DBI SALA 8001717 Installation instructions

© Copyright 2002 DB Industries, Inc.

User Instruction Manual

Tripod Anchorage Connectors

This manual is intended to meet the

Manufacturer'sInstructionsasrequiredby

ANSI Z359.1 and ANSI A10.14, and

shouldbe usedas partof anemployee

trainingprogramas requiredbyOSHA.

The 8000000 and 8000010 Tripods

are Classified by Underwriters

Laboratories Inc. as to the 350 lb.

load capacity only.

WARNING:

Thisproduct ispartofapersonalfallarrest,work positioning,

personnelriding, material handling,orrescue andevacuationsystem.The

user must read and follow the manufacturer's instructions for each

component or part of the complete system. These instructions must be

providedtotheuserofthisequipment.The user mustreadandunderstand

these instructions or have them explained to them before using this

equipment.Manufacturer's instructions mustbefollowed forproperuseand

maintenance of this product. Alterations or misuse of this product or failure to

follow instructions may result in serious injury or death.

IMPORTANT:

Ifyou haveany

questions on the use, care,

application, or suitability for

use of this safety equipment,

contact DBI/SALAimmediately.

IMPORTANT:

Beforeusingthis

equipment,recordthe product

identificationinformationfound

on the ID label of the tripod on

theinspectionandmaintenance

log in section 9.0 of this

manual.

* If additional information on

this product is necessary,

supplementalinstructions

will be included.

3

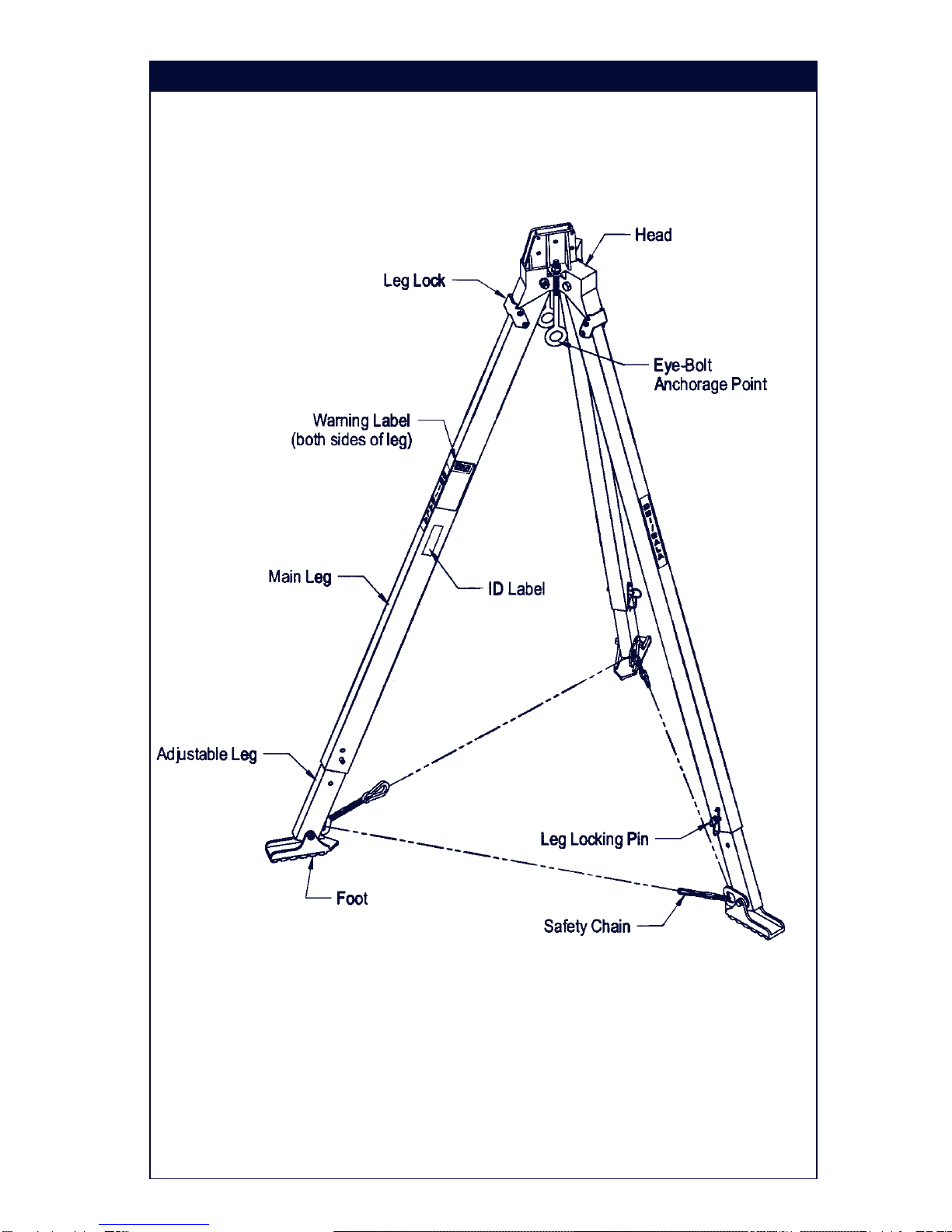

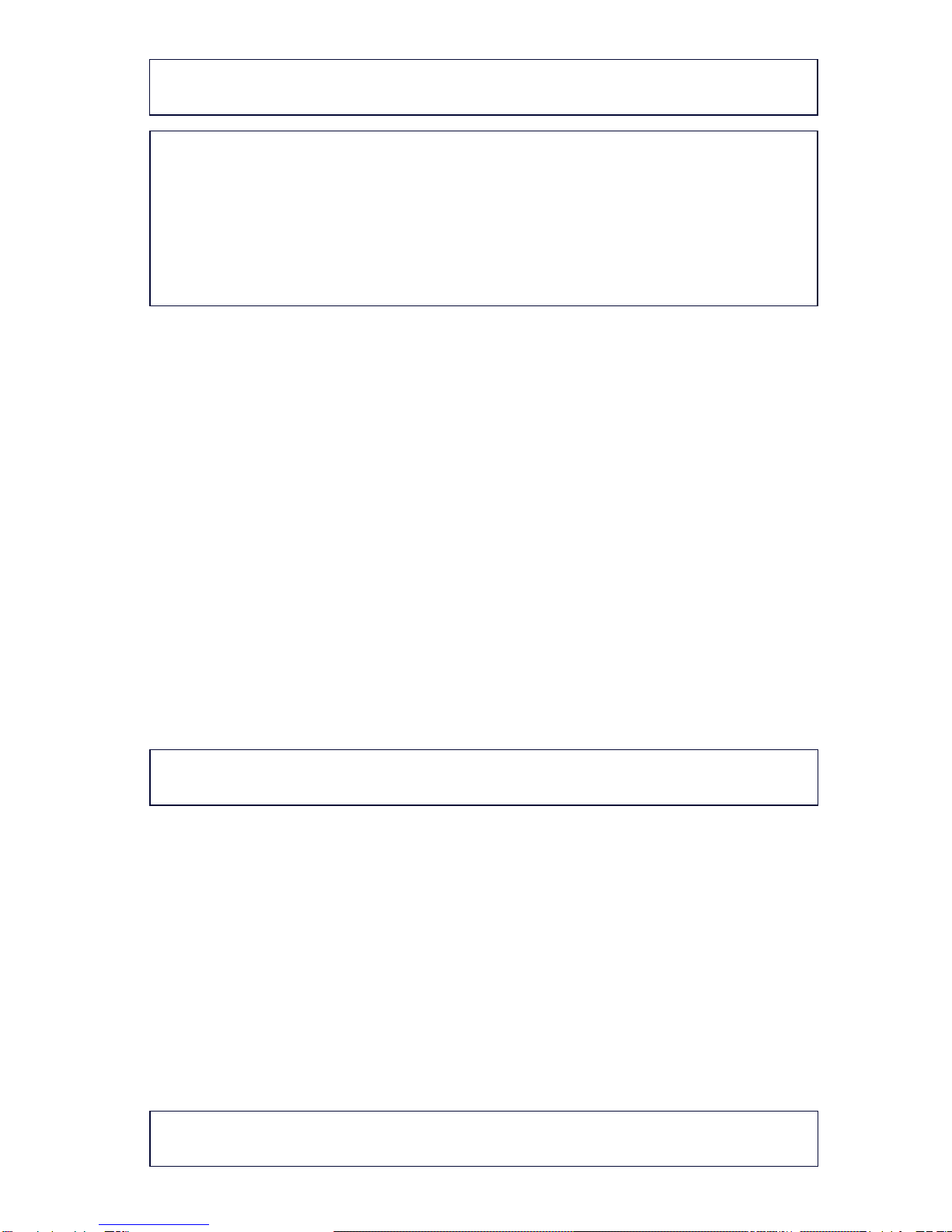

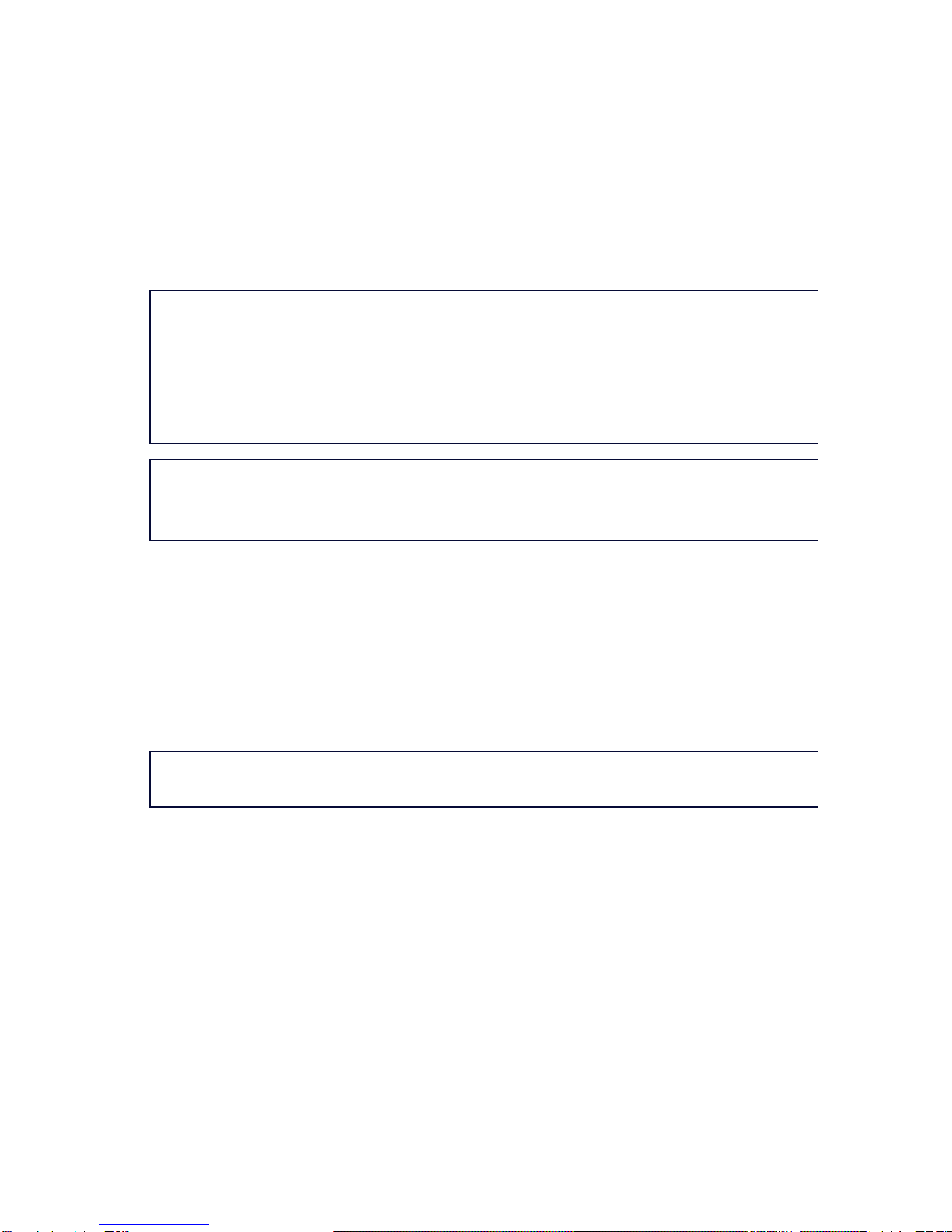

Figure 1

8001717and 8001718 Parts Identification

4

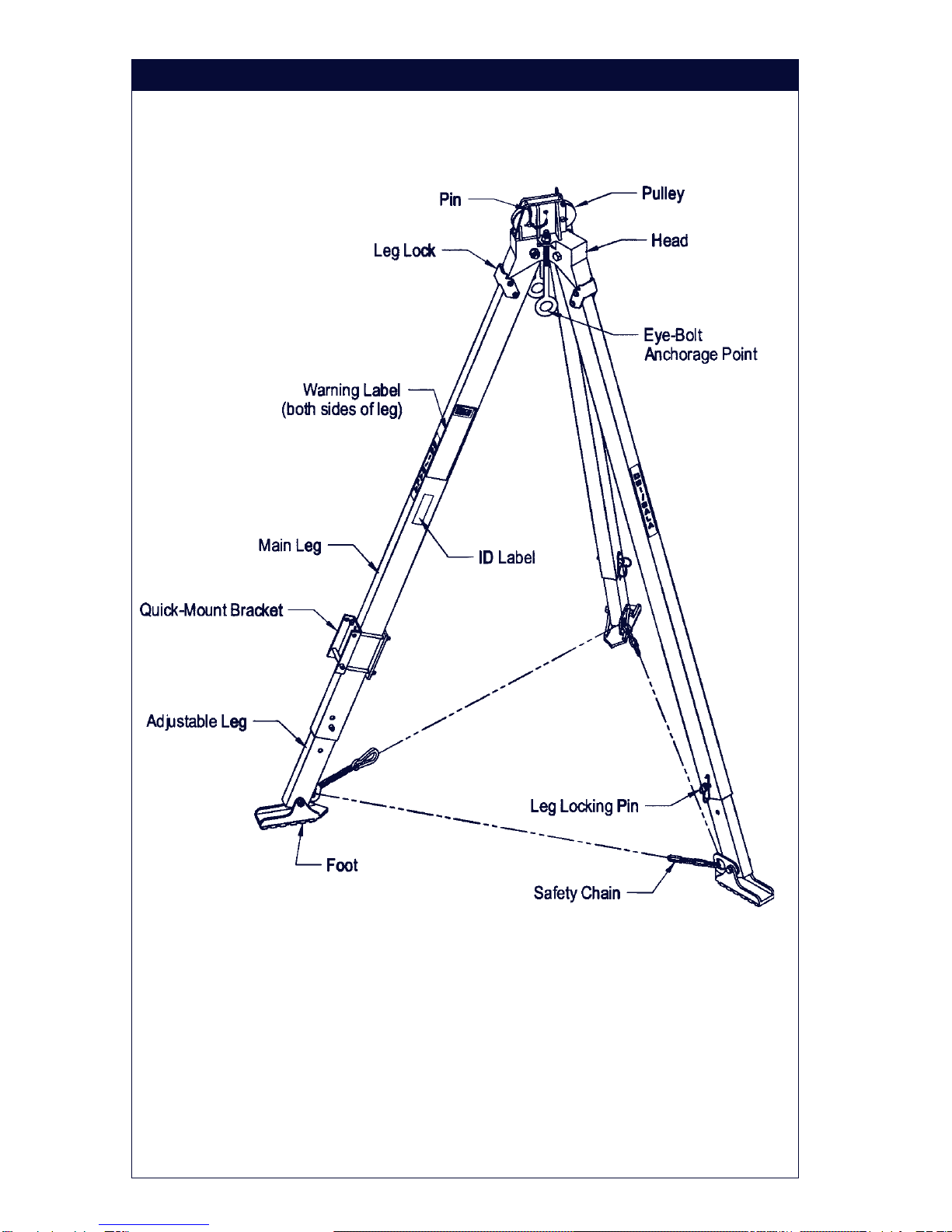

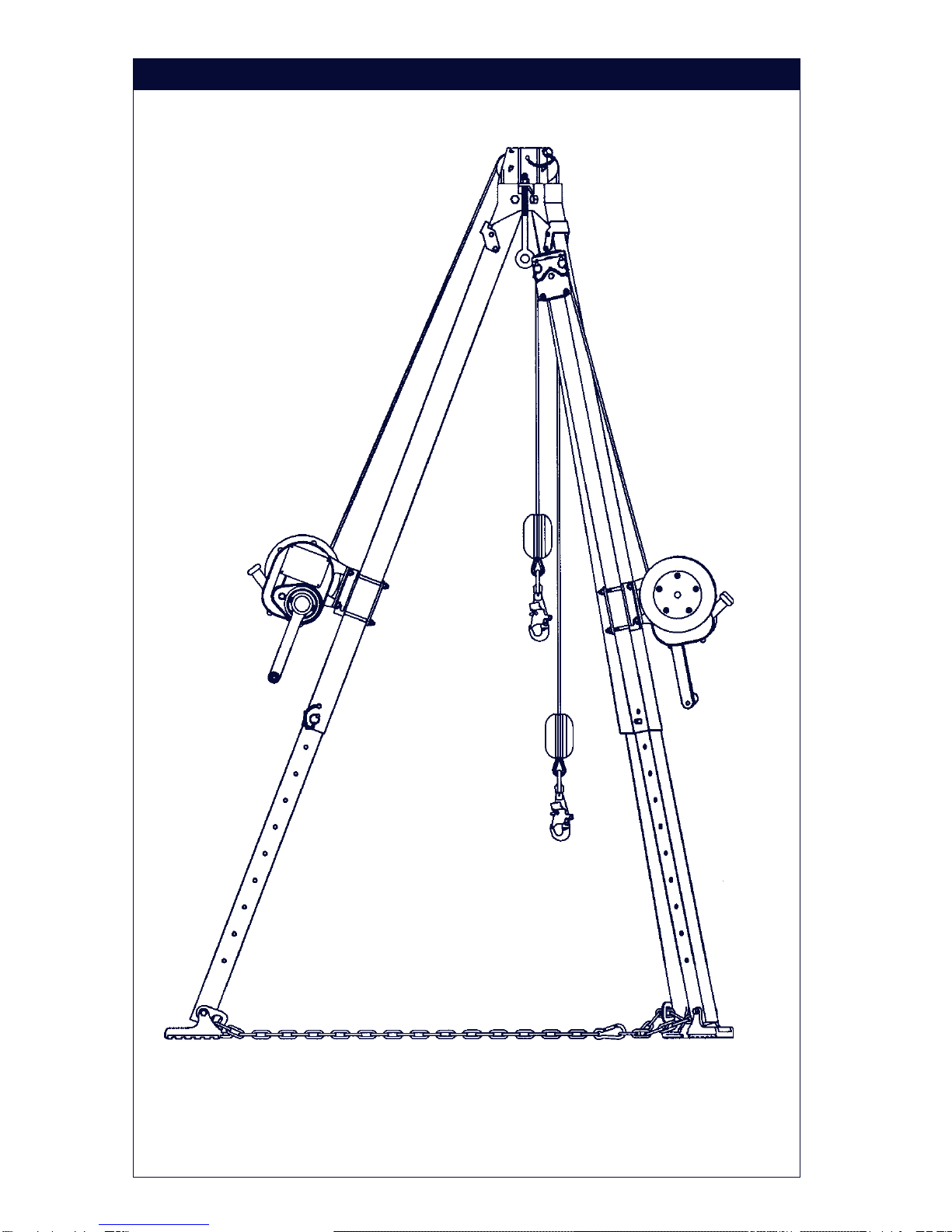

Figure 2

8000000and 8000010 Parts Identification

5

DESCRIPTIONS

8001717 Tripod: 7 ft. maximum height to eye bolt, 5 ft. minimum.Aluminum

construction with adjustable locking legs and safety chains. Fitted rubber

safety shoes with spiked edges.

8001718 Tripod: 9 ft. maximum height to eye bolt, 7 ft. minimum.Aluminum

construction with adjustable locking legs and safety chains. Fitted rubber

safety shoes with spiked edges.

8000000 Tripod: 7 ft. maximum height to eye bolt, 5 ft. minimum.Aluminum

construction with adjustable locking legs and safety chains. Fitted rubber

safety shoes with spiked edges. Includes head mount pulley assembly and

mounting bracket for DBI/SALASalalift® Winch or Self Retracting Lifeline.

8000010 Tripod: 9 ft. maximum height to eye bolt, 7 ft. minimum.Aluminum

construction with adjustable locking legs and safety chains. Fitted rubber

safety shoes with spiked edges. Includes head mount pulley assembly and

mounting bracket for DBI/SALASalalift® Winch or Self Retracting Lifeline.

IMPORTANT: Forspecial(custom) versionsofthisproduct, followthe

instructionsherein.If enclosed, seeattachedsupplement foradditional

instructionstobe followedwhenusing acustomproduct.

1.0 APPLICATIONS

1.1 PURPOSE: DBI/SALAtripods are to be used as part of a work

positioning,personnel riding, personalfallarrest, materialhandling,or

rescue and evacuation system.The tripod is a support structure or

anchorage for these systems.

1.2 LIMITATIONS:Thefollowingapplication limitationsmustbe

consideredbefore using thisproduct.Failure to observeproduct

limitations could result in serious injury or death.

A. INSTALLATION: The tripod mustbeproperly installed in

accordance with the requirements stated in section 3.0 of this

manual.

B. CAPACITY: Themaximum working loadfor this productis 350lbs.

(160kg).

C. PERSONAL FALLARREST SYSTEMS: Personalfall arrest

systems used in combination with the tripod must meet applicable

stateand federalregulations and therequirements insection 3.3.

6

D. PHYSICALAND ENVIRONMENTALHAZARDS: Use ofthis

equipmentin areas containingphysicalor environmentalhazards

mayrequire thatadditional precautionsbe taken to reduce the

possibility of damage to this equipment or injury to the user.

Hazards may include, but are not limited to; high heat (welding

metalcutting); strong orcaustic chemicals; corrosiveenvironments

(seawater);high voltage powerlines; explosive ortoxic gases;

moving machinery; or sharp edges. Contact DBI/SALA if you have

any questions about the application of this equipment in areas

wherephysicalor environmentalhazardsare present.

E. TRAINING:Thisequipment isto be installed and used by persons

who have been trained in its correct application and use.

1.3 Refer to national standards, including; ANSI Z359.1, ANSI A10.14,

ANSI Z117.1, and applicable local, state, and federal (OSHA)

requirements,including 29 CFR1910.146,for moreinformationon the

applicationof thisandassociated equipment.

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF COMPONENTS: DBI/SALAequipmentis

designedfor use withDBI/SALA approvedcomponents and

subsystems only. Substitutions or replacements made with non-

approved components or subsystems may jeopardize compatibility of

equipment and may effect the safety and reliability of the complete

system.

2.2 COMPATIBILITY OF CONNECTORS: Connectorsare considered to

becompatible withconnecting elements whenthey havebeen

designed to work together in such a way that their sizes and shapes

do not cause their gate mechanisms to inadvertently open regardless

of how they become oriented. Contact DBI/SALA if you have any

questionsabout compatibility.

Connectors(hooks, carabiners, andD-rings) mustbecapable of

supportingat least5,000 lbs. (22kN). Connectors must be compatible

with the anchorage or other system components. Do not use

equipmentthat is notcompatible. Non-compatibleconnectors may

unintentionallydisengage.See Figure 3.Connectorsmust be

compatible in size, shape, and strength. Self locking snap hooks and

carabinersare required byANSI Z359.1 andOSHA.

2.3 MAKING CONNECTIONS: Onlyuseself-lockingsnap hooks and

carabiners with this equipment. Only use connectors that are suitable

to each application. Ensure all connections are compatible in size,

7

shape and strength. Do not use equipment that is not compatible.

Ensure all connectors are fully closed and locked.

DBI/SALAconnectors (snaphooks and carabiners)are designedto be

used only as specified in each product’s user’s instructions. See

Figure4 for inappropriateconnections. DBI/SALA snaphooks and

carabinersshould not beconnected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

NOTE:Largethroatopeningsnap hooksshouldnotbeconnectedto

standardsize D-ringsor similarobjects whichwill resultina loadon thegate

ifthe hookorD-ring twistsorrotates. Largethroat snaphooksare designed

foruseon fixedstructuralelements suchas rebarorcross membersthatare

not shaped in a way that can capture the gate of the hook.

C. Ina falseengagement, where features that protrudefrom thesnap

hook or carabiner catch on the anchor and without visual

confirmation seems to be fully engaged to the anchor point.

D. Toeachother.

E. Directly to webbing or rope lanyard or tie-back (unless the

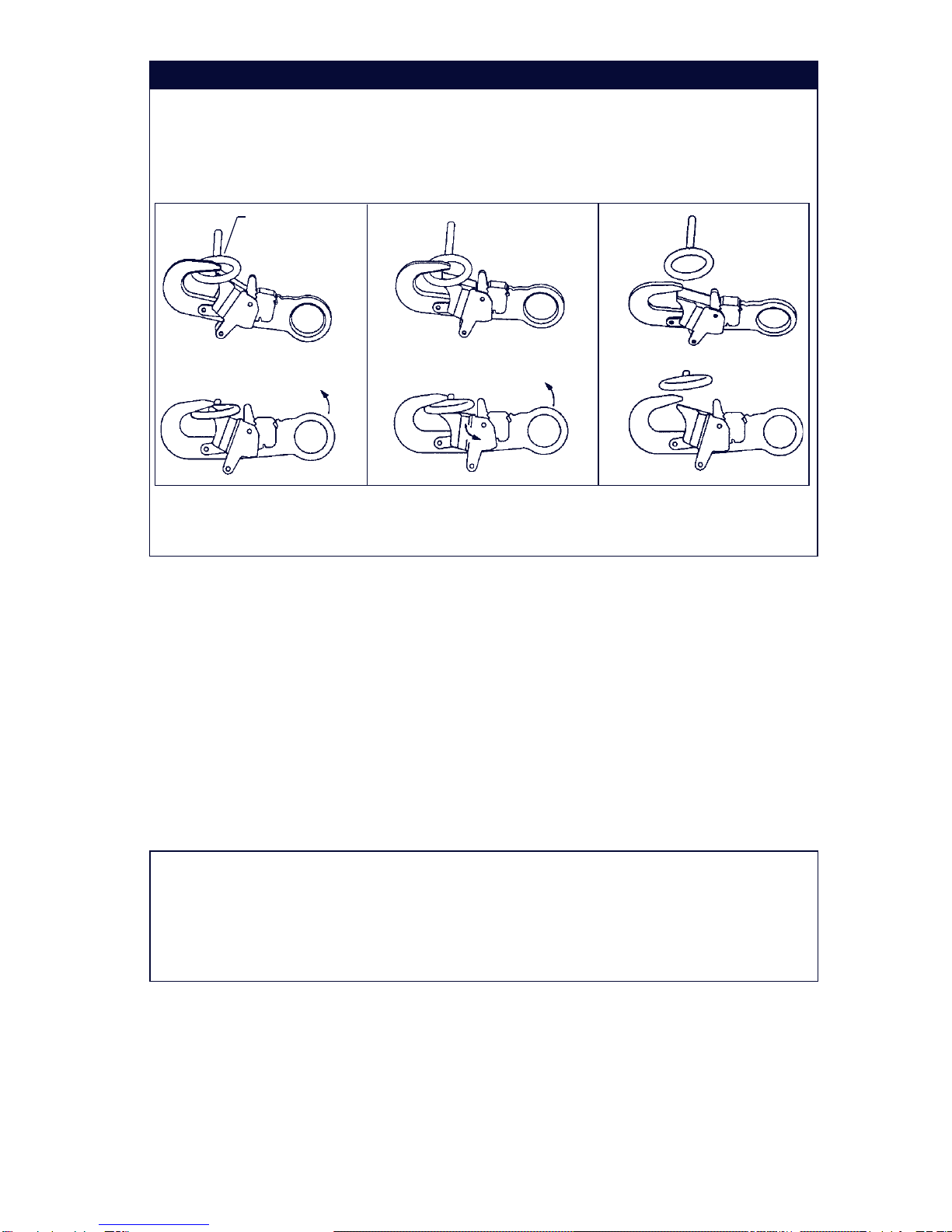

Figure 3 - Unintentional Disengagement (Roll-out)

If the connecting element that a snap hook (shown) or carabiner attaches to is

undersized or irregular in shape, a situation could occur where the connecting

element applies a force to the gate of the snap hook or carabiner. This force may

cause the gate (of either a self-locking or a non-locking snap hook) to open,

allowing the snap hook or carabiner to disengage from the connecting point.

1. Force is applied to

the snap hook. 2. The gate presses against

the connecting ring. 3. The gate opens

allowing the snap

hook to slip off.

Small ring or other

non-compatibly

shapedelement

8

manufacturer’sinstructionsforboth the lanyardand connector

specifically allows such a connection).

F. To any object which is shaped or dimensioned such that the snap

hook or carabiner will not close and lock, or that roll-out could

occur.

2.4 STRUCTURALSTRENGTH: The structure (mounting surface) onto

which the tripod is erected (floor, tank top, roof, etc.) must meet

minimum strengths given below for the applications selected:

FallArrest: FromANSIZ359.1; “The structure(mountingsurface)

selected for personal fall arrest systems (PFAS) shall have a strength

capable of sustaining static loads in the direction(s) permitted by the

PFAS when in use of at least (A) 3,600 lbs. (16kN) when certification

exists (seeANSI Z359.1 for certification definition), or (B) 5,000 lbs.

(22.2kN) in absence of certification. When more than one tripod is

installed on a structure for fall arrest, and the systems will be used

simultaneously, the strengths set forth in (A) and (B) above shall be

multiplied by the number of systems attached to the structure.” From

OSHA1926.500and1910.66;“Anchorages (mounting surface)used

for attachment of personal fall arrest systems (PFAS) shall be

independentof any anchoragebeing usedtosupport orsuspend

platforms, and capable of supporting at least 5,000 lbs. (22.2kN) per

user attached, or be designed, installed, and used as part of a

complete PFAS which maintains a safety factor of at least two and is

underthe supervision ofaqualified person.”

Figure 4 - Inappropriate Connections

9

Work Positioning:Thestructure (mountingsurface)selectedfor work

positioning applications must sustain a static load of at least 5,000 lbs.

applied in the directions permitted by the work positioning system

when in use. Each tripod installation must independently sustain this

load.

Personnel Riding:The structure(mountingsurface) selectedfor

personnel riding applications must sustain a static load of at least

2,500lbs. appliedin the directionspermitted bythe personnel riding

system when in use. Each tripod installation must independently

sustain this load.

Material Handling: Thestructure (mounting surface)selectedfor

material handling applications must sustain a static load of at least

2,500lbs. appliedin the directions permitted by the material handling

system when in use. Each tripod installation must independently

sustain this load.

Rescue: Thestructure(mounting surface) selectedforrescue

applications must be capable of sustaining a static load of at least

2,500 lbs. applied in the directions permitted by the rescue system

when in use. Each tripod installation must independently sustain this

load.

3.0 OPERATION AND USE

WARNING: Do notalterorintentionally misusethisequipment.Consult

DBI/SALAwhen usingthisequipment incombination withcomponentsor

subsystemsotherthanthose describedinthismanual.Some subsystemand

componentcombinationsmay interferewiththe operationof this equipment.

Usecautionwhenusing thisequipmentaroundmovingmachinery,electrical

hazards,chemicalhazards,andsharpedges.

WARNING: Consultyour doctorif thereisreason todoubtyour fitnessto

safelyabsorb theshock fromafall arrest.Age andfitness seriouslyaffect a

worker'sabilityto withstandfalls. Pregnantwomenor minorsmustnot use

theDBI/SALAtripods exceptfor emergencysituations.

3.1 BEFORE EACH USE: Before each useof thisequipment carefully

inspect it to ensure that it is in good working condition. Check for worn

or damaged parts. Ensure all parts (nuts, bolts, etc.) are present and

secure. Check legs to ensure they are straight, free of cracks, dents,

etc. Ensure pulleys rotate freely and entire system is free of corrosion.

Refer to section 5.0 for further inspection details. Do not use if

inspectionreveals anunsafe condition.

10

3.2 PLANNING:Plan your workpositioning,personnelriding, personal fall

arrest,material handling,or rescue andevacuation systembefore

starting your work. Consider all factors that affect your safety at any

timeduring use.Some important pointsto considerwhen planning

your system are:

A. HAZARD EVALUATION: An evaluation ofjob site hazardsis

necessary prior to starting work. Consult applicable OSHAand

industrystandardsfor guidelinesandregulatoryrequirements on

issues such as confined space entry, personal fall arrest

systems, single point adjustable suspended scaffolds, etc.

B. WORK SITE GEOMETRY: The installationand use ofthe tripod

must be consistent with the geometric requirements given in

section3.4 or3.5. When suspendingworking linesfrom the tripod

check for obstructions or sharp edges in the work path.Avoid

working where the user may swing and hit an object or where lines

may cross or tangle with that of another worker in the area.

C. SECONDARYOR BACK-UPFALLARRESTSYSTEM: When

using the tripod as a support for suspending a worker at a work

level,or forpersonnel ridingapplications, asecondary or back-up

fall arrest system is required. See OSHA 29 CFR 1910.28 and

1926.451.Thetripod has provisionsfor connectionof a secondary

or back-up personal fall arrest system. See sections 3.3 and 3.5.

D. RESCUE: In the event of an accident with injuries or other

medical emergency, it is critical that a means of dealing with such

asituation hasbeen plannedin advance.Response timeoften

plays an important role in the survival of an injured worker. Users

ofthis equipment must be trainedin emergency procedures.

3.3 REQUIREMENTS FOR PERSONAL FALLARREST SYSTEMS:

Personal fall arrest systems used with this tripod must meet

applicableOSHArequirements. Whenin use, thePFAS shouldbe

rigged to minimize any potential free fall and never allow a free fall

greater than six feet. It is recommended that the PFAS used with this

equipment include a full body harness as the body support

component.PFAS's that incorporate full bodyharnesses must

maintain fall arrest forces below 1,800 lbs. and arrest the fall within 42

inches. Body belts, unless incorporated into a full body harness, not

recommended for use with this equipment.Atypical PFAS includes a

full body harness, a connecting subsystem or component (self

retracting lifeline or a lifeline and rope grab) and the connectors to

couple the system together.

11

WARNING: Follow themanufacturer'sinstructionsforthe personalfallarrest

equipmentselected foruse withthe tripod.

IMPORTANT: Forfree fallandrescue applications,bodybelts arenot

recommendedforuse. Bodybeltsincrease therisk of injuryduring fallarrest

incomparisonto afullbody harnessanddrastically reducethetolerable

suspensiontimecompared toafullbody harness.Limitedsuspension time,

increasedrisk ofinjury,and thepotentialfor improperlywearing abody belt,

mayresult inadded dangerto theuser.DBI/SALArecommends usinga full

bodyharnessforfall arrestandrescueapplications.

3.4 INSTALLATION REQUIREMENTS OF TRIPOD

A. LOAD REQUIREMENTS: Dependingontheapplication,the

strengthrequirements forthe supporting structureonto whichthe

tripod is erected vary. See section 2.4 for application types and

the supporting structure load requirements. If an installation will be

used for more than one type of application, always select the

loadingfor the applicationwith the greaterloadrequirements.

B. GEOMETRIC REQUIREMENTS: Thetripodmustbemounted

where it can be leveled using the leg adjustments. The footing

must be solid under each leg, and support the intended loading.

Position the tripod such that the lifeline will be directly over the

intendedwork area wheninstalled. Do notposition the tripod

where the worker will have to swing under the tripod to reach the

workarea.Avoidpositioningthe tripodwherethe workingline may

abradeagainstsharp edges. SeeFigure5.

WARNING: Neverallow theworking linetoextend outsidethe legsofthe

tripod.Tippingof thetripodcould occur.

C. TO ERECT TRIPOD: The tripod is shipped with the legs set at full

retraction. Erect as follows, see Figure 5: 1) Lay the tripod on the

workingsurface; 2)Adjust legs to requiredworking height;3)Tilt

the tripod into an upright position; 4) Fully spread the legs, ensure

legsare against bearingsurface onhead.Thelegswill

automatically lock in place.To collapse tripod, pull leg down to

disengage leg lock and swing leg in; 5) Position tripod over

opening so working line will be located approximately in the center

of the opening. Ensure footing is solid under each leg and can

support the intended loads. Level the tripod by adjusting the leg

height; 6) Adjust the leg chain by removing excess slack.

WARNING:Exceptforemergencysituationswherelegchainsmayinterfere

withrescue, thetripod mustnever beusedwithout theleg chainsin place.

12

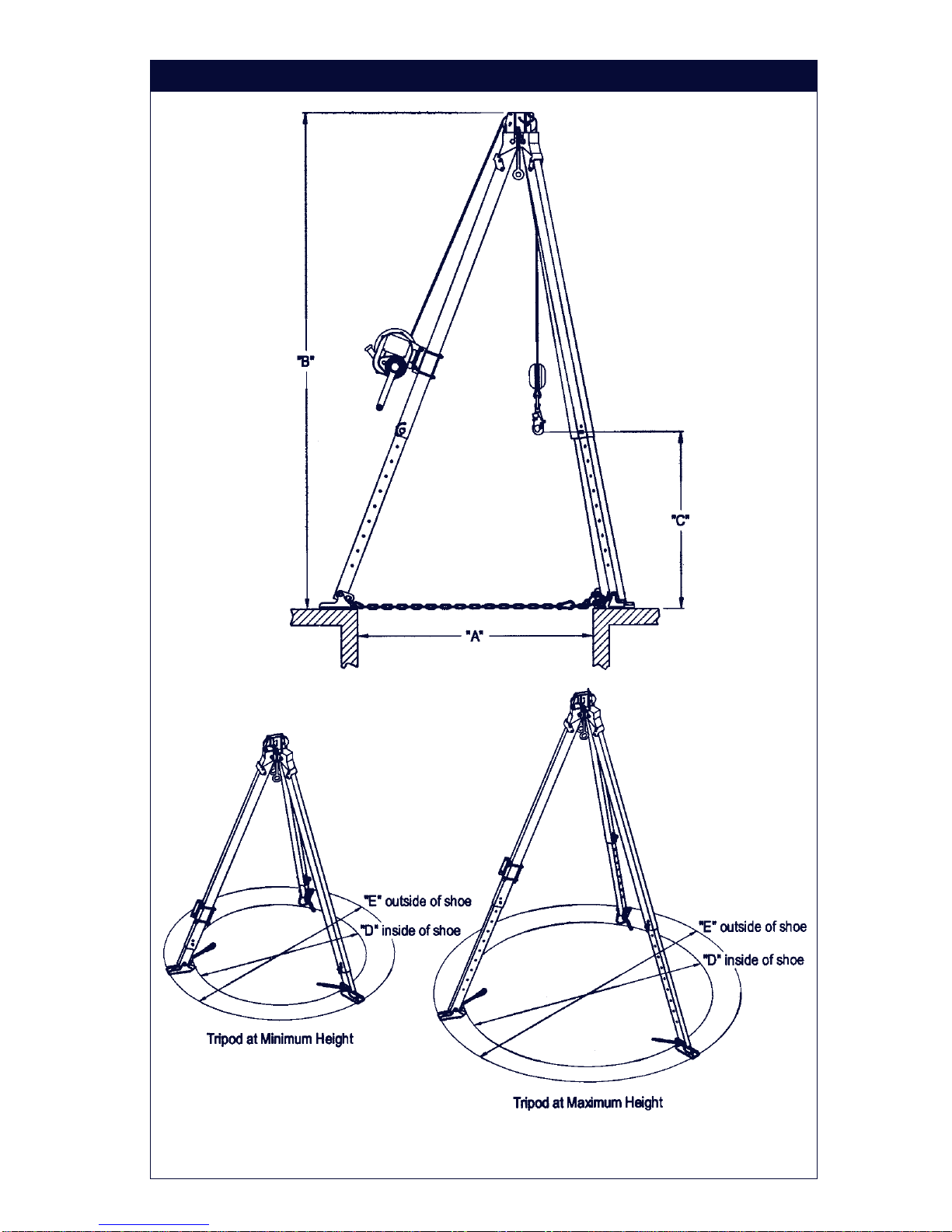

Figure 5

13

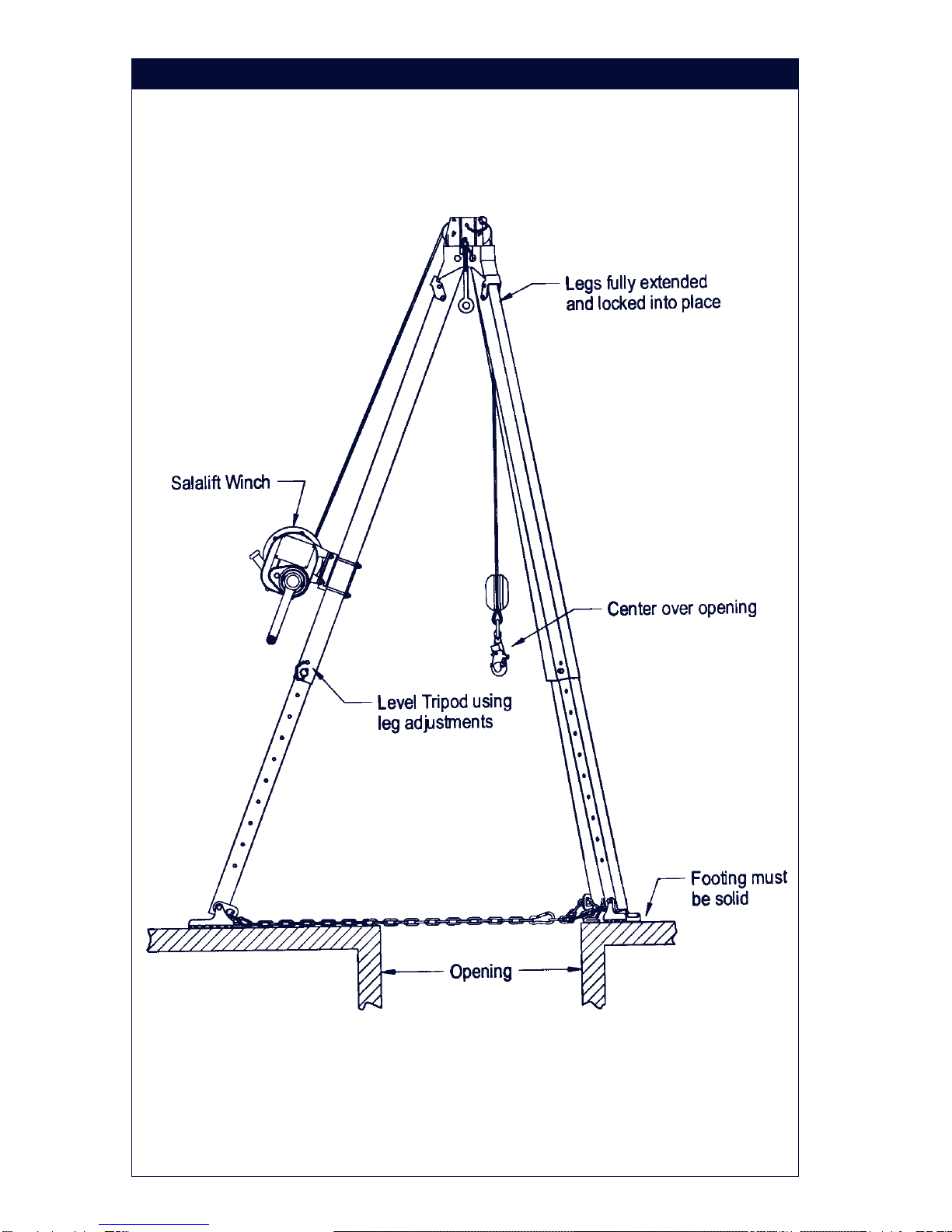

Figure 6

Figure 7

IMPORTANT: The tripodmust bepositionedso theworking linewill be

directlyover theintended workarea. Itmust bepositioned toensureasafe

workingareaforthe operator.

WARNING: Do not usethe tripodif oneor more ofthe legsare notlocked

intotheerect position(completely spreadout).

3.5 CONNECTING EQUIPMENT TOTHE TRIPOD: The tripod hasbeen

designed for multi-purpose applications that may involve the use of

one or more systems attached to the tripod.The following details the

connection of equipment to DBI/SALA tripods. See associated

equipmentinstructions for furtherinformation:

A. EYE-BOLT:Acomponent (self

retractinglifeline,rope grab/

lifeline system) can be

attached to either one of the

eye-boltanchoragepoints.

SeeFigure6.Connect

equipment to the eye bolt

anchoragepoint by usinga

clevis and pin (minimum

breakingstrength of 5,000

lbs.), self locking carabiners or

self locking snap hooks.

B. LEG MOUNT PULLEY:

Figures 7 and 8 shows the

optionalleg mountpulley model 8003238.This pulleyis used

when more than one device is mounted to the tripodlegrequiringa

directionalpulley. The leg mount pulleywill accommodateup to 1/4

inch diameter line. Install the leg mount pulley on the desired

tripod leg as shown in Figure 7. Position the leg mount pulley

directly under the leg lock

near the top of the tripod.

The pulley may be

positionedon either side

of the tripod leg. It may be

necessaryto removeone

of the eye bolts to gain

clearancefor the lifeline.

Tighten the clamp plate

bolts to 15 ft.-lbs. Do not

use or install more than

one system on a single

tripodleg.

14

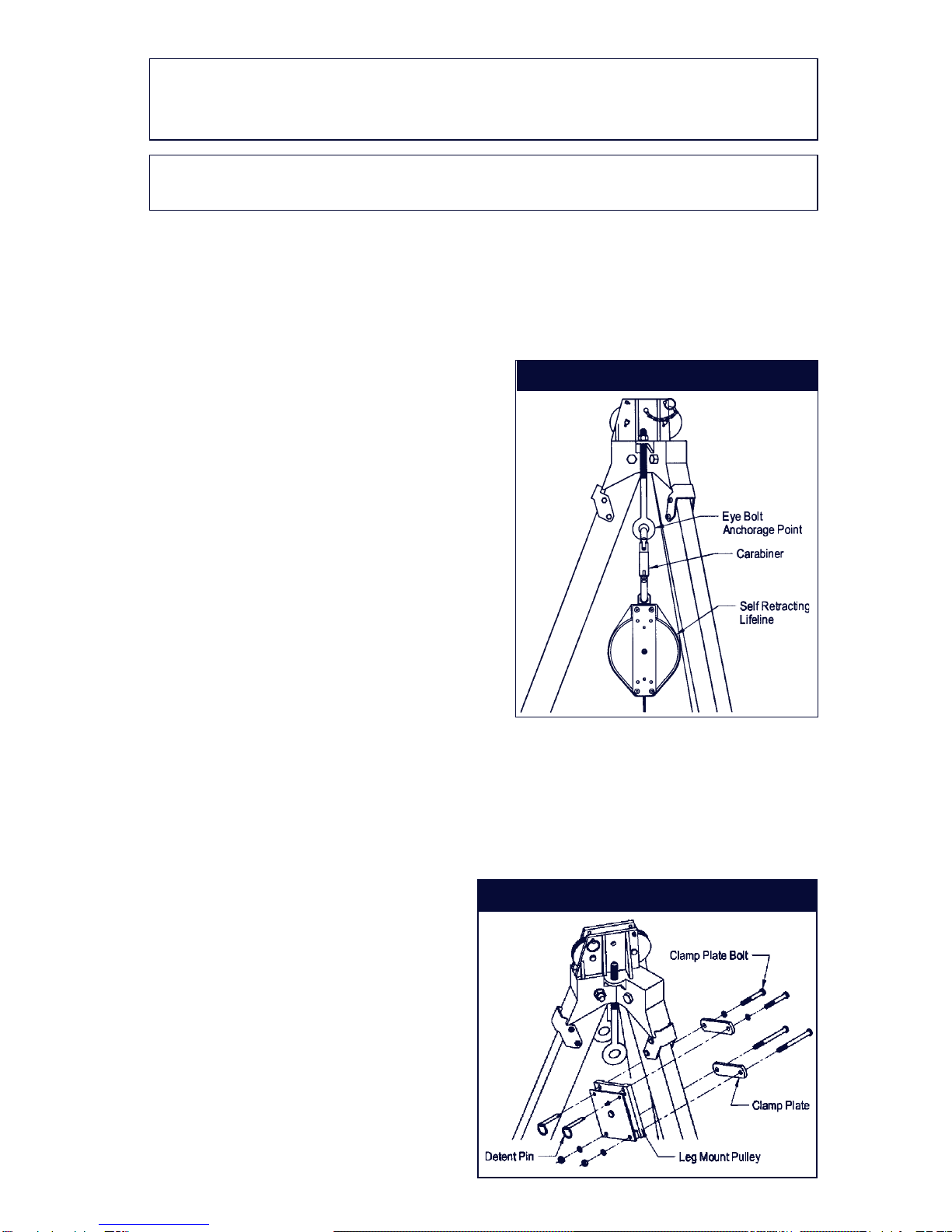

C. QUICK-MOUNT BRACKET: Figure8showsthetripodquick-mount

legbracket8005048(optionalon8001717and 8001718 models).

To install the quick-mount bracket to the tripod leg, assemble as

shown in Figure 8. Adjust bracket to desired position on the leg

and tighten bolts to 15 ft.-lbs. Do not over tighten. Do not install

quick-mountbracket onto thelower (telescoping) leg.The quick-

mount bracket must be used for connection of the Salalift® winch

(8101000series),the WorkWinch(8103000 series) andforleg

mounting of DBI/SALA Self Retracting Lifelines.

D. HEAD MOUNT PULLEYS: The8000000 and 8000010 model

tripodscome equipped withheadmounted pulleys.These pulleys

should be used for mounting the line of the primary use system

overthe tripodheadwhen usedin the legmounted position.The

head mount pulleys will accommodate up to a 1/4 inch diameter

line. See Figure 8, 9, and 10.

E. SNATCH BLOCK PULLEY: Figures8and10 show theoptional

snatch block pulley assembly model 8003205. The snatch block is

used when more than one device is mounted to the tripod

requiring a directional pulley. The snatch block is attached to one

of the unused eye-bolts and will accommodate up to 1/4 inch

diameter line. Do not use the Salalift winch with the snatch block

Figure 8

15

pulley because of possible cable rubbing on the tripod leg, and

uneven winding of the cable onto the winch drum.

F. SALALIFT® WINCH: WhenusingtheSalaliftwinch(8101000

series) with the tripod, the winch must be mounted to the leg

in-line with the head mount pulleys. Route the winch line over the

head mount pulleys as instructed in the Salalift® winch user

instruction manual. Do not use winch with snatch block pulley

(seesection 3.5.E).

WARNING: Multiple systemsmaybe attachedtothetripod (primarysupport

lifelineand back-uplifeline), butthe tripodis forone personuse only.

Exception:Emergencyrescueapplications only.Amaximum ofonesystem

canbe attachedto anyone tripod leg.A maximumof twosystems shouldbe

attachedto onetripod,except back-uplifelines(fallarrest)whichare limited

toone system.

IMPORTANT: Knotsmust notbe used forload-bearing endterminations

(seeANSI Z359.1). Some knots reducethe strength of thelifeline by 50

percentor more.

4.0 TRAINING

4.1 It is the responsibility of the user to assure they are familiar with these

instructions, and are trained in the correct care and use of this

equipment.User mustalso beaware ofthe operatingcharacteristics,

application limits, and the consequences of improper use of this

equipment.

IMPORTANT: Training mustbeconductedwithout exposingthetraineeto a

fallhazard.Training shouldberepeatedona periodicbasis.

5.0 INSPECTION

5.1 FREQUENCY:

•Before Each Use: Visually inspect per steps listed in sections 5.2

and5.3.

•Monthly: A formal inspection of the tripod should be done by a

competent person other than the user. See sections 5.2 and 5.3 for

guidelines. Record results in the inspection and maintenance log in

section 9.0.

•After Fall Arrest: Inspectentiretripodandbasepersection5.2.

16

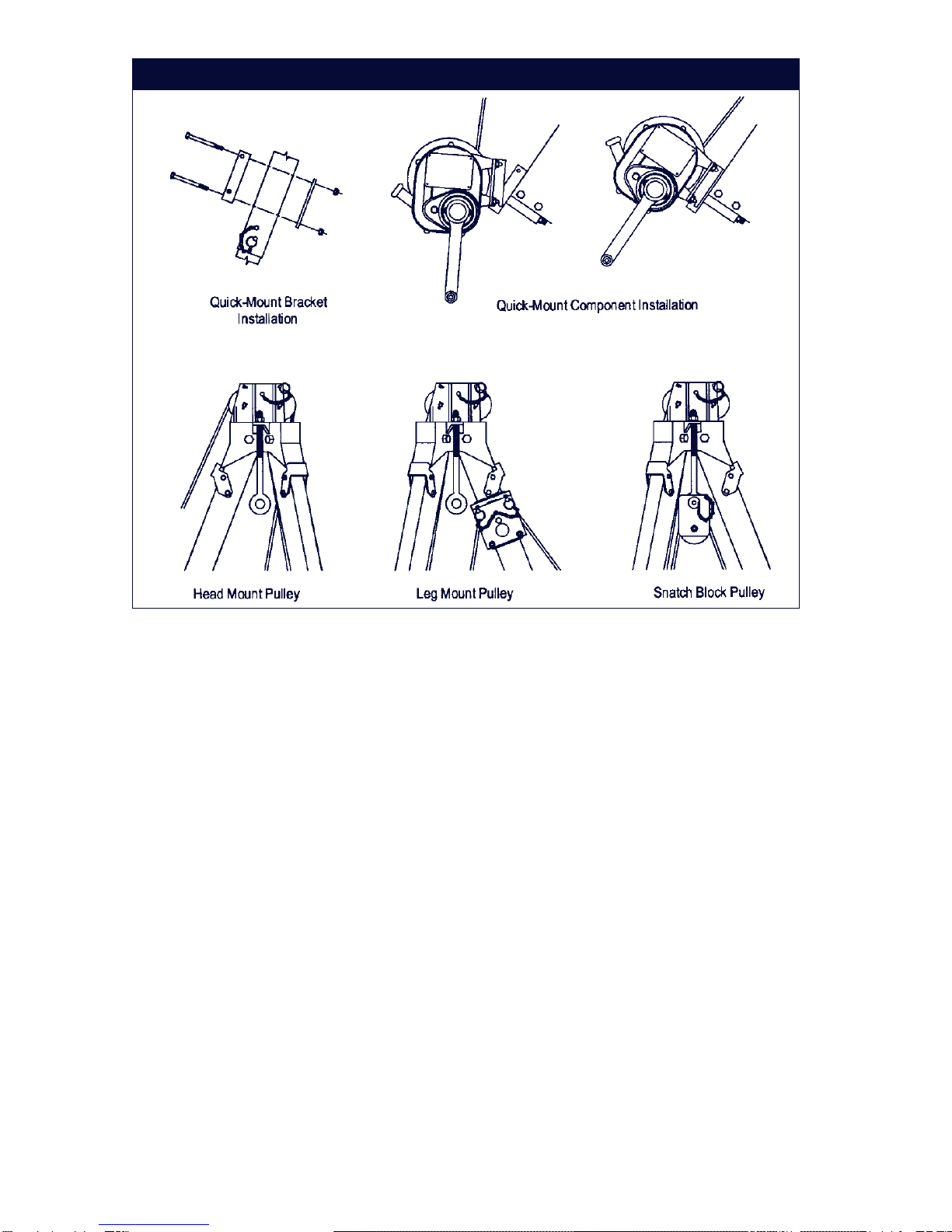

Figure 9

Two Salalift® Winches Mounted to Tripod

Lifelines routed through Head Mount Pulley and Leg Mount Pulley

17

Figure10

Salalift® Winch and Self Retracting Lifeline Mounted to Tripod

Lifelines routed through Head Mount Pulley and Snatch Block Pulley

18

WARNING: If thetripod hasbeen subjectedto fallarrest or impactforces, it

mustbe immediatelyremovedfrom serviceand inspected.If thetripod fails

topass theinspection, donot use;the equipmentmustbe destroyedor sent

toDBI/SALAforpossible repair.

IMPORTANT: Extremeworkingconditions(harshenvironment,prolonged

use,etc.)mayrequire increasingthefrequencyof inspections.

5.2 INSPECTION STEPS FOR TRIPOD

Step 1. All bolts and nuts must be securely attached. Check for

missing, altered, or substituted bolts, nuts, locking detent

pins or other parts. Inspect the tripod for signs of corrosion

which may weaken or affect parts in their function.

Step 2. Check each leg to see that it can be telescoped in and out

freely. Inspect legs for straightness. Ensure legs lock into

place when tripod is erect.

Step 3. Check the feet on each leg; ensure they pivot and the rubber

pad is in place.

Step 4. Check leg chain and connections; Ensure they are tight and

undamaged, chain must be free of defects and hook must be

inplace and workproperly.

Step 5. Checkthe head. Ensurethe eye-boltanchoragepoints arein

placeand arefree from damage.Ensure thecable pulleysare

cleanandrotate freely (8000000and8000010 modelsonly).

Step 6. Inspect the labels. Ensure all labels are present and fully

legible. See section 8.0.

Step 7. Record the results of inspection in the inspection and

maintenance log in section 9.0 of this manual.

Step 8. Inspect each system component according to manufacturer's

instructions.

5.3 If inspection or operation reveals a defective condition, remove the

tripod from service immediately and contact an authorized service

centerforrepair.

NOTE: OnlyDBI/SALAor parties authorizedin writingmay makerepairs to

thisequipment.

19

ledoMthgieWdaoLgnikroWdetaRlairetaM

7171008.sbl73 krowrof.sbl053 lennosreprogninoitisop ,snoitacilppagnidir tserrallafrof.sbl013 snoitacilppa

yltnanimoderP cnizdnamunimula leetsdetalp

8171008.sbl64

0000008.sbl74

0100008.sbl65

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 Periodically clean the exterior of the tripod using water and a mild

detergentsolution.Clean labels asrequired.

6.2 Replacementparts and additionalmaintenanceand servicing

procedures must be completed by a factory authorized service center.

An authorization and a return number must be issued by DBI/SALA.

6.3 Clean and store the body support and associated system components

accordingto separate instructionsprovided with thatequipment.

6.4 Store this equipment in a cool, dry, clean environment out of direct

sunlight.Avoid areas where chemical vapors may exist. Inspect after

anyperiod of extendedstorage.

7.0 SPECIFICATIONS

SeeFigure11.

snoisnemiD )11erugiFees(

sledoM.tf7sledoM.tf9

muminiM thgieH )mm(hcni

mumixaM thgieH )mm(hcni

muminiM thgieH )mm(hcni

thgieHmumixaM )mm(hcni

htgneLegarotS)877,1(07----)195,2(201----

retemaideloH* dennaps "A" )485(32)318(23)838(33)811,1(44

thgiehllarevO "B" )727,1(86)263,2(39)314,2(59)840,3(021

thgiehtfilelbaliavA "C" )542,1(94)088,1(47)039,1(67)565,2(101

stnemercnithgieH)67(3----)67(3----

sgelfodaerpS "D"

eohsfoedisnI )811,1(44)006,1(36)156,1(56)431,2(48

sgelfodaerpS "E"eohsfoedistuO )374,1(85)659,1(77)700,2(97)515,2(99

20

* Note: Tripods will span a larger opening; the leg chains will cross

overa portion of the opening.

•These tripods meet ANSI Z359.1, ANSI A10.14, and OSHA

requirements.

•The8000000and8000010 are U.L.classified.Seeproduct label for

details.

8.0 LABELING

8.1 The following labels must be present and fully legible:

Warning Label

Models8001717

and8001718

Specification Label

Models 8001717 and

8001718

Overtighten

Label Model

1001190

Warning Label

Models8000000

and8000010

Specification

Label Models

8000000and

8000010

21

Figure11

GeometricRequirements

This manual suits for next models

4

Table of contents

Other DBI SALA Camera Accessories manuals