DAYCO D165DC User manual

1Page

D165DC DAYCO

OPERATORS MANUAL

2Page

WARNING - SAFETY NOTE

IMPORTANT - DO NOT OPERATE THIS EQUIPMENT UNTIL YOU READAND FULLY

UNDERSTAND THIS MANUAL AND ITS ASSEMBLY INSTRUCTIONS

ALWAYS WEAR EYE PROTECTION

WARNING!!

!!

! USE ONLY THOSE HOSE AND COUPLING COMBINATIONS AND

CRIMPING EQUIPMENT SPECIFIED IN DAYCO HYDRAULIC PUBLISHED

LITERATURE. DAYCO RECOMMENDATIONS ARE BASED ON TESTING,

AND USE OF HOSE AND COUPLING COMBINATIONS OTHER THAN

THOSE RECOMMENDED BY DAYCO CAN RESULT IN SERIOUS INJURY,

DEATH OR SUBSTANTIAL PROPERTY DAMAGE. DAYCO DISCLAIMS ALL

LIABILITY FOR ANY HOSE AND COUPLING ASSEMBLY THAT IS NOT MADE

ACCORDING TO DAYCO RECOMMENDATIONS. CONSULT YOUR LOCAL

DAYCO REPRESENTATIVE OR DAYCO DISTRIBUTOR IF YOU HAVE ANY

QUESTIONS.

file: D165DC/D160D-DC MarkIV Manual(Rev 10/27/2005).pmd

3Page

TABLE OF CONTENTS

D165DC

Parts Identification-----------------------------------------------------------------4

D165DC Quick Start Guide-----------------------------------------------------5

Hose Preparation-------------------------------------------------------------------6

Hose Crimping-Standard Dies--------------------------------------------------7

Calibration--------------------------------------------------------------------------10

Troubleshooting -------------------------------------------------------------------11

Kwikrimp® Concept-------------------------------------------------------------12

Parts Breakdown-----------------------------------------------------------------13

Limited Warranty-----------------------------------------------------------------18

4Page

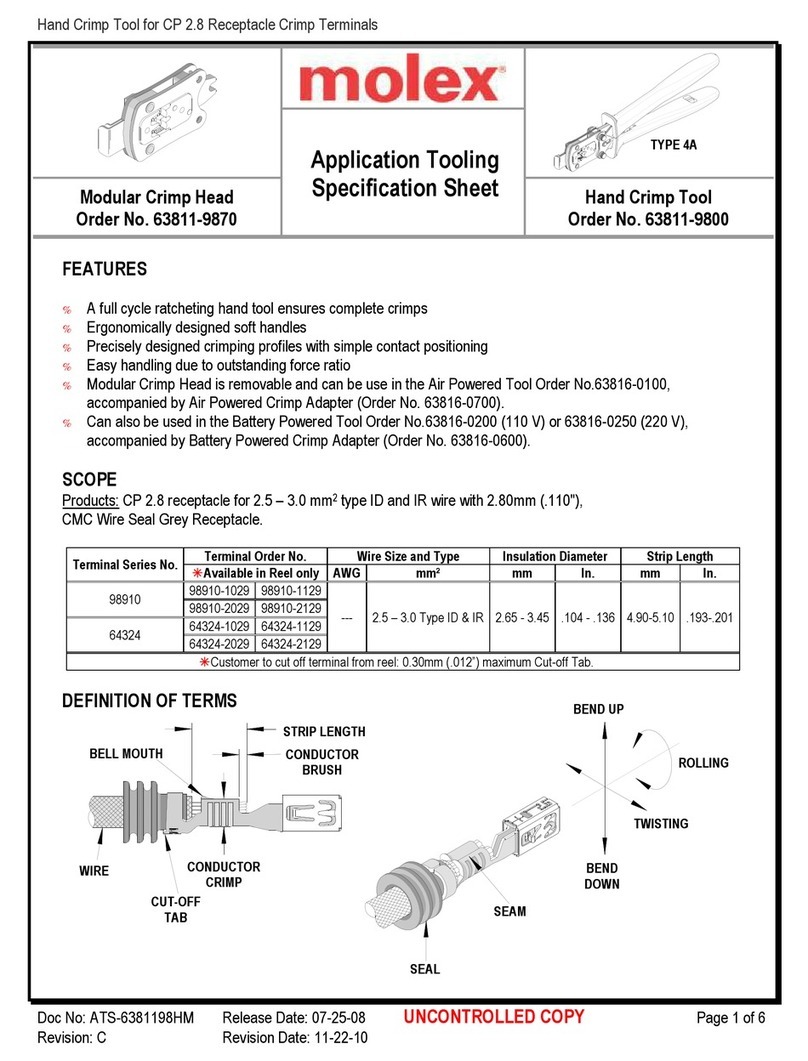

D165DC PARTS IDENTIFICATION

10,000 PSI PUMP

1HP, 110V-15 AMP MOTOR

60 TON HYDRAULIC

CYLINDER

OIL FILLAND

VENT PLUG

ADJUSTABLE RAM

RETRACTION STOP

MICRO-CRIMP

ADJUSTER

CALIBRATION

ADJUSTMENT

SCREW

MANUAL PNEUMATIC

START-STOP SWITCH

AUTOMATIC STOP

SWITCH

STANDARD DIE

SET

PRESSURE PLATE

POWER ON/OFF

CIRCUIT BREAKER

SWITCH

COMPPRESSION

RING

5Page

D165DC QUICK START GUIDE

CALIBRATION CHECK FOR THE D165DC

(See the following page for D160S-DC Calibration)

PLUG THE CRIMPER DIRECTLY INTO A 110 VOLT 20

AMP SINGLE PHASE WALL OUTLET.

DO NOT USE AN EXTENSION CORD OR RUN FROM

PORTABLE POWER SOURCES AS LOW VOLTAGE CAN

DAMAGE THE MOTOR.

THE OIL LEVEL IN THE PUMP SHOULD BE APPROX.

1 1/2 INCHES BELOW THE FILLER/VENT PLUG.

PLACE THE STANDARD PRESSURE

PLATE, ANY STANDARD DIE SET AND THE

STANDARD COMPRESSION RING IN THE

BASE OF THE CRIMPER IN THE ORDER

SHOWN.

SLIDE THE PUSHER ONTO THE

STUD OF THE HYDRAULIC RAM.

SET THE MICRO-CRIMP ADJUSTER

AT “95”.

PRESS AND HOLD THE START SWITCH.

IF THE RAM EXTENDS AND SHUTS OFF THE MOTOR

IN APPROXIMATELY ONE SECOND AFTER THE PUMP

STARTS TO BUILD PRESSURE, (THE SOUND OF THE PUMP

WILL CHANGE) AND THE DIE SET IS FULLY CLOSED, THE

CRIMPER IS CORRECTLY CALIBRATED.

IF THE TIME TO SHUT OFF IS NOT APPROXIMATELY

1 SECOND, THE CRIMPER MUST BE RECALIBRATED. SEE

INSTRUCTIONS.

FOLLOW THESE STEPS BEFORE YOU USE YOUR

CRIMPER FOR THE FIRST TIME

CALIBRATION CHECK PROCEEDURE

6Page

HOSE PREPARATION

Dayco recommends that all users familiarize themselves with Dayco’s warning

statements, SAE J1273, and the Kwikrimp® concept, found in this operator’s manual.

Select the Dayco hose and coupling to be assembled.

Determine the correct crimp

setting from the crimp specifications

sheet.

Determine hose cut length

by subtracting the cutoff factor for

each coupling from the overall

length of the assembly. For these

cutoff factors, see Dayco’s

published catalog data.

Cut the hose square and to the proper length with a suitable saw.

Coat the coupling stem with Dayco hose assembly lubricant (HAL16) to ease hose

insertion. Insert the hose until it “bottoms” in the coupling shell.

To insure that the hose is bottomed in the collar, mark the insertion depth on the hose

before inserting it into the coupling (see figure below).

Using a clockwise twisting motion or fixing the hex on the coupling in a vise may help when

tolerances are tight.

7Page

D165 SERIES HOSE CRIMPING

CRIMPING PROCEDURE

Insert the Standard Pressure Plate in the bottom flange making

certain that the Pressure Plate is seated squarely in the bottom flange.

Make certain that the seating area of the bottom flange is clean and

allows the Pressure Plate to seat squarely in the bottom flange

Select the correct die set for the combination of hose and fitting

being crimped.

The number etched on the die ring represents the fully closed diameter

of the die set in either inches or millimeters depending upon the die

set.

Lubricate the contact surfaces of the die fingers and the

Compression Ring with the die lubricant furnished with the crimper.

Failure to lubricate the contact surfaces with the correct lubricant

can cause the dies to seize in the compression ring.

Align the hose and fitting in the die set. If the fitting has knurl

marks, align as shown. If there are no knurl marks on the fitting,

obtain the correct crimp length from the crimp specification chart and

mark the fitting at the proper point.

CAUTION: The notches on the die set must be

completely covered by the Compression Ring prior

to starting the crimp. If the notches are visible,

you must go to a larger die set. Crimping with

an incorrect die size could result in personal

injury

8Page

D165 SERIES HOSE CRIMPING

Position the dies in the crimper as shown making certain that

the die rings set squarely on the pressure plate and that the die ring

halves do not overlap each other.

Align the hose and fitting in the die set and place the

Compression Ring loosely over the die set. Manually depress the

compression ring until the fitting is held loosely in the die set.

Select the proper crimp setting from the Crimp Specification

chart and set the Micro Crimp adjuster at the setting recommended.

Note: Each die set has a limited range of diameters for which a

satisfactory crimp can be obtained. As a “rule of thumb” a standard

die set can crimp 3 mm (.120 inches) above the closed diameter etched

on the die ring. Always consult the hose and fitting manufacturer’s

recommendation for the correct die set to use.

9Page

D165 SERIES HOSE CRIMPING

COUPLING STOP RAM RETRACTION STOP

Slide the Pusher into position on the hydraulic ram

Recheck the fitting for correct alignment and depress the

pneumatic Start/Stop switch bulb. Keep it depressed until the crimper

shuts off automatically.

Measure the finished fitting diameter to be certain that it is

within the crimp specification tolerances.

If multiple fittings are being crimped set the Coupling Stop to

automatically position the fitting and set the Ram Retraction Stop to

limit the ram retraction to the position where the hose and fitting can

just be easily removed.

Magnets embedded in the Pusher will retract the Compression Cone

with the Pusher while still permitting the Compression Cone to align

correctly for the next crimping operation.

10Page

CALIBRATION PROCEDURE

When the crimper is correctly calibrated, the ram will extend and fully

close the die set. After the die set is fully closed, the time from which

the pump starts to build pressure and the point at which the motor

shuts of automatically will be approximately 1 second.

Many problems associated with incorrect crimp diameters are caused

by incorrect calibration.

CALIBRATION

Insert the Standard Pressure Plate, any die

set, and the compression ring in the order

illustrated.

Set the Micro-Crimp adjuster at “95”

Press and hold the start Switch

If the ram extends closing the dies to their fully closed position

and the motor shuts off approximately 1 second after the pump starts

to build pressure (the sound of the pump will change), then the crimper

is correctly calibrated.

If the crimper requires re-calibration, hold the

micrometer barrel with a 5/16 inch open end wrench and

rotate the stem either in or out with a 5/32 inch hex key.

If the time from which the pump starts to build pressure is

greater than approximately 1 second, rotate the stem out

slightly.

If the time is less than approximately 1 second, rotate the

stem in slightly.

Recheck calibration.

11Page

TROUBLESHOOTING

PROBLEM: CRIMPER WILL NOT RUN AT ALL

The white rocker switch is also a circuit breaker. Check to see that the circuit breaker has

not been tripped

Check the wall outlet. The crimper comes from the factory wired for a 110 volt single phase

circuit. .Use of extension cords or outlets with inadequate power can damage the motor . Do

not run the crimper from a portable power source.

Check the stop switch mounted to the switch bracket under the Micro-Crimp Adjuster. This

is a normally closed switch and if it does not close the crimper will not operate.

CAUTION: Do not operate the crimper with this switch jumpered as the pump will not shut off

and the brackets can be damaged.

Check the pneumatically actuated switch in the electrical box mounted on the motor. This

switch controls power to the motor and is actuated with air pressure from the bulb on the end of

the hose going into the box

PROBLEM: CRIMP DIAMETER TOO LARGE

Check crimper calibration and re-calibrate if required.

Incorrect die being used. Each die has a range of approximately 3mm (.120 in) above the

closed diameter of the die. The closed diameter is the die size stamped on the die ring.

Incorrect setting of the Micro-Crimp Adjuster. Check hose manufacturer’s specifications.

Inadequate pump pressure. Check oil level in the pump. It should be 1-1/2 to 2 inches below

the fill plug. Replenish with ISO Viscosity Grade 46 hydraulic oil.

Inadequate lubrication of the dies and compression ring causing the pump to work harder

than normal to reach the required diameter.

Inadequate pressure being generated by the pump. This is most likely if the crimper can

crimp the smaller size hoses and not the larger hoses. When correctly adjusted, the pump should

generate approximately 10,000 psi.

Do Not adjust pump to produce in excess of 10,000 psi as damage to components or personal

injury may result

No pressure being generated by the pump. There should be a definite change in pitch of the

pump as it cycles into high pressure mode and begins to “work” harder.

PROBLEM: CRIMP DIAMETER TOO SMALL

Check crimp diameter and re-calibrate if necessary

Incorrect die being used (See die range under Crimp Diameter too Large)

Incorrect setting of the Micro-Crimp Adjuster. Check hose manufacturer’s specifications.

PROBLEM: DIES STICKING IN COMPRESSION RING

Inadequate lubrication of the compression ring and die surfaces.

12Page

KWIKRIMP® CONCEPT

THE KWIKRIMP® CONCEPT IS AN ENGINEERED PROGRAM, DESIGNED TO

INCORPORATE DAYCO HOSE, FITTINGS AND CRIMPERS INTO ONE EFFECTIVE AND

RELIABLE HOSE ASSEMBLY SYSTEM.

The Kwikrimp® Concept is an affirmation to all Dayco Distributors, OEMs and users of the

Kwikrimp® system that Dayco will support only those who use Dayco hose and couplings in the

Kwikrimp® assembly system. However, the Kwikrimp® Concept is also a statement that serves to

warn that Dayco will not be responsible when interchanging a Dayco hose and/or couplings with

hose and/or couplings of any other manufacturer. Dayco products are part of an engineered

system, which must be assembled and used in accordance with Dayco instructions and limitations.

Dayco hose, couplings and crimping machines are designed into an effective and reliable assembly

system and the use of other than Dayco products may produce hose assemblies that will not meet

rated performance. Failure to follow Dayco instructions and limitations could lead to premature

hose failures resulting in property damage, serious injury or death.

Dayco’s limited warranty shall apply only if the customer uses hose, fittings, hose fitting

components and crimp equipment specifically engineered, designed and produced to Dayco

process specifications.

DAYCO DISCLAIMS ANY RESPONSIBILITY OR LIABILITY FOR ANY CRIMPED HOSE

ASSEMBLIES NOT PRODUCED FROM GENUINE DAYCO HOSE FITTINGS, HOSE AND

EQUIPMENT, IN CONFORMANCE WITH DAYCO PROCESS SPECIFICATIONS FOR EACH

SPECIFIC HOSE ASSEMBLY.

The argument that hoses branded with identical SAE numbers are the same and can be

interchanged with Dayco couplings is not true! Hose with identical brand can be expected to

perform only to the requirements of SAE when assembled with compatible couplings. SAE

recognizes this fact as shown by the following statement taken from the 1998 SAE Handbook,

J1273, Volume 2, and page 22.198.

3.10 Proper End Fitting – Care must be taken to insure proper compatibility exists between

the hose and coupling selected based on the manufacturer’s recommendations substantiated by

testing to industry standards such as SAE J517.

All Dayco distributors, OEMs and Kwikrimp® users must recognize that the following points are

critical when considering any and all aspects of the Kwikrimp® program.

1. The data supplied with each Crimper was developed after extensive impulse testing with

Dayco hose and couplings. All Dayco hose styles are tested with the proper Kwikrimp® couplings

before they are added to the Dayco Approved List. Dayco is constantly checking and upgrading

hose quality.

2. Dayco Kwikrimp® data does not apply to all hose and couplings, only those products

bearing the Dayco identification with the proper Dayco catalog number.

Dayco couplings used with other than Dayco branded hose will not necessarily produce a good

assembly. Identical hose styles, made by different suppliers, are not the same when it comes to

performance with Dayco couplings.

13Page

1

2

43

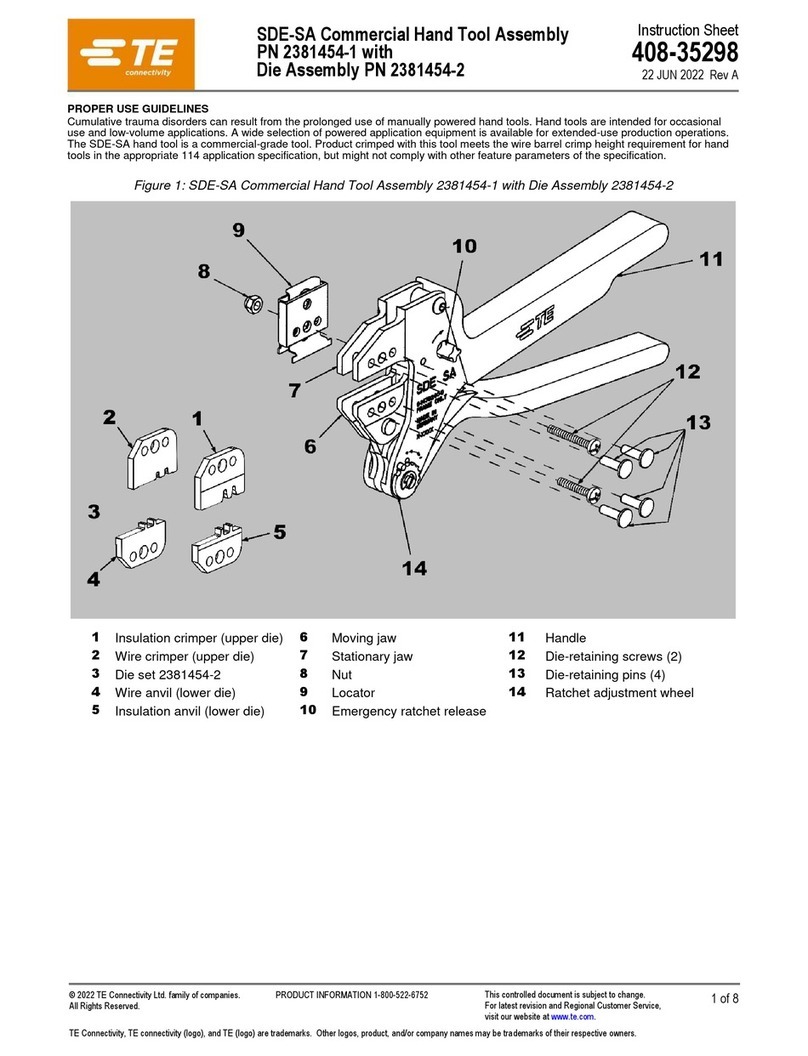

COMPONENT PARTS BREAKDOWN

D100 Standard Series Dies

1) Die Ring 101065-COLOR

2) Die Finger Varies with die set

3) Die Spring LC 022D 01 M NF

4) Die Screw EN84-115

Color Options

Red

Orange

Yellow

Purple

Green

Blue

Black

Silver

Brown

14Page

2

26

345

12

10

8

9

10

25

6

15

23

24

22

13

192021

18

16

17

14

11

910

7

1

1101430 D165 Base Plate 1

2101633 Pump Assembly 1

392865A540 1/4-20 x 3/4 HHCS 4

491102A029 1/4 Lock Washer 4

590126A029 1/4 Flat Washer 4

6102161 D165 Crimper Head Assembly 1

7101429 Crimper Head Mounting Bracket 1

892865A626 3/8-16 x 1 1/4 HHCS 2

991102A031 3/8 Lock Washer 4

10 90126A031 3/8 Flat Washer 6

11 92865A623 3/8-16 x 7/8 HHCS 2

12 95462A031 3/8-16 Hex Nut 2

13 102160 Front Handle Assembly 1

14 92323A516 1/4-20 x 3/4 HHFCS 4

15 102222 Rear Handle Assembly 1

16 102052 Crimper Head Brace 2

17 91255A578 5/16-18 x 1/2 BHCS 2

18 91255A585 5/16-18 x 1 1/4 BHCS 2

19 95462A030 5/16-18 Hex Nut 2

20 91102A030 5/16 Lock Washer 2

21 90126A030 5/16 Flat Washer 2

22 60TA-06X08 45 Deg Swivel Fitting 1

23 102225 D165 High Pressure 1/2" Hose 1

24 60TA-08X08 45 Deg Swivel Fitting 1

25 100954 Coupling Stop Assembly 1

26 101349 Pneumatic Pendant Switch 1

D165 Crimper Assembly (102221)

Item Part Number Description Qty

COMPONENT PARTS BREAKDOWN

15Page

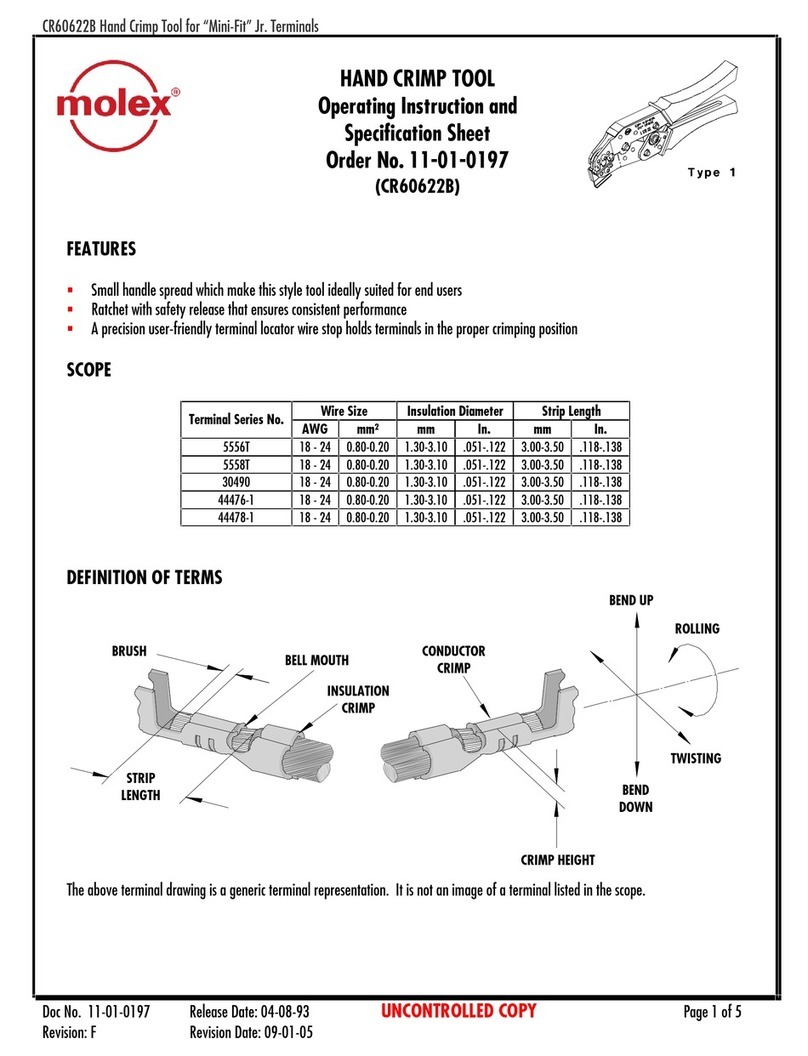

13

15

14

7

6

1

4

5

19

22

21

17

20

3

16

12

10

9

8

11

18

2

23

1 102219 60 Ton Cylinder / Top Flange 1

2102212 Strain Rod 4

3102159 Bottom Flange 1

47/8 Special 7/8 Narrow Rim Washer 4

590499A845 7/8 - 14 Hex Nut 4

6102224 Retraction Stop Rod 1

7KHA-126 Stop Rod Locking Handle 1

8102220 Micrometer Mount Assembly 1

9100812 Pusher Retaining Disc 1

10 91253A624 3/8-16 x 1 HSFHCS 1

11 100628 Standard Micrometer Assembly 1

11 101489 DC Micrometer Assembly 1

11 101587 Metric Micrometer Assembly 1

12 100727 Micrometer Nut 1

13 100825 Pusher With Magnets 1

14 102211 Pressure Plate 1

15 102213 Compression Cone 1

16 101092 Limit Switch Bracket 1

17 903 Switch Limit Switch 1

18 91255A537 1/4-20 x 1/2 BHCS 2

19 100692 Limit Switch Guard 1

20 91255A190 8-32 x 1/4 BHCS 2

21 95630A237 #6 Teflon Washer 2

22 102218 Die Retaining Clip 2

23 91251A146 6-32 x 3/8 SHCS 2

D165 Crimper Head Assembly (102161)

Item Part Number Description Qty

COMPONENT PARTS BREAKDOWN

16Page

1102158 60 Ton Body / Top Flange 1

2100651 60 Ton Piston 1

3227-9250 227 Disogrin O-Ring 1

4101106 Piston End Cap 1

591251A424 3/8-24 x 1 SHCS 6

6100760_12 60 Ton Spring 1

7100653 Spring Plug 1

8F1-POM-3.75X4.00X0.375 3.75 x 4.00 x 0.375 Wear Ring 2

93500-4000-0375 POLYPAK 3.50 x 4.00 x 0.375 Polypak 1

10 93744A160 3/8 Copper Flat Washer 1

11 91251A633 3/8-16 x 2 1/4 SHCS 1

12 SH940-35 375 Ram Wiper 1

13 102169 60 Ton Retaining Ring 1

60 Ton Cylinder / Top Flange Assembly (102219)

Item Part Number Description Qty

12

13

8

5

4

3

2

9

8

6

7

111

10

1

5

4

2

3

1102214 Micrometer Suspension Flange 1

2102217 Micrometer Brace 1

3102215 Micrometer Base Bracket 1

491253A194 8-32 x 1/2 HSFHCS 4

598296A245 3/16 Dia. x 1/2 Spring Pin 1

D165 Micrometer Mount Assembly (102220)

Item Part Number Description Qty

COMPONENT PARTS BREAKDOWN

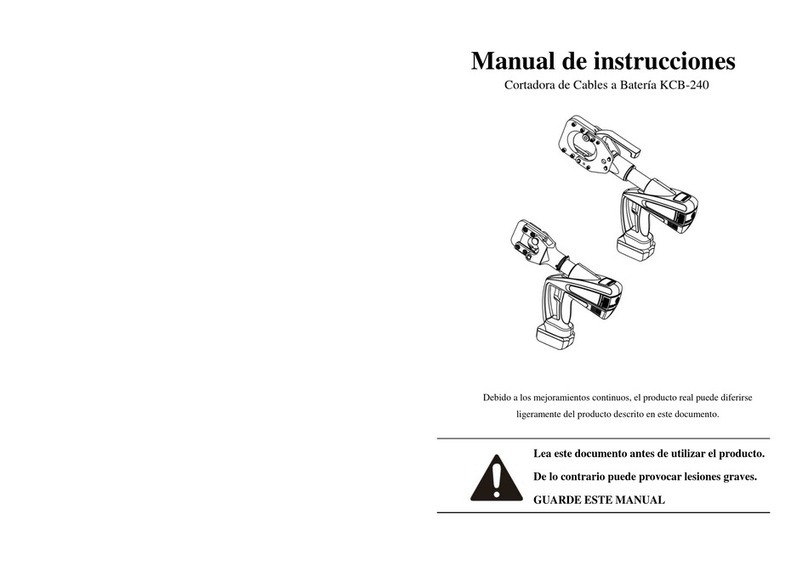

17Page

1

11 94052A133 Push-On Cap 1

Item Part No. Description Qty

Coupling Stop Assy (100954)

11

10

5

4

6

7

8

9

2

4

1

3

1 100950 Coupling Stop Block 1

2 98381A544 Stop Block Pin 2

3 100951 Stop Block Rod 1

4 91251A540 1/4-20 X 3/4 SHCS 2

5 9489T47 Eye Bolt 1

6 100952 Adjustable Stop Arm 1

7 DK-655 Knob 1

8 100953 Fixed Stop Arm 1

9 94750A588 T-Nut (1/4-20) 1

10 90126A029 1/4 Flat Washer

COMPONENT PARTS BREAKDOWN

18Page

LIMITED WARRANTY

D165 SERIES is warranted to be free from defects in material and workmanship under normal

operating conditions and recommended usage for a period of ninety (90) days from date of

delivery. Any product which is shown to be defective shall be replaced or repaired free of charge

or extended a credited refund of the original acquisition cost to purchaser. This limited warranty

is contingent upon the conditions that prompt receipt of notice of any defect, that purchaser

establish the product has been property installed, maintained, and operated within the limits of

related and normal usage as specified, and that upon request purchaser will return the defective

product.

The terms of this limited warranty do not in any way extend to any product or part which have a

life, under normal usage, inherently shorter than ninety (90) days.

THESE LIMITED WARRANTIES TO REPAIR OR REPLACE DEFECTIVE PRODUCTS AS

SET FORTH ABOVE AND ANYADDITIONAL WARRANTY EXPRESSLY STATED TO BE A

WARRANTYAND SET FORTH IN WRITINGARE IN LIEU OFALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FORA PARTICULAR USE OR

PURPOSE.

PURCHASER’S SOLE AND EXCLUSIVE REMEDY PURSUANT TOANY CLAIM OFANY

KIND, INCLUDING BUT NOT LIMITED TO,A CLAIM IN CONTRACT, WARRANTY,

NEGLIGENCE OR STRICT LIABILITY, SHALL BE (a) THE REPAIR OR REPLACEMENT

AT THE OPTION OFTHE MANUFACTURER OF DEFECTIVE PRODUCTS OR (b) A

CREDITED REFUND OF THE PRICE OF THE DEFECTIVE PRODUCT OR PART IF THE

PRODUCT OR PART IS UNABLE TO BE EFFECTIVELY REPAIRED, REPLACED OR

CORRECTED IN A REASONABLE TIME AFTER USING BEST EFFORTS. CLAIMS OF

ANY KIND INCLUDE BUT ARE NOT LIMITED TO THOSE FOR ANY LOSS OR DAMAGE

ARISING OUT OF, CONNECTING WITH, OR RESULTING FROM THE DESIGN,

MANUFACTURE, SALE, DELIVERY, RESALE, INSTALLATION, TECHNICALDIRECTION

OF INSTALLATION, INSPECTION, REPAIR, OPERATION OR USE OFANY PRODUCT OR

PART. IF, HOWEVER, ANY WARRANTIES ARE EXPRESSLY SET FORTH IN WRITING IN

ADDITION TO THOSE SET FORTH HEREIN, THE LIABILITY UNDER SUCH

ADDITIONALWARRANTY SHALLTERMINATE NINETY (90) DAYS FROM THE DATE OF

SHIPMENT TO PURCHASER.

UNDER NO CIRCUMSTANCES SHALLANY LIABILITY WHATSOEVER BE IMPOSED

FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, SUCH AS, BUT NOT

LIMITED TO, LOSS OF PROFIT OR REVENUE, LOSS OF USE OF THE PRODUCT, COST

OF CAPITAL, COST OF REPLACEMENT EQUIPMENT, OR CLAIMS RESULTING FROM

CONTRACTS WITH THIRD PARTIES, UNLESS EXPRESSLY PROVIDED IN WRITING, IN

NO EVENT SHALLANY LIABILITY OR RESPONSIBILITY BE ASSUMED FOR

PENALTIES, PENALTY CLAUSES OR LIQUIDATED DAMAGES OFANY DESCRIPTION,

CERTIFICATIONS OR INDEMNIFICATIONS OF PURCHASERS OR OTHERS OR COSTS,

DAMAGES OR EXPENSES ARISING OUT OF OR RELATED TO THE PRODUCTS.

19Page

NOTES

Table of contents

Other DAYCO Crimping Tools manuals

Popular Crimping Tools manuals by other brands

molex

molex 64001-2800 Operating Instruction Sheet And Specifications

Emerson

Emerson Klauke EKM 60IDISM manual

Emerson

Emerson Klauke EK 60VPCFM manual

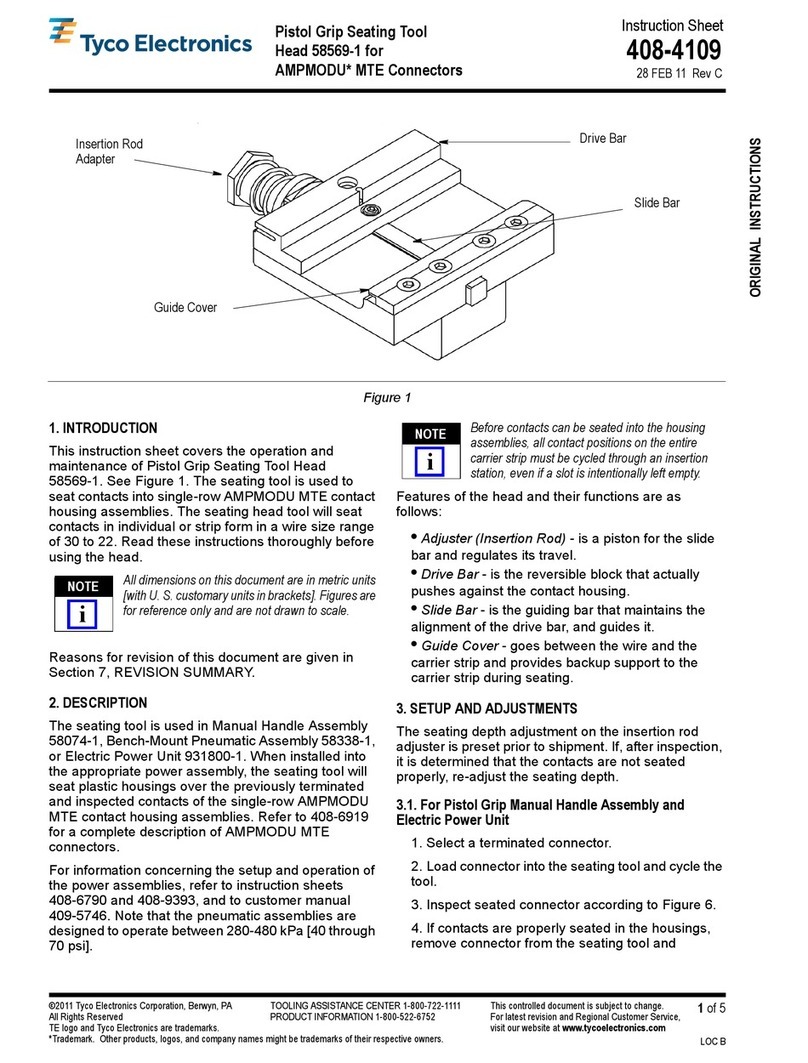

Tyco Electronics

Tyco Electronics 58569-1 instruction sheet

Danfoss

Danfoss FT1330 Operator's manual

MM Kembla

MM Kembla KemPress KPSA2 Design & installation guide