DECKEL FP1 User manual

g'

n

F

!

t

I

t

il

I

I

I

I

l

I

,l

l

I

-: ::. : : ,'. - .::.. ,..:.:'.i.:t:la.

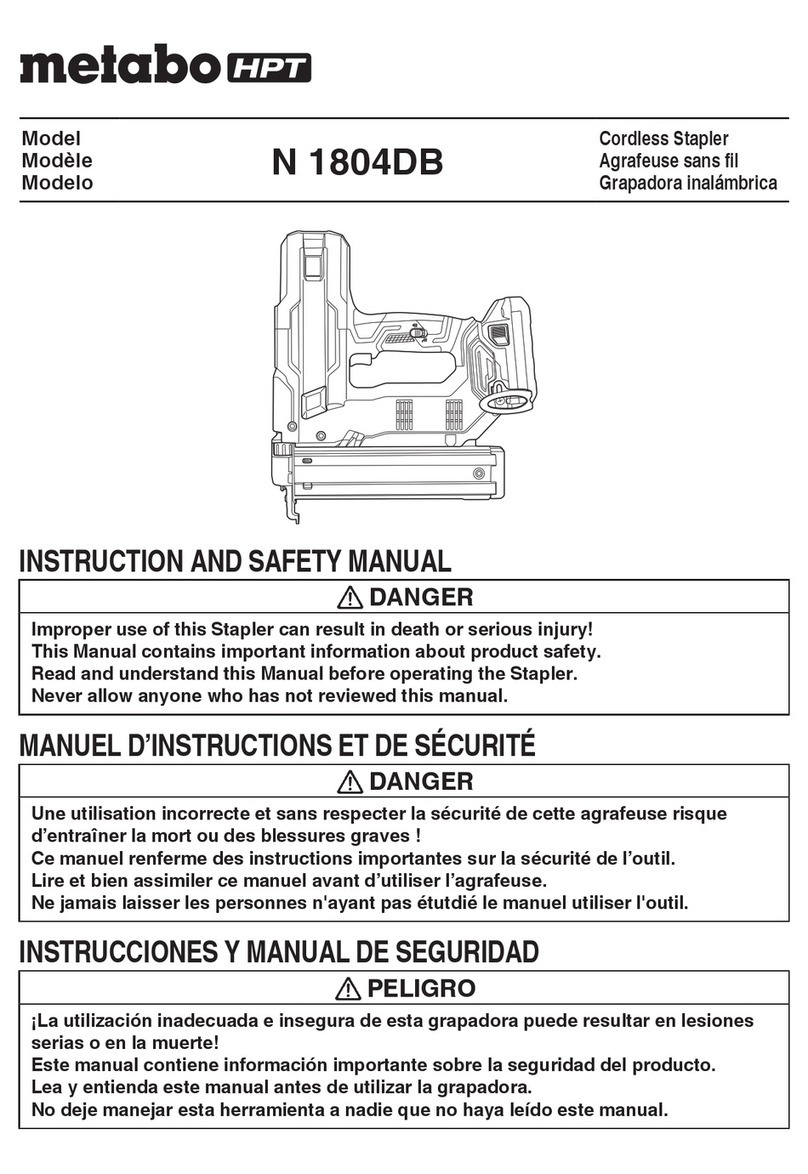

Operator's Manual

FPI

Universal Tool Milling and Boring Machine

E611 - 7.81 Edition

Active digital position readout unit, cont'd

Moving past reference Points

The reference points are located near the zero position of

the coarse scale in all three axes.

- Operate M t.t (unless LED is already illuminated).

- Operate @ t.y' LEDs (6) and (9) will light up; actual'

value readout blocked.

- Operate @t.t and the two feed buttons on operator

control panel if reference marks are to be approched at

feed rate.

- Move machine axes (slides) beyond reference marks

consecutively by operating feed control lever and rapid

traverse button: actual-value readouts will start counting

from reference mark; LEDs (9) will be extinguished.

Setting the reference Points

(only in 'manual'mode)

After aligning the machine with the workpiece datum, set

actual-value counters to a reference value, usually zero lref'

erence point = zero point of actual-value readout).

Align in spindle longitudinal direction, for example with a

bore or workpiece edge, by moving end face of tool into

contact with workPiece.

- Align with reference point (in at least one axis)'

- Operate one of the reference point keys (8).

- Operate El t.t (to zero setpoint readout), key refer-

ence value into setpoint readout (5) on keyboard (l) and

use [l key to determine sign.

- Operate transfer key (2) of axis just aligned: keyed-in

value will appear in actual-value readout. Reference

point in this axis is now stored.

- Repeat this procedure in the other axes.

lf several reference points have been set, the actual-value

readout will show the distance from each reference point

upon operating the associated reference point key.

Example

The 4 reference points definable can be stored as shown below

for machining a workpiece.

Fig2

Use reference point @ for workpiece edges in X and Y

axes.

Reference point @l may be assigned to the lst bore in a

row of bores positioned in chain dimensions.

Reference points @ and @ may be assigned to the central

bores of boring patterns.

Refinding reference points

Switch on unit and move past reference marks as described

above.

o-

d

#

E 9O2 (12.81)

'rctive digital position readout unit, c-ont'd

Positioning

First set at least one reference point with or without refer'

ence mark evaluation. The position readout will count from

the momentary reference Point.

ln'manual'mode Sl

Use handwheel or pow.er feed to move machine slide(s).

Feed motions

- Operate 'Feed'keY @.

- Operate both feed buttons on operator panel and rapid

traverse but in addition, if required.

Automatic positioning

,odes:'absolute dimensions';

'incremental (chain) dimensions'.

Absolute d imensions: all dimensions, including setpoints,

refer to the reference point in the axis concerned.

lncremental (chain) dimensions: each dimension refers to

the last previous actual position. Setpoint values will be

keyed in as chain dimensions, but actual-value readouts

show absolute dimensions.

Starting situation: 'manual' mode, necessary reference

points already set.

Preparing the positioning operation

- lf 'REF' lamp (6) is still illuminated, operate 'REF' key

to extinguish LED.

- Operate mode key E otE.

- Set feed rate o,n operator control panel and operate feed

buttons.

rosltlOnlng

- Operate CE key (1)

{not required if previous preset value has already been

transfered to an actual-value counter).

- Key in setpoint value on keyboard (1 ) in either absolute

or chain dimensions. depending on mode selected.

- Operate transfer key X, Y or Z (21 .

- Engage feed control lever in accordance with external

axis and direction indicator (Fig 3): axis will start mov-

ing and stop in setpoint position.

- Disengage feed control lever (move lever to middle posi-

tion).

Any positioning operation can be interrupted by means of

El n.t (131. To resume the positioning operation, again

operate transfer key in the axis concerned.

To change the direction of a motion, disengage feed control

t.ver, key in new position and then operate transfer key in

,e axis concerned.

E 9O2a ( 12.81)

lmportant

lf a 'chain dimension' positioning operation is interrupted

by means of 'stop' button (13), the actual position at that

point will be the reference point for the next positioning

operation in chain dimension.

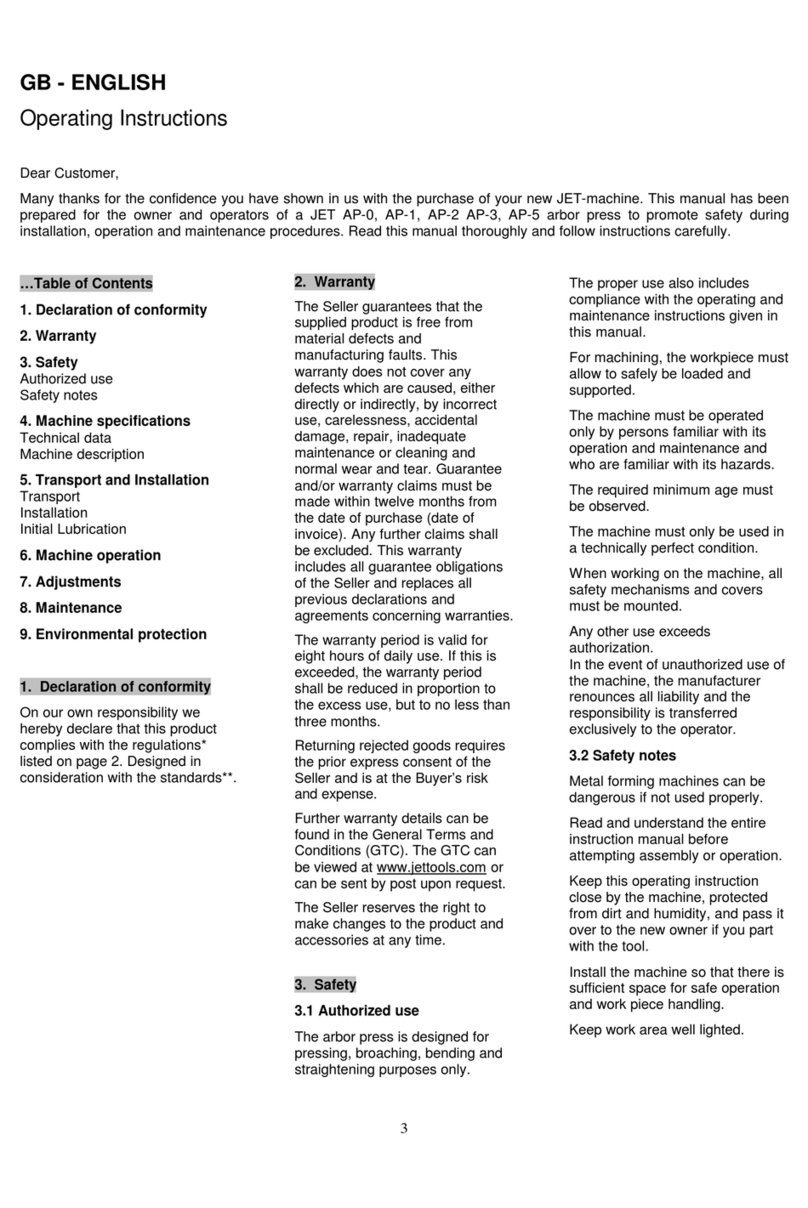

Fig 1

g, 4,.

6 6 re

* not on FP1 Fis 3

The external axis and direction indicator (Fig 3) is con-

nected in parallel with the digital readout unit. lt shows

the operator the direction of feed selected and thus indi-

cates which feed control lever has to be moved in what

direction.

lmportant

Always move all feed control levers to zero position before

any change in mode or operating any of the transfer keys

X,Y,Z.

trtr

trtr

trtr

trtr

@@

Bg

Etr

oo

tr

tr

tr-

a

o

E}

E[

@

tr

o

E

E

o

-riaSrJ-50

t73r!5EA

Active digital position readout unit, cont'd

Tool radius compensation

The active digital readout unit permits tool radius compen'

sations with the aid of keys (10). This requires the input

of the cufter diameter.

Proceed in the following order:

- Use keyboard ( l) to key cutter diameter into setpoint

readout (5).

- Operate t.v E (10) : the control will calculate the cut-

ter radius. This will then appear in setpoint readout (5)

and will be stored automatically.

- Key in setpoint on keYboard (l).

- Operate either E key {10) to add cutter radius or p

( I 0) to subtract cutter radius from setpoint value (5).

- When operating tool compensation keys twice, the full

diameter will be either added or subtracted, for example

for machining the opposite wall of a pocket.

- Transfer to actual-value counters and automatic position'

ing as described above.

Fault diagnosis

ln the event of faults or defects, the active digital readout

unit will automatically give diagnosis readouts.

- Measuring system defective:

associated actual-value counter will start flashing. To

cancel diagnosis readout, switch off power supply,

remedy fault and restart the unit-

- Defect in electronics:

LEDs above reference point keys will light up.

To cancel diagnosis readout, switch off power supply.

lf fault diagnosis reappears after switching off and on

again, return digital readout unit for repair (state LEDs

lighting up).

- Positioning error:

if feed control lever is moved in wrong direction for a

selected positioning operation. the feed motion will be

switched off after 200 pm. Actual-readout (7) will show

'u'symbols.

To cancel diagnosis readout, operate E4 t.v, then rnove

feed control lever in correct direction.

Caution

Never remove or insert plugs while unit is energized.

Additional setup and maintenanpe instructions, as well as

examples of operating the unit, will be found in the oper'

ator's manual supplied with the digital position readout

unit.

Printed in the Fedaral Republic of Germany

12

11 Fig 1

tr8tr

trtrtr

@@ @

E@g

Etrtr

@@@

-ri aJ rJ ao

!c3Li5E[i

E 9o2a ( 1 2.81 )

\ctive digital position readout unit

Electronic linear measuring and positioning system for

automatic slide motions to preselected positions in absolute

and incremental (chain) dimensions.

Def inition of 4 reference points; storage of tool compensa-

tions; meiric inch conversion.

Technical data

Numberof digits ........7

Resolution (selectable) . . 0.01/0.005 mm

swirchableto... 0.0005/0.0002inch

,denti{ication of controls

1 lnput k

E,o val ues

Decimal point key

Sign input key

(plus sign will not appear in readout)

Cancelling key for setpoint values or

error indications

eyboard

E Numerical keys for preset or setpoint

.2

x

€

.E

o

C

o-

tL

Fig 1

Switching on

Switch on machine (main disconnect switch) and digital

readout unit (switch on rear side of housing).

At f irst all LEDs and readouts will light up (lamp test).

Setpoint readout: 88888888

Actual-value readout + 18888888

After approx 1.5 sec the actual-value readouts (counters)

will show the position values assigned to the reference

marks by def ining the reference point [] before the unit

was switched off.

(All scales are provided with a reference mark in addition

to the scale divisions.l

- The readouts will count in the measuring system (mm or

inch) last used. lf required, operate 'inch' key (1 1 )-

- Check resolution (smallest increment shown) in active-

value readouts (71. operatinS key (12) if required.

Move past reference marks if reference points are to be set

reproducibly or previously set reference points are to be

reproduced after switching the readout unit off and later

on again (for details see below).

trtr

El tr

Etr

trtr

@@

Bg

trtr

@o

tr

tr

E

a

@

trl

Mil

@

tr

@

EI

ffi

o

-rtat rJ{o

l;:3,L!.58fr

te lL.584

tr

a

@

2 Command keYs

tr tr tr Transfer keys with LEDs (4) 'Positionins

in progress'

3 Mode-of-operation keys

m Manual positioning mode

r'.' Automatic positioning mode

E=J 'Absolute dimensions'

trl Automatic positioning mode

' I ncremental (chain) dimensions'

@} Feed activation

Key to activate feed buttons on

operator control panel in 'manual'

mode.

4 LEDs 'Positioning in progress'

5 Setpoint readout (preset)

6 Reference point key

7 Actual value readouts for X, Y, Z

8 Reference point selection keys

9 Reference point LEDs lor X, Y , Z

10 Tool compensation keys

1 1 Metric/inch conversion key

l2 Resolution selector key 0.01/0.005 mm or

0.0005"/0.0002"

- Stop key for interruption of positioning operation.

E 902 (12.81)

Table of contents

Popular Power Tools manuals by other brands

Glenair

Glenair band-master ATS 601-118 operating instructions

One Stop Gardens

One Stop Gardens 94593 Assembly and operating instructions

Desoutter

Desoutter PT070-T4000-S13S manual

Qonnect

Qonnect PLR operating instructions

Axminster

Axminster AW318BT Original instructions

Kraissmann

Kraissmann 2002 HLP 3 user manual