DDM DDMMSE User manual

Masonry Saw Series

Masonry Saw Series

Masonry Saw Series

TABLE OF CONTENTS

TABLE OF CONTENTS

Manual Part No. 156

WARNING

Masonry Saw Series

DDMMSE

Masonry Saw Series

DDMMSE

Masonry Saw Series

DDMMSG

2

SAFETY INSTRUCTIONS FOR THE 2000 BRICK SAW

SAFETY MESSAGES

CALIFORNIA PROPOSITION 65 MESSAGE

Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

Additional information as to the nature of the hazard is provided by the Hazard Symbols which appear throughout

the manual in conjunction with safety message alert symbols.

Immediate hazards which WILL result in severe personal injury or death.

Hazards or unsafe practices which COULD result in severe personal injury or death.

DANGER

CAUTION

WARNING

WARNING

3

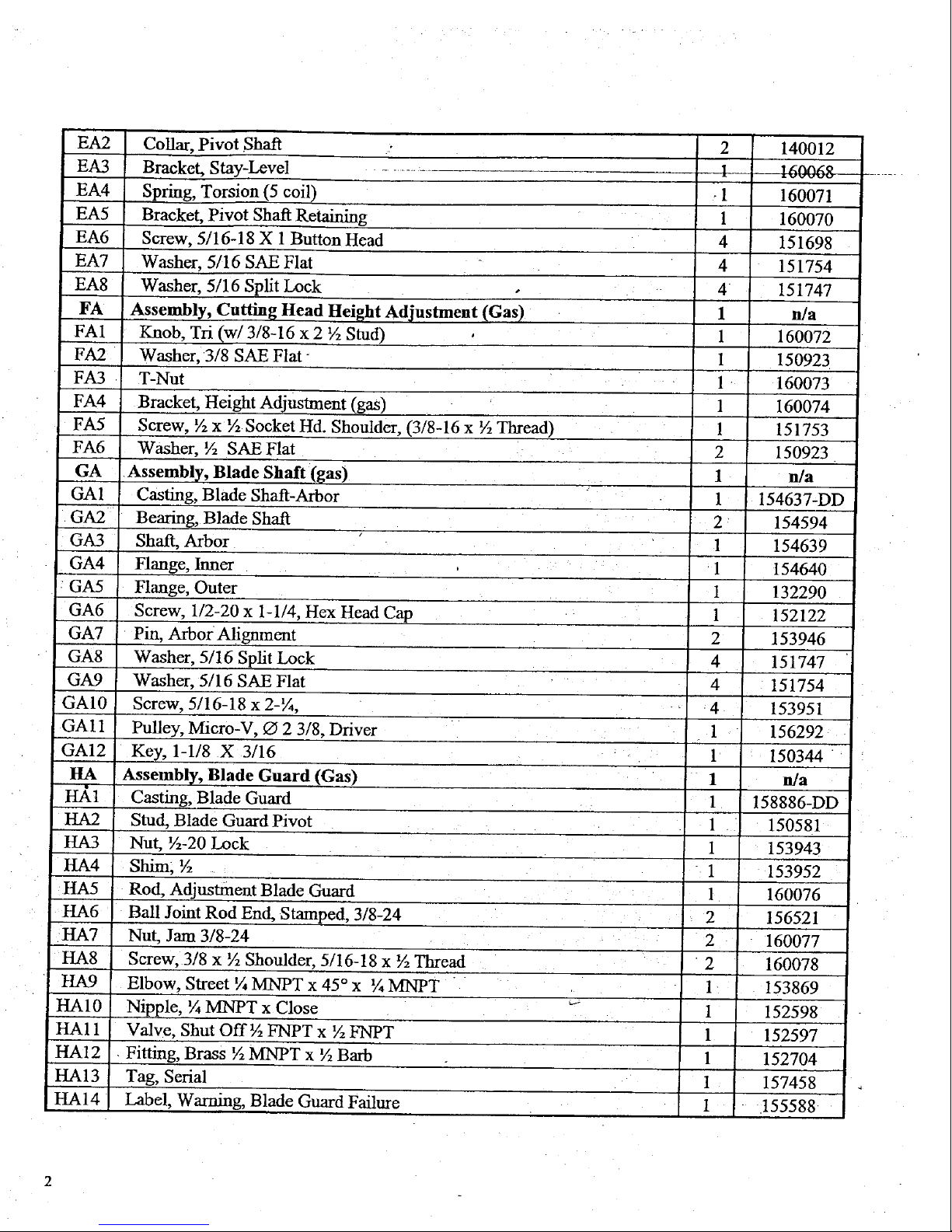

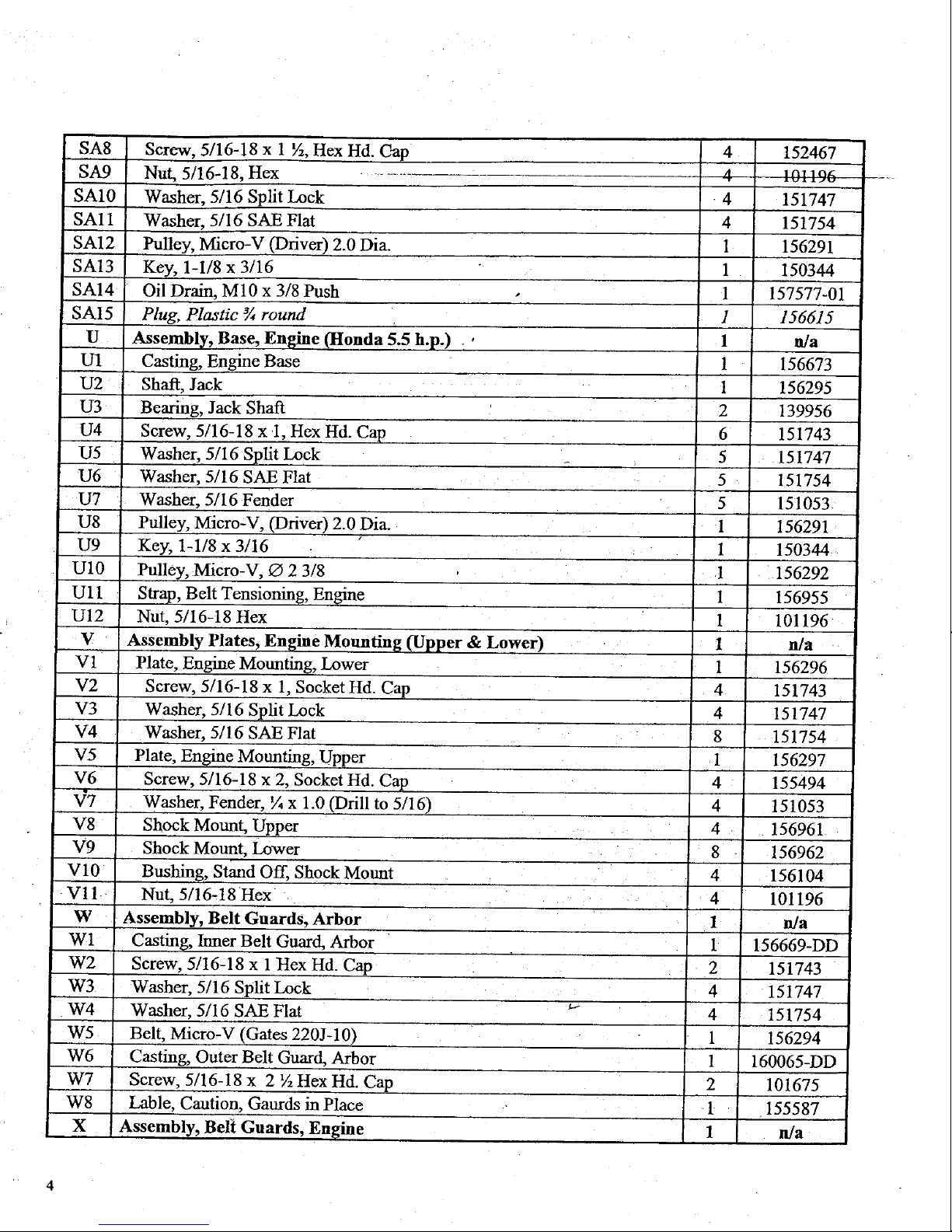

Item

Location

Description

Part #

SAFETY LABEL LOCATIONS

14 inch (356mm) blade capacity

SAW FEATURES

ASSEMBLY

Unpacking and Preparation

Accessory Pack contains:

The DDMMS is a versatile cutting machine designed to use diamond blades and operate under wet or dry

general application sawing depending on type of blade selected. Its function is to cut a variety of materials

to include block and brick. This saw is engineered as a self-contained unit consisting of a powerful “dual-

voltage” AC induction motor for electric models and Honda OHV engine with cyclone air ltration for the gas

model, removable water reservoir and water recirculating system. The motor operates on standard 115V cur-

rent, and the water pump is conveniently energized by the motor.

Motor

The DDMMS features a powerful motor with the following speci cations:

Model

Motor/Engine H.P. Type

Power Spec.

DDMMSE

Electric Motor, 1-1/2 Hp Dual Voltage AC

115/230V 60Hz 3,450RPM

DDMMSG

Gas Motor, 5-1/2 Hp Cyclone

Honda GX160 2,500RPM

4

INITIAL ASSEMBLY

WARNING

INSTALLING THE WATER PUMP

INSTALLING THE WATER PUMP

INSTALLING THE BLADE

OPERATIONS

ELECTRICAL REQUIREMENTS AND GROUNDING INSTRUCTIONS

CAUTION

WARNING

WARNING

WARNING

The DDMMS is wired for 115V, single phase operation, and draws 12.4 AMPS at 115V. This is not a large load, however if the machine is

The DDMMS is wired for 115V, single phase operation, and draws 12.4 AMPS at 115V. This is not a large load, however if the machine is

operated on any circuit that is already close to its capacity, the circuit breaker may be tripped. If this occurs, eliminate other loads from

the circuit. A separate circuit protected by a 20 amp breaker is ideal. If other loads do not exist and power failure still occurs, have the

circuit inspected by a quali ed electrician. If a generator is used, use one rated at 3.5Kw minimum.

The recoil spring (part#??) should be lubricated with light machine oil prior to operation of the DDMMS Brick Saw.

The recoil spring (part#??) should be lubricated with light machine oil prior to operation of the DDMMS Brick Saw.

5

EXTENSION CORDS

Figure 1

Grounding methods

Table 1

Minimum gage for cord

Volts

Total length of cord in feet

120V

—

25 ft.

50 ft.

100 ft.

150 ft.

Ampere Rating

240V

—

50 ft.

100 ft.

200 ft.

300 ft.

more than

not more than

AWG

0

6

18

16

16

14

6

10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

not recommended

AWG

more than

not more than

drip loop

power

power

supply cord

supply cord

THERMAL OVERLOAD PROTECTION

THERMAL OVERLOAD PROTECTION

WARNING

WARNING

A

6

square cut

diagonal

--------------

--------------

--------------

--------------

RIP CUTTING

----------------

----------------

----------------

----------------

GENERAL CUTTING GUIDELINES

WARNING

TABLE MARKINGS

ADJUSTING THE CUTTING HEAD

BELT ADJUSTMENT AND REPLACEMENT

BLADE SHAFT ASSEMBLY

The

utilizes

a

unique

maintenance-free

blade

shaft

bearing

assembl

y

.

The

aluminum

casting

supports (2) double sealed bearings, a heavy-duty blade shaft and an inner and outer blade flange. The

bearings are permanently lubricated, totally enclosed, and are self-aligning. Over a period of time and

usage, the shaft may begin to make excessive noise and vibrations, signaling the necessity for component

replacements. The maintenance is easily accomplished by replacing this (1) piece assembly in its entirety.

The assembly is removed and replaced by (4) bolts, is self-aligning, and is immediately ready for work.

The DDMMS Saws utilize a premium oil & heat treated V-belt the is tensioned at the factory. The belt may require a slight

adjustment after it “breaks-in” and seats on the pulleys (usually after several months of usage). Additionally, after heavy

usage over time, the belt may become worn, frayed or cracked. For retension or replacement of your V-belt, loosen the (4)

nuts that secure the motor base to the cutting head, remove the belt guard casting, loosen the motor strap bolt, replace/

reseat the V-belt, tightening the motor strap bolt (provide @ 1/2” pinch/de ection from the center of the V-belt), replace the

reseat the V-belt, tightening the motor strap bolt (provide @ 1/2” pinch/de ection from the center of the V-belt), replace the

belt guard casting, tighten the (4) motor plate screws & resume operations.

7

MAINTENANCE

GENERAL RECOMMENDATIONS

on

WARNING

The

permits

the

operator

many

di

f

ferent

options

in

cutting

relative

to

the

design

of

the

sa

w

.

The

cutting

head may be adjusted to a fixed position for “forced” cutting, or the action of pushing the material steadily into the

blade completing the cut in one pass. The material may also be “Step” cut. This process requires several passes

of the blade at various depths as a means to incrementally cut the piece. Also, the “Chopping” action of the saw

can be employed to speedily “come down onto” and “push through” the material utilizing the mechanics of the saw.

Whatever

the

preferred

technique

of

the

use

r

,

the

following

are

general

guidelines

when

operating

the

1.

Hold the material firmly against table and table backstop. If the material is allowed to slip, the blade may bend,

get caught up in the cut, or twist so violently that the blade may break off a diamond segment.

2.

Do not force material into blade. Allow the diamonds to do the grinding. When nearing the completion of the

cut, retard and slightly hold back the table. If this is not done, the material may be pulled into the blade so fast that

excessive pressure on the rim may cause warping or twisting of the steel core.

3.

When using a brand new diamond blade, make the first cuts slowly until the blade is “broken in” and cuts freely

and easily.

4.

After continuous cutting of extremely hard and dense materials, the bladeʼs cutting efficiency may slow down.

Should this occur, it will be necessary to “redress”, or “sharpen” the diamond blade. The blade can be redressed

by making several slow passes against a very abrasive product such as: soft cinder block or lightweight sandstone.

FORCE OR STEP-CUTTING WITH DIAMOND BLADES

OPERATION IN ENCLOSED AREAS

WARNING

Motor Problems

TROUBLE SHOOTING

ENGINE STARTING PROCEDURES DDMSG ONLY

Pre-start Checklist DDMSG

(800)-654-7224

8

If Blade Won’t Cut Properly

Table Motion

Water Flow Problems

Optional Accessories

All parts listed may be ordered from your local distributor or from Dixie Diamond. If the part is not stocked locally, call our toll free number listed

below and ask for our customer service department. For technical support call: 1 (800) 654-7224. There is a $25.00 minimum order.

1-(800)-654-7224

1-(800)-654-7224

This manual suits for next models

1

Table of contents