ED2K N10100003V – Operating Manual Rev10LD EN. docx

5

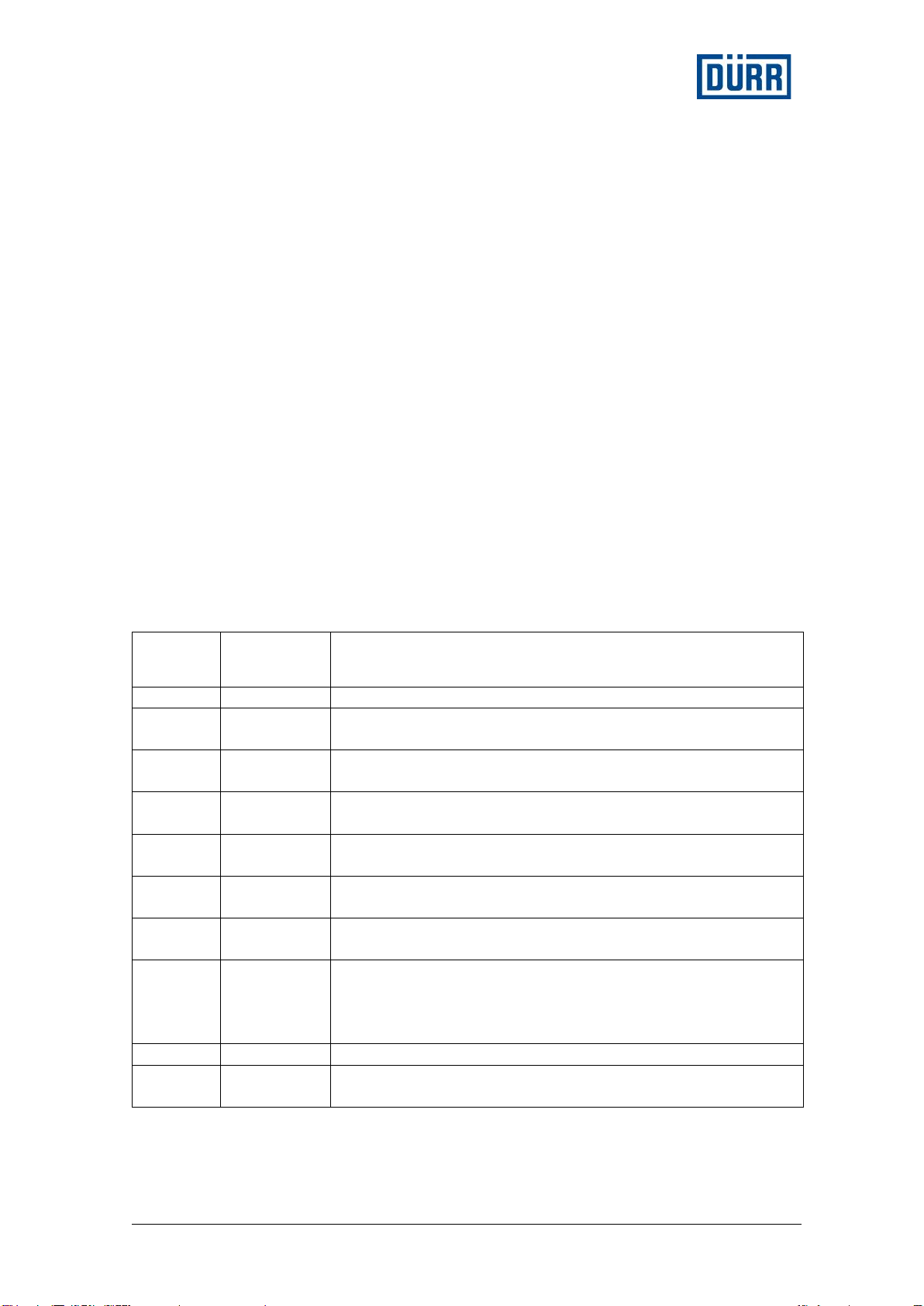

7.2 System configuration............................................................................................... 35

7.3 Management of PLC alarms for consumable components................................ 36

8 Operations................................................................................................... 37

8.1 Overview controls.................................................................................................... 37

8.2 Operative modes...................................................................................................... 38

8.3 Visualization.............................................................................................................. 39

8.4 Browsing windows ................................................................................................... 41

8.4.1 System page ................................................................................................. 41

8.4.2 Cycle program page .................................................................................... 43

8.4.3 Parameters page.......................................................................................... 43

8.4.4 Pre-purge and purge cycle page............................................................... 47

8.4.5 Active alarm page ........................................................................................ 47

8.4.6 Alarm history page....................................................................................... 48

8.4.7 Consumption page....................................................................................... 48

8.4.8 External control interface signal page....................................................... 49

8.4.9 Calibration data page................................................................................... 49

8.4.10 User management page............................................................................ 50

8.4.11 Reset passwords page.............................................................................. 50

8.4.12 Settings page.............................................................................................. 51

8.5 Description and operation of each visualization window ................................... 52

8.5.1 System page functions................................................................................ 52

8.5.1.1 Switching the operating modes.................................................... 52

8.5.1.2 Language switching........................................................................ 54

8.5.1.3 User administration ........................................................................ 55

8.5.1.4 Date and time setting ..................................................................... 57

8.5.1.5 Data backup to USB storage......................................................... 58

8.5.1.6 USB Data Save/Load Operations................................................. 59

8.5.1.7 Screen cleaning .............................................................................. 61

8.5.1.8 Change passwords......................................................................... 62

8.5.1.9 Reset passwords............................................................................. 63

8.5.1.10 Change IP address....................................................................... 64

8.5.1.11 Change calibration data............................................................... 66

8.5.1.12 Lamp test ....................................................................................... 67

8.5.2 Cycle programs – recipe selection............................................................ 68

8.5.2.1 Cycle programs............................................................................... 68

8.5.2.2 System status list............................................................................ 72

8.5.2.3 Relay external signal system ready.............................................. 72

8.5.2.4 Recipe selection.............................................................................. 73

8.5.3 Spray – valves............................................................................................... 74

8.5.3.1 Status indicator valves ................................................................... 75

8.5.3.2 Manual control valves .................................................................... 76

8.5.4 Spray data…………………………………………………………………… 77

8.5.5 Recipes data ................................................................................................. 78

8.5.6 Pre-purge, purge program.......................................................................... 79

8.5.6.1 Pre-purge......................................................................................... 80

8.5.6.2 Purge ................................................................................................ 80

8.5.7 Consumption................................................................................................. 81