9OF20

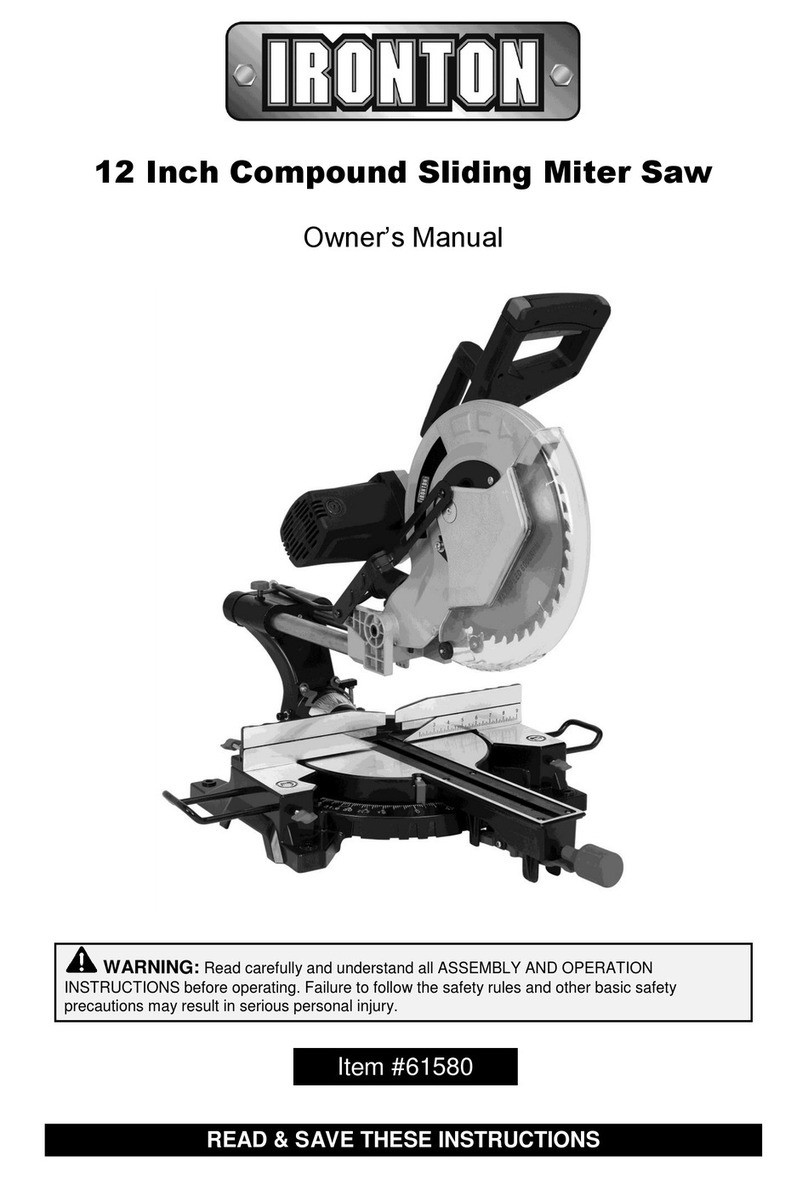

ADJUSTING THE MITER ANGLE

zA miter cut is one that is at an angle across the horizontal surface of the material. You will

commonly make 45º miter cuts to join two pieces in a right angle corner. A 30º cut is often used for

a scarf joint or to make a chamfered end.

zTo make a miter cut, loosen the Miter Lock Knob by turning it approximately 1/4 turn

counterclockwise. Press down the Thumb Lever to unlock the Table. While holding the Thumb

Lever down, move the Table to the desired angle. The Miter Angle Indicator will indicate the

selected angle. The table will lock into place at often used miter angles, including 22.5º, 30º, 45º,

and 90º on both left and right sides.

zWith the Table adjusted to the desired angle, place the work piece flush against the Fence, secure

it with the Hold Down Clamp and make the cut.

ADJUSTING THE BEVEL ANGLE

zA bevel cut is one that is at an angle to the vertical plane of the material.

zBevel cuts can be used to miter relatively wide and thin material. Bevel cuts can be used in

combination with a miter cut to form a compound angle. Compound angle cuts are often used in

crown moldings, picture frames and similar trim materials.

zTo set the bevel angle, loosen the Bevel Lock Handle at the rear of the saw. To do this, press in the

Lock Button and rotate the Handle 1/2 turn counterclockwise. Move the blade assembly left to the

desired angle. You can read the angle on the Bevel Angle Indicator. Lock the blade assembly into

position by pressing in the Lock Button and rotating the Bevel Lock Handle clockwise. Tighten

firmly but not over-tight.

zMake a sample cut in a piece of scrap and check to be sure the bevel angle is correct. If it is not,

correct the angle before cutting your work material.

USING THE DEPTH STOP

zIf you want to make a kerfing or rabbet cut which does not cut through the work piece, you can use

the Depth Stop Screw to control the depth of the cut.

zTo limit blade assembly travel, turn the Depth Stop Screw clockwise. The further you screw down

the Depth Stop Screw, the shallower the cut will be.

zAfter the desired cut has been made, return the Depth Stop Screw to its open position by turning it

counterclockwise.

GENERAL OPERATING INSTRUCTIONS

zWhen the Handle is lowered, the Blade Guard raises automatically. When the Handle is raised the

Blade Guard returns to its safety position. Keep hands clear of the Blade when the Handle is

lowered. Never interfere with the proper movement of the Blade Guard.

zThere are locking mechanisms for the miter angle and the Slides. Unlock the Table to set the miter

angle, then re-lock it before making the cut. Unlock the Slide using the Slide Lock Wing Screw

before making a cut if the work material is too wide to “chop.”

zTo rotate the Table, press down the Miter Thumb Lever, rotate the Table to the desired angle, then

release the Miter Lock Lever. Notches are machined into the Base of the tool, which will lock the

Table into several often used miter angles. These angles are 0º (centered), 15º, 22.5º, 30º and 45º

both left and right cut.

zOn wider pieces, you will have to slide the blade while making the cut. To unlock the Slide, loosen