2 2-11-93 TI648-93-0

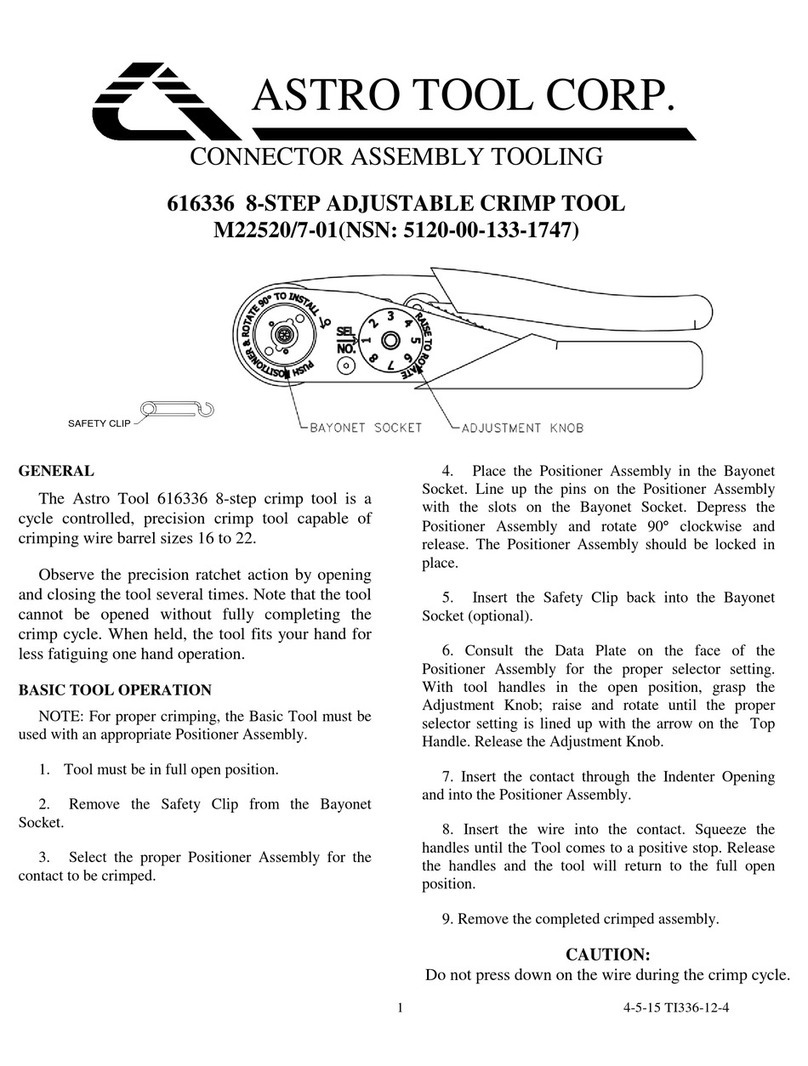

1. The tool must be in the fully open position as

shown in figure #2.

Figure # 2

2. Locate the Movable Pop-in Die and insert the

die post into the die nest. Note the off-center die

post. The Movable Pop-in Die can only be inserted

in one direction. See figure # 2

NOTE: The Movable Pop-in Die must be installed

first.

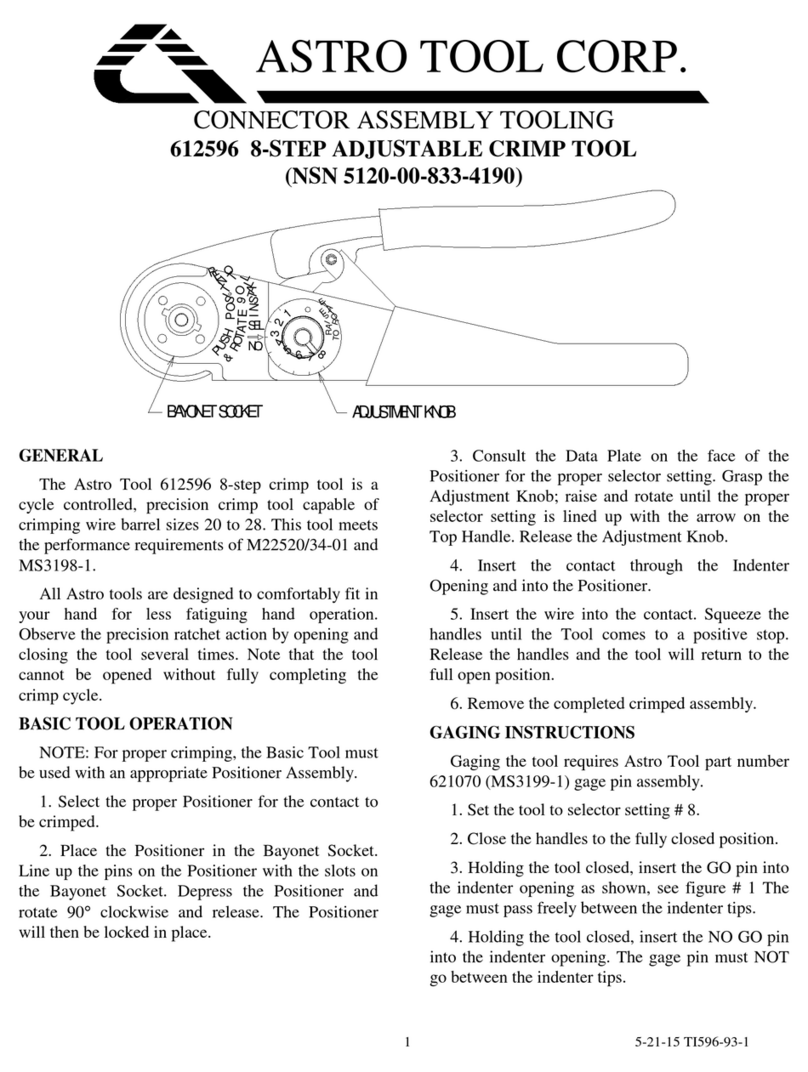

3. Locate the Stationary Pop-in Die and engage the

flat end of the Die with the housing cleat. Rotate the

die in a clock-wise direction to engage it with the

Stationary Die Retaining Detent, see figure #3.

Observe that the Stationary Pop-in Die is installed

parallel to the side plates and that it is not skewed in

any way.

Stationary Die

Retaining Detent

Figure #3

CAUTION:

VERIFY THAT THE STATIONARY DIE IS

INSTALLED CORRECTLY. IMPROPER

INSTALLATION WILL RESULT IN DAMAGE

TO THE TOOL OR THE DIE SET.

4. Cycle the tool to set the die.

d. Crimping Operation

1. The tool must be in the fully open position.

Insert the prepared connector through the tool

opening and place in the appropriate cavity. For RF

connector fittings use the die face as a locational

stop. For shield terminations locate the crimp by eye.

2. Squeeze the handles together until the positive

stop is reached. The tool will release and return to

the fully open position.

3. Remove the crimped termination.

e. Die Removal

1. The tool must be in the fully open position.

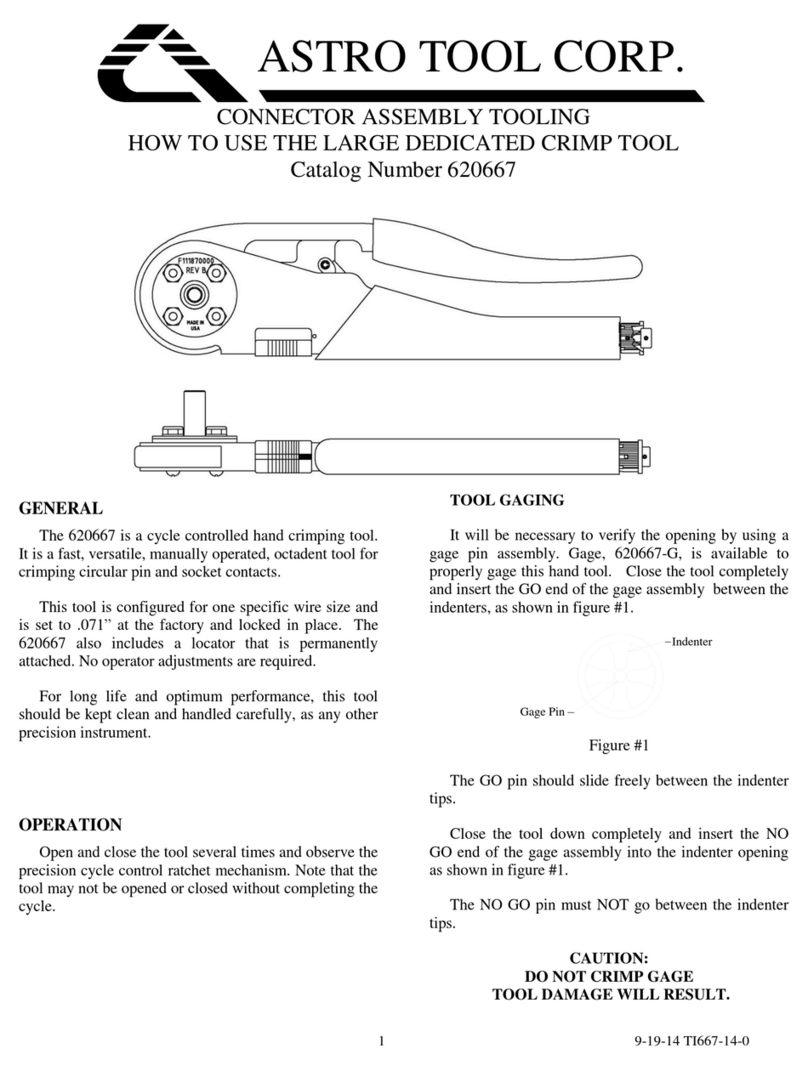

2. To remove the Stationary Pop-in Die, locate the

DRT7. Insert the DRT7 into the hole in the top of

the tool, as shown in figure #4, and tap lightly on

the end indicated. The Stationary Pop-in Die will

drop from the tool.

NOTE: Always remove the Stationary Pop-in Die

First.

Figure #4

3. To remove the Movable Pop-in Die, position the

DRT7 as shown in figure #4, and tap upward lightly

to release the die.

f. Tool Calibration

1. The hand pressure required to cycle the tool

with a set of dies in it should be set at 20-50 lb.

Astro has the AT903 spring tester available for this

purpose.