DAYLIFF ULTRASUN UFD Installation instructions

Installation &

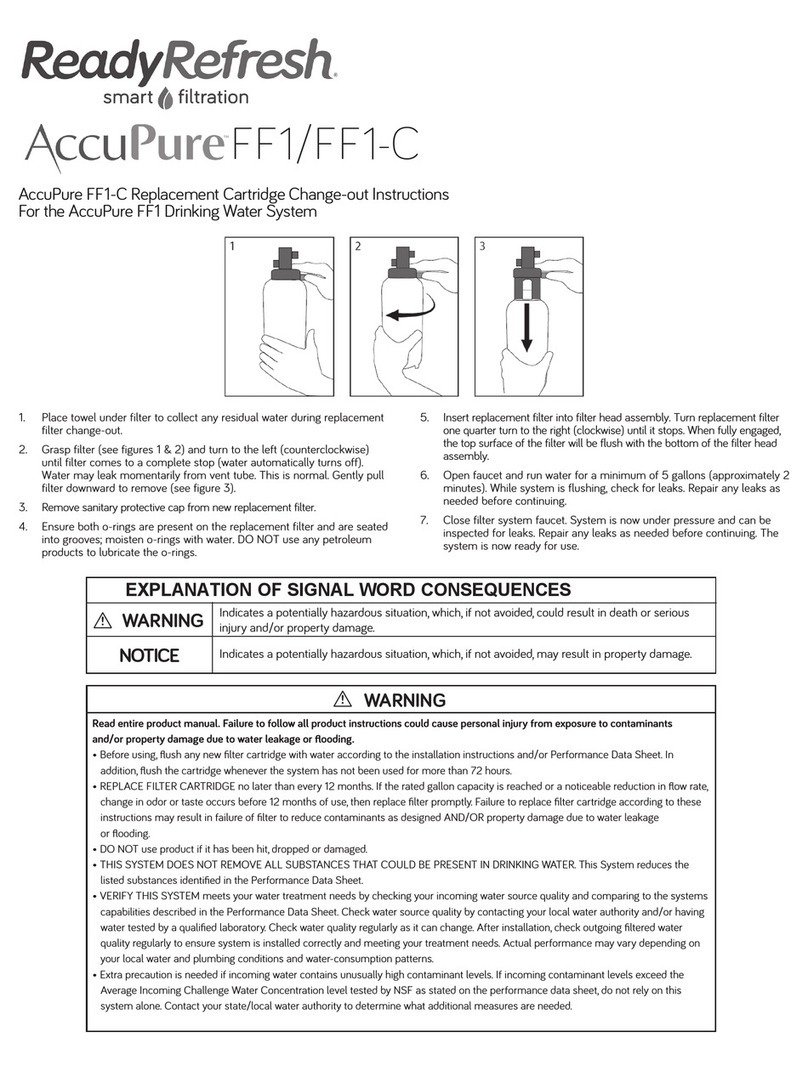

Operating Manual

ULTRASUN UFD

Flatplate Solar Systems

SPECIFICATIONS

1.

1

4.

SITING 5

INDEX

© Davis & Shirtliff Ltd 2020

Contents herein are not warranted

5.

INSTALLATION 6

6.

SYSTEM COMMISSIONING 7

7.

USAGE 7

8.

MAINTENANCE 7

9.

TROUBLE SHOOTING 8

10.

TERMS OF WARRANTY 10

3.

WARNINGS & SYMBOLS 3

2.

EQUIPMENT SPECIFICATIONS 3

1

1. SPECIFICATIONS

Ultrasun UFD Flatplate solar hot water systems are established and effective heaters that

provide excellent performance, good value and guaranteed long life. They are of Open

Loop thermosyphon type with the water flow circulating through the collectors and being

stored in the tank ready for use. Features include:-

• Heavy duty tank that features a resin insulated totally weather proof GRP casing, a

heavy duty galvanised cylinder internally piped to optimise hot water availability and

magnesium sacrificial anode for cathodic corrosion protection. An in-built 3kW

electric water heater with thermostat is included as standard.

• Solar collectors that incorporate full area copper absorption plates ultrasonically

welded to copper circulation tubes, high specification insulation and tempered

security glass to provide energy absorption of up to 95%.

• Low thermal conductivity high specification plastic collector tank connection piping

with silver foil coated polystyrene insulation jackets.

• Connection piping that includes an incoming non-return valve, a thermosyphon

0

diverter valve controlling max water temperature to 60 C to avoid scalding on hot

days, pressure release valve and drain cock. All fittings are provided from the inlet to

the outlet for simple installation.

• Galvanised mounting frame.

Ultrasun UFD Flatplate solar water systems are available in various tank sizes and collector

configurations to suit domestic and small scale institutional applications. They are effective

and robust products designed for many years of trouble free operation with a 5 year

guarantee to demonstrate the product quality. With the benefits of progressive design and

high quality components they are the ideal solution for all solar water heating applications.

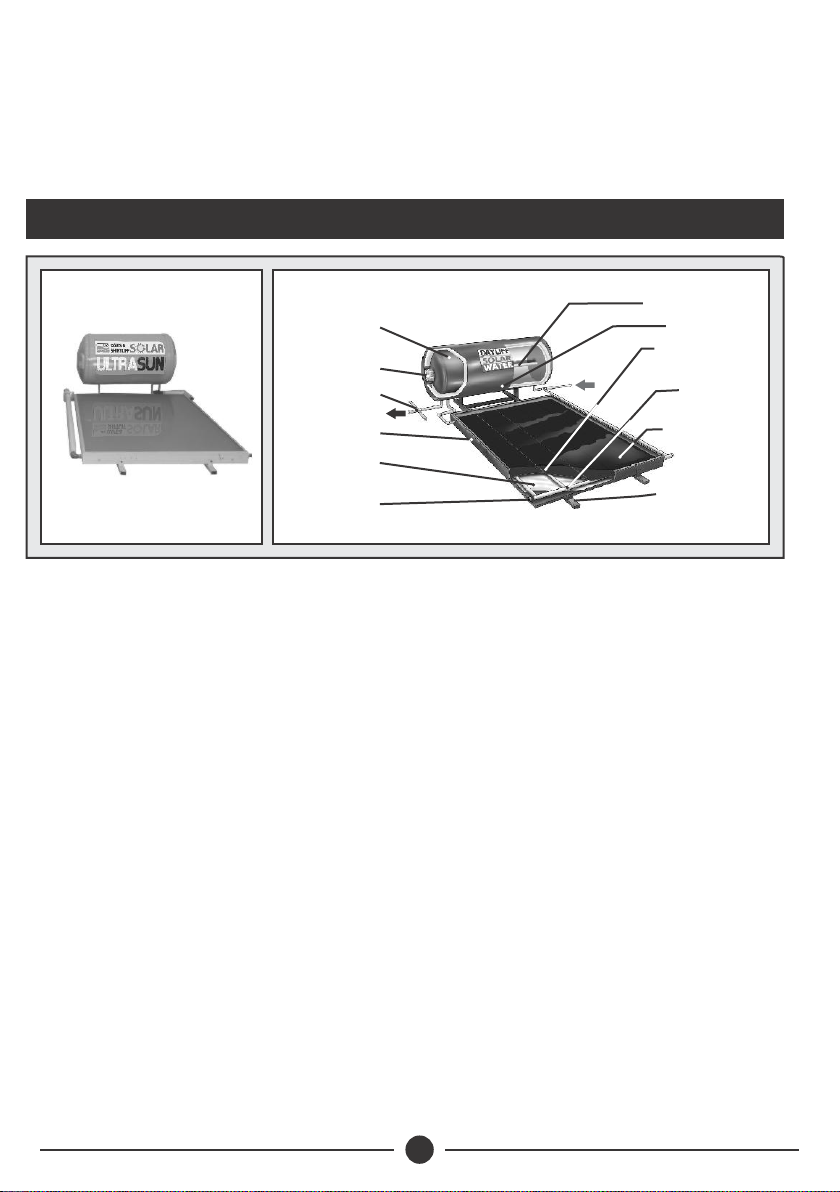

DESIGN FEATURES

Congratulations on selecting a Ultrasun UFD Flatplate Solar Hot Water

System. They are manufactured to the highest standards and if

installed and operated correctly will give many years of efcient and

trouble free service. Careful reading of this Installation Manual is

therefore important, though should there be any queries they should

be referred to the equipment supplier.

Magnesium anode bar

for corrosion protection

Elegant long life GRP resin

insulated tank casing

Copper riser pipes and

manifold tubes

High transmittance

tempered security glass

cover

Rigid galvanised rectangular

section mounting frame for

ease of installation

Screwed brass outlets

3kW electric booster

heater

High pressure galvanised

steel storage tank with internal

piping designed to optimise

hot water availability

Pure aluminium powder

coated frame

Outlet piped from hottest area

of tank with air bleed and

pressure release valve fitted

Multi layer internal

insulation including injected

polyurethane base coated

with mineral wool and covered

with aluminium foil

Full area black coated copper

absorber sheet ultrasonically

welded to the risers to

maximise heat transfer

OPERATING CONDITIONS

Water Quality: Water outside the following limits should be appropriately pre-

treated:

Direct: Clarity: Clear, TDS: <600mg/l, Hardness: <200mg/l CaCo , Saturation

3

Index: >0.8<1.0

Test Pressure: Tank - 5Bar, Collector -10Bar

Max Operating Pressure - 3.5Bar

3

Max Flow Rate - 2m /hr

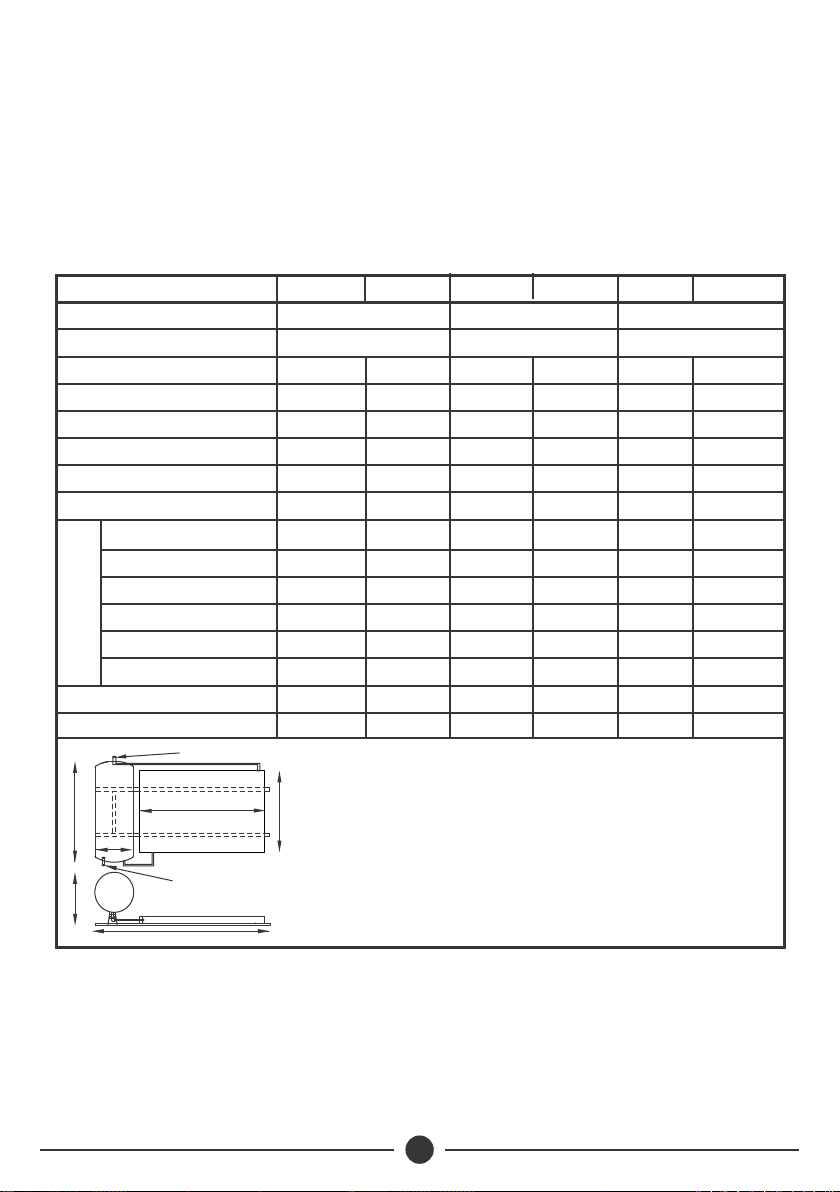

SPECIFICATIONS

Model

Typical Household (People)

Collector Model

UFD320DL

Max Heat Output/Day (kWhrs)

Collector Fluid Capacity (litres)

Min Heat Output/Day (kWhrs)

Collector Weight (kg)

3

Collector Area (m )

UFD160DS UFD220DL

5

160

1.7

1.2

9

1 X FCP1.7 2 X FCP1.7

25

6

UFD160DL

2.4

1.5

14

1 X FCP2.4 2 X FCP2.4

38

10

UFD220DS

7

220

2.4

1.5

14

38

10

3.4

2.4

20

50

14

10

320

4.8

3.0

29

76

19

System Tank Size (Litres)

1 X FCP3.01 X FCP2.4

UFD320DS

3.0

1.7

18

48

12

A

B

C

D

E

Full Weight (kg)

Empty Weight (kg)

Dimensions (mm)

F

800

1920

2620

2780

700

253

93

600

800

1890

2590

2780

700

270

110

600

800

1890

2590

2780

700

355

135

600

1760

1920

2620

2780

700

376

156

600

800

2440

3140

2780

700

490

180

600

1760

1890

2590

2780

700

534

214

600

2

A

D

C

B

Inlet 3/4” BSP

Outlet 3/4” BSP

F

E

NOTE

1. Standard output systems (S Models) should be used in hot locations and

high output systems (L Models) in more temperate ones. However hot

water availability will vary throughout the year depending on prevailing

irradiation levels and electric boosters may be necessary on cooler days.

2. Maximum heating output is based on average irradiation levels of

2

6000W/m /day prevailing in September - March and minimum Heating

2

output is based on average irradiation levels of 4000W/m /dayprevailing

in June/July and are for indicative purposes only.

33

Tanks are manufactured from galvanised steel plate and all have an in-built electric

booster heater and magnesium anode to prevent corrosion. They are encased in an

insulated fibreglass housing.

Collectors incorporate full area copper absorption plates ultrasonically welded to copper

circulation tubes which are enclosed in an insulated glass covered housing.

Heater systems are supplied complete with all piping connections including a bleed cock

and a pressure release valve at the tank outlet.

3. WARNING AND SYMBOLS

The installation of the solar system must be in accordance with

the relevant requirements of the local authority building

regulations as well as regulations for the prevention of

accidents when carrying out works such as solar installation. It

is necessary to do so in a safe and workman like manner,

taking due care of any aspects of the works that could result in

injuries to person in or about the building as well as workers,

passers by and the general public at large.

2. EQUIPMENT SPECIFICATIONS

The equipment supplied comprises of two principal components, the tank and the

collectors which are mounted together on a frame. The units work on the thermosyphon

principal whereby the temperature differential between the top and bottom of the system

creates water circulation thus facilitating the heating process. Two tank specifications are

available offering direct or indirect heating. Indirect heating uses a separate flow of pure

water through the collector which transfers heat to the service water through a jacket

around the storage tank. Indirect heating tanks are slightly less efficient though should be

used when the service water is highly mineralised. Tank layouts are shown below:-

34

These instructions describe mounting and installation of

thermosiphon solar water heaters. All installations must be

done by authorised people.

Installers must adhere to the valid work protection regulations,

in particular when working on the roof. Anti-fall protection

must be employed whenever there is a risk of falling.

To avoid the risk of being burned or scalded by hot

components, Installation and replacement of collectors or

parts should be done on cloudy days. Installation work on

sunny days should be carried out only in the morning or

evening or with the collector covered.

To avoid the risk of being burned or scalded by hot solar fluid

or components, fill and flush the solar system when the

collectors are cold. The collectors should be covered while

doing so.

Steam can escape from the expansion relief valve of the solar

pump unit if the system is shut down. To avoid injuries an

expansion relief valve must be connected to a collecting

container with a hose line

In order to ensure a seamless operation of the product, the

safety valve should be cleaned periodically and checked for

proper functions. In areas with very calcareous water the calk

residuals on the valve should frequently be cleaned off.

The product shall be installed in an area where children cannot

access.

Immersion heater is intended as standby device for water

heating and should not be used continuosly.

In areas with hard water hot water temperature should not

0

exceed 45 C to avoid calcification.

Work should be preceded by a risk assessment covering all

aspects of health and safety risks, or training requirements

that can reasonably be foreseen to be associated with the

work.

5

After the expiry of the guarantee period, if the magnesium

anode rod is worn out, the anode rod shall be replaced by a

new one in accordance with the instructions in the users’

manual.

4. SITING

Correct siting is critical for the effective operating of a solar water heater, the following

being important guidelines:-

l Orientate the principal axis of the units in a North/South direction, with the collector

facing the equator. This orientation is important to maximise sun exposure on the

collector as it tracks on its East /West axis throughout the day.

0

l Tilt at approx 15 . This is important as it optimises irradiation and also assists in the

thermosyphon process. Heater units should never be laid flat.

l Avoid any shade, especially between 10am and 4pm. Shade hugely reduces system

efficiency.

Preferably, solar panels should be installed on roofs where solar irradiation is highest and

they are also less exposed to damage. If this is not possible a protected ground sitting is

acceptable.

NORTH

EASTWEST

SOUTH

Hot Water OutCold

Water In

NORTH

EAST

WEST

SOUTH

Hot Water Out Cold

Water In

ORIENTATION OF SYSTEM

NORTH OF THE EQUATOR

ORIENTATION OF SYSTEM

SOUTH OF THE EQUATOR

This product is designed for water heating purposes using

solar energy and it may not be changed or modified in any

way. It should be installed by a qualified person, who should

observe the applicable local regulations and the building

code.

6

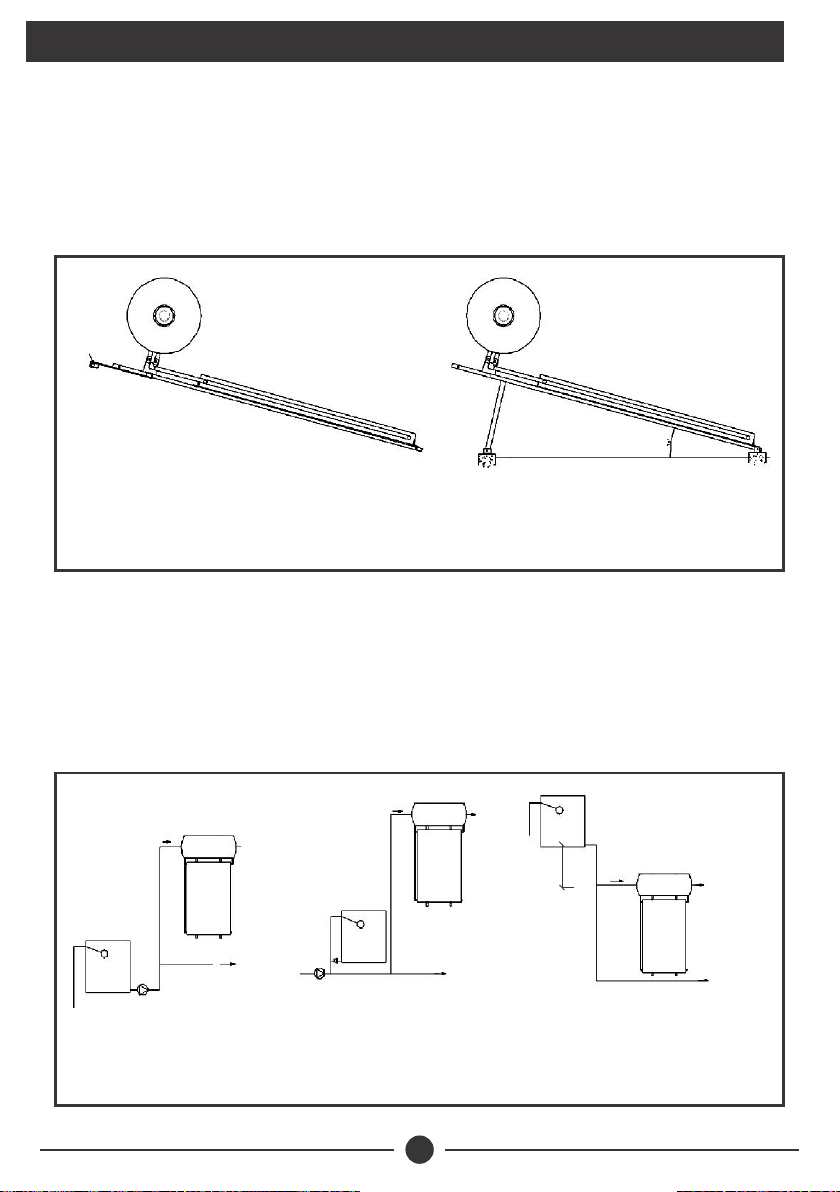

5. INSTALLATION

Ultrasun UFD solar heaters are provided with drilled frames incorporating a support cross

bar. On roofs the preferable mounting arrangement is by means of hooks affixed to the

cross bar and secured to an appropriate mounting point on the roof beams. Suspension

from the hooks is generally sufficient and fixed location is not necessary.

For ground installation rear support legs are available which should be mounted on small

concrete feet as shown below:-

ROOF INSTALLATION

TRUSS

GROUND INSTALLATION

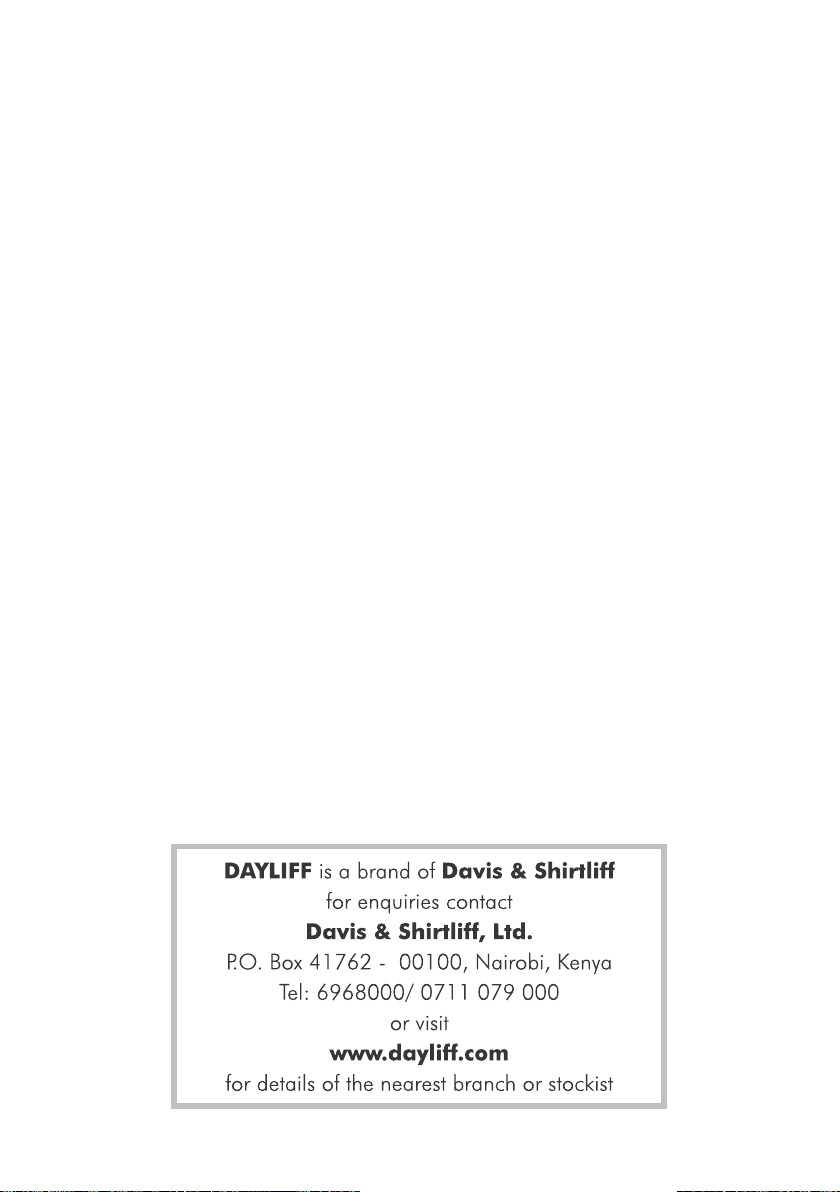

The units can be installed using a gravity system or pressurised supply. Pressurised systems

are preferable as they give higher line pressures up to a maximum of 3.5 Bar. Note that in

the case of pressurised supply hot and cold lines must be pressurised at the same pressure

to ensure even temperature control. The systems are easy to plumb being provided with two

piping connections only, the inlet and outlet. It is important to fit a non-return valve and

isolating valve on the inlet line. Suggested installation layout arrangements are shown

below:-

Cold In

Cold

Water

Supply

Hot

Water

Supply

Cold In Hot

Water

Supply

Cold

Water

Supply

Cold

Water

Supply

Hot

Water

Supply

Cold

In

Cold In

PUMPED SUPPLY

FROM TANK

DIRECT PUMPED SUPPLY

WITH COLD WATER STANDBY

HEADER TANK

GRAVITY SUPPLY

7

All units are fitted with 3kW electric booster heaters which should be connected to the

mains supply via 20A fuse or MCB by a qualified electrician. Manual control is suggested

with the switch mounted in a convenient place.

6. SYSTEM COMMISSIONING

a) Direct Systems

On installation or after service it is important that the system is primed. This is carried

out by first opening the incoming feed followed by the bleed cock and then observing

when all air is expended from the bleed outlet. Proper priming is important or else the

unit will not operate at full efficiency

b) Indirect Systems

As well as priming the service water as indicated above, it is important to fill the

heating system with pure water. Ordinary lowly mineralised tap or drinking water is

suitable and care must be taken to completely fill the collector and tank jacket. This is

done using the priming plug on top of the tank and carefully filling the unit until all air

is expended. It is also important to open the top collector bleed plug to ensure air

pockets are eliminated in the collection capillaries. Once primed, it is vital to ensure

that the system is properly sealed as fluid loss will render the system ineffective. The

system must therefore be thoroughly checked for leaks when operating and they must

be sealed accordingly.

7. USAGE

It is important that the hot water availability is properly managed as solar energy

heating only occurs between the hours of 9:00am - 4:00pm. This effectively means

that hot water is available in the evening as any draw off will result in temperature

reduction from the replacement cold water. If hot water is required in the morning

there should either be no night time draw off or the booster heater should be used.

Users should plan hot water usage accordingly.

8. MAINTENANCE

a) Direct Systems

Direct hot water system have no moving parts and are essentially maintenance free,

though periodically the collector glass cover should be cleaned as a dust layer will

reduce efficiency.

b) Indirect Systems

Indirect systems rely on the small volume of circulated heating water in the sealed

system and full efficiency is obtained only when it is fully charged with water. The units

must therefore be regularly checked, recommended on a monthly basis and any

leaked water replaced.

8

Periodically, recommended every three months a general inspection should be made

and the following items checked:-

l Collector condition, leaking unions, dirty or broken glass, damaged water seals.

l Tank condition including casing damage, piping leaks and valve operation.

l Electric heater power connections.

l Replace worn out magnesium anode periodically.

l Booster pump and pressure tank settings (if applicable).

l Check shading of collectors

Once a year, it is recommended to flush the collectors to remove any settled

sediments that may affect the thermosyphon flow.

9. TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Insufficient

hot water

High hot water usage at night Rotation use or replace with a larger

system

Prevailing weather conditions

Incorporate complimentary electric

heater to be used when irradiation

is low

Non-operation of electric booster Replace the electric heater

Air locks in the collectors Ensure tank connections are higher

than collectors connection

Slow leaks by system or pipe work

Pressure test the pipes

Visually inspect for leaks. Raise top

right hand corner on the system

Blockage in the connection pipes

Unblock then pipes

Collectors blocked with sediments

Flush collectors with clean water to

clear the sediments

Replace the blocked pipes

Incorporate a filter in the pipework

DIRECT SYSTEMS

9

INDIRECT SYSTEMS

POSSIBLE CAUSE SOLUTION

Heated water

loss Leaking water pipes Check regularly for leaks and repair

PROBLEM

Inoperative

electric heater

Power supply or booster switch off Switch on power or booster switch

Blown fuse Replace fuse

Tripped circuit breaker Switch on the breaker

Thermostat failure Replace the thermostat

Low thermostat setting Adjust the thermostat

Faulty electric element Check element circuit continuity and

replace the element if faulty

Water discharge

from pressure

release valve

Pressure above 3 bar Lift valve hand lever and reset valve

High mains pressure Use a pressure tank to regulate and

reduce pressure levels

Pressure is below specification settings Replace the valve if discharge

continues

Pressure feedback from another device

Check that there is no feedback

pressure from another device

connected to hot reticulation

circuit

Insufficient

pressure

Inlet water strainer blocked Unblock the strainer

Unit supply pipework blocked or

undersized

Unblock the pipe work

Replace with correct pipework

Mains supply pressure below 1 bar Consult supply authority for

modifications to the system

Pressure control valve flow insufficient

for user’s requirements

Install a large valve but should not

exceed rated tank pressure of 3.5

bar

10

10. TERMS OF WARRANTY

i) General Liability

ii) Standard Warranty

• In lieu of any warranty, condition or liability implied by law, the liability of Davis &

Shirtliff (hereafter called the Company) in respect of any defect or failure of

equipment supplied is limited to making good by replacement or repair (at

the Company's discretion) defects which under proper use appear therein and

arise solely from faulty design, materials or workmanship within a specified

period. This period commences immediately after the equipment has been

delivered to the customer and at its termination all liability ceases. Also the

warranty period will be assessed on the basis of the date that the Company

is informed of the failure.

• This warranty applies solely to equipment supplied and no claim for

consequential damages, however arising, will be entertained. Also the

warranty specifically excludes defects caused by fair wear and tear, the effects of

careless handling, lack of maintenance, faulty installation, incompetence on

the part of the equipment user, Acts of God or any other cause beyond the

Company's reasonable control. Also, any repair or attempt at repair carried out

by any other party invalidates all warranties.

General Terms

If equipment failure occurs in the normal course of service having been competently

installed and when operating within its specified duty limits warranty will be

provided as follows:-

• Up to three years - The item will be replaced or repaired at no charge.

• Over three years, less than ve years - The item will be replaced or

repaired at a cost to the customer of 50% of the Davis & Shirtliff market

price.

The warranty on equipment supplied or installed by others is conditional upon the

defective unit being promptly returned free to a Davis & Shirtliff ofce and

collected thereafter when repaired. No element of site repair is included in the

warranty and any site attendance costs will be payable in full at standard chargeout

rates.

INS455A-07/20

This manual suits for next models

6

Table of contents

Other DAYLIFF Water System manuals

Popular Water System manuals by other brands

AutoAqua

AutoAqua Smart ATO Lite manual

ReadyRefresh

ReadyRefresh AccuPure FF1 instructions

Kinetico

Kinetico Drinking Water System Plus Deluxe owner's manual

Grundfos

Grundfos alpha2 l instructions

Watts

Watts WQC4 RO SERIES Installation, operation and maintenance manual

salmson

salmson Siriux Series Installation and starting instructions