English . . . . . . . . . . . . . . . . . . . . . .1

Français . . . . . . . . . . . . . . . . . . . .39

Deutsch . . . . . . . . . . . . . . . . . . . .79

Español . . . . . . . . . . . . . . . . . . .119

ENGLISH

Section 1: Introduction . . . . . . . . . . .2

Unpack . . . . . . . . . . . . . . . . . . . . . . . .2

Quickstart . . . . . . . . . . . . . . . . . . . . . . .2

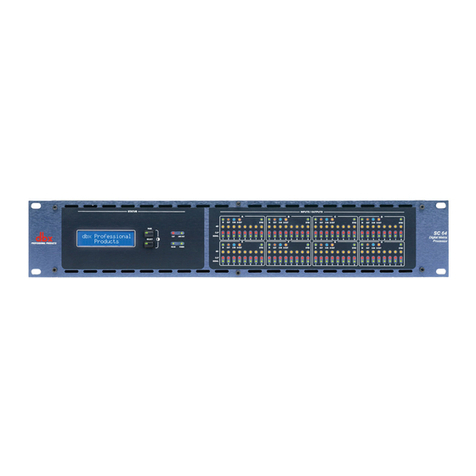

Section 2: The DDP Tour . . . . . . . . .3

Hardware . . . . . . . . . . . . . . . . . . . . . . .3

Front Panel/Display . . . . . . . . . . . . . .3

Rear Panel . . . . . . . . . . . . . . . . . . . .3

Signal Flow . . . . . . . . . . . . . . . . . . . .4

Software . . . . . . . . . . . . . . . . . . . . . . . .5

Setups and Programs . . . . . . . . . . . .5

Gate Section . . . . . . . . . . . . . . . . . . .5

Compressor Section . . . . . . . . . . . . . .5

Limiting Section . . . . . . . . . . . . . . . . .5

De-essing Section . . . . . . . . . . . . . . .5

Sidechain EQ Section . . . . . . . . . . . . .5

Dither . . . . . . . . . . . . . . . . . . . . . . .5

Section 3: Setup/Basic Operation . . .6

Analog Connections . . . . . . . . . . . . . . . .6

Digital Connections . . . . . . . . . . . . . . . . .6

MIDI Connections . . . . . . . . . . . . . . . . . .7

The Curve Window . . . . . . . . . . . . . . . . .7

Software Navigation . . . . . . . . . . . . . . . .8

Threshold Metering . . . . . . . . . . . . . .8

Operating Modes . . . . . . . . . . . . . . . .9

Program Mode . . . . . . . . . . . . . .9

The Bypass Button . . . . . . . . . . .10

Setup Mode . . . . . . . . . . . . . . . .10

Ext. S-chain and the Digital Meters .12

Viewing Elements of a Chain . . . . .14

Linked Programs . . . . . . . . . . . .14

Dual-Mono Programs . . . . . . . . .14

Section 4: Editing/Recalling/Saving

Presets . . . . . . . . . . . . . . . . . . . 15

The Store Button . . . . . . . . . . . . . . . . . .15

Moving Around . . . . . . . . . . . . . . . . . . .15

Editing Gates . . . . . . . . . . . . . . . . . . . .15

Editing Compressors . . . . . . . . . . . . . . .16

Editing Limiters . . . . . . . . . . . . . . . . . . .18

Editing De-Essers . . . . . . . . . . . . . . . . . .18

Editing the Dither Parameters . . . . . . . . .19

Editing the Sidechain EQ . . . . . . . . . . . . .19

More About Sidechain EQ . . . . . . . . . . . .20

Changing Chain Types . . . . . . . . . . . . . . .21

Saving Programs and Setups . . . . . . . . . .21

Saving a Program . . . . . . . . . . . . . . .21

Saving a Setup . . . . . . . . . . . . . . . . .22

Replace Old . . . . . . . . . . . . . . . .23

Store New . . . . . . . . . . . . . . . . .23

Section 5: Utility Functions . . . . . . .24

Contrast . . . . . . . . . . . . . . . . . . . . . . .24

Sample Rate . . . . . . . . . . . . . . . . . . . . .24

AutoLoad . . . . . . . . . . . . . . . . . . . . . . .24

Input Mode . . . . . . . . . . . . . . . . . . . . .24

Output Mode . . . . . . . . . . . . . . . . . . . .25

Digital Input Level Controls . . . . . . . . . . .25

MIDI/SysEx . . . . . . . . . . . . . . . . . . . . .25

A/D Calibration . . . . . . . . . . . . . . . . . . .25

High-Pass Filter . . . . . . . . . . . . . . . . . . .26

Section 6: Appendices . . . . . . . . . . .27

APPENDIX 1: Misc. Information . . . . . . . . .27

Hard Reset . . . . . . . . . . . . . . . . . . .27

Change Default Startup Program . . . . .27

Front Panel Lockout . . . . . . . . . . . . .27

TYPE IV™ Conversion System . . . . . . .27

TSE™ Tape Saturation Emulation . . . . .27

TCM™ Transient Capture Mode . . . . .28

LINKED SETUPS VS. MONO SETUPS . . . . . . .28

DITHERING . . . . . . . . . . . . . . . . . . . . .28

APPENDIX 2: Factory Setup Listing . . . . . . .29

APPENDIX 3: Factory Program Listing . . . .31

APPENDIX 4: MIDI/SysEx/CC Guide . . . . . .32

MIDI Basics . . . . . . . . . . . . . . . . . . . . .32

MIDI Channels . . . . . . . . . . . . . . . . .32

MIDI Changes . . . . . . . . . . . . . . . . .32

Continuous Controller Listing . . . . . . . . . .32

SYSEXBasics . . . . . . . . . . . . . . . . . . . .33

General Format . . . . . . . . . . . . . . . .33

Hex Value Definitions . . . . . . . . . . . . .33

Procedures . . . . . . . . . . . . . . . . . . .33

SysEx Program Dump Sample . . . . . . .35

APPENDIX 5: Factory Service/Warranty . . . .36

APPENDIX 6: Specifications . . . . . . . . . . . .37