DE-STA-CO DirrectConnect DPE Series User manual

Product Specifications

Voltage 24 VDC

Power Max. 40 W

Operating Temperature 5° / 50° C (40° / 120°F)

Protection Class IP54

Clean Room 100

Clean Room with Scavenge Port* 10

*Contact Tech Support.

Maintenance Specifications

Field Repairable Yes

Application Restrictions

• Timing, power and load beyond specifications

• Suitable for external gripping only

Technical Specifications:

Gripper can be mounted and operated in any orientation

Mounting Information:

G

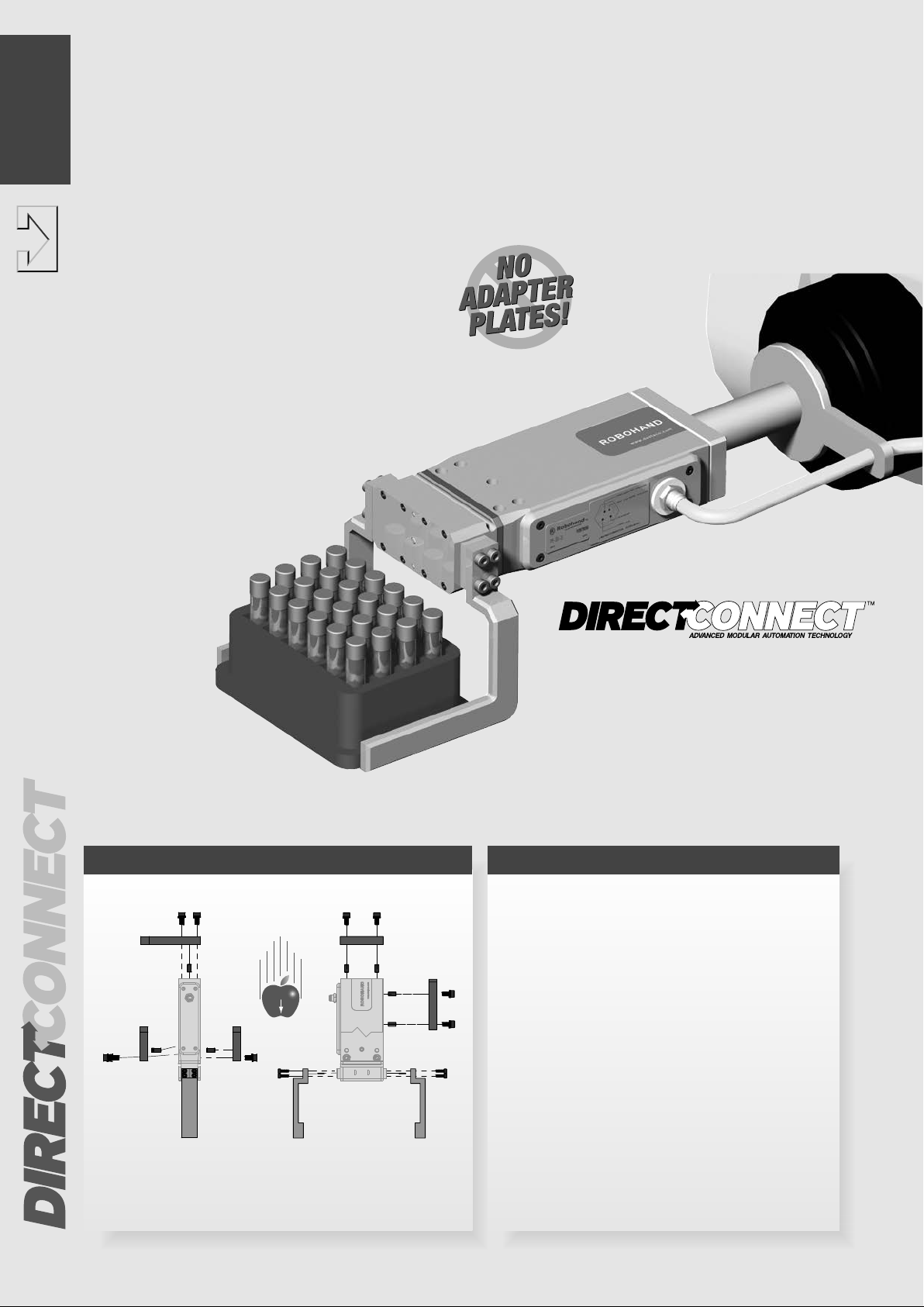

• Electrically Actuated

24 VDC, 4-wire input: power, ground, open & closed signals.

100% duty cycle for high throughput.

• “Light Switch” Simplicity

Plug and play. No programming, tuning or adjusting required.

As easy as a pneumatic gripper to control and operate.

• Energy Efficient

Only 3W required. Can be driven directly by most PLC’s

without a separate power supply. Can be battery driven

for remote applications.

• High Cycle Life

20+ million cycles with zero maintenance!

High reliability eliminates down time.

Lowest cost of ownership of any gripper,

pneumatic or electric.

• Built-in Electronics

All electronics are sealed

within the gripper. No external

control board needed.

4-pin/wire control cable

sold separately.

• Long Stroke, Fast Actuation

25mm stroke for picking multiple sized parts.

Full actuation in 0.25 second. Pick up to 150

parts per minute (with reduced stroke).

• Failsafe operation

In case of a power loss, the jaws will not

separate but grip force will be diminished.

Finger design should include features other

than just friction to retain part for critical

applications.

DPE Parallel Gripper-

Electric Gripper Series

Patent Pending.

Please see back cover for DE-STA-CO Global Locations. www.destaco.com

Body mounts with screws

and locates with slip fit

dowel pins for accuracy

Fingers attach to jaws

with screws and locate

with dowel pins

TM

1.8

DPE SERIES

1_8-1_13 DPE_(ENG_A4)_Layout 1 09.05.11 14:33 Seite 8

Product Features

• Apply +24 VDC from the PLC to the gripper “Close“ wire.

• The motor rotates a planetary gear reduction box that is connected to the drive

pinion by a coupling

• The pinion drives the integral jaw racks causing the jaws to close synchronously

• Power is maintained to the closed signal to continue gripping force throughout

the grip cycle.

• To open, remove signal to “Close” wire and apply +24 VDC from the PLC to the

gripper “Open“ wire

• Design is suitable for internal or external gripping

Style-DPE

Size -200-25

See

Page 1.10

Style: DPE-200-25

Stroke: 25 mm 0.98 in

Grip Force: 90 N 20 lbs

Weight: 0.53 Kg 1.16 lbs

Slip Fit Dowel

Pin Holes

Located in body and jaws

for precision mounting.

One-Piece Body

One-piece, lightweight aircraft

quality aluminum body ensures

product accuracy.

Hardcoat Anodize

The body and jaws are hard-

coat anodized to 60Rc with

Teflon impregnation.

Sealed Design

IP 54 rating for tough

application environments.

Superior Jaw

Support

Ridged design and full body

support of the jaws allows

for long finger lengths.

DirectConnect Mounting

Mounts directly to other automation

products without adaptor plates.

Versatile mounting on top, side front

and back of body.

Cover Cap

Motor + Gearbox

Coupling

Electronics

Jaw

Operating Principle

Body

Please see back cover for DE-STA-CO Global Locations. www.destaco.com

Patent Pending

Rack & Pinion Drive

Precision drive components for

smooth actuation. Zero backlash

while gripping ensures excellent

repeatability and accuracy.

Multiple Position Sensing

Slot mounted magneto-resistive sensing. Sense up

to 4 gripping positions. Internal magnetic targets

and external sensor mounting slots come standard.

Sensors & quick disconnect cables sold separately.

TM

1.9

DPE SERIES

1_8-1_13 DPE_(ENG_A4)_Layout 1 09.05.11 14:33 Seite 9

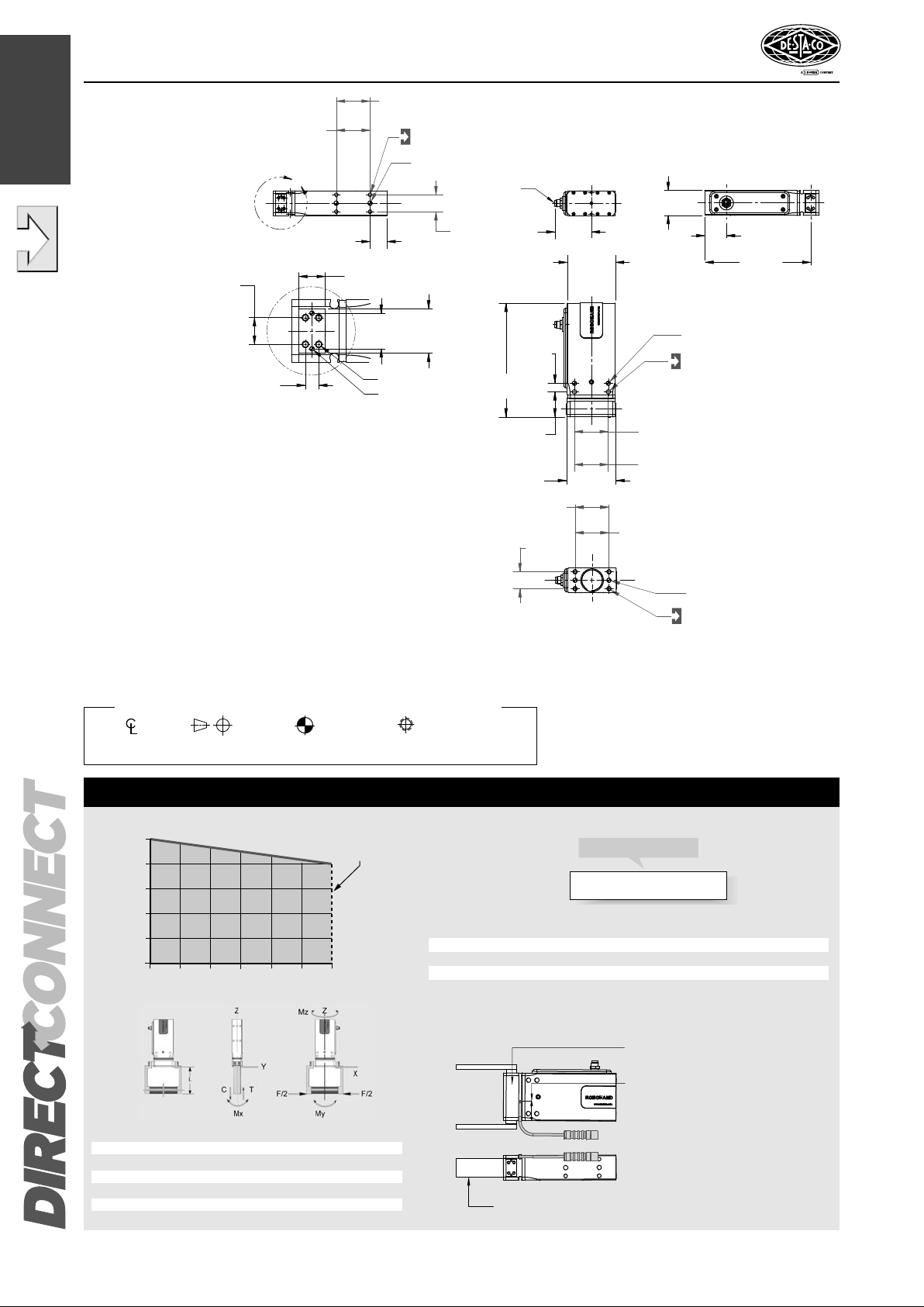

[1.62]

41.0

[5.039]

128.0

2.126

[54.0]

1.121

[28.5]

[.375]

9.5

38.1

[1.500]

2X

ØM5 [H7] X 6.2 DP

(NEAR & FAR SIDE)

2X M5 X 6.2 DP

56.0

[2.20]

CLOSED AS SHOWN

81.0

[3.19]

OPENED

38.10

(DOWEL)

[1.5000]

38.1

[1.500]

38.10

(DOWEL)

[1.5000]

38.1

[1.500]

38.10

(DOWEL)

[1.5000]

[.75]

19.1

4X M5 X 10.0 DP

2X M5 (H7) X 6.4 DP

[.75]

19.0

A

[.472]

12.0

[.236]

6.0

[.472]

12.0

[.787]

20.00

[.6299]

16.00

4X M3 X 6DP

2X

Ø2[H7] X 6 DP

DETAIL A

(JAW FEATURES-FINGER MOUNT)

4X M5 X 0.8 X 10.0 DP

2X

ØM5 [H7] X 6.2 DP

19.1

[.750]

[.95]

24.2

[4.685]

119.0

[1.102]

28.0

M8X1 MALE

(CABLE SOLD

SEPARATELY)

C

L

C

L

C

L

C

L

C

L

C

L

C

L

PARALLEL GRIPPER DPE-200-25

E-GRIPPER SERIES

How to Order: (Order Accessories separately from Basic Model)

DPE-200-25

BASIC MODEL

Loading Information

Loading Capacity†Static

Maximum Tensile T75 lbs [10 N]

Maximum Compressive C75 lbs [10 N]

Maximum Moment Mx120 lbf-in [14 Nm]

Maximum Moment My150 lbf-in [17 Nm]

Maximum Moment Mz120 lbf-in [14 Nm]

†Capacities are per set of jaws and are not simultaneous

44

35

16

18

9

0

N

10

8

6

4

2

0

lbs.

EFFECTIVE FINGER LENGTH - L

FINGER FORCE - F/2

FORCE VS LENGTH

0 0.5 1.0 1.5 2.0 2.5 3. 0 in.

0 13 25 38 51 64 76 mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric [mm]

[0.] = [±.25]

[0.0] = [±.13]

[0.00] = [±.013]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance ±.013mm

UNLESS OTHERWISE NOTED ALL TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

ACCESSORIES*

4-wire Power and Signal Cable, 5m long CABL-046 1

NPN Magneto Resistive Sensor OHSN-017 1 or 2

PNP Magneto Resistive Sensor OHSP-017 1 or 2

Quick Disconnect 5 Meter Cable Length* CABL-013 1 or 2†

*Sensor and cables sold separately. †Power cable plus 1 or 2 sensor cables.

Specifications DPE-200-25

Maximum Finger Length . . . . . . . . 76.2 mm (3.00 in)

Stroke . . . . . . . . . . . . . . . . . . . . . . . 25 mm (0.98 in)

Gripping Force in Closing . . . . . . . . 90 N (20 lbs)

Closing Time/Opening Time . . . . . . 250 ms (250 ms)

Repeatability . . . . . . . . . . . . . . . . . . ± 0.025 mm (0.001 in)

Accuracy . . . . . . . . . . . . . . . . . . . . . ± 0.051 mm (0.002 in)

Voltage . . . . . . . . . . . . . . . . . . . . . . 24 VDC

Power Req. @ 100% Duty Cycle . . 3 Watts

Current - Peak . . . . . . . . . . . . . . . . 0.5 Amps Max.

Current - Continuous . . . . . . . . . . . . 0.125 Amps

Min./Max Operating Temperature . . 5° / 60° C (40° / 140° F)

Protection Class . . . . . . . . . . . . . . . IP54

Clean Room . . . . . . . . . . . . . . . . . . 100

Clean Room with Scavenge* . . . . . 10

Weight . . . . . . . . . . . . . . . . . . . . . . 0.53 Kg (1.16 lbs)

*Contact Tech Support.

INSTALL MAGNET HEAD INTO THE SLOT,

ADJUST IT'S LOCATION, AND LOCK ITS

POSITION WITH THE PROVIDED

LOCK SCREW.

SENSOR TARGET SUPPLIED

INSIDE WITH THE JAWS

CUSTOMER SUPPLED FINGER

Please see back cover for DE-STA-CO Global Locations. www.destaco.com

TM

1.10

DPE SERIES

1_8-1_13 DPE_(ENG_A4)_Layout 1 09.05.11 14:33 Seite 10

PARALLEL GRIPPER DPE-200-25

E-GRIPPER SERIES

Installation and Operation:

1. Mount fingers (customer supplied) to gripper jaws using dowel pins and threaded fasteners. See dimensional drawing for hole sizes.

Use Loctite®242 threadlocker or equivalent.

2. Mount gripper using dowel pins and threaded fasteners. Gripper can be mounted and operated in any orientation. See dimensional drawing

for mounting hole pattern and sizes. Use Loctite® 242 threadlocker or equivalent.

3. To operate the DPE gripper, follow the instructions below:

Apply +24VDC to pin 1 (brown) and Ground to pin 3 (blue) to turn on the gripper. To open the fingers, apply +24VDC to pin 2 (white).

To close the fingers, remove +24VDC from pin 2, and apply +24VDC to pin 4 (black). +24VDC signal must remain present on the open / close

line to maintain the force output. The gripper will do nothing if a +24VDC signal is present on the open and close lines at the same time.

WARNING:

• Operating gripper outside of power voltages and can cause damage and void warranty

• Disconnect power from gripper before performing maintenance or making adjustments.

PIN OUT

(LOOKING INTO HEADER CONNECTOR ON GRIPPER)

1 ........ BROWN

2 ........ WHITE

3 ........ BLUE

4 ........ BLACK

(+ 24 VDC)

(OPEN GRIPPER) +24 VDC = ACTIVE

(GROUND)

(CLOSE GRIPPER) +24 VDC = ACTIVE

CABLE # CABL-046

ELECTRICAL INTERFACE

2

43

1

Please see back cover for DE-STA-CO Global Locations. www.destaco.com

TM

1.11

DPE SERIES

1_8-1_13 DPE_(ENG_A4)_Layout 1 09.05.11 14:33 Seite 11

12 35

7

8

9

32

10

15

33

16

17

18

21

24

20 22

23

4

19

21

2715

28

25

25

28

30

31

29

6

711

12

13

1

14

26 Will be installed

above the cover

Item Qty Name

01 1 Body

02 1 Bottom Plate

03 1 Cap

04 1 Cover

05 2 Bumper

06 2 Jaw

07 2 Coupling Pin

08 1 Drive Pin

09 1 Motor Control Board

10 1 Coupling Insert

11 2 Tag-Destaco-Robohand

12 1 Tag-Electric Pin Out

13 1 Tag-Production

14 1 Tag-VBL Collar

15 2 Magnet

16 1 Bearing

17 8 SHCS, M1.6*5mm, Alloy

18 3 SHCS, M2.5*5mm, Alloy

19 1 Dowel Pin: 1/8 Dia X 3/8

20 2 Dowel Pin: 2mm

dia*6mm lg

21 8 Screw, Fillister HD,

M2x6mm

22 2 Dowel Pin: 3mm

dia*6mm lg.

23 0 Jam Nut-Ref Only (Part Of

Motor Control Board)

24 8 Washer

25 2 Set Screw

26 0 O-Ring - Ref Only (Comes

With Connector)

27 1 O-Ring

28 2 Set Screw

29 1 O-Ring

30 1 Set Screw

31 4 O-Ring, Buna, 70d,

0.026 CS, .097id

32 1 Gear Motor

33 1 Ret. Ring

NOTE: Contact the DE-STA-CO Customer

Service for a complete spare parts list

with order numbers and prices.

Assembly Procedure

1) Clean all make details free of dirt, oil and

other contaminants.

2) Insert # 32 motor into the # 1 body, line up

the motor holes and assemble motor to the

body by using # 18 screws. Make sure that

the motor wires are carefully routed to the top

for it's

connection to the motor control board.

3) Assemble # 25 set screws one of the # 7

coupling hubs, but not all the way in. Assem-

ble the coupling to the motor shaft, with flat

on the motor shaft facing one of the set

screws and adjust the inside face of the cou-

pling, flat with end face of the motor shaft.

Tighten the set screw on the motor shaft thru

the acccess

hole at set screw # 30 location.

4) Assemble the # 10 coupling insert into the

# 7 hub, as asssembled to the motor shaft,

as above.

5) Assemble # 8 drive pinion with it's shaft all

the way into the second # 7 coupling hub and

tighten the set screws. Assemble # 16 bear-

ing and # 19 dowel pin into the drive pinion.

Now install this assembly hub / insert as-

sembly installed earlier to the motor shaft.

7) Assemble # 15 magnets into # 6 jaws,

using lok-tite as recommended.

8) Lubricate the pinion, the bearing, the jaws

and inside surfaces of jaw-ways with lubri-

cant as recommended.

9) Install the jaws into the body, meshed with

the pinion and symmetrically positioned w.r.t

the pinion.

10) Install # 5 stop and # 22 dowel pins into

the jaws.

11) Assemble # 2 cover to the body, with dowel

pins # 19 and # 29 aligned to the cor-

rosponding holes in the cover. Install fasten-

ers # 17 to secure the cover to the body.

12) Install / connect the motor cable connector

the motor control board. Use # 21 & # 24

fasteners and install the motor control board

to the body. Note: Remove the hex nut sup-

plied with the connector on the motor con-

trol board.

This hex nut will be re-installed after # 4

cover is installed.

13) Install # 4 cover to the body with # 29 gas-

ket and # 21 screws as shown.

14) Installed the previously removed hex nut

back to the connector. Caution: Only snug

tighten this hex nut.

15) Install # 3 cap with O ring and snap ring,

as shown.

16) Install tags and labels as shown.

DPE SERIES EXPLODED VIEW

Please see back cover for DE-STA-CO Global Locations. www.destaco.com

TM

Third Angle

Projection

Seal Kit

Items

Thread

Locker

Krytox™

Lubricant

Teflon™Based

Grease

Lightweight

Machine Oil

Super

Bonder

SK

KRYTOX

KRYTOX

1.12

DPE SERIES

1_8-1_13 DPE_(ENG_A4)_Layout 1 09.05.11 14:33 Seite 12

Third Angle

Projection

Seal Kit

Items

Thread

Locker

Krytox™

Lubricant

Teflon™Based

Grease

Lightweight

Machine Oil

Super

Bonder

SK

KRYTOX

KRYTOX

1

2

5

4

3

7

6

8

Item Qty Name

01 1 Body

02 2 Jaw

03 1 Motor/Gear ASM

04 1 Coupling Asm

05 1 Pinion

06 1 Bearing

07 1 Motor Control Board

84 1 End Cap

NOTE: Contact the DE-STA-CO Customer

Service for a complete spare parts list with

order numbers and prices.

DPE SERIES EXPLODED VIEW

Please see back cover for DE-STA-CO Global Locations. www.destaco.com

TM

1.13

DPE SERIES

1_8-1_13 DPE_(ENG_A4)_Layout 1 09.05.11 14:33 Seite 13

This manual suits for next models

1

Table of contents