DCCconcepts Cobalt IP Analog User manual

Installing the Cobalt iP Analog turnout motor

First, assemble your Cobalt ip Analog turnout motor: The throw

arm is already pre-centred to make this easy for you.

(1) Insert the fulcrum bar into the slides (The horizontal part of the bracket with the

holes can be either at the top or bottom . We usually have it at the bottom).

(2) Now add the throw wire, passing the straight end upwards through the centre hole

of theadjustable fulcrum bar and then inserting the bent end of the wire into

the smaller top hole on the end of the throw arm.

Secure the throw wire in place with the washer head screw provided.

(3) Add the pre-cut self adhesive foam pad to the top of the Cobat iP Analog

motor (leave the protective top on the pad until ready to install)

Now we are ready for the installation.

As well as the pre-cut foam pad, we include mounting screws with every

Cobalt iP Analog turnout motor so all you will need are basic tools.

You will need a screwdriver and a drill, plus both 1.5mm (for screw pilot

holes) and 10mm drills for the throw-wire installation. (The exact drill sizing

you use is not critical so close or imperial sized drills will be OK). If the

baseboard is over 20mm/0.75” thick, increase the larger drill size.

(1) Mark the position of the hole in the turnout tie-bar with the turnout blades

held at their mid-way position. This hole may be at the centre or at the end

of the tie-bar.

(2) Make a pilot hole at that mark, then drill right through the baseboard

using the larger drill bit. Be sure to keep the drill vertical as you drill.

(It is also good practice to use a countersink bit to clean up the hole top and

bottom a little after drilling)

(3) Remove the top protective layer from the self adhesive pad and from

below the baseboard, insert the throw wire into the hole in the tie bar. When

you are sure that your Cobalt iP Analog is centralised relative to the hole,

and aligned properly along the turnouts axis, press it into position on your

baseboard. (it can face either way). Test operation.

(4) Adjust the fulcrum bar as needed by raising or lowering it. Lowering it

increases throw & blade pressure. Raising it reduces throw & pressure.

(5) When happy with operation, add a small drop of PVA to the case where it

meets the fulcrum bar to hold it in position.

(6) Use screws provided to screw Cobalt iP Analog permanently in position.

Cobalt turnout motors and the Co-

balt accessory range are designed

& manufactured by

DCCconcepts Ltd.

salesuk@DCCconcepts.com

www.DCCconcepts.com

Cobalt iP Analog turnout motor Specications

Dimensions:

Power:

Connection:

Control:

DCC/Digital:

Body only: 28mm x 38mm x 52mm deep

Top overall inc Fulcrum and tabs: 40mm x 45mm

Depth inc soldering-free connectors: 68mm

7~23v DC. Drive static <5mA, active average <40mA

9 way spring terminals. Wire diameter up to 32x.2 or 18g.

Ideal .16x.2 or 20g. Minimum 7x.2 or 24g

Change turnout by reversing polarity of DC voltage. Use

SPDT switch & DCCconcepts PSU-2, DC supply plus DPDT

switches. DCCconcepts switch packs are economical and

include both switches and a panel LED selection.

Use with our DCCconcepts ADfx-2 or ADfx8 decoders for

the best overall performance. If you will use other brands

pre-check their performance. (Cobalt iP Analog draws very

little, but some brands are actually very weak).

Cobalt iP Analog Life-time Warranty

DCCconcepts’ guarantees and warranties are always made in respect of the orig-

inal owner of the products. While our rst priority is to always be sure that users

of our products are given the best possible service we do also reserve the right to

request proof of purchase so we can properly establish that you were the original

purchaser and user of the product.

DCCconcepts use the best quality materials, thoroughly testing each and every

Cobalt iP Analog motor multiple times prior to packaging them for sale and so we

have no hesitation in providing you with the best warranty possible.

Simple promises only need simple words:

If your Cobalt iP Analog ever fails or needs service when it is being used

under fair and reasonable conditions we will repair/replace it at no charge.

We offer this guarantee to you for as long as you own it.

Owners Manual

Cobalt iP Analog turnout motor.

iP stands for “Intelligent power”.

The DCCconcepts Cobalt iP Analog turnout motor includes a

sophisticated internal electronic control system that interactively

adapts itself to a wide range of power supply voltages. Cobalt

iP Analog also manages its own power usage, montoring need

and only drawing power only when it is needed. Cobalt ip

analog is comfortable with drive voltages from 7 to 23 volts and

it is usable with all scales, from the diminutive T scale, to Z, N,

TT, HO, OO, EM, P4, S, O & G.

Cobalt iP Analog is easy to install, quiet and very reliable. It

has three inbuilt SPDT switches - One is directly “Diode linked”

to the drive power inputs for computer IO (feedback) or other

low power applications. The other SPDT switches are fully

independent with higher power handling for frog power control

or any other switching needs you may have. This makes

DCCconcepts ip analog incredibly versatile and the answer to

almost any conceivable layout wiring need!

Cobalt iP Analog can be powered by any voltage between 7 and

23v DC and it is changed by reversing the polarity of the DC

power. Interactive power management ensures that your Cobalt

iP Analog is also very comfortable with larger scales that have

higher accessory voltage power supplies or DCC accessory

decoders with higher output voltages.

Please read all of this manual before you install your Cobalt iP

Analog. It contains lots of detailed information you’ll need.

OWNERS

MANUAL

Cobalt

Analog

iP

CB iP Analog -A-0314

20181216

Advanced wiring diagram for DIGITAL control with the

versatile DCCconcepts AD2fx & AD8fx Series Decoders

DCCconcepts AD2fx andAD8fx Decoders have enough power to change

several Cobalt plus new features including optional 1 or 2 button control

AND direct computer IO or feedback. They work well with DCC & DC too

Left Rail (L)

Right Rail (R)

Turnout Frog (C)

Common (C)

Left (L)

Right (R)

Use this wire for

LED, Signals or

anything similar

Add LEDs to your control panel

by putting them in series with the

BLUE wire to each Cobalt Motor

DCC POWER 7~23v

(or DCC accessory bus)

ADfx

output

#1

ADfx

output

#2

ADfx

output

#3

Advanced wiring diagram for analog control using the

innovative DCCconcepts SPS 12 Split power supply

Add LEDs to your control panel

by putting them in series with the

BLUE wire to each Cobalt Motor

Left Rail (L)

Right Rail (R)

Turnout Frog (C)

Common (C)

Left (L)

Right (R)

Use this wire for

LED, Signals or

system feedback

Cobalt iP Analog has a convenient “direction change switch” right on the

PCB, so if your computer or layout operations need you to reverse the

direction of turnout control all you will need to do is change the switch!

Basic wiring diagram for analog control using a more

conventional single output regulated DC power supply

If you do not use our Switch packs,

then you will need to cross-wire a

DPDT switch like this example.

Left Rail (L)

Right Rail (R)

Turnout Frog (C)

Common (C)

Left (L)

Right (R)

Use this wire for

LED, Signals or

system feedback

Add LEDs to your control panel

by putting them in series with the

BLUE wire to each Cobalt Motor

Regulated DC

(7~23v DC acceptable)

Power in Power out

Wiring your Cobalt iP Analog turnout motor

Important: Cobalt iP Analog has a different range of

connections to the original “Cobalt Classic” motor

There are 9 spring terminals on the motor. The terminals

will accept a wide range of wire sizes. Use the heaviest

convenient wire size. The wire should be stripped carefully

exposing appx 10mm of bare wire. The best method is to

“ring-strip” the insulation and then twist it as it is removed,

This ensures that there are no free copper strands.

Note: The wire will always be more secure if it is NOT tinned

This drawing shows the label that is applied to each

Cobalt iP Analog turnout motor. Wiring information is also

repeated on the bottom of the PCB to ensure it’s never lost.

1,2

3

4

5

6

7

8

9

DC / DCC decoder power input. Range 7~23v

Common for 1 & 2. For feedback, LEDs, other

Switch 2, Left terminal

Switch 2, Right terminal

Switch 2, Common Terminal

Switch 3, Common Terminal

Switch 2, Left terminal

Switch 2, Right terminal

Note please:

Switch 1 is for

low power use.

Switch 2 and 3

are both high

power / max 5A

1 2 3 4 5 6 7 8 9

These should be

SPDT switches

(on-on type) PB

or Toggle OK

Other DCCconcepts Engine manuals

Popular Engine manuals by other brands

Siemens

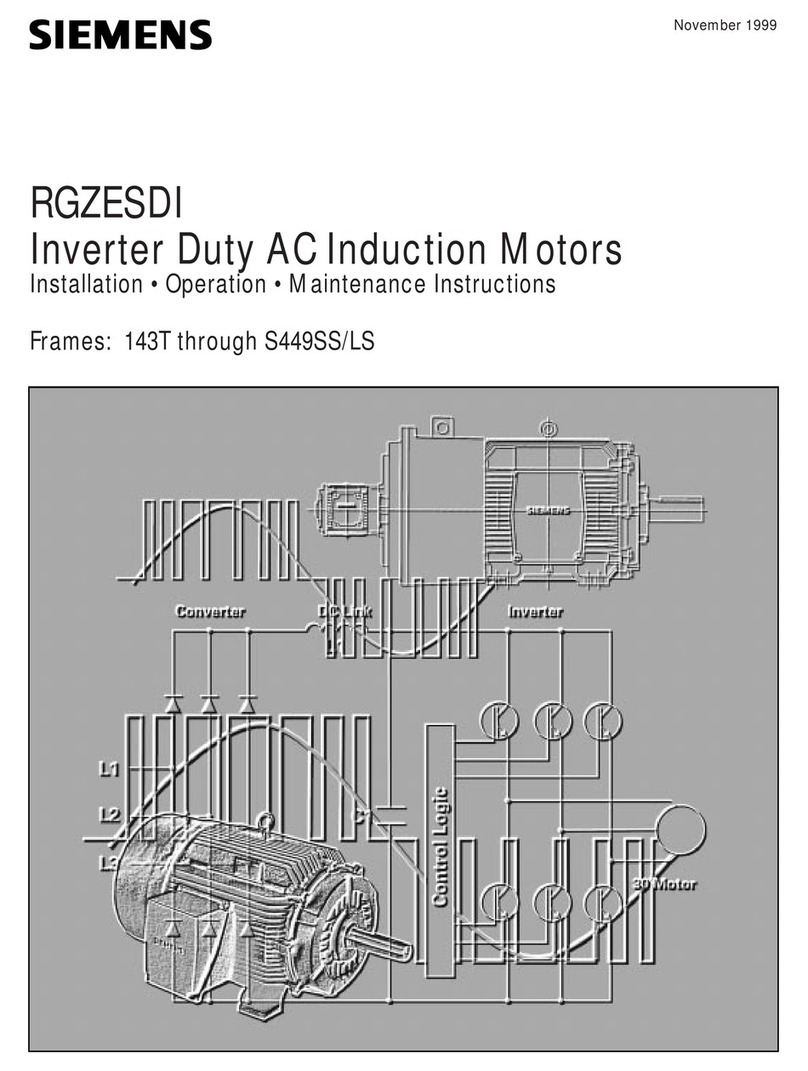

Siemens RGZESDI Installation and operation manual

Sumitomo Drive Technologies

Sumitomo Drive Technologies IB Series manual

Siemens

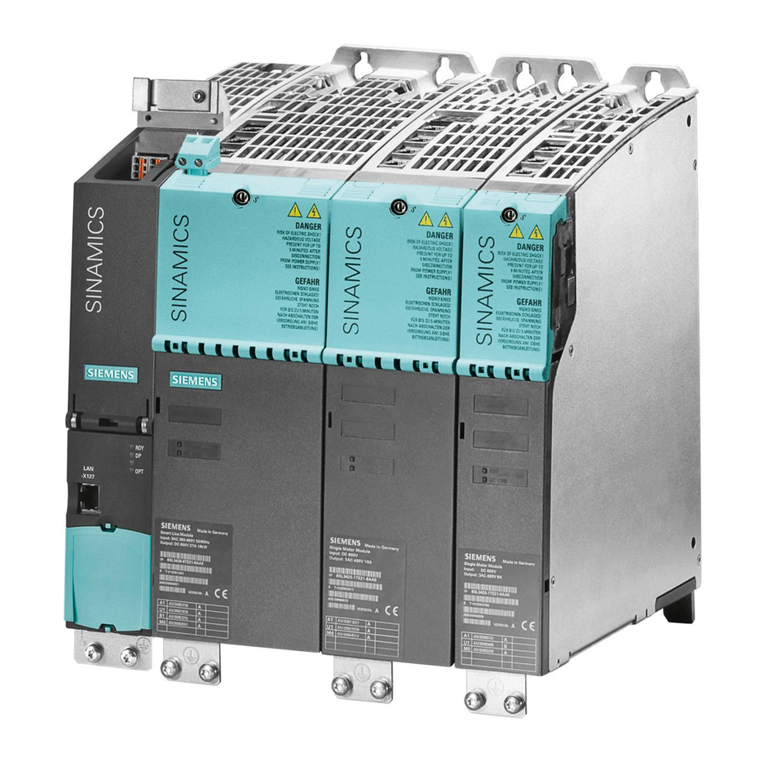

Siemens SINAMICS S120 Configuration manual

Volvo Penta

Volvo Penta AQ145A Workshop manual

Ebmpapst

Ebmpapst M3G084-DF18-81 operating instructions

Chicago Electric

Chicago Electric 07570 Assembly and operating instructions