DB Electronics DSW-100 Series User manual

DSW-100

SHANGHAI DIGITAL BALANCE ELECTRONIC CO., LTD

version1.4 2020.12

INTRODUCTION

Thank you for purchasing the DSW-100 series simple weighing scale from SHANGHAI

DIGITAL BALANCE ELECTRONIC CO., LTD.

The DSW-100 series has many features and designed functions that are conducive to

operate and increase customer satisfaction. We believe that all your needs will be fully match.

You can discover many convenient functions and features through this manual.

DSW-100 has weighing and counting functions.

Backlit display with automatic energy saving mode. In addition, the brightness of

the backlight and the auto-off time are set by the user.

In addition to using the AC adapter, it can also be powered by a built-in universal

dry battery (alkaline dry battery with battery model R20P SIZE-D 1.5V), which is

very suitable for use in a mobile working environment.

Display backlight brightness level can be set from 0 to 9, level 0 turns off the

backlight, level 9 is the brightest.

SCALE FEATURE

I

Contents

Operational Warning.................................................................................... I

Precautions................................................................................................... II

1. Conventional............................................................................................ 1

1.1 Product Specifications................................................................................... 1

1.2 Indicator display ............................................................................................ 2

1.3 Basic function keys ....................................................................................... 2

1.4 Global view.................................................................................................... 3

1.5 Interface......................................................................................................... 4

1.6 Display........................................................................................................... 4

2. Basic operation........................................................................................ 5

2.1 Boot operation ............................................................................................... 5

2.2 Shutdown operation...................................................................................... 6

2.3 Zero operation ............................................................................................... 7

2.4 Tare operation ............................................................................................... 8

2.5 Counting and weighing operation.................................................................. 9

2.6 Weight unit switch.......................................................................................... 12

2.5 Backlight brightness setting........................................................................... 13

3. Edit settings............................................................................................. 14

3.1 Keyboard shortcuts ....................................................................................... 14

3.2 Customer function entry ................................................................................ 15

3.3 Customer function SPEC definition ............................................................... 16

3.4 System function entry.................................................................................... 18

3.5 System function definition.............................................................................. 19

4. Calibration operation ............................................................................... 23

4.1 Full scale calibration...................................................................................... 23

4.2 Full scale rate correction ............................................................................... 25

4.3 Internal code check/display ........................................................................... 27

5. Factory settings ....................................................................................... 28

5.1 Reset ............................................................................................................. 28

5.2 Factory default............................................................................................... 29

6. Prompt message ..................................................................................... 30

Prompt information list......................................................................................... 30

7. Serial and USB........................................................................................ 31

7.1 POS serial protocol used in China ................................................................ 31

7.2 Standard POS serial port protocol................................................................. 35

Please follow the instructions below to operate the

product to ensure product and personal safety.

Before installation,

it is important to

check whether

the power supply

indicated by the

brand name matches

to ensure the normal

operation of the

machine.

Sharing sockets with

other high-power

devices can cause

large fluctuations.

Make sure that one

scale uses a matching

power outlet.

Do not insert metal

or ammable objects

at the interface to

avoid damage to the

machine or re.

If the scale falls,

please turn off the

switch and power

Plug immediately,

suspend use, and

contact the service

personnel in time to

avoid re or electric

shock.

Make sure that the

scale and extension

cable are properly

grounded, as this

can cause external

metal parts to be

electrostatically

charged to prevent

re or electric shock.

Immediately turn

off the switch and

Plug when metal

fragments or liquids

enter the interior,

suspend use and

contact service

personnel to avoid

re or electric shock.

Metal objects or

liquids can cause

fire or rust in the

scale. Keep an

appropriate distance

from the scale to

avoid damage.

Do not scratch

or modify the

power cord, bend

excessively or place

heavy objects on

top to avoid fire or

short circuit.

When the scale

emits smoke or

strange smell,

please stop using it

immediately, turn

off the switch and

power supply, and

contact the service

personnel in time.

To avoid

disconnection of

the power cord or

peeling of the cord

when unPlugging

the power cord, do

not pull on the cord.

Do not remove,

repair or modify the

scale body, high-

voltage, high-heat

parts or internal

edges to ensure

personal safety.

Keep your fingers

dry when inserting

or removing the

power Plug to avoid

electric shock.

OPERATIONAL WARNING

1

II

Maximum range

Internal fractional value

Display division value

Nonlinear error

Maximum counting range

Display device

3 kg 6 kg 15kg 30kg 30lb

60lb 3/6kg 6/15kg 15/30lb 30/60lb

Up to 100,000

Range 1000 ~ 20000

<0.008% FS (display only)

0 ~ 60000PCS

Operating temperature

Use relative humidity

0 ~ 40℃

15% ~ 85%RH( No condensing )

Monitor

Capacity indicator

Unit of weight

Status Indicator

Decimal symbol

Operation buttons

Power supply

Interface

6-digit LCD, 14 indicators

4

5 of them, g/kg/lb/oz/pcs

6 of them are ZERO/STABLE/NET/S1/S2/S3

You can choose "." or ","

[REZERO]/[UNIT/ ← ]/[TARE/ ↑ ]/[ON/OFF]

1. 4 R20P SIZE D 1.5V dry batteries

2. External AC adapter DC 5~12V/0.5A

1 RS-232 interface (data 600 ~ 57600 bit/s

baud, 8bit Data, 1bit Stop, No parity bit)/1

USB communication interface

1.1 Product specications

1000

3000 4000 5000 6000 7500

10000 12500 20000

1250 1500 2000 2500

Please avoid placing the product in the following locations:

If the temperature is too high or too low, direct sunlight, wet place;

At the shared power supply, excessive vibration, dust, and moisture.

Do not press the button too hard, please touch the button.

Do not suddenly bump into the machine to avoid damaging the load cell.

Do not press the center of gravity on the weighing platform to avoid damage to the load cell.

To clean the weighing pan and keyboard, use a dry cloth and wipe with a detergent. Do not use

thinner or other volatile solvents.

In order to ensure the normal use of the scale, before starting the operation every day, adjust the

level and lock the foot nut, and place a known weight of the item on the weighing platform to check

the weighing of the scale.

Do not place the instrument on an unstable or inclined surface to avoid dropping.

Use standard thermal paper to store thermal paper under direct sunlight, high temperatures, dust, or

moisture.

When the mechanical equipment is moved to a higher temperature in a place with a lower

temperature (such as a refrigerating room), because the temperature difference is large, the power

supply cannot be turned on immediately to prevent the condensation of the water vapor and cause

damage to the machine.

Keep one socket and one machine, avoiding high voltage or equipment that may cause power

interference.

Thermal print head failure is not covered by the warranty. Please use and maintain the equipment

properly according to the instructions or service personnel's recommendations.

Do not use the long-distance line of the power Plug of the scale. Be sure to keep it in the AC

socket. Keep the hand dry when pulling the Plug. Excessive bending and pulling will damage the

power cord and cause re or electric shock.

Please follow the prompts to extend the life.

*NOTICE

PRECAUTIONS

If you have any questions,

please contact your local

dealer or visit our website:

www.dbscale.com.cn

Thank you.

1. CONVENTIONAL

1.1 Product specications

3

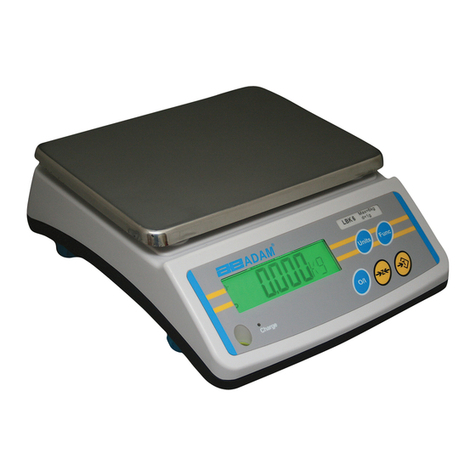

2

Front view Back view

Side view

Top view

1.4 Global view

1.2 Indicator display

®

-

100

W

1 2 3

·Weight zero

indicator, light when

the weight is "0"

·When the weight

value is stable, the

indicator lights

·When the displayed

value is net weight, the

indicator lights ·When the counting mode is

set in the number of samples,

this indicator lights

·When S2 is displayed, when the electronic

scale is in the process of setting and

calibration, this indicator lights

The unit of weight is “g”

(gram)/“kg” (kg)/“lb” (pound)/“oz”

(ounce)/when in counting mode,

the corresponding “g”/“kg”/“lb”/

"Oz"/"PCS" indicator lights

·When S3 is displayed,

when the weight is locked

(HOLD), the indicator lights

It is the operation confirmation and data

save button in the setting mode, and the zero

operation button in the weighing mode

Host power switch, exit setting in setting mode

In the setting mode, select the set digit, in

the weighing mode, the peeling operation or

long press for 3 seconds to enter the function

(counting mode) button key (only valid under

the conditions allowed by the counting mode)

In setting mode, select set digit, in weighing

mode, unit conversion and or counting sampling

confirmation button (only valid under the

conditions allowed by counting mode)

1.3 Basic function keys

UNIT

←

TARE

↑

REZERO

ON

OFF

Zero key

Power key

Tare mode key

Unit

conversion

key

Keyboard type Specic display

1. CONVENTIONAL 1. CONVENTIONAL

1.2 Indicator display

1.4 Global view

5

4

Main/sub screen

USB socket

RS232

1.5 Interface 2.1 Boot operation

1.6 Display

·Toggle the reset switch on the bottom left side of the scale

Note:

1. During the field check, press the [REZERO] key to exit the field check

and enter the weighing mode.

2. When the battery capacity indicator shows only one frame, it means

that the internal battery voltage is too low, please replace the battery.

(Please use 4 alkaline batteries with R20P SIZE-D 1.5V battery type).

3. DSW100 is the instrument model; Ur.341 is the software version

number

1. CONVENTIONAL 2. BASIC OPERATION

1.5 Interface

2.1 Boot operation

7

6

2.2 Shutdown operation

Method one: click [ON/OFF] button to shut down Make sure that the scale is in a stable state and put a heavy

object, the weight must be less than the set allowable zero

setting range, such as 0.500kg

Method 2: Turn o the reset switch

Click [REZERO] and remove the heavy object, which shows

-0.500kg

Method 2: Unplug the AC power and shut down

Click [REZERO] again to reset to zero

ON

OFF

Note:

When charging is not required, unplug the AC power

Note:

1. If the placed weight exceeds the zero setting range, press the

[REZERO] key, and the tare operation will be completed.

2. The zero setting range can be selected by setting SPEC 04 BIT 3,

BIT2.

2.3 Zero operation

REZERO

REZERO

2. BASIC OPERATION 2. BASIC OPERATION

2.2 Shutdown operation

2.3 Zero operation

9

8

2.4 Tare operation 2.5 Counting and weighing operation

Make sure that the scale is in a stable state and put on heavy

objects. The weight must be less than the set allowable

peeling range, such as 2.500kg

Click [TARE] and remove the heavy object, which is displayed

as -2.500kg

Click [TARE] again to resume zero setting

Note:

1. If the placed weight exceeds the allowable zero setting range, the tare

operation will be performed after pressing the tare key.

2. The peeling range can be modified by SPEC 04 BIT 0 to select the

allowed peeling range of 50%FS or 100%FS

TARE

↑

(1) Ensure that the scale is in a stable state

(2) Press and hold the [REZERO] button for a long time, and

click the [ ← ] button three times to enter the customer

function settings

(3) Click the [REZERO] button to turn down to Spec03

(4) Modify the default "1011" to "1010"

(5) Click the [REZERO] button to save, press [ON/OFF] to exit

the setting

Method one

Enter weighing mode by setting button

REZERO

REZERO

TARE

↑

REZERO

ON

OFF

2. BASIC OPERATION 2. BASIC OPERATION

2.4 Tare operation

2.5 Counting and weighing operation

11

10

(6) Click the [ ↑ ] button to enter the counting operation,

the default display is 10 pieces, you need to put 10 pieces of

goods on the weighing pan to count

(2) Click the [ ↑ ] button to enter the counting operation, the default

display is 10 pieces, you need to put 10 pieces of goods on the weighing

pan to count

(7) Click the [ON/OFF] button to check the total weight. If

the number of pieces placed on the weighing pan exceeds

10 pieces, click the [ ↑ ] button to increase the number of

objects placed on the weighing pan

(3) Click the [ON/OFF] button to view the total weight. If the number

of pieces placed on the weighing pan exceeds 10 pieces, click the [ ↑ ]

button to increase the number of objects placed on the weighing pan

Make sure the scale is stable

(1) Press and hold the [ ↑ ] key for 5 seconds to enter the weighing mode

If there is already weight on the weighing pan when entering

the counting and weighing, click the [REZERO] button to

execute the peeling function, after which the weighing items

can be placed

Click [ ← ] key again to select the quantity, click [ON/OFF]

key to exit the selected state

ON

OFF

ON

OFF

Method Two Long press【↑】key to enter weighing mode

Note:

Increase the number of pieces by increasing to "10, 20, 30, 40, 50, 100,

200, 300, 400, 500, 1000", after reaching the maximum value "100",

then press [ ↑ ] will display the total weight interface, again Click [ ↑ ] to

enter the counting and weighing default "10 pcs"

REZERO

ON

OFF

2. BASIC OPERATION

2.5 Counting and weighing operation

2. BASIC OPERATION

2.5 Counting and weighing operation

13

12

2.6 Weight unit switch 2.7 Backlight brightness setting

Make sure the scale is stable Make sure the scale is stable

Press and hold the [ ← ] key for 5 seconds, knowing that "bL.S

3" appears on the screen, and the displayed "3" is the backlight

brightness level

Click [ ← ] to increase the brightness, the minimum brightness is 0

(without backlight), and the maximum brightness is 9

Click [REZERO] to save and exit

Put a heavy object on the weighing pan, such as 0.545kg

Click the [ ← ] key, it is displayed as 1.202lb; click the [ ← ] key

again, it is displayed as 19.22oz; the third click the [ ← ] key, it

is displayed as 545g; the fourth time it is restored to 0.545kg

After removing the heavy objects, click [REZERO] to resume zero setting

REZERO

Note:

To enable this switching function, SPEC03 bit.2 must be set to 0

Note:

When working with batteries, reduce the brightness level of the

backlight as much as possible. To reduce battery consumption and

extend battery life

UNIT

←

UNIT

←

2. BASIC OPERATION 2. BASIC OPERATION

2.6 Weight unit switch

REZERO

2.5 Backlight brightness setting

15

14

3.1 Keyboard shortcuts 3.2 Customer function entry

No. Setting type Quick operation

1+

+

+

+

+

2

3

4

5

Enter user function

setting mode

Enter system function

setting mode

Enter system internal

code detection mode

Enter the system full

calibration mode

Restore factory SPEC

settings

REZERO

REZERO

REZERO

REZERO

REZERO

UNIT

←

UNIT

←

UNIT

←UNIT

←

UNIT

←

UNIT

←

UNIT

←

UNIT

←UNIT

←+

REZERO UNIT

←UNIT

←UNIT

←

TARE

↑

TARE

↑

TARE

↑

TARE

↑

TARE

↑

TARE

↑

TARE

↑

ON

OFF

Note:

(1) When performing quick operations, you need to hold down the

[REZERO] key for a long time while pressing other keys;

(2) Before restoring the factory SPEC settings, you need to open the

calibration switch at the bottom of the scale body

Press and hold the [REZERO] button, and click the [ ← ]

button three times to enter the spec setting

Click [ ↑ ] key to enter the setting, [ ← ] key becomes the shift

key, will increase "0" from right to left; [ ↑ ] key becomes the

increment key, increase "1" from right to left

After the operation, click [REZERO] to save and enter the next

item; click [ON/OFF] to exit without saving

REZERO

ON

OFF

3. EDIT SETTINGS 3. EDIT SETTINGS

3.1 Keyboard shortcuts

3.2 Customer function entry

17

16

3.3 Customer function SPEC definition

SPEC NO.00

SPEC NO.03

SPEC NO.01

00:10 seconds

00:Weight display

lock(HOLD)

000: Port closed

100: 9600

00:10 seconds

【BIT 3/BIT 2】Backlight auto-off time setting

【BIT 3】Allow "comma" as decimal point

【BIT 3】Backlight function settings

【BIT 0】Automatic shutdown time setting (after 3 minutes of no operation)

【BIT 1/BIT 0】[TARE/ ↑ ] key function setting (in weighing mode) after the clock)

01:20 seconds

01: Gross weight/

net weight

switch

001: 1200

101:19200

0:Allow

0:Allow

0:Allow

0:Allow

10:30 seconds

10: Function

key for counting

mode

010: 2400

110:38400

1:Forbid

1:Forbid

1:Forbid

1:Forbid

10:30 seconds

11:Do not close

11: Tare

operation key

only

011: 4800

111: 57600

【BIT 1】Allow automatic entry into power saving mode

【BIT 2】Weight unit conversion (kg/LB) [UNIT / ← ]

【BIT 2/BIT 1/BIT 0】RS-232 baud rate setting

Note:

(1) When the backlight brightness is set to "0", the backlight will not

automatically turn on;

(2) 60 seconds to enter power saving mode

*The default is 1100, the backlight does not turn off automatically; allow to

enter the power saving mode; no automatic shutdown

*The default is 1011, it is forbidden to use a comma as the decimal point; it

is allowed to use the [ ← ] key to switch the weight unit; [ ↑ ] key is only the

tare operation key in the weighing mode

*The default is 0100, the backlight function is turned on; the baud rate of

RS-232 is 9600

3. EDIT SETTINGS 3. EDIT SETTINGS

3.3 Customer function SPEC denition

3.3 Customer function definition

0:Allow

0:Standard

1:Forbid

1:Special

SPEC NO.02

【BIT 3/BIT 2】RS-232/USB communication mode setting

【BIT 1】Allow RS-232 port data output when the weight is unstable

【BIT 0】RS-232 port data output format setting

00:General command response method

10: POS/ECR communication method

01: Simple command (A) response method

11: Continuous weight data output method

*The default is 1000, the RS-232/USB communication mode is set to POS/

ECR communication mode; the RS-232 port data output is allowed when the

weight is unstable; the standard RS-232 port data format is output

00: 8 data bits,

NO Parity

01: 7 data bits,

Even Parity

00: Special format 1: Data format protocol 1

10: 7 data bits,

Odd Parity

01: Special format 2: Data format protocol 2

11: 7 data bits,

Mark Parity

SPEC NO.20

【BIT 1/BIT 0】RS-232 SERIES DATA BIT AND PARITY VALUES

【BIT 3/BIT 2】RS-232 SPECIAL DATA MODE SELECT

10: Special format 3: TOLEDO MODE protocol 11: Special format 4: DIGI MODE protocol

*The default is 0000, the special data format protocol 1; RS-232

communication protocol uses 8 data bits, no check

SPEC NO.21

000: POS/ECR

TYPE-0

Most P.O.S, ECRs

and Some TEC

P.O.S System

100: POS/ECR

TYPE-4

CRS, NCR2170

and Many other

ECRs, Most P.O.S

110: POS/ECR

TYPE-6

SAMSUNG ER-670,

ER-5100, SPS-520,

Most P.O.S

111: POS/ECR

TYPE-7

DELTA cash

register protocol

101: POS/ECR

TYPE-5

NCI General,

SAMSUNG SPS-300,

ER-900, Most P.O.S

001: POS/ECR

TYPE-1

NOT USE

010: POS/ECR

TYPE-2

SHARP ER-Axxx,

ER-A450T, New

SANYO ECRs

011: POS/ECR

TYPE-3

NOT USE

[BIT 2/BIT 1/BIT 0] POS/ECR communication protocol selection

(can be switched by pressing [Tare key] when turning on)

0: Synchronize with the displayed weight unit 1: Use the original set weight unit

【BIT 3】Data (serial port) output weight unit selection

Note:

1. SPEC21 command "D, CR, LF" response mode

2. For the PROTOCOL (interface protocol) of POS/ECR TYPE-0 ~ 7 in

SPEC21, please refer to the following description of this article (POS/ECR

INTERFACE) 9600 Baud rate, 7 Data bit, Even Parity, 1 Stop bit

(TYPE-6: 9600 Baud rate, 8 Data bit, None Parity, 1 Stop bit)

3. Set the unused setting bits to "0"

19

18

4. RS232C interface data format, stop bit is 1 bit, data bit 7 or 8 bits are

optional. (SPEC 01,02 = SELECT .)

5. After the USB port is connected, the machine will automatically detect the

data input by the USB port. If there is data input, the data communication of

the USB port will be turned on

*The default BIT 3 is 1, use the original set weight unit

No default BIT 2/BIT 1/BIT 0, POS/ECR communication protocol selection

(can be switched by pressing [Tare key] when turning on)

3.4 System function entry

Use the tool to click the (SPAN SW) button at the bottom of the

screen to make the calibration switch on.

Press and hold the [REZERO] key for a while, and click [ ← ] [ ↑ ] [ ← ]

to enter the spec setting.

+

REZERO UNIT

←UNIT

←

TARE

↑

UNIT

←

TARE

↑

After clicking the [ ↑ ] key to enter the setting, the [ ← ] key becomes

a shift key and will increase "0" from right to left; the [ ↑ ] key

becomes an incremental key and increases "1" from right to left.

After the operation, click [REZERO] to save and enter the next

item; click [ON/OFF] to exit without saving.

REZERO

ON

OFF

3.5 System function definition

SPEC NO.04

SPEC NO.05

00: ± 2% FS

00: ± 2% FS

0:<50% FS

0:Allow

【BIT 3/BIT 2】Reset range selection

【BIT 3】Auto clear conduction

【BIT 0】TARE RANGE

【BIT 0】AUTO CLEAR TARE

01: ± 4% FS

01: ± 4% FS

0:Forbid

0: When the net weight is greater

than 5d

10: ± 10% FS

10: ± 10% FS

1:Allow

1: When the net weight is greater than 5d

and the gross weight is greater than 21d

1: <100% FS

1:Forbid

11: Unlimited

11: Unlimited

【BIT 1】NO PRESET TARE OP.

【BIT 2/BIT 1】SYSTEM ON START ZERO RANGE

*The default is 0100, the reset range is ±4%FS; preset tare weight is

prohibited; tare range <50% FS

*The default is 1101, then the automatic clearing conditions are when the net

weight is greater than 5d and the gross weight is greater than 21d; the initial

zero point is allowed to be within ± 10% FS; automatic tare weight removal

is prohibited

3. EDIT SETTINGS 3. EDIT SETTINGS

3.4 System function entry

3.5 System function definition

21

20

【BIT 3】Do not use

0:Allow

0:Allow

【BIT 1】Manual TARE CLEAR

【BIT 0】When the calibration permission switch is

closed, the weight inner code display is allowed

1:Forbid

1:Forbid

*The default is 1001, there is no negative weight prompt display, showing

the weight value; manual tare weight clearing is allowed; weight inner code

display is prohibited when the calibration switch is allowed to be closed

SPEC NO.09

SPEC NO.10

【BIT 3】 NO Tare Accumulation

【BIT 1】Reset after peeling

0:Forbid

0: Weight calibration mode

0: Allow

0: Forbid

0: Free weight full value setting

1: Allow

1: Full correction mode

1: Forbid

1: Allow

1: Fixed weight full value setting

【BIT 2】 No Tare Subtraction

【BIT 0】 System mode select

*The default is 1010, both are dual range display; dual range is automatically

converted to single range; fixed range is 3000

*The default is 1100, which allows tare weight increase operation; allows tare

weight decrease operation; allows zero reset operation after tare removal;

range setting mode selection is set by free weight full value

*The default is 0011, the weight display decimal places are three decimal

places (000.000)

*The default is 0001, then the full-scale calibration method is the heavy

calibration mode; the minimum weight division value is 2

【BIT 2/BIT 1/BIT 0】

Decimal point position on of scale

【BIT 3】CALIBRATION MODE

【BIT 3】Dual rang weight check by

0:Only the net weight is dual range

0:Single range

1:Both are dual range display

1:Dual range

【BIT 2】Dual range automatic conversion (fixed range)Multi interval (only for fix mode1)

SPEC NO.11

SPEC NO.12

000: No decimal

point

100: Four decimal

places(00.0000)

001: One decimal

(00000.0)

101: Five decimal

places(0.00000)

010:Two decimal

places(0000.00)

011: Three decimal

places(000.000 )

000: 1

100: 20

001: 2

101: 50

010: 5

110: 100

011: 10

111: Not used

【BIT 2/BIT 1/BIT 0】Weight minimum division value

3. EDIT SETTINGS

3.5 System function definition

3.5 System function definition

3. EDIT SETTINGS

SPEC NO.06

【BIT 3/BIT 2】Negative weight display

00: When the net

weight is less

than negative 2D,

"UF." is displayed

01: When gross

weight is less

than negative 2D,

"UF." is displayed

10: There is no

load weight

prompt display,

showing the load

value

11: Invalid

setting

【BIT 1/BIT 0】Fix full capacity select mode(Only

when SPEC 10, bit0=”1”)

00: 6000 01: 15000 10: 3000 11: Invalid setting

0:Allow

0:Allow

0:Allow

1:Forbid

1:Forbid

1:Forbid

【BIT 3】After the weight unit is converted,

the weight unit symbol flashes to allow setting

【BIT 2】Do not use

【BIT 1】Allow counting operation

【BIT 0】Exceeding the zero point area at

startup allows the use of the original zero position

*The default is 0001, the weight unit symbol is allowed to flash after the

weight unit is converted; counting operation is allowed; the original zero is

forbidden to be used when the area exceeds the zero point when starting

SPEC NO.07

00: g

0:Allow

0:Allow

01: kg 10: lb

1:Forbid

1:Forbid

11: OUNCE

【BIT 0】Not Stable Hold

SPEC NO.08

*The default is 1101, then the base (when calibration) weight unit is OUNCE;

when the weight is not zero, zero setting is allowed; when the weight is

unstable, locking is prohibited

【BIT 3/BIT 2】Benchmark (when calibrated) weight unit (g/kg/lb)

【BIT 1】WHEN WEIGHT IS NOT ZERO, NO PRESE TARE OP.

23

22

*The default is 1001, the number of divisions allowed for overload display is 9d

*The default is 0000

*The default is 1111

*The default is 1111, which allows displaying the measured internal value

*The default is 0000, the battery voltage is displayed in the project clock for

measuring voltage

SPEC NO.14

SPEC NO.15

SPEC NO.16

SPEC NO.17

SPEC NO.18

0000: 0d

1000: 8d

0100: 4d

1100: 12d

0001: 1d

1001: 9d

0101: 5d

1101: 13d

0010: 2d

1010: 10d

0110: 6d

1110:14d

0011: 3d

1011: 11d

0111: 7d

1111:15d

【BIT 3/BIT 2/BIT 1/BIT 0】Allow overload to display the number of divisions

【BIT 3/BIT 2/BIT 1/BIT 0】Do not use

【BIT 3/BIT 2/BIT 1/BIT 0】Do not use

【BIT 3/BIT 2/BIT 1】Do not use

【BIT 3/BIT 2/BIT 1】Do not use

0: Allow

0: Display battery voltage

1: Forbid

1: Displays the percentage of

battery power remaining

【BIT 0】Display measured internal values

【BIT 0】Display items for measuring voltage

*The default is 0000

SPEC NO.19

【BIT 3/BIT 2/BIT 1/BIT 0】Do not use

Note:

1. Set the unused setting bits to "0"

2. FS is full weighing value

3. The system function is used to define the setting of measurement

specifications. The user cannot change it by himself, and it must be set by a

professional technician.

4.1 Full scale calibration

Modify BIT 3 of SPEC 12 to "0"

Click [REZERO] button to save

Click the switch below the scale body to open the calibration

Turn on the calibration switch again. Long press [REZERO],

click [ ← ] [ ↑ ] [ ↑ ] to enter the calibration, display the

maximum weight of calibration

REZERO

+

REZERO UNIT

←TARE

↑

TARE

↑

3. EDIT SETTINGS

3.5 System function definition

4.1 Full scale calibration

4. CALIBRATION OPERATION

*The default is 0101, the resolution is 3000d

1000: 6000d

1100: 15000d

1001: 7500d

1101: 20000d

1010: 10000d

OTHERS

1011: 12500d

Not used

SPEC NO.13

0000: 1000d

0100: 2500d

0001: 1250d

0101: 3000d

0010: 1500d

0110: 4000d

0011: 2000d

0111: 5000d

【BIT 3/BIT 2/BIT 1/BIT 0】Resolution selection

25

24

Modify BIT 3 of SPEC 12 to "1"

Click [REZERO] to enter zero calibration and wait

Put the corresponding weights, and click the [REZERO] button to

enter the full-scale calibration

Remove the weight to complete the calibration and return to the

weighing interface

Note:

1. The DSW-100 instrument system can be fully calibrated with a standard

weight greater than 10% of the full weight

2. The calibration switch (SPAN SW) must be on

4.2 Full scale rate correction

Click [REZERO] button to save

Click the switch below the scale body to open the calibration

Put a heavy object on the weighing platform, such as 10.005,

the weight has deviation

REZERO

Turn on the calibration switch again. Long press [REZERO],

click [ ← ] [ ↑ ] [ ↑ ] to enter the calibration, display the

previous calibration Scaling parameters, such as 37.500

+

REZERO UNIT

←TARE

↑

TARE

↑

4. CALIBRATION OPERATION

4.1 Full scale calibration

4. CALIBRATION OPERATION

4.2 Full scale rate correction

Click [ ← ] Shift, [ ↑ ] Increment, can be modified to the

weight to be calibrated, such as 5kg

27

26

4.3 Internal code check/display

Click[ ← ] Shift, [ ↑ ] Increment, modify to the calculated

scale parameter

Modify BIT0 in SPEC 05 to "1"

Remove the heavy object, and press [REZERO] to enter the

zero conrmation and wait, click [REZERO] again to enter the

zero conrmation

Put on the weight, and display the actual weight value of the

modied weight

Remove heavy objects and return to weighing mode

Note:

1. When there are items on the load-bearing table or zero confirmation is

not required, you can press the [ON/OFF] key to directly exit the calibration

mode and return to the weighing mode.

2. The calibration switch (SPAN SW) must be turned on.

3. Calculation of the new standard rate:

Actual weight W1=10.00kg Display weight W2=10.005kg The original

standard rate of the instrument is V1= 37.500

Then the correction rate V2 = W1*V1/W2=10.00*37.500/10.005=37.48

Click [REZERO] button to save

Click the switch below the scale body to open the calibration

Long press [REZERO] key, click [ ↑ ] [ ↑ ] [ ← ] to enter the

internal code check

Click [ ↑ ] button to display [A/D] internal code

Click [ON/OFF] key to return to weighing mode

REZERO

ON

OFF

4. CALIBRATION OPERATION

4.2 Full scale rate correction

4.3 Internal code check/display

4. CALIBRATION OPERATION

29

28

5.1 Reset 5.2 Factory default

Click the button below the scale body to turn on the

calibration switch

Long press [REZERO] key and click [ ↑ ] [ON/OFF] [ ← ] Restore

factory settings

+

REZERO UNIT

←

TARE

↑

ON

OFF

Note:

Restoring factory settings does not include restoring the modified values of

BIT 3/ Spec 10 BIT 0/ Spec 09/ Spec 11/ Spec 12/ Spec 13

Coding Coding

SPEC00

SPEC01

SPEC02

SPEC03

SPEC20

SPEC21

Defaults Defaults

1100

0100

0100

1011

1100

0000

SPEC04

SPEC05

SPEC06

SPEC07

SPEC08

SPEC09

SPEC10

SPEC11

SPEC12

SPEC13

SPEC14

SPEC15

SPEC16

SPEC17

SPEC18

SPEC19

0100

1101

1001

1010

0111

1010

1100

0011

0001

0101

1001

0000

1111

1111

0000

0000

5. FACTORY SETTINGS 5. FACTORY SETTINGS

5.1 Reset

5.2 Factory default

31

30

Prompt information list 7.1 POS serial protocol used in China

Weight overload

Gross or net weight is negative

When the [REZERO] button is pressed

System zero error

System zero exceeds the allowable range

Calibration switch is in "on" state

Calibration switch is in "o" state

OF

UF.

888888

0 – E r

z r . E r r

S O n

S O F F

6. PROMPT MESSAGE 7. SERIAL AND USB

6. Prompt information list

7.1 POS serial protocol used in China

7.1.1. RS232C Interface protocol: The baud rate is set by SPEC01,

bit2~0 (1200~57600). The stop bit is 1 bit and the data bit is 8 bits.

7.1.2. The RS232C interface can be used by setting SPEC 02, 20,

21.

7.1.3. The RS232C interface is commonly used as a digital

communication protocol. Provide continuous weight data output

format.

The factory settings are: baud rate=9600bit/s, data=8, STOP=1,

no parity bit.

SPEC 01=X100, Baud=9600bit/s

SPEC 02=1100, continuous weight data output

SPEC 20=XX00, Data=8bit, Stop=1bit, no parity

SPEC 21=0XXX. The output data is synchronized with the display

data (when there is weight unit conversion)

SPEC 21=1XXX. The output data is not synchronized with the

display data (only the output calibration is the set weight unit)

7.1.4. Digital weighing protocol, continuous weight data output

(standard) format: (according to factory settings)

Standard format of serial data output:

SPEC SETUP: SPEC 01=0100,SPEC 02 = 1100,SPEC 20 = 0000,

SPEC 21 = 0000。

DATA FORMAT. 06 20 67 30 0D 47 30 30 31 2E 30 30 30 0D 54

① ② ③ ④ ⑤ ⑥ ④ ⑤

30 31 30 2E 30 30 30 0D 0A

⑥ ④ ⑦

① 06H boot byte, the rst byte of the message output.

② 20H 67H "_ g" weight unit, (6BH, 67H "kg", 6CH, 62H "lb", 6CH,

7AH "oz")

③ 30H/31H weight is stable/weight is unstable.

④ 0DH data segment separator.

⑤ 47H "G" gross weight data eld start byte, 4EH "N" net weight

data eld start byte, 54H "T" tare data eld start byte

⑥ Weight data eld

⑦ 0AH End of telegram.

7.1.5. Serial continuous weight data output special format

7.1.5.1Continuous data output, special format 1 (Special data type

1)

SPEC SET: SPEC02 =11X1 ,SPEC20= 0000,SPEC21= XXXX

DATA FORMAT. 3DH(=),3XH(MSB),3XH,3XH,2EH(“.”),3XH,

33

32

[SW2] and [SW3]

Ex1. The NET WEIGHT is -124.50kg

The data format is 0x02,0x7c,0x59,0x70,0x30,0x31,0x32,0x34

,0x35,0x30, 0x30,0x31,0x32,0x34,0x35,0x30,0x0d.

7.1.5.4 Special data type 4 TERAOKA SCALES TYPE

DIGI RS232 Communication type.

SPEC SET: SPEC02 =11X1 ,SPEC 20= 1100,SPEC 21= XXXX

The mode efficiency NET WEIGHT data length is 7 digital With

decimal point & with stable word .

STABLE word 0x30 (30H)= STABLE , 0x31(31H) = UNSTABLE

RS_CR 0x0D (0DH)

RS_LF 0x0A (0AH)

Note 1: The above setting value 'X' is the bit that does not

aect this mode of operation, (0/1 is ok)

Note 2: No weight unit symbol. When weight is converted, the

value output is the value of the unit of weight set at the time of

calibration.

Ex1. The NET WEIGHT is -124.50kg (The negative weight

display function spec06.bit3,2=10 has been set)

The data format is 0x30,0x2d,0x31,0x32,0x34,0x2e,0x35

,0x30,0x0d,0x0a

Ex2. When NET WEIGHT is overload. (Weight overload)

The data format is 0x30,0x20,0x20,0x20,0x20,0x20,0x4F,0

SPECIAL DATA TYPE

7.2

SPECIAL DATA TYPE

7.2

7. SERIAL AND USB 7. SERIAL AND USB

3XH,3XH(LSB),0DH

7.1.5.2 Continuous data output, special format 2 (Special data

type 2)

SPEC SET: SPEC02 =11X1, SPEC 20= 0100, SPEC 21= XXXX

DATA FORMAT. 3XH(MSB),3XH,3XH,3XH, 2EH("."),3XH,3XH(LSB),

0DH

Note 1: All characters are printed in ASCII code. Contains only

the numerical symbol, the net weight value, and the ending

character CR(0DH), with the higher value coming first. When

the value is "negative", the highest bit output is 2EH(" - "). The

numeric elds are 7-byte (ASCII) characters.

Note 2: No weight unit symbol. When weight is converted, the

value output is the value of the unit of weight set at the time of

calibration.

For example: 1. The weight value of 2.56,

The output data: 30H, 30H, 30H, 32H, 2EH, 35H, 36H, 0DH

2. The weight value of -2.56,

The output data: 2DH, 30H, 30H, 32H, 2EH, 35H, 36H, 0DH

7.1.5.3 Continuous data output, Special data type 3 (TOLEDO

SCALES TYPE)

SPEC SET: SPEC02 =11X1 ,SPEC 20= 1000,SPEC 21= XXXX

No decimal point command. Total has 17 digital ASCII code.

[STX] WORD ASCII START FLAGE (02H) , [CR] WORD ASCII (0DH)

STATE WORD ,[SW1]

STATE WORD 1

BIT 0,1,2

BIT 0 BIT 1 BIT 2 DECIMAL POINT POSITION

DISPLAY SUBBSECTION

BITS 3 BITS 4

1

1

1

1

1

1

1

1

0

0

0 0

0

0

0

0

XXXXX0

XXXXXX

XXXX, X

XXX. XX

XX. XXX

X1

0

0

0

BITS 5

BITS 6

BITS 7

1

1

1

0 X2

X5

=“1”

=“1”

=“0”

SW 2 STATE WORD 2 SW 3 STATE WORD 3

BITS BITSFOUNCTION FOUNCTION

GROSS =”0”, NET =”1”

NEGTIVER =”1” positive=”0”

Stable=”1”,Not stable“0”

Weight Unit :

g=”00”,kg=”01”lb=”10”,

once=”11”

OVER FULL =”1”,NOMRA=”0”

0 0

1 1

“1”

“0”

=“0”

=“0”

=“0”

=“0”

=“0”

=“1”

=“1”

=“1”

2 2

3 3

4 4

5 5

6 6

7 7

STX

NET WEIGHT TARE WEIGHT

SW 1 SW 2 SW 3

CR

STABLE WORD NET WEIGHT TEXT (With decimal point) + RS_CR + RS_LF

CR

NET WEIGHT(XXX.XXX)

Table of contents

Other DB Electronics Scale manuals