting manufacturer’s

recommendation for the correct die set to use.

10Page

D100 SERIES HOSE CRIMPING

COUPLINGSTOP RAMRETRACTIONSTOP

SlidethePusherinto position onthehydraulicram

Recheck the fitting for correct alignment and depress the

pneumaticStart/Stopswitchbulb. Keepitdepresseduntilthecrimper

shutsoffautomatically.

FortheD100S-DC,bringthePusherdownuntilthewhiteMicro-

Site line just appears on the micrometer and release the pressure

sourceallowingthe Pushertoretract.

Measure the finished fitting diameter to

becertainthatit iswithinthecrimpspecification

tolerances.

Checkthe diameterofthe finishedcrimp

to be certain that it is within the hose and fitting

manufacturer’sspecifications.

Ifmultiple fittingsarebeingcrimped setthe CouplingStopto

automaticallyposition thefitting andset theRam RetractionStop to

limitthe ram retractionto thepositionwhere thehoseand fittingcan

just be easily removed.

Magnetsembedded inthePusher willretractthe CompressionCone

withthe Pusherwhile still permittingthe CompressionCone toalign

correctlyforthenextcrimpingoperation.

11Page

CRIMPINGWITH DOUBLEANGLE DIES

CRIMPING WITH DOUBLE ANGLE DIES

Double Angle dies double the radial crimping force of the die set

allowing heavier fittings to be crimped. Due to the doubling of the

radial crimp force, they are effective for a smaller range of diameters

thanastandarddieset. Also,the fittingmustbeapproximately centered

axially along the crimping face to avoid taper in the final crimp.

Remove the standard flat Pressure Plate and replace it with

theDBLBASEbottom compressionring.

Note: The angles are not the same on standard and double angle dies

and the standard compression rings are not interchangeable with

double angle compression rings.

Lubricate the contact surfaces of both the upper and lower

compressionringsandtheoutersurfacesofthe double angledieswith

thedielubricantfurnishedwiththecrimper.

Seattheappropriate size doubleanglediein theconicalrecess

of the DBL BASE lower compression ring and align the fitting as

specifiedby the hosemanufacturer.

PlacetheDBL TOPcompressionring on topofthe diesetand

manuallycompress thedieset untilit contactsthefitting.

SlidethePusherontothecylinderstudandsettheMicro-Crimp

Adjusterattheappropriate setting.

PressandholdtheStart/Stopswitchuntilthecrimpershutsoff.

For the D100S-DC, bring the Pusher down until the Micro-Site ring

justappearson the micrometer.

When the crimp cycle is complete, check the fitting diameter

tomakecertainthatitiswithinthehosemanufacturer’sspecifications.

12Page

CALIBRATION PROCEDURE

Whenthecrimperiscorrectlycalibrated,theramwillextendandfully

closethe dieset. Afterthe dieset isfully closed, the time fromwhich

the pump starts to build pressure and the point at which the motor

shutsofautomatically willbeapproximately1 second.

Many problems associated with incorrect crimp diameters are caused

by incorrect calibration.

CALIBRATION

Insertthe StandardPressurePlate, anydie

set, and the compression ring in the order

illustrated.

SettheMicro-Crimp adjusterat“95”

Pressandhold thestartSwitch

Iftheram extends closingthedies totheirfullyclosed position

andthemotor shutsoffapproximately1 secondafterthepump starts

tobuildpressure(thesoundofthepumpwillchange),thenthecrimper

iscorrectlycalibrated.

Note:forD105S-DC calibration,see QuickStart Guide

If the crimper requires re-calibration, hold the

micrometer barrel with a 5/16 inch open end wrench and

rotate the stem eitherin or out with a 5/32 inch hex key.

If the time from which the pump starts to build pressure is

greater than approximately 1 second, rotate the stem out

slightly.

If the time is less than approximately 1 second, rotate the

stemin slightly.

Recheckcalibration.

13Page

TROUBLESHOOTING

PROBLEM: CRIMPERWILLNOTRUNATALL

The white rockerswitch is also a circuit breaker. Check to see that the circuit breaker has

notbeentripped

Checkthewall outlet. Thecrimpercomesfromthefactory wired fora110 voltsinglephase

circuit. .Use of extension cords or outlets with inadequate power can damage the motor . Do

not runthecrimperfroma portable powersource.

Checkthestopswitchmountedtotheswitch bracket underthe Micro-CrimpAdjuster. This

isa normallyclosed switch and if it doesnot close the crimperwill notoperate.

CAUTION: Do not operate the crimper with this switch jumpered as the pump will not shut off

and the brackets can be damaged.

Checkthe pneumaticallyactuated switchin theelectrical boxmounted onthe motor. This

switchcontrolspowerto the motorandisactuatedwith air pressurefromthebulbon theendof

the hose going into the box

PROBLEM: CRIMPDIAMETER TOOLARGE

Checkcrimpercalibrationandre-calibrateifrequired.

Incorrect die being used. Each die has a range of approximately 3mm (.120 in) above the

closed diameter of the die. The closed diameter is the die size stamped on the die ring.

Incorrectsettingof theMicro-CrimpAdjuster. Checkhosemanufacturer’s specifications.

Inadequatepumppressure. Checkoillevelin thepump. Itshouldbe1-1/2to2 inchesbelow

thefill plug. Replenish withISOViscosityGrade 46hydraulicoil.

Inadequatelubrication ofthe diesand compressionring causing thepump towork harder

thannormaltoreachtherequired diameter.

Inadequate pressure being generated by the pump. This is most likely if the crimper can

crimpthesmallersizehosesandnotthelargerhoses. Whencorrectlyadjusted,thepumpshould

generateapproximately 10,000psi.

Do Not adjust pump to produce in excess of 10,000 psi as damage to components or personal

injury may result

Nopressurebeing generatedbythe pump. There shouldbea definitechangein pitch ofthe

pumpas itcyclesinto highpressure modeand beginsto“work” harder.

PROBLEM:CRIMP DIAMETERTOOSMALL

Checkcrimpdiameter andre-calibrateif necessary

Incorrectdie beingused(See dierange underCrimp Diameter tooLarge)

Incorrectsettingof theMicro-CrimpAdjuster. Checkhosemanufacturer’s specifications.

PROBLEM: DIES STICKING IN COMPRESSION RING

Inadequatelubricationof the compressionringand diesurfaces.

14Page

KWIKRIMP® CONCEPT

THE KWIKRIMP® CONCEPT IS AN ENGINEERED PROGRAM, DESIGNED TO

INCORPORATE DAYCO HOSE, FITTINGS AND CRIMPERS INTO ONE EFFECTIVE AND

RELIABLE HOSE ASSEMBLY SYSTEM.

The Kwikrimp® Concept is an affirmation to all Dayco Distributors, OEMs and users of the

Kwikrimp® system that Dayco will support only those who use Dayco hose and couplings in the

Kwikrimp® assembly system. However, the Kwikrimp® Concept is also a statement that serves to

warn that Dayco will not be responsible when interchanging a Dayco hose and/or couplings with

hose and/or couplings of any other manufacturer. Dayco products are part of an engineered

system, which must be assembled and used in accordance with Dayco instructions and limitations.

Dayco hose, couplings and crimping machines are designed into an effective and reliable assembly

system and the use of other than Dayco products may produce hose assemblies that will not meet

rated performance. Failure to follow Dayco instructions and limitations could lead to premature

hose failures resulting in property damage, serious injury or death.

Dayco’s limited warranty shall apply only if the customer uses hose, fittings, hose fitting

components and crimp equipment specifically engineered, designed and produced to Dayco

process specifications.

DAYCO DISCLAIMS ANY RESPONSIBILITY OR LIABILITY FOR ANY CRIMPED HOSE

ASSEMBLIES NOT PRODUCED FROM GENUINE DAYCO HOSE FITTINGS, HOSE AND

EQUIPMENT, IN CONFORMANCE WITH DAYCO PROCESS SPECIFICATIONS FOR EACH

SPECIFIC HOSE ASSEMBLY.

The argument that hoses branded with identical SAE numbers are the same and can be

interchanged with Dayco couplings is not true! Hose with identical brand can be expected to

perform only to the requirements of SAE when assembled with compatible couplings. SAE

recognizes this fact as shown by the following statement taken from the 1998 SAE Handbook,

J1273, Volume 2, and page 22.198.

3.10 Proper End Fitting – Care must be taken to insure proper compatibility exists between

the hose and coupling selected based on the manufacturer’s recommendations substantiated by

testing to industry standards such as SAE J517.

All Dayco distributors, OEMs and Kwikrimp® users must recognize that the following points are

critical when considering any and all aspects of the Kwikrimp® program.

1. The data supplied with each Crimper was developed after extensive impulse testing with

Dayco hose and couplings. All Dayco hose styles are tested with the proper Kwikrimp® couplings

before they are added to the Dayco Approved List. Dayco is constantly checking and upgrading

hose quality.

2. Dayco Kwikrimp® data does not apply to all hose and couplings, only those products

bearing the Dayco identification with the proper Dayco catalog number.

Dayco couplings used with other than Dayco branded hose will not necessarily produce a good

assembly. Identical hose styles, made by different suppliers, are not the same when it comes to

performance with Dayco couplings.

15Page

1

2

43

4

31

2

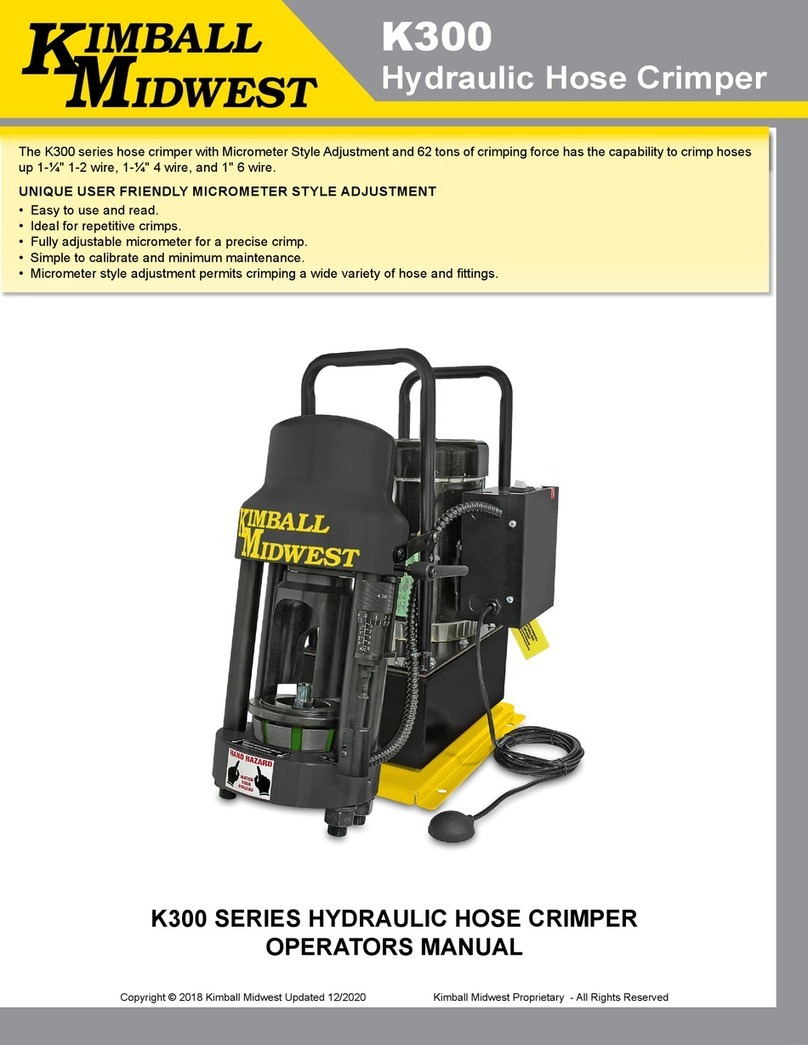

COMPONENT PARTS BREAKDOWN

D100 Standard Series Dies

1) Die Ring 101065-COLOR

2) Die Finger Varies with die set

3) Die Spring LC 022D 01 M NF

4) Die Screw EN84-115

D100 DA(Double Angle Dies

1) Die Ring 101072-COLOR

2) Die Finger Varies with Die Set

3) Die Spring LC 022D 05 M MD

4) Die Screw EN84-115

NotShown:

DA Cone Insert 100880

DATop Cone 100881

ColorOptions

Red

Orange

Yellow

Purple

Green

Blue

Black

Silver

Brown

16Page

COMPONENT PARTS BREAKDOWN

17Page

COMPONENT PARTS BREAKDOWN

18Page

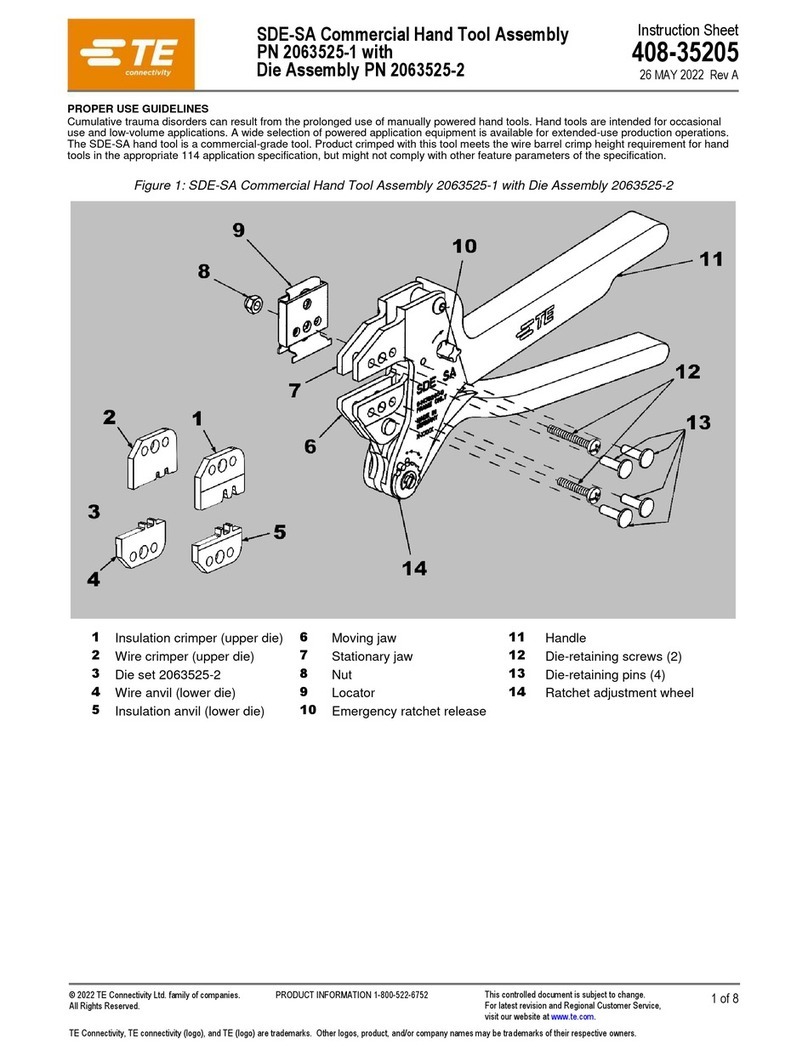

6

5

4

3

2

1

1100325 (Yellow) Bottom Flange 1

2100329 Strain Rod - 8 1/2" 4

3100326 (Yellow) Top Flange 1

43/4 Special 3/4 Flat Washer - Special 4

595462A538 3/4-10 Hex. Nut 4

6100685 35-Ton Cylinder Assembly 1

Item Part Number Description Qty

35-Ton Head Sub-Assembly (101209)

COMPONENT PARTS BREAKDOWN

19Page

COMPONENT PARTS BREAKDOWN

20Page

COMPONENT PARTS BREAKDOWN

This manual suits for next models

3

Table of contents

Other DAYCO Crimping Tools manuals

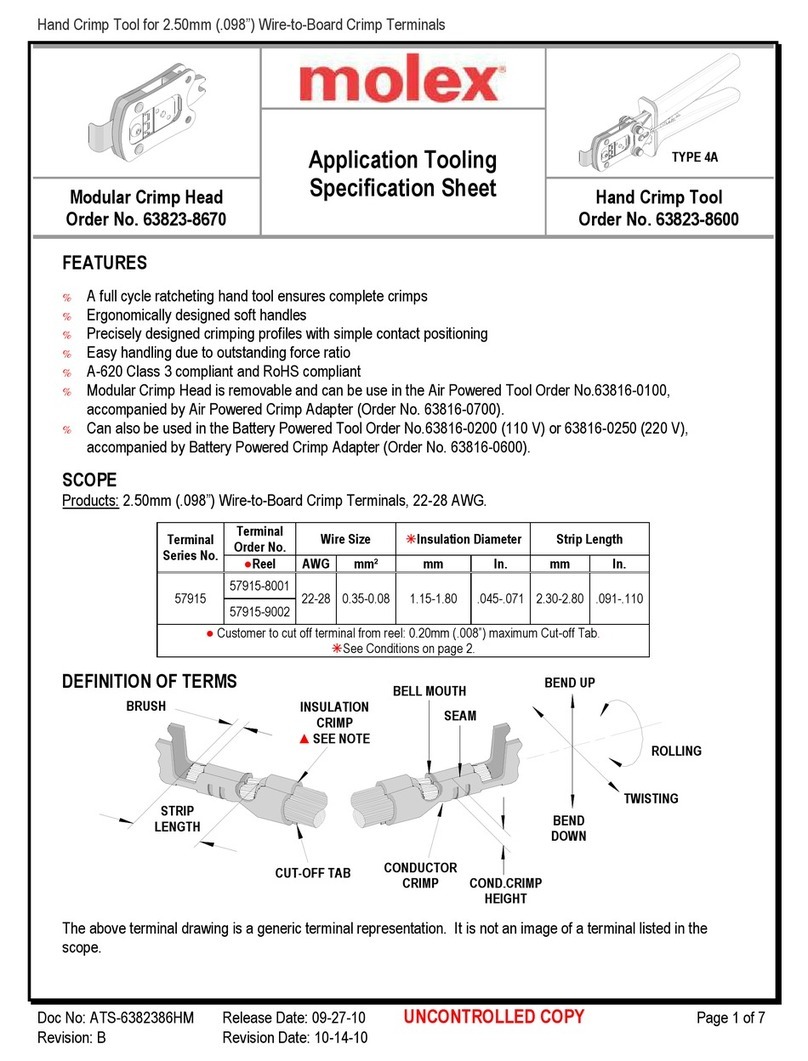

Popular Crimping Tools manuals by other brands

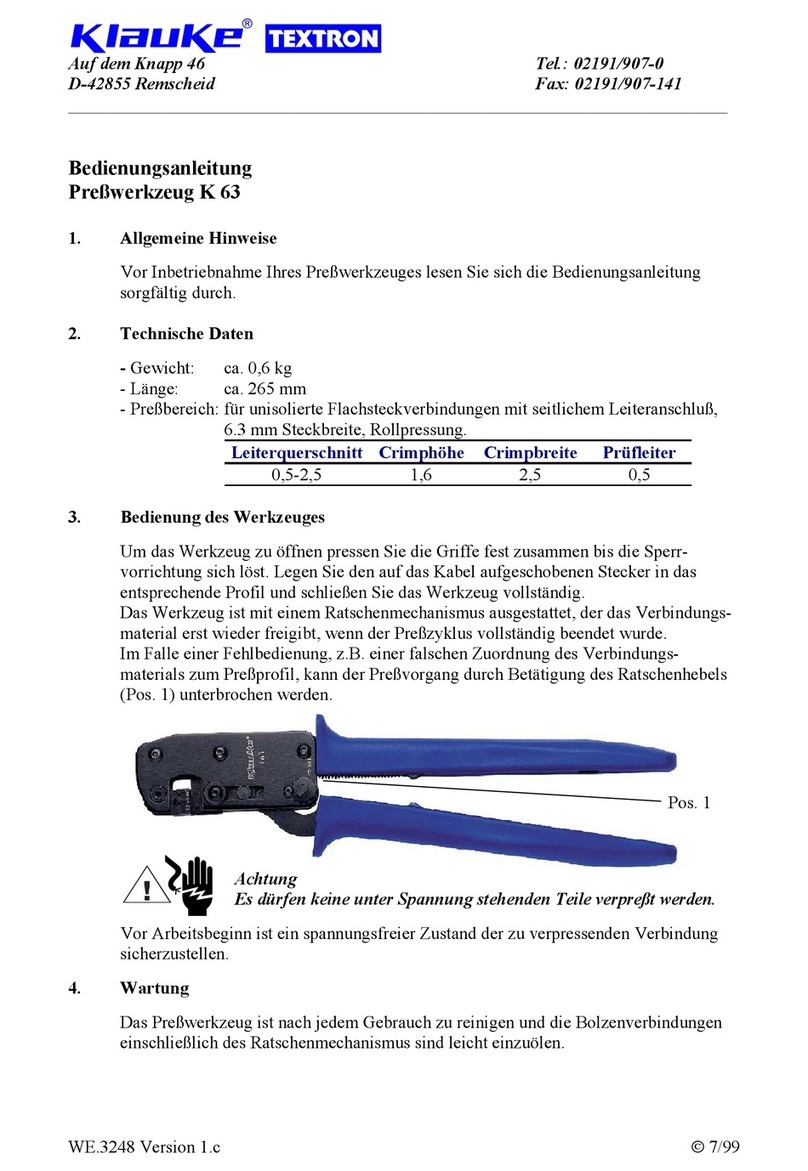

Textron

Textron Greenlee GATOR EK1240KLX Operation manual

Eastwood

Eastwood CRIMP-RIGHT WEATHER-TIGHT 31676 instructions

Greenlee

Greenlee GATOR EK1550LX Operation manual

Westward

Westward 13H894 Operating instructions and parts manual

Burndy

Burndy PATRIOT 444S Series SAFETY OPERATING & MAINTENANCE INSTRUCTIONS

Textron

Textron Klauke K 63 instruction manual