DAYCO D206DC User manual

1Page

REPLACES DAYCO DE60 MODELS

D206DC-DAYCO OPERATORS MANUAL

2Page

WARNING - SAFETY NOTE

IMPORTANT-DONOTOPERATETHISEQUIPMENTUNTILYOUREADANDFULLY

UNDERSTANDTHISMANUALANDITSASSEMBLYINSTRUCTIONS

ALWAYSWEAREYEPROTECTION

WARNING!!

!!

!USE ONLYTHOSE HOSEAND COUPLING COMBINATIONSAND

CRIMPING EQUIPMENT SPECIFIED IN DAYCO HYDRAULIC PUBLISHED

LITERATURE. DAYCO RECOMMENDATIONS ARE BASED ON TESTING,

AND USE OF HOSEAND COUPLING COMBINATIONS OTHER THAN

THOSE RECOMMENDED BY DAYCO CAN RESULT IN SERIOUS INJURY,

DEATH OR SUBSTANTIALPROPERTY DAMAGE. DAYCO DISCLAIMSALL

LIABILITY FORANY HOSEAND COUPLING ASSEMBLY THAT IS NOT MADE

ACCORDING TO DAYCO RECOMMENDATIONS. CONSULTYOUR LOCAL

DAYCO REPRESENTATIVE OR DAYCO DISTRIBUTOR IF YOU HAVEANY

QUESTIONS.

file: D205DC MarkIV Manual(Rev 4-20-2005).pmd

3Page

TABLE OFCONTENTS

PartsIdentification------------------------------------------------------------------4

QuickStartGuide-------------------------------------------------------------------5

HosePreparation--------------------------------------------------------------------6

HoseCrimping-Standard Dies---------------------------------------------------7

Hose Crimping-DoubleAngle Dies--------------------------------------------10

Calibration---------------------------------------------------------------------------11

Troubleshooting-------------------------------------------------------------------12

Kwikrimp®Concept--------------------------------------------------------------13

PartsBreakdown------------------------------------------------------------------14

LimitedWarranty------------------------------------------------------------------21

4Page

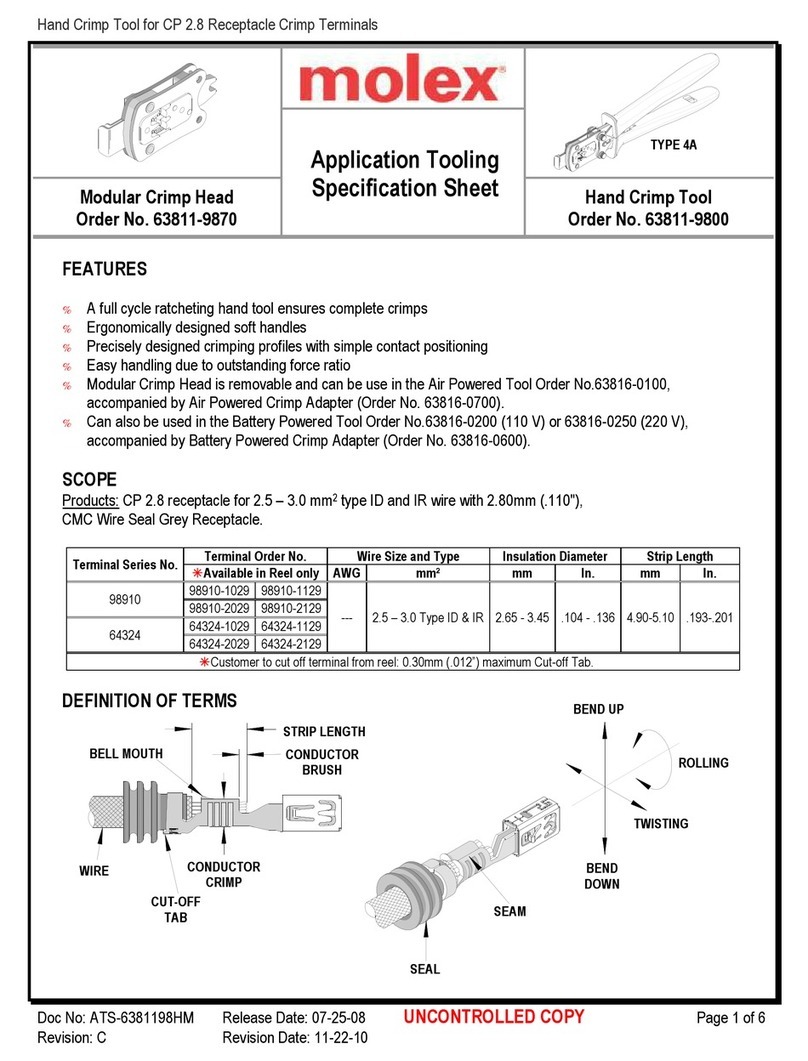

D206DC-MARKIVPARTSIDENTIFICATION

10,000PSI PUMP

1HP, 110V-15AMPMOTOR

80TONHYDRAULIC

CYLINDER OILFILLAND

VENTPLUG

ADJUSTABLERAM

RETRACTIONSTOP

MICRO-CRIMP

ADJUSTER

CALIBRATION

ADJUSTMENT

SCREW

MANUALPNEUMATIC

START-STOPSWITCH

AUTOMATICSTOP

SWITCH

DOUBLEANGLETOP

COMPRESSION

RING

DOUBLE

ANGLEDIESET

DOUBLEANGLE

BASE RING

STANDARD DIE

SET

STANDARD

PRESSUREPLATE

POWERON/OFF

CIRCUITBREAKER

SWITCH

STANDARD

COMPPRESSION

RING

5Page

D206DC QUICK START GUIDE

RETAINING

SCREW(1/8HEXKEY)

PLUG THE CRIMPER DIRECTLY INTO A 110 VOLT 20

AMP SINGLE PHASE WALL OUTLET.

DO NOT USE AN EXTENSION CORD OR RUN FROM

PORTABLE POWER SOURCES AS LOW VOLTAGE CAN

DAMAGE THE MOTOR.

THE OIL LEVEL IN THE PUMP

SHOULD BE APPROX. 1 1/2 INCHES

BELOW THE FILLER/VENT PLUG.

PLACE THE STANDARD PRESSURE

PLATE, ANY STANDARD DIE SETAND THE

STANDARD COMPRESSION RING IN THE

BASE OF THE CRIMPER IN THE ORDER

SHOWN.

SLIDE THE PUSHER ONTO THE

STUD OF THE HYDRAULIC RAM.

SET THE MICRO-CRIMP

ADJUSTER AT “95” FOR THE D206DC

PRESS AND HOLD THE START SWITCH.

IF THE RAM EXTENDS AND SHUTS OFF THE MOTOR

IN APPROXIMATELY ONE SECOND AFTER THE PUMP

STARTS TO BUILD PRESSURE, (THE SOUND OF THE PUMP

WILL CHANGE) AND THE DIE SET IS FULLY CLOSED, THE

CRIMPER IS CORRECTLY CALIBRATED.

IF THE TIME TO SHUT OFF IS NOT APPROXIMATELY

1 SECOND, THE CRIMPER MUST BE RECALIBRATED. SEE

INSTRUCTIONS.

FOLLOW THESE STEPS BEFORE YOU USE YOUR

CRIMPER FOR THE FIRST TIME

CALIBRATION CHECK PROCEEDURE

6Page

HOSE PREPARATION

Daycorecommendsthatall users familiarize themselveswithDayco’s warning

statements,SAEJ1273,and the Kwikrimp®concept,foundinthisoperator’smanual.

Select the Dayco hose and coupling to be assembled.

Determinethecorrectcrimp

settingfromthecrimp specifications

sheet.

Determinehose cutlength

bysubtractingthecutofffactorfor

eachcouplingfromthe overall

length of the assembly. For these

cutoff factors, see Dayco’s

publishedcatalogdata.

Cutthe hosesquareandtothe properlength withasuitable saw.

Coatthe couplingstem withDayco hoseassembly lubricant(HAL16) toease hose

insertion. Insertthe hose untilit“bottoms” inthecoupling shell.

To insure thatthehose isbottomed inthecollar,mark the insertiondepth onthehose

beforeinserting it intothecoupling (seefigurebelow).

Usinga clockwise twistingmotionor fixingthehex on thecouplingin avisemay helpwhen

tolerancesare tight.

7Page

D206DC HOSE CRIMPING

CRIMPING WITH STANDARD DIES

InserttheStandardPressurePlateinthebottomflangemaking

certainthatthePressurePlate is seatedsquarelyinthebottomflange.

Note that the bottom Pressure Plate is held in place by a set screw.

This screw can be loosened through the access hole in the front of the

machine through the “Hand Hazard” decal

Selectthecorrectdiesetforthecombinationofhoseandfitting

beingcrimped.

Thenumber etchedon the diering representsthe fully closeddiameter

of the die set in either inches or millimeters depending upon the die

set.

Lubricate the contact surfaces of the die fingers and the

CompressionRing withthedielubricantfurnishedwiththecrimper.

Failure to lubricate the contact surfaces with the correct lubricant

can cause the dies to seize in the compression ring.

Alignthehose andfittinginthe dieset. Ifthefitting has knurl

marks, align as shown. If there are no knurl marks on the fitting,

obtainthecorrectcrimplengthfromthecrimpspecificationchartand

markthefittingattheproper point.

CAUTION: The notches on the die set must be

completelycoveredbytheCompression Ringprior

to starting the crimp. If the notches are visible,

you must go to a larger die set. Crimping with

an incorrect die size could result in personal

injury

8Page

D206DC HOSE CRIMPING

Positionthedies inthecrimperasshown makingcertainthat

the die rings set squarely on the pressure plate and that the die ring

halves do not overlap each other.

Align the hose and fitting in the die set and place the

Compression Ring loosely over the die set. Manually depress the

compressionring untilthefitting isheld loosely inthe dieset.

Selectthe propercrimp setting fromthe CrimpSpecification

chartandset theMicroCrimpadjuster at thesettingrecommended.

Note: Each die set has a limited range of diameters for which a

satisfactory crimp can be obtained. As a “rule of thumb” a standard

die set can crimp 3 mm (.120 inches) above the closed diameter etched

on the die ring. Always consult the hose and fitting manufacturer’s

recommendation for the correct die set to use.

9Page

D206DC HOSE CRIMPING

SlidethePusherintoposition on thehydraulicram

Recheck the fitting for correct alignment and depress the

pneumaticStart/Stopswitchbulb. Keepitdepresseduntilthecrimper

shutsoffautomatically.

Measure the finished fitting diameter to be certain that it is

withinthecrimpspecificationtolerances.

If multiple fittings are being crimped set the coupling stop to

automatically position the fitting and set the retraction stop to limit

the ram retraction to the position where the hose and fitting can just

be easily removed.

Checkthediameterofthefinishedcrimp to becertainthatitis

withinthehoseandfittingmanufacturer’sspecifications.

10Page

CRIMPINGWITH DOUBLEANGLE DIES

CRIMPING WITH DOUBLE ANGLE DIES

Double Angle dies double the radial crimping force of the die set

allowing heavier fittings to be crimped. Due to the doubling of the

radial crimp force, they are effective for a smaller range of diameters

thanastandarddieset. Also,thefittingmustbe approximatelycentered

axially along the crimping face to avoid taper in the final crimp.

Remove the standard flat Pressure Plate and replace it with

theDBLBASEbottom compression ring.

The bottom Pressure Plate is held in place with a set screw. Access to

this set screw is through the hole in the hand hazard decal.

Note: The angles are not the same on standard and double angle dies

and the standard compression rings are not interchangeable with

double angle compression rings.

Lubricate the contact surfaces of both the upper and lower

compressionringsandtheoutersurfacesofthedoubleangledieswith

thedielubricantfurnishedwiththecrimper.

Seattheappropriatesize doubleangledieintheconical recess

of the DBL BASE lower compression ring and align the fitting as

specifiedby the hosemanufacturer.

Placethe DBLTOP compressionringon topof

the die set and manually compress the die set until it

contactsthefitting.

Slide the Pusher onto the cylinder stud and set

theMicro-CrimpAdjusterattheappropriatesetting.

Press and hold the Start/Stop switch until the

crimpershutsoff.

When the crimp cycle is complete, check the

fittingdiametertomakecertainthatitiswithinthehosemanufacturer’s

specifications.

11Page

CALIBRATION PROCEDURE

Whenthecrimperiscorrectlycalibrated,theram willextendandfully

closethe dieset. Afterthedie set is fullyclosed, the timefromwhich

the pump starts to build pressure and the point at which the motor

shutsofautomatically will beapproximately1second.

Many problems associated with incorrect crimp diameters are caused

by incorrect calibration.

CALIBRATION

Insertthe StandardPressurePlate,anydieset,

andthecompressionringin theorderillustrated.

SettheMicro-Crimp adjusterat“95”

Pressandhold thestartSwitch

Iftheramextendsclosing thediestotheirfully

closedposition andthemotor shutsoffapproximately 1second after

thepumpstartstobuildpressure(thesoundofthepumpwill change),

thenthecrimperiscorrectly calibrated.

Ifthecrimperrequiresre-calibration,holdthe

micrometerbarrelwitha 5/16inchopenendwrench

androtatethestemeither in oroutwitha5/32inhex

keywrench.

If the time from which the pump starts to build

pressure is greater than approximately 1 second,

rotatethestem outslightly.

Ifthetimeislessthanapproximately1second,rotate

the stem in slightly.

RecheckCalibration

12Page

TROUBLESHOOTING

PROBLEM: CRIMPERWILLNOTRUNATALL

The white rockerswitch is also a circuit breaker. Check to see that the circuit breaker has

notbeentripped

Checkthewall outlet. Thecrimpercomesfrom thefactorywiredfora110voltsingle phase

circuit. .Use of extension cords or outlets with inadequate power can damage the motor . Do

not runthecrimperfromaportable power source.

CheckthestopswitchmountedtotheswitchbracketundertheMicro-CrimpAdjuster. This

isa normallyclosed switch andif it doesnot close the crimper willnot operate.

CAUTION: Do not operate the crimper with this switch jumpered as the pump will not shut off

and the brackets can be damaged.

Checkthe pneumaticallyactuatedswitch intheelectrical boxmounted on themotor. This

switchcontrolspowertothe motor andisactuatedwithairpressurefromthebulb on theendof

the hose going into the box

PROBLEM: CRIMPDIAMETER TOO LARGE

Checkcrimpercalibrationandre-calibrateifrequired.

Incorrect die being used. Each die has a range of approximately 3mm (.120 in) above the

closed diameter of the die. The closed diameter is the die size stamped on the die ring.

Incorrect settingof theMicro-CrimpAdjuster. Checkhosemanufacturer’sspecifications.

Inadequatepumppressure. Checkoillevelinthe pump. It shouldbe1-1/2to2inchesbelow

thefillplug. Replenish withISOViscosity Grade46hydraulicoil.

Inadequatelubrication ofthedies andcompressionring causingthepump toworkharder

thannormaltoreachtherequireddiameter.

Inadequate pressure being generated by the pump. This is most likely if the crimper can

crimpthesmallersizehosesandnotthelargerhoses. Whencorrectlyadjusted,thepumpshould

generateapproximately 10,000 psi.

Do Not adjust pump to produce in excess of 10,000 psi as damage to components or personal

injury may result

Nopressurebeing generated bythepump. Thereshould be adefinitechangein pitch ofthe

pumpas it cyclesintohigh pressuremode andbeginsto “work” harder.

PROBLEM:CRIMP DIAMETER TOOSMALL

Checkcrimpdiameter andre-calibrateifnecessary

Incorrectdie being used(Seedie rangeunderCrimp DiametertooLarge)

Incorrect settingof theMicro-CrimpAdjuster. Checkhosemanufacturer’sspecifications.

PROBLEM: DIES STICKING IN COMPRESSION RING

Inadequatelubricationof the compressionringanddiesurfaces.

13Page

KWIKRIMP®CONCEPT

THE KWIKRIMP® CONCEPT IS AN ENGINEERED PROGRAM, DESIGNED TO

INCORPORATE DAYCO HOSE, FITTINGS AND CRIMPERS INTO ONE EFFECTIVE AND

RELIABLE HOSE ASSEMBLY SYSTEM.

The Kwikrimp® Concept is an affirmation to all Dayco Distributors, OEMs and users of the

Kwikrimp® system that Dayco will support only those who use Dayco hose and couplings in the

Kwikrimp® assembly system. However, the Kwikrimp® Concept is also a statement that serves to

warn that Dayco will not be responsible when interchanging a Dayco hose and/or couplings with

hose and/or couplings of any other manufacturer. Dayco products are part of an engineered

system, which must be assembled and used in accordance with Dayco instructions and limitations.

Dayco hose, couplings and crimping machines are designed into an effective and reliable assembly

system and the use of other than Dayco products may produce hose assemblies that will not meet

rated performance. Failure to follow Dayco instructions and limitations could lead to premature

hose failures resulting in property damage, serious injury or death.

Dayco’s limited warranty shall apply only if the customer uses hose, fittings, hose fitting

components and crimp equipment specifically engineered, designed and produced to Dayco

process specifications.

DAYCO DISCLAIMS ANY RESPONSIBILITY OR LIABILITY FOR ANY CRIMPED HOSE

ASSEMBLIES NOT PRODUCED FROM GENUINE DAYCO HOSE FITTINGS, HOSE AND

EQUIPMENT, IN CONFORMANCE WITH DAYCO PROCESS SPECIFICATIONS FOR EACH

SPECIFIC HOSE ASSEMBLY.

The argument that hoses branded with identical SAE numbers are the same and can be

interchanged with Dayco couplings is not true! Hose with identical brand can be expected to

perform only to the requirements of SAE when assembled with compatible couplings. SAE

recognizes this fact as shown by the following statement taken from the 1998 SAE Handbook,

J1273, Volume 2, and page 22.198.

3.10 Proper End Fitting – Care must be taken to insure proper compatibility exists between

the hose and coupling selected based on the manufacturer’s recommendations substantiated by

testing to industry standards such as SAE J517.

All Dayco distributors, OEMs and Kwikrimp® users must recognize that the following points are

critical when considering any and all aspects of the Kwikrimp® program.

1. The data supplied with each Crimper was developed after extensive impulse testing with

Dayco hose and couplings. All Dayco hose styles are tested with the proper Kwikrimp® couplings

before they are added to the Dayco Approved List. Dayco is constantly checking and upgrading

hose quality.

2. Dayco Kwikrimp® data does not apply to all hose and couplings, only those products

bearing the Dayco identification with the proper Dayco catalog number.

Dayco couplings used with other than Dayco branded hose will not necessarily produce a good

assembly. Identical hose styles, made by different suppliers, are not the same when it comes to

performance with Dayco couplings.

14Page

1

2

43

4

31

2

COMPONENT PARTS BREAKDOWN

D200 Standard Series Dies

1) Die Ring 100753-COLOR

2) Die Finger Varies with die set

3) Die Spring LC 026 06 M

4) Die Screw EN82-004

ColorOptions

Red

Orange

Yellow

Purple

Green

Blue

Black

Silver

Brown

D200 DA (Double Angle Dies

1) Die Ring 100873-COLOR

2) Die Finger Varies with Die Set

3) Die Spring LC 022D 05 M

4) Die Screw EN83-034

NotShown:

DA Cone Base

Insert 100870

DATopComp. Cone 100871

15Page

18

12

13

19

2

14

16

6

3

8

7

5

4

3

9

17

1

6

3

10

15

11

1101585 D205 Base 1

2101624 D205 Support Rod 2

390126A031 3/8 Flat Washer 10

492865A622 3/8-16 X 3/4 Hex Bolt 4

5101621 D205 Support Rod Brace 1

692865A624 3/8-16 X 1 Hex Bolt 4

791102A031 3/8 Lock Washer 4

895462A031 3/8-16 Nut 4

9101634 D205 Head Assembly 1

10 101633 Pump Assembly 1

11 90126A029 1/4 Flat Washer 4

12 91102A029 1/4 Lock Washer 4

13 92865A540 1/4-20 X 3/4 Hex Bolt 4

14 60TA06X08 45T

Hydraulic Fitting 1

15 101645 D205 Hydraulic Hose 1

16 101631 D205 Coupling Stop Assembly 1

17 91251A544 1/4-20 X 1 1/4 SHCS 1

18 101349 Pendant Switch & Plug 1

19 101625 D205 Die Shelf Assembly (Optional) 1

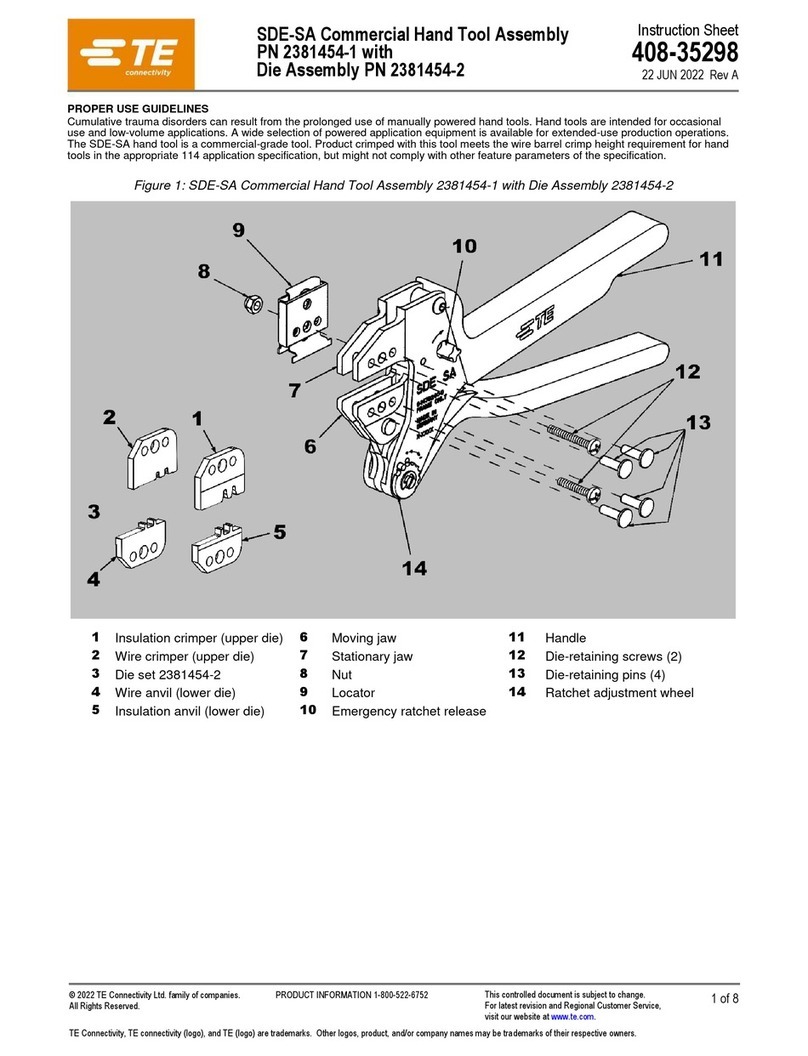

D205/D206 Crimper Assembly (101626)

Item Part Number Description Qty

3

7

8

COMPONENT PARTS BREAKDOWN

D206DC 1 HP110V CRIMPER

16Page

1100679 80 Ton Cone Base 1

2100642 Strain Rod 4

390500A040 Heavy Hex Nut 1 1/4-12 Gd.8 8

4100661 Limit Switch Bracket 1

56_32X375SHCS 6-32 X 3/8 SHCS 2

6903 Switch Limit Switch 1

7100692 Limit Switch Guard 1

891255A190 8-32 X 1/4 BHCS 2

9100641 Micrometer Mount Assembly 1

10 100628 Standard Micrometer Assembly 1

10 101489 DC Micrometer Assembly 1

10 101587 Metric Micrometer Assembly 1

11 100727 Micrometer Nut 1

12 100640 80 Ton Top Flange 1

13 100663 80-Ton Cylinder Assembly 1

14 100648 Pusher Suspension Pin 1

15 100711 Stop Rod 1

16 100710 Stop Rod Locking Handle 1

17 100818 Pusher 1

18 100712 Compression Cone 1

19 100843 Retaining Clip 2

20 91251A540 1/4-20 X 3/4 SHCS 2

21 100713 Pressure Plate 1

22 100680 Mounting Bracket 2

23 90126A031 3/8 Flat Washer 4

24 91102A031 3/8 Lock Washer 2

25 92865A622 3/8-16 X 3/4 Hex Bolt 4

D205 Head Assembly (101634)

Item Part Number Description Qty

13

15

25

23

22

16

3

6

8

7

4

17

14

19

20

18

21

2

1

22

25 24

23

12

5

9

10

11

3

COMPONENT PARTS BREAKDOWN

17Page

1 100636 Top Cap 1

2 100653 Retaining Plug 1

3 90962A357 1/4 X 2 Roll Pin 1

4100760 Spring (21 Coils) 1

5 100637 Cylinder Ram - 80 Ton 1

6 450 Polypak 4-1/2 X 4 X 3/8 Polypak 1

7 227 O-Ring 227 O-Ring - Disogrin 1

8 100635 End Cap 1

9 91251A424 3/8-24 X 1 SHCS (Gd. 8) 6

10 157 O-Ring 157 O-Ring - Disogrin 1

11 GP2C04500-T47 Ram Wear Ring 1

12 100639 Cylinder Body - 80 Ton 1

13 GR2B03750-T47 Ram Guide Wear Ring 1

14 375 Wiper Wiper (SH940-35) 1

15 100663-REPAIR Seal Repair Kit (Not Shown) 1

Item Part Number Description Qty

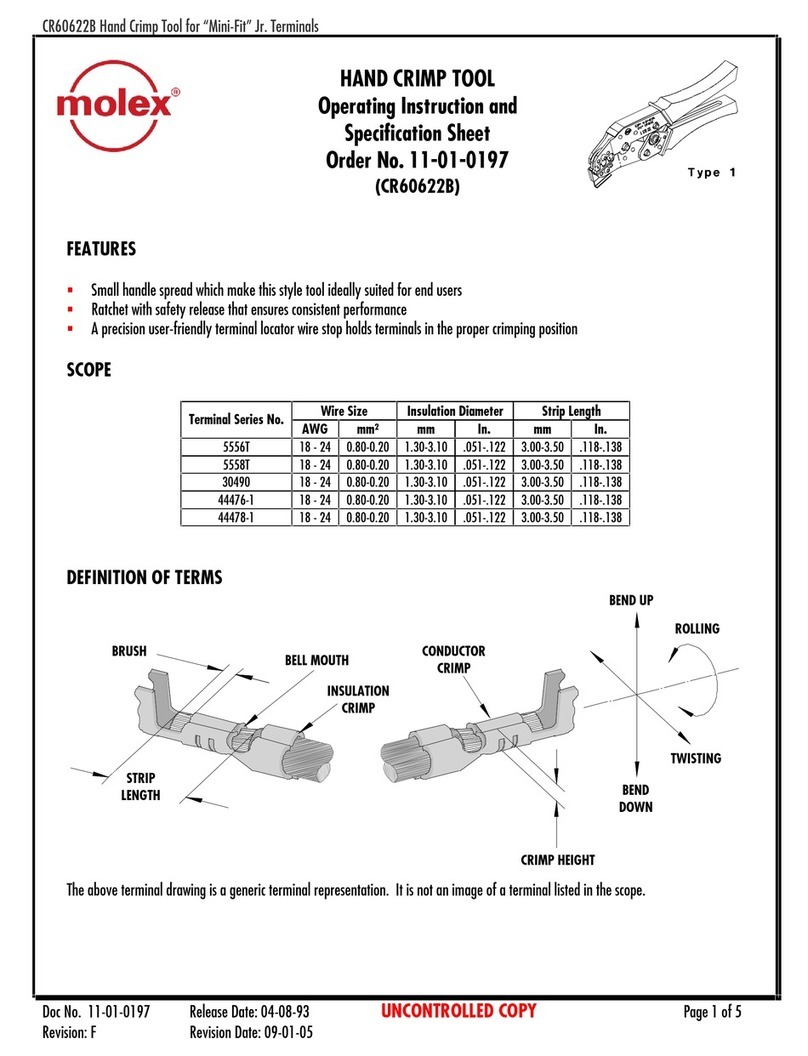

80 Ton Cylinder Assy (100663)

31

2

10

11

6

5

7

8

9

14

13

12

COMPONENT PARTS BREAKDOWN

18Page

1101435 1 Gallon Reservoir 1

1101336 2 Gallon Reservoir 1

2 101358 015 Buna 70 O-Ring Seal 4

3 101432 Reservoir Standoff 4

495462A525 1/2-20 Hex Nut 4

5 101395 1HP/2HP Pump Sub-Assembly 1

6 101470 Square Shaft Key 1

7 116259 1HP Electric Motor 1

7 116260 2HP Electric Motor 1

8 101338 3/8-16 x 7/8 SHCS 4

9 101339 1/4-20 x 1/2 SHFCS 10

10 101377 3/8-18 NPTF Pipe Plug 1

11 101378 3/8-18 NPT Shipping Plug 1

12 101341 3/8-18 NPT Vented Filler Cap (Shipped Loose) 1

13 101438-110 110V Electrical Enclosure 1

13 101438-220 220V Electrical Enclosure 1

14 91251A540 1/4-20 x 3/4 SHCS 2

15 90126A029 1/4 Flat Washer 4

16 90675A029 1/4-20 KEPS Nut 2

Pump Assembly (101633)

Item Part Number Description Qty

7

16

13

611 9

10

5

12

8

4

2

3

1

14

15

COMPONENT PARTS BREAKDOWN

110V1 HPPUMP

19Page

Motor Gasket 1 121300

5 101329 Reservoir Gasket 1 121305

6 101400 Upper Plate 1 151300

7 101375 1/16-27 NPTF Pipe Plug 5

8 9528K15 Ø1/4" Precision Ball 2 350301

9 101340 1/4-20 X 2 1/4 Serrated Hex FLHCS 4 345307

10 101477 Lower Plate & Gear Pump Ass'y. 1 200467

11 101406 Wear Washer 2 364300

12 101425 Eccentric - 5/8" Shaft 1 190300

13 101473 Bearing Sleeve Assembly 1 349200

14 101382 1/8 X 3/8 Dowel Pin 4 342301

15 101478 Piston Block Assembly 2 200215

16 101352 010 O-Ring 4354313

17 101476 Unloading Block Assembly 1 200346

18 101355 014 Disogrin O-Ring 3 354302

19 101443 Dump Block Assembly 1 200203

20 92323A525 1/4-20 X 2" Serrated Hex FLHCS 8 345306

21 101385 1/4-20 X 2 1/2 Serrated Hex FLHCS 4345308

22 101328 CR-6247 Shaft Seal 1 355303

Item Part Number Description Qty Ref. Part No.

1 HP/2 HP Pump Sub-Assembly (101395)

414 122

5

6

11 15

16

12

13

11 10

21

20

20

19

2

9

8

17

18

7

7

3

1 101335 Reservoir Cover 1 132301

2 101337 Port Block Gasket 1 121304

3 101584 Port Block Assembly 1

4 101330

COMPONENT PARTS BREAKDOWN

20Page

Driver Shaft - 5/8 1

10 101379 Retaining Ring 4

11 98381A470 1/8 X 3/8 Dowel Pin 2

12 101361 Gear - 5/8 2

13 101410 Center Gear Plate - 5/8 1

14 101409 Lower Gear Plate 1

15 BA88ZOHX Needle Roller Bearing 2

16 4534K42 1/4-18 NPTF Pipe Plug 1

17 92316A552 1/4-20 X 2 1/2 Hex Flg. Hd. Screw 4

18 101419 Screen 1

19 90272A827 10-32 X 3/8 Phillips Pan Hd. Mach. Screw 2

Item Part Number Description Qty

Lower Plate & Gear Pump Assembly (101477)

1

2

3

4

5

6

7

8

10 11

12

9

10

10

11

12

10

13

15 14

16

17 18

19

1 101401 Lower Plate - 2 Piston 1

2 101466 Intake Seat Assembly 2

3 9528K11 Ø 1/8 Precision Ball 2

4 101447 Ball Retainer 2

5R10 - Open 5/8 Ball Bearing 1

6 4534K39 1/16-27 NPTF Pipe Plug 1

7 98381A510 3/16 X 1 Dowel Pin 2

8 101446 Idler Shaft - 5/8 1

9 101426

COMPONENT PARTS BREAKDOWN

Table of contents

Other DAYCO Crimping Tools manuals

Popular Crimping Tools manuals by other brands

molex

molex 64001-2800 Operating Instruction Sheet And Specifications

Emerson

Emerson Klauke EKM 60IDISM manual

Emerson

Emerson Klauke EK 60VPCFM manual

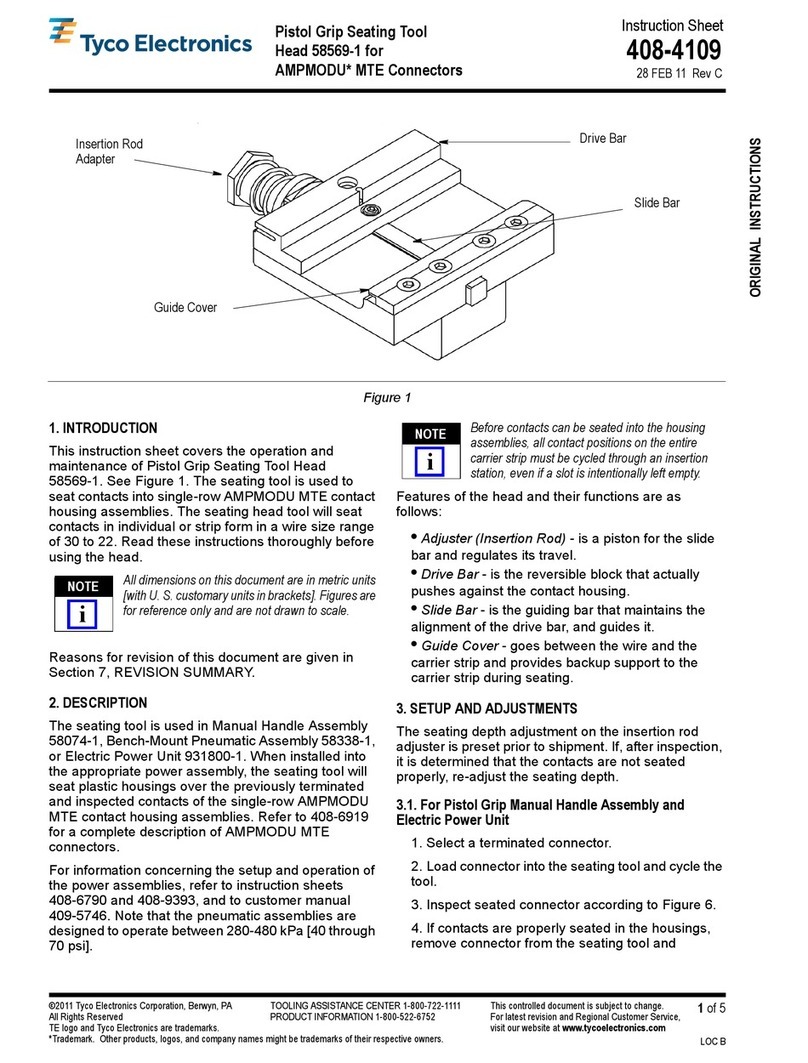

Tyco Electronics

Tyco Electronics 58569-1 instruction sheet

Danfoss

Danfoss FT1330 Operator's manual

MM Kembla

MM Kembla KemPress KPSA2 Design & installation guide