5

8) Close the door. Electrolyzed water becomes available when the

tank level lamp comes on.

Note: The dispensing method depends on the dispensing valve

installed. Follow the instructions of the installer.

To use other than the optional dispensing valve, consult an

authorized Hoshizaki service company.

Refer to the instruction manual provided with the optional

dispensing valve.

5. SHUT DOWN

1) Press the ON/OFF switch on the operation panel. The operation

lamp goes off, and the unit stops.

2) Open the door.

3) Turn off the power switch (earth leakage circuit breaker).

4) Close the door.

5) Unplug the unit or turn off the main power supply.

6) Close the water supply line shut-off valve and water supply valve.

The water supply valve must be closed to prevent possible water

leaks in case of failure.

Note: Each installation may have different water supply connections.

Locate the shut-off valve, water supply valve and drain valve in

your site.

6. WATER FAILURE

In case of water failure, follow the instructions below:

1) Shut down the unit according to “5. SHUT DOWN”.

2) Wait until water supply is resumed.

3) Check that the water supply valve is closed.

4) Open the drain valve.

5) Open the water supply line shut-off valve. Drain water until no rusty

water comes out.

6) Close the drain valve.

7) Start up the unit according to “4. START UP”.

7. MAINTENANCE

IMPORTANT

1. Use a neutral cleaner for daily maintenance. As a sanitizer,

we recommend the use of invert soap (benzalkonium

chloride) available at a drugstore.

2. To prevent damage to the painted or plastic surfaces, do

not use thinner, benzine, alcohol, petroleum, soap powder,

polishing powder, alkaline detergent, acid, scrub brush, and

especially cleanser for use on fans and cooking ranges.

Also, to prevent corrosion, do not use a chlorine bleach.

3. Follow the manufacturer’s instructions when using a

disposable cloth.

4. Remove heavy soil as required.

[a] STAINLESS STEEL (AS REQUIRED)

The stainless steel parts are easily damaged. Clean them as follows:

1) Wipe with a soft cloth containing a calcium chloride based liquid

cleanser, tap water, and cleaning water.

2) Wipe clean with a damp cloth.

IMPORTANT

1. Do not damage the stainless steel surfaces. Use of a

steal brush or steel wool may break oxide film to develop

corrosion inside.

2. Use a calcium chloride based liquid cleanser to remove

corrosion, dirt, and chlorides.

3. Clean the stainless steel surfaces along with their grains if

any.

[b] CLEANING WATER CIRCUIT (MONTHLY)

The cleaning water circuit has calcium and magnesium deposits.

Continuous use may build up these deposits and obstruct the water

ow,resultinginshutdownorinadequatewaterproperties.

Topreventsuchtroubles,ushthewatercircuitonceamonth.

Note:Theushinglengthandfrequencydependonwaterquality,but

should be around two hours once a month.

It is best to use the unit for a month with the flush (reverse

dispense) lamp on.

Flushing is required if there is a big difference in dispensing

volume between sanitizing water and cleaning water.

1) Press the ON/OFF switch on the operation panel. The operation

lamp goes off, and the unit stops.

2) Open the dispensing valves to drain out the left and right water

tanks.

3) Close the dispensing valves.

4)Press andhold the ushbutton on thecontrol panel (A)for more

than5seconds.Theush(reversedispense)lampcomeson,and

the water outlets are switched.

5) Press the ON/OFF switch on the operation panel. The operation

lamp comes on, and the unit starts.

Note:While the ush (reverse dispense) lamp is on, cleaning water

and sanitizing water are dispensed from the opposite outlets:

Water tank (left) = sanitizing water

Water tank (right) = cleaning water

6)Aftertheushingprocesscompletes,repeattheabovesteps1)to5).

Thistimetheush(reversedispense)lampgoesoff,andthewater

outlets are switched back to normal.

Note: Cleaning water and sanitizing water are dispensed from the

normal outlets:

Water tank (left) = cleaning water

Water tank (right) = sanitizing water

8. INSPECTION

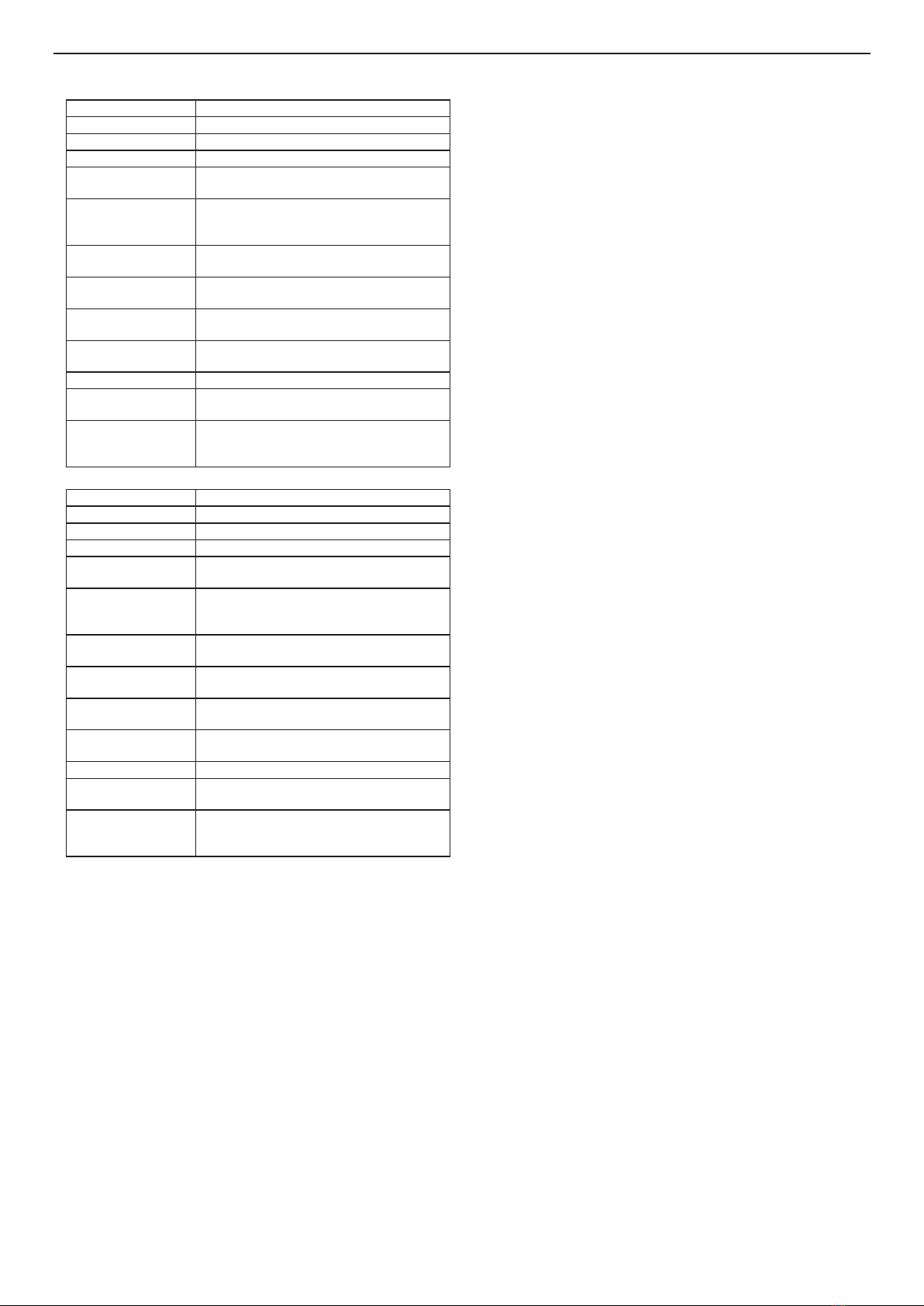

Use a copy of “14. [a] DAILY INSPECTION SHEET” and “14. [b]

MONTHLY INSPECTION SHEET” to keep records.

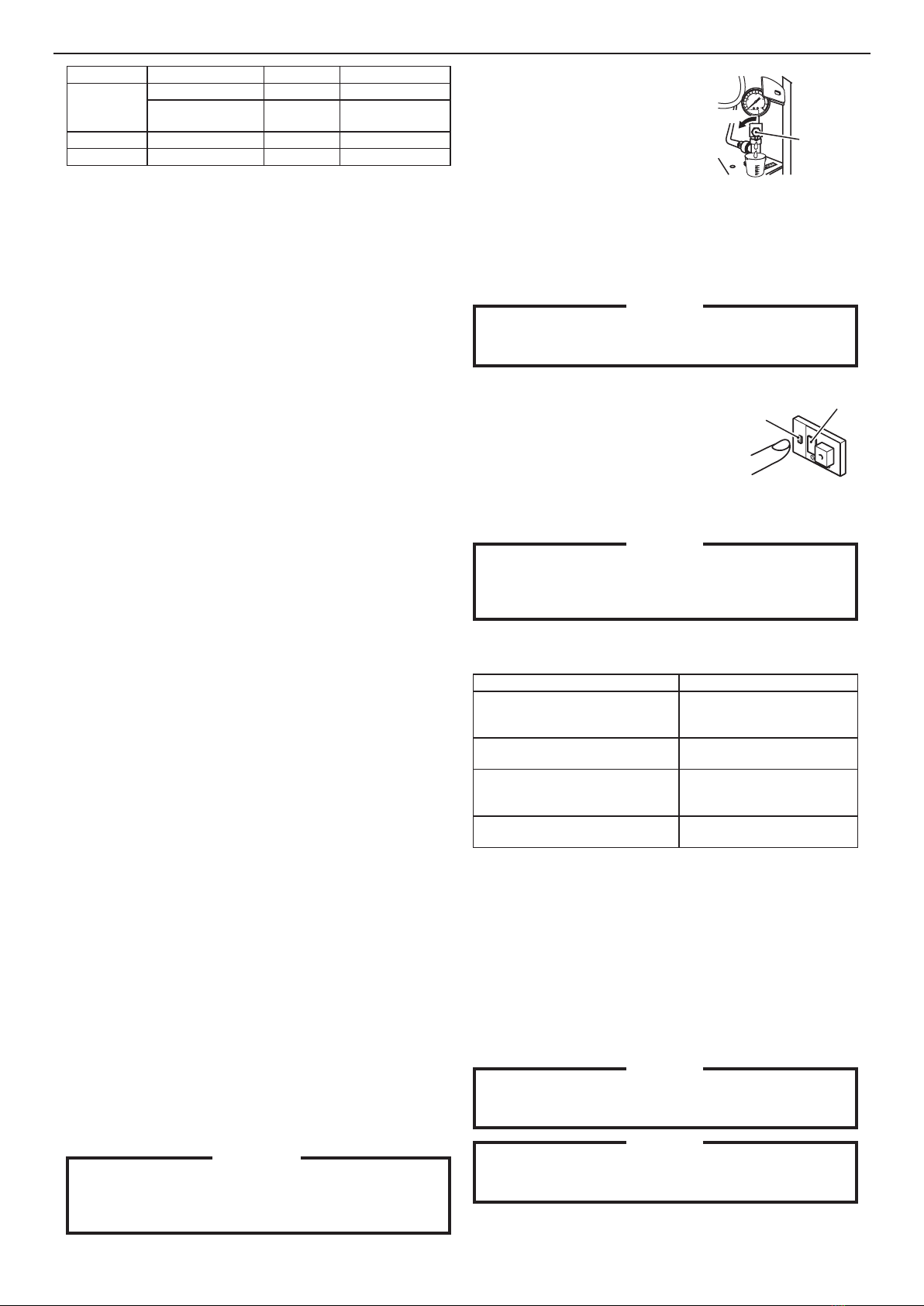

[a] pH, AVAILABLE CHLORINE CONCENTRATION (DAILY)

1) Drain more than 1 liter each of sanitizing water and cleaning water.

Sample each water from its outlet into separate containers.

2) Use the pH and chlorine test papers to check that each value is

within the following range. Use the pH test paper to directly check

water in the neutralizer.