DCA AQW5.5/10 User manual

Edition 2 Aug., 2019

Read through carefully and understand these instructions

before use.

GENERAL POWER TOOL SAFETY WARNINGS

Please read and comply with these original instructions prior to the initial operation.

Danger! The high pressure produced by the appliance is very hazardous if

connected with power source.

Warning! This appliance must not be operated by children or untrained

personnel.

Before starting the appliance, carefully check whether there is some possible

failure. The cable insulation layer must be intact.

The operator and people near the appliance must take protection to avoid the

splash during the operation.

Pull out the power plug when clean, maintain the appliance or replace the spare

parts.

Follow all safety rules during the operation.

a) Accessories and Spare Parts

CAUTION: To ensure appliance safety, use only original spare parts from the

manufacturer or approved by the manufacturer.

High pressure pipes, fittings and couplings are important for the safety of the

appliance.

b) Physical, Sensory or Mental Capacities

This appliance is not intended for use by persons(including children) with reduced

physical, sensory or mental capacities.

C) Application

Use this high-pressure washer for private households only and the intended use of

this product covers the cleaning of vehicles, buildings, terraces, garden equipment

and hay mowers.

All other uses are improper, and our company will take no responsibilities for the

damage caused by those improper uses.

Proper use also includes correct operation, maintenance, and repair.

d) Clothing and Equipment

Be careful to protect your body during the operation.

Wear antiskid shoes. Wear goggles, earmuffs and protective clothing during the

operation.

e) Cleaning Agent

The appliance has been designed for use with the cleaning agent supplied or

recommended by the manufacturer.

f) Checking the Appliance Before Operation

Do not use the machine if a supply cord or important parts of the machine are damaged,

e.g. safety devices, high pressure pipes, trigger gun.

Always check to see that the trigger on the spray handle actuates easily and returns to

the original position when released.

Always keep the high-pressure pipe and gun barrel accessories in good condition, and

are mounted properly.

g) Electrical Connection

Warning! The voltage and frequency of the appliance must accord with those of the

power source.

The appliance may only be connected to an electric supply by a professional electrician.

For safety reasons, we recommend that you operate the appliance only via a residual

current device (max. 30mA or 30ms).

The extension cable must be watertight and must never lie in water. The specification of

the extension cable must apply to the power of this appliance.

h) Water Connection

According to applicable regulations , the appliance must never be used on the drinking

water net without a backflow preventer.

Caution: use only water without any impurities. Install an external strainer if there is

quicksand in inlet water.

i) Working Period

Warning!

The appliance may not be operate in explosive atmospheres.

Do not clean asbestos-containing surface under high-pressure mode.

Never draw in fluids containing solvents or undiluted acids and solvents! This includes

petrol, paint thinner and heating oil.

Do not direct the jet against yourself or others in order to clean clothes or foot-wear.

The jet must not be directed at persons, live electrical equipment or the machine itself.

-1- -2-

The water jet that is emitted from the high pressure nozzle results in a repulsion

power acting on the hand spray gun. Make sure that you have a firm footing and are

also holding the hand spray gun and spray lance firmly.

Do not operate the appliance at temperatures below 0ºC.

Do not start the appliance when it is frozen.

Make sure the basic fastness and security.

The washer must be used on a secure and stable surface in a standing, upright

position

Do not cover up the appliance and use it in a room with poor ventilation.

j) After Work

Warning! Disconnect the mains plug from the socket when there is no

pressure in the system.

Disconnect the water inlet pipe between the machine and waterhead.

After work, completely drain appliance and accessories before storage.

k) Protection and Maintenance

Warning! Disconnect the mains plug from the socket before maintaining or

cleaning this appliance.

Repair work can only be performed by an authorized customer service and with

original spare parts of our company.

Turn off the appliance and read the troubleshooting table in the manual or contact

the local franchiser when some malfunctions occur, for example, the machine

refuses to start, stops, pulsates, or the motor makes noise.

Do not repair the machine, change the original structure of this product or change

the cord connection way.

l) Recycle

Stop using the old washer immediately.

Pull off the plug from power source.

Cut off the cable.

Do not throw the electrical equipment with household garbage.

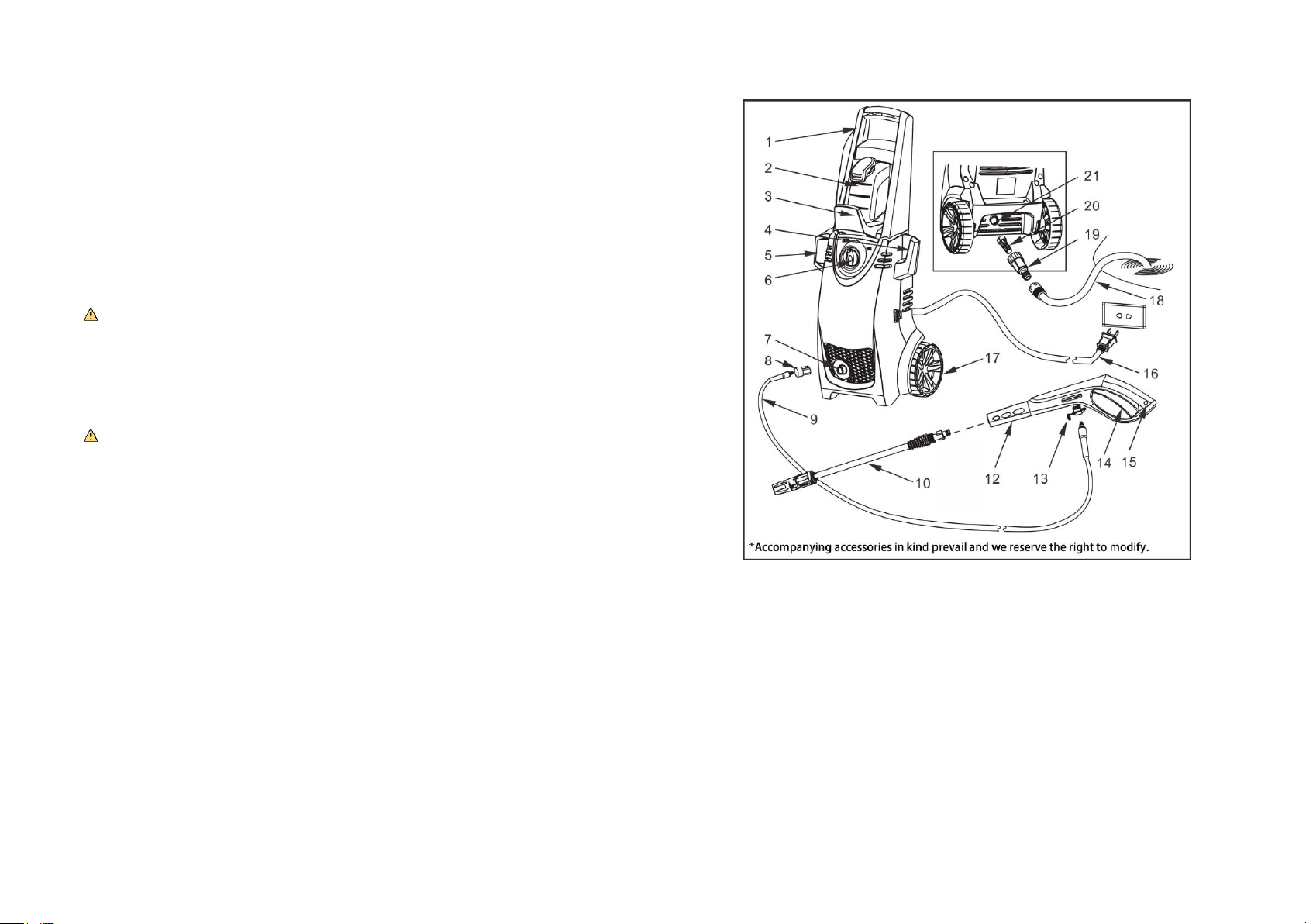

GENERAL DESCRIPTIONS

1.

Handle

12.

Pikestaff

2.

Cleaning Pot

13.

Gun Valve Bush

3.

Pressure Pipe Hook

14.

Switch Trigger

4.

Wire Rack

15.

Latch

5.

Gun Rack

16.

Cord

6.

Adjust Switch OFF/ON

17.

Wheel

7.

Water Outlet

18.

Water Inlet

8.

Quick Connector

19.

Inlet Nut

9.

High-pressure Pipe

20.

Inlet Strainer

10.

Gun Barrel

21.

Water Inlet

-3- -4-

SPECIFICATIONS

Rated Flow

5.5 L/min

Rated Temperature

0~40 ℃

Rated Power Input

1600 W

Max. Inlet Pressure

7 Bar

Insulation Level

Ⅱ

Sound Power Level

LPA=77dB(A)

Protection Grade

IPX5

Rated Pressure

100 Bar

Allowable Pressure

140 Bar

※Due to the continuing program of research and development, the specifications

herein are subject to change without prior notice.

INSTRUCTIONS FOR OPERATION

Installation of Accessories

Inlet strainer must always be installed to

filter out sand, lime and other impurities

which will damage the pump valve.

1) Insert the handle into the slide cone on

top and fix it onto the body with two

pieces of 4.8 x20 cross screw. (Fig. 1)

2) Place pressure pipe hook in correct position

according to drawing and fix it onto the body

with two pieces of 3.5 X20 cross screw stud.

(Fig. 2)

3) Propel the cleaning pot into the frame in the

middle of handle according to drawing until

clamped, then plug the suction tube of cleaning

pot in to joint on the body, and make it clamped

in the groove at back of handle. (Fig. 3)

4) For initial installation of inlet nut, you should

check whether the filter is mounted into the

machine inlet by the factory or not before

tightening it into the inlet. (Fig. 4)

Connection of High Pressure Water Pipe

1) Aim the high-pressure water pipe at pikestaff valve bush and push inward to complete

the connection. Otherwise press the button and you can dismantle the high pressure water

pipe.

2) Aim the high-pressure water pipe at the machine outlet and rotate clockwise to the

-5- -6-

bottom. (Fig. 5)

Installation of Gun Barrel

1) Push gun barrel into pikestaff, which needs to be pressed down to the ground and

rotate 90 degrees to the left until the parts are completely geared and don't fall off. The

gun barrel of this machine can regulate the shape of water spray by rotating the

nozzle to the left and right.

2) When using the cleaning liquid, put it

into the cleaning pot and set the gun

nozzle to low pressure, and then start the

machine to press the trigger, it can spray

the cleaning liquid on the surface to be

cleaned. (Built-in cleaning pot) (Fig. 6)

Water Connection

•Connect to Pressurized Waterhead

The maximum inlet pressure is 0.7MPa/7bar and the highest temperature is 40℃,

refer to nameplate.

1) Ensure inlet strainer is put into inlet nut and not blocked.

2) Mount to inlet pipe with quick connector and the other end connects with

Waterhead.

•Note: according to the national and local regulations, for connection to drinking water

mains, water must flow through the pipe to prevent ingression of dirt and sand into

machine before connecting water pipe to the machine.

3) Turn off water supply, connect water intake to water inlet nut with quick connector.

•Connect to the water supply with lower pressure

The machine can also operate in self-suction mode, which means the machine can be

connected to water containers, rivers, lakes and pools, no backflow preventer is needed

when diverse from non-portable water mains. External filter must be used when connecting

the machine from water source of lower pressure to prevent suction of impurities; water

inlet pipe should be 3m in length. We recommend using original inlet pipe kit in order to

meet these requirements, and the machine is designed to pump at the maximum distance

to water level at 50cm.

1) The machine will be placed above water

level at maximum height of 0.5 meters and

separate high-pressure pipe from water outlet.

(Fig. 7)

2)Ensure the filter is in place, connected to

water inlet pipe and ensure it is tightly

connected to water inlet.

3) Turn on the machine and press the switch to

ON position.

4) Wait until steady flow from water outlet.

5) Turn off the machine and connect high

pressure water pipe and gun assembly. (Fig. 8)

Start the Pressure Washer

Warning! Before starting the cleaning operation, check whether the machine is in upright

position and placed on flat surface, do not put it in grass. The voltage and frequency of

machine (refer to nameplate) must be consistent with that of power supply.

-7- -8-

This manual suits for next models

1

Table of contents