Deckma AFMS3000 User manual

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 1 of 24

20140208BA

AFMS3000

Operating instructions

ALARM INSEQU.

FIRE

FAULT

RESET

DECKMAGMBH

MAINS

DISCONNECT

PRE - ALARM

TEST MODE

1

FIREALARMSYSTEM AFMS 3000

4

7

23

56

8 9

0

AA

A

Version history

Version

Date Author Checked Notes

0.5.10 23/09/09 STO FWU commissioning

0.5.11 28/06/11 TF TM revised

0.6 05/02/14 JB TK layout revised, terms adapted

0.7 07/02/14 JB TK revised

0.8 08/02/14 TK STO revised and further errors corrected

0.9 21/04/16 TK STO Improved information to earth fault measurements (1.4.)

1.0 18/03/17 TK STO Information about the system’s functions added

Checker: Thomas Kruse, Technical Manager, DECKMA

2018/03/17

name – company Date

Approved:

Sven Torbeck, General Manager, DECKMA

2018/03/17

name – company Date

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 2 of 24

Index

1. Description of the modules.......................................................................................................... 4

1.4. Power supply TR01-E ......................................................................................................... 4

1.5. Main module NM01-E.......................................................................................................... 4

1.6. Output module AM01-E....................................................................................................... 5

1.7. Fire loop module AFM01-E.................................................................................................. 5

1.8. Fire loop module FM01-E.................................................................................................... 5

1.9. Printer module DM01-E....................................................................................................... 6

1.10. VDR module VM01-E.......................................................................................................... 6

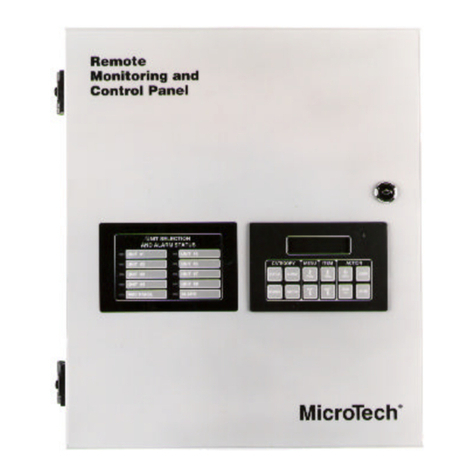

1.11. Main panel AHT01-E........................................................................................................... 7

1.12. Main panel HT01-E ............................................................................................................. 7

1.13. Data module DT01-E........................................................................................................... 7

2. Operation of the AFMS................................................................................................................ 8

2.4. Overview............................................................................................................................. 8

2.5. Access levels...................................................................................................................... 8

2.5.1. Access level 1............................................................................................................. 8

2.5.2. Access level 2............................................................................................................. 8

2.5.3. Access level 3............................................................................................................. 8

2.5.4. Access level 4............................................................................................................. 8

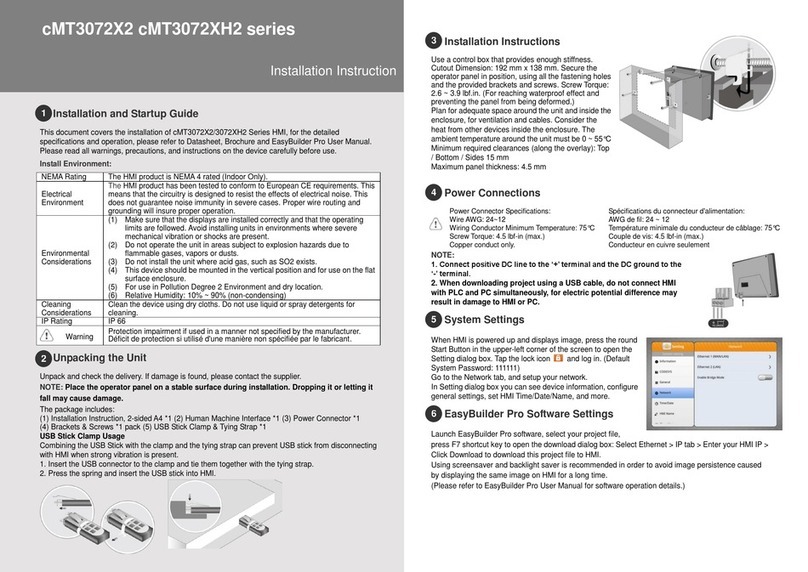

2.6. Display and operating elements of the panel (AHT)............................................................. 8

2.6.1. Graphic display..........................................................................................................10

2.6.2. Menu keys (soft keys) ................................................................................................10

2.6.3. Number block.............................................................................................................11

2.6.4. "HOME" and "BACK" keys .........................................................................................11

2.6.5. "FIRE"/"SILENCE", "FAULT"/”SILENCE” and "RESET" keys......................................12

2.6.6. "FIRE", "FAULT" and "RESET" illuminated fields........................................................12

2.6.7. "ALARM IN SEQU." illuminated field...........................................................................13

2.6.8. "MAINS", "DISCONNECT", "PRE-ALARM" and "TEST MODE" illuminated fields........13

2.7. Operating modes of the AFMS ...........................................................................................14

2.7.1. Fire alarm ..................................................................................................................14

2.7.2. Faults.........................................................................................................................15

2.8. Operation functions............................................................................................................15

2.8.1. Show firmware...........................................................................................................16

2.8.2. RESET of the AFMS..................................................................................................16

2.8.3. Set date and time.......................................................................................................16

2.8.4. Perform lighting test of the illuminated fields...............................................................16

2.8.5. Set background brightness of display.........................................................................17

2.8.6. Set display colours.....................................................................................................17

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 3 of 24

2.8.7. Set brightness of green LED ......................................................................................17

2.8.8. Set brightness of yellow and red LEDs.......................................................................17

2.8.9. Change password and/or change display language....................................................17

2.8.10. Activate one man test.................................................................................................17

2.8.11. Activate/deactivate detectors, zones or outputs..........................................................18

2.8.12. Set delay times of the detectors .................................................................................18

2.8.13. Set thresholds for detectors........................................................................................18

2.8.14. Overview display status of the detectors.....................................................................18

2.8.15. Activate/deactivate loops............................................................................................18

2.9. Main panel in parallel operation..........................................................................................18

3. Glossary ....................................................................................................................................19

3.1. Acoustic sounder................................................................................................................19

3.2. Fire detector.......................................................................................................................19

3.3. Fire zone............................................................................................................................19

3.4. Graphic display..................................................................................................................19

3.5. Configuration (Config Tool).................................................................................................19

3.6. LED ...................................................................................................................................20

3.7. Loop ..................................................................................................................................20

3.8. Illuminated fields ................................................................................................................20

3.9. Power supply .....................................................................................................................20

3.10. Loops.................................................................................................................................20

3.11. Loop name.........................................................................................................................20

3.12. Fault (error)........................................................................................................................21

3.13. Working principle of sensors (smoke sensor)......................................................................21

4. Menu structures .................................................................................................................22

4.1 Menu Main Page .............................................................................................................22

4.2 Menu Service ..................................................................................................................23

4.3 Menu Fire Alarm System .................................................................................................24

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 4 of 24

General

The AFMS3000 serves to detect, report and warn of fires and faults. The AFMS3000 can be operated

with both addressable and non-addressable (conventional) fire detectors.

The AFMS3000 is of modular construction. The individual modules are connected to each other by an

internal BUS and a common electricity supply voltage (24V DC). All modules, except for the main

panel (AHT) and the main panel (HT), are intended for support rail mounting, but they can also be

installed together in a metal cabinet or housing. The main panel (AHT) and the main panel (HT) are

constructed as built-in devices, which are normally installed in a bridge control console. The

AFMS3000 can either be wall-mounted or installed in a console.

All modules of the FMS3000 can also be used in the AFMS3000 and have already been tested

and approved under MED-Zulassung 61 075 – 13 HH.

1. Description of the modules

The AFMS3000 consists of several modules in their own metal housings. The modules are connected

by and internal bus through an RS485 data cable. If a fire detector registers an event (fire or smoke),

the fire loop module recognises this event. The main panel (AHT, also the BUS Master) queries in a

cycle the status of all modules, so it receives the existing fire alarm of the fire loop module.

Independent of the configuration, the main module transmits to the output module which outputs it

should now connect. It also sends this alarm to the VDR module and the printer module (if present).

The VDR and printer modules output the fire alarm through a VDR output or printer respectively. In

addition, the main panel warns the user acoustically and optically of the event (fire/fault).

1.4. Power supply TR01-E

The power supply supplies the entire AFMS with a system voltage of 24V DC. For this purpose, the

module has a toroidal core transformer, which can be operated as required with a supply voltage of

230V/AC or 115V/AC. The selection is made with a knob, the appropriate relay and the use of the

appropriate fuses (1.6AT or 3.15AT).

The module is connected to a mains or emergency supply. It switches automatically to emergency

power when the mains supply fails and vice versa. The electricity supply inputs are protected by

miniature fuses (which can be changed).

1.5. Main module NM01-E

The power supply is connected directly to the main module. The main module distributes the power

supply and the BUS (knob setting = 1) to the other modules. If the mains and the emergency power

fail, the main module switches to power supply from an accumulator. The main module has a charging

circuit for this accumulator, an accumulator charge monitoring system, a cut out circuit and an energy

management system. The main module also has a real time clock (RTC). The time is buffered in a

button cell when no operating voltage is present.

The main module has 9 connections (all together counted) for various modules, for which max. 4A

current can be delivered.

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 5 of 24

1.6. Output module AM01-E

The output module has eight relays, three switched 24V outputs and one input for an external button.

To the outputs can be connected, for example, a machine alarm system, a VDR, fault and common

status displays, sirens, an automatic general alarm system, fire doors and/or flashing lights. Max. 2

output modules can be connected to the AFMS. The BUS address is set with a rotary switch on the

device. The configuration on the SD card must (as with all modules) correspond to the number of

assemblies being used.

A microcontroller controls the relays, the 24V outputs, the button input and communicates with the

master. On a command from the master, the output module switches its outputs. The rules for the

switching of these outputs are set in the configuration (NO, NC or alternating).

1.7. Fire loop module AFM01-E

Addressable fire detectors are connected to the fire loop module (AFM). The fire detectors are

addressed through a BUS. A fire loop module (AFM) contains two loops. Up to 127 detectors can be

connected to one single loop. Up to four fire loop modules (AFM) can be used in one AFMS. This

gives a maximum count of 1016 sensors.

The currently valid regulations for the maximum permissible number of fire detectors in a fire zone, an

area, and the necessity for the use of short circuit isolators at the transition into different fire zones, or

transitions from deck to deck are to be observed!

Each loop consists of two equivalent connection pairs (Drive & Return). A three-core wire is connected

to connectors. The data transmission and electricity supply of the fire detectors is run through this

wire. All fire detectors are parallel connected to this wire. The detector loops are monitored for short

circuit, cable breakage and earth connection, so the live wires and the grounding wire can be switched

individually through a microcontroller + further hardware. Due to the fact, that only one power input

and only one metal housing exists, an earth connection cannot be measured individually or displayed.

So all given earth fault events are only module based earth faults.

In order to ensure safe starting of the fire detectors, the outputs can be started slowly by a soft start

voltage.

For each loop, there is a modulator and a demodulator for data transmission on the fire loop module

(AFM) present.

Data transmission itself is according to ESP from HOCHIKI with 8Vss and 1200Baud.

The module also contains, in addition to the connections for the fire detectors, 8 potential-free outputs,

which can be configured as required for fire or fault. Two microcontrollers control and monitor the

loops, their outputs and communicate with the internal BUS.

1.8. Fire loop module FM01-E

Only non-addressable (conventional) fire detectors are connected to the fire loop module (FM). Up to

16 conventional detectors can be connected in parallel to one loop. Up to eight loops can be

connected to one module. Up to 4 fire loop modules (FM) can be used in an AFMS (16*8*4 = 512

conventional detectors). The BUS address is also set with a rotary switch on the module itself. The

configuration must correspond to the number of assembled units (see above).

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 6 of 24

In this case again, the currently valid regulations about the maximum permissible number of fire

detectors in a loop are to be observed, too!

In normal operation, a minimum (closed-) current flows through each loop. In order that this is

possible, the last detector in a loop is equipped with an EOL termination resistor (3k Ohm). In case of

a fault (e.g. through the removal of a detector or a broken wire), no more current flows through the

loop. The (FM) fire loop module monitors this current and informs the main module in case of a fault.

The main module reacts to this incident according to its configuration.

In case of a fire alarm, a resistor (in the range from 390 to 560 Ohm) is switched on the loop by the

relevant detector. The increased current is detected by the (FM) fire loop module and the main module

is informed about a fire in the relevant loop.

The (FM) fire loop module monitors all the loops for a possible short circuit. In case of a short circuit,

the relevant loop is switched off and the fault is reported to the main module. The maximum loop

current in a loop is around 400mA. The sum of all loop currents (after activation of several loops) must

not exceed 1.6A. Is the total current exceeded, the microcontroller switches off the loop with the

highest current.

The module, in addition to the connections for the fire detectors, also contains 8 potential-free outputs,

which can be configured as required for fault or fire. Two microcontrollers control and monitor the

loops, their outputs and communicate with the BUS.

1.9. Printer module DM01-E

The printer module is used as an interface card to the connection of a "Centronics" (or similar),

compatible printer. All messages (fault or fire alarms), as they are shown in the display of the main

panel too, are automatically sent to this printer, but with much reduced information (see sample

printouts underneath). The module receives the data from the BUS master.

Example of printout:

Date Time Information

30.12.06 15:33:02 AN loop 13

30.12.06 15:34:12 AR loop 13

1.10. VDR module VM01-E

The VDR module sends data, which it filters from the BUS, through its own RS485 or RS232 interface

to an “externally connected” VDR (Voyage Data Recorder). The communications profile of the VDR

interface is according to the specifications:

IEC 61162-1 Part 1 Single talker and multiple listeners

IEC 61162-100 Extra requirements for the UAIS

IEC 61162-102 Extra requirements for the Voyage Data Recorder

Example:

$--FIR,E,083945.00,FD,11,005,000,A,V,AN loop 5 *08 - fire alarm in loop 5 ,FM01

$--FIR,E,084030.00,FD,11,005,000,A,A,AA loop 5 *1C - fire has been accepted

$--FIR,E,084035.00,FD,11,005,000,A,A,AR loop 5 *0A - fire has been reset

$--ALA,084225.00,FR,OT,11,910,H,V,FN loop 16 *56 - fault with cable breakage

(open loop)

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 7 of 24

$--ALA,084410.00,FR,OT,11,910,H,V,FN power batt *36 - fault with battery defect

$--ALA,084720.00,FR,OT,11,910,H,V,FN module FM 4 *2A - fault with a missing

module (FM01)

1.11. Main panel AHT01-E

The AFMS can be operated from the main panel (AHT) and also from an additionally connected main

panel (HT). There must always be at least one main panel (AHT as principal) in an AFMS! In addition

to the main panel (AHT as principal), additional panels (main panel [HT] and main panels [AHT]) can

be used in parallel. The operating possibilities are considerably reduced on all parallel-operated main

panels, whether HT or AHT.

The operation of the main panel (AHT) is based on the operation of the main panel (HT) and is similar

to it. Nonetheless, the main panel (AHT) offers more comfortable operation and operator guidance

thanks to its larger display and an additional internal memory.

The main panel (AHT) is normally installed in a bridge control console on the command bridge near to

the other modules.

The main panel (AHT) consists of a large graphic display, 19 keys, 7 illuminated display fields (3-

coloured red-yellow-green) and an acoustic sounder. In order to be able to adapt the illuminated

display fields optimally to the local conditions, the light intensity can be adjusted. The contrast and the

brightness of the background lighting can also be adjusted (day/night operation).

1.12. Main panel HT01-E

The AFMS can be operated through the main panel (AHT) and the main panel (HT). There must

always be at least one main panel (AHT) in an AFMS (as master).

The main panel (HT) in parallel operation is normally installed in the MCR (machine control room) or

another safety station. On river ships, installation is also possible in the reception or on the bridge, as

well as other installations in firefighting locations.

The main panel (HT) consists of a display (2 rows each with 20 characters), 10 keys with the

associated multi-coloured illuminated fields, 2 further LEDs (with illuminated display fields) and an

acoustic sounder. All illuminated display fields, the display and the LEDs can also be adjusted for

brightness (as above), which also applies for the contrast of the LCD display.

A maximum of 2 main panels (HT) can be connected to an AFMS in addition to one main panel (AHT).

The connected main panels (HT) always run only parallel to an AFMS and this restricts their function.

The operation of a main panel (HT) is in the operating instructions of the MED-approved FMS3000,

which in this case is included in the delivery.

1.13. Data module DT01-E

The data module is intended for saving the configuration data of the AFMS and data created during its

operation on a special SD card. For this purpose, the module has its own microcontroller for reading

and writing onto the SD card. Operation is thus ensured independently of superior systems. The

module is connected through its own interface.

On the back of the module is a small slot for such card. It locks into position after insertion it into the

card holder. In order to remove the SD card, it must be first ‘pressed’ a little – the card unlatches,

comes out slightly and can then be removed easily.

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 8 of 24

2. Operation of the AFMS

2.4. Overview

The component of the AFMS that is first visible is either the main panel (AHT) or the main panel (HT).

The operation of the AFMS by the user is performed exclusively through the main panel (AHT) or the

main panel (HT). All main panels have a display, keys with illuminated display fields, LEDs and an

acoustic sounder. These operating units are connected to the AFMS through a bus cable (including

power supply).

Except for the displays on the main panel itself, the outputs of the fire loop module and the output

module serve as further signalling elements. The outputs can be used to connect, for example,

machine alarm systems, VDR, fault displays, sirens, a general automated alarm system, fire doors

and /or blinkers.

2.5. Access levels

The AFMS has 4 access levels. Certain displays, operating elements and functions can only be

accessed at the appropriate level.

2.5.1. Access level 1

Level 1 is directly accessible without having to open anything and without using tools. Operation of

level 1 is possible without any knowledge of the AFMS by simply pressing a key and/or calling up on

screen.

2.5.2. Access level 2

Level 2 is directly accessible without having to open anything and without using tools Level 2 can only

be activated with knowledge of the AFMS and not by randomly pressing a key. It is possible to call up

menus at this level, some of which are protected by a password.

2.5.3. Access level 3

The AFMS is located in a closed steel Switchgear cabinet or is mounted on a support rail in a bridge

console. In order to perform functions in level 3, tools have to be used to open the Switchgear cabinet

or the installation doors in the bridge console. This would result in changes to the configuration by SD

card.

2.5.4. Access level 4

The AFMS is located in a closed steel Switchgear cabinet or is mounted on a support rail in a bridge

console. In order to perform functions in level 4, tools have to be used to open the Switchgear cabinet

or the installation doors in the bridge console. Additional equipment is required, like for example the

ATMEL J-TAG programmer, the software and a computer for it. This includes updates for the

firmware, which could change basic functional procedures.

2.6. Display and operating elements of the panel (AHT)

The main panel (AHT) as principal is used for display and operation of the AFMS. In addition, a main

panel (AHT), and 2 further main panels (HT) can be connected in parallel. The panels in parallel

operation have restricted functions.

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 9 of 24

ALARM INSEQU.

FIRE

FAULT

RESET

DECKMAGMBH

MAINS

DISCONNECT

PRE - ALARM

TEST MODE

1

FIREALARMSYSTEM AFMS 3000

4

7

2 3

5 6

8 9

0

AA

A

The Menus for the various functions are structured in a strict hierarchy starting from a main menu

(display without operation, system runs without messages). It is thus possible to select the relevant

functions of the system by navigating forwards and backwards.

Graphic display

Number

block

"HOME"

key

"BACK" key

Soft keys

"FIRE" and "A"

key

"FAULT" and

"A" key

"RESET" key

Illuminated fields

ALARM IN SEQU. illuminated

field

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 10 of 24

2.6.1. Graphic display

·In the menu field, only the current menu entry is shown. Additional information is also

displayed such as the number of new and accepted fire alarms or faults (soft keys).

·In the actions field, certain elements of the menu navigation or an action are shown.

·In the four soft key menu fields with surrounds, the functions of the directly subordinate

menu are shown.

2.6.2. Menu keys (soft keys)

Menu fields

Action field Current timeMenu bar

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 11 of 24

Four soft keys are available directly beneath the graphical display for menu navigation. The function of

each key is shown in the graphical field directly above the relevant key (menu field).

2.6.3. Number block

An extra number block (with numbers 0 - 9) is available for the input of parameters or numerical

values such as date or sensitivities of individual detectors.

2.6.4. "HOME" and "BACK" keys

The "Home" key can be used to return directly to the main menu. The "Back" key only serves to jump

back to the relevant higher menu entry.

BACK HOME

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 12 of 24

2.6.5. "FIRE"/"SILENCE", "FAULT"/”SILENCE” and "RESET" keys

FIRE

FAULT

RESET

AA

A

Three keys are available for the user to process incidents such as a fire alarm or a fault.

·FIRE/A

opress 1st key: switch off signal (silence)

opress 2nd key: accept fire alarm or

opress 2nd key: open fire menu (required for a RESET)

·FAULT/A

opress 1st key: switch off signal (silence)

opress 2nd key: accept fault or

opress 2nd key: open fault menu (required for a RESET)

·RESET

oReset fire alarm or fault

2.6.6. "FIRE", "FAULT" and "RESET" illuminated fields

FIRE

FAULT

RESET

AA

A

As normal operation, all fields illuminate green. If a new fire alarm occurs, the field "FIRE" lights up

red. The acoustic sounder emits a steady note.

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 13 of 24

If the fire alarm is accepted, the field lights permanently red. After resetting of the fire alarm (using

RESET), the "FIRE" field returns to green.

The "FAULT" field behaves correspondingly in case of a fault, except here with a beeping from the

sounder. If the fault is accepted, the field lights up permanently yellow. After the resetting the fault

(once again using RESET), the "FAULT" field also returns to green.

If there are several new fire alarms or faults respectively, the relevant field ("FAULT", "FIRE") blinks

until all messages have been accepted.

If there are several accepted fire alarms or faults respectively, the relevant field remains illuminated

until all messages have been reset.

The "RESET" illuminated field can also turn from green to yellow for a short time. During this time, for

example, a system reset is being transmitted to a module and executed.

After a restart of the AFMS, the "RESET" field blinks until all modules and assemblies are initialised

(also in case a previously switched off loop is reconnected).

2.6.7. "ALARM IN SEQU." illuminated field

ALARM INSEQU.

In normal operation, the "ALARM IN SEQU." field is illuminated green. If there is more than one fire

alarm, the field turns from green to red.

When the fire alarms are reset except for one fire, the illuminated field changes back to green.

2.6.8. "MAINS", "DISCONNECT", "PRE-ALARM" and "TEST MODE" illuminated fields

MAINS

DISCONNECT

PRE- ALARM

TEST MODE

In normal operation, all fields are illuminated green. In certain cases, these can also be illuminated

yellow.

·MAINS Fault in the power supply (mains or emergency power)

·DISCONNECT Detectors, zones, loops or outputs are switched off

·PRE-ALARM Preliminary alarm at a smoke detector

·TEST MODE The AFMS is in test mode (one man test )

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 14 of 24

2.7. Operating modes of the AFMS

2.7.1. Fire alarm

If a fire alarm occurs, the illuminated field "FIRE" blinks red and the acoustic sounder sounds

permanently. If the system is in the main menu, this jumps automatically to the menu entry "New Fire".

Information about the new fire is shown in the display.

FIRE

When the key "FIRE"/"A" is pressed once, the acoustic sounder stops. The display is renewed. If the

system is not yet in the menu entry "New Fire", this is now repeated (e.g. in case a new fire alarm

occurs while the user is navigating through the sub-menus).

FIRE

AA

Pressing the "FIRE"/"A" key accepts all the fire alarms that are currently shown in the display. By

accepting a fire alarm, the user signals acknowledgement of the fire alarm and that further measures

have been introduced. If all fire alarms have been accepted, the field "FIRE" illuminated permanently

red.

If the alarm is not accepted within two minutes, the switching of the 3rd output of the output module

automatically activates an externally connected automatic general alarm system. The display then

shows at top right corner "general alarm!"

If more than the five (5) fire alarms that can be displayed accumulate, it is possible to change between

the fire alarms by pressing the ">>>" menu key. The display is changed from fire alarm to a fault by

pressing the relevant "FIRE" or "FAULT" key. The display always shows the newest and the oldest fire

alarm and the newest and oldest fault for 30s after the last interaction. The last fire alarm that occurred

appears in the top position.

With a reset action of the fire alarm, the user signs, that the fire has been extinguished. In order to

reset a fire alarm (condition "cleared"), the menu entry "Accepted Fire" (repeated pressing of the

"FIRE" key) must be selected. All accepted fire(s) are shown in this menu tab. Pressing the "RESET"

key again only resets the fire alarm selected with the white arrow! The relevant detector is then

automatically set to “armed”. Each fire alarm has to be reset individually! If all fire alarms have been

reset, the "FIRE"-field turns back into green colour. If a new fire alarm occurs (after resetting of a fire

alarm), then this fire detector is still active or is active again (e.g. due to residual smoke in the optical

chamber of a smoke detector). In this case a new alarm will come up!

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 15 of 24

2.7.2. Faults

In case of a fault, the "FAULT" field illuminates yellow, the acoustic sounder sounds alternatively and

the relay at output JP10 on the main module drops to ‘off’. Should the system be in the main menu, it

jumps automatically to the menu tab "New Fault". Information about the new fault is shown in the

display.

FAULT

Pressing the "FAULT"/"A" key silences the acoustic sounder. The display is renewed. Should the

system not yet be in the menu tab "New Fault", this is now shown (e.g. when a new fault occurs while

the user is navigating in the sub-menus).

FAULT

A

Pressing the "FAULT"/"A" key accepts all displayed faults. With the accepting of a fault, the user

signals that the fault has been acknowledged and corresponding measures have been introduced to

remedy it. When all faults have been accepted, the "FAULT" field illuminates once more permanently

yellow.

If more faults have accumulated than the five that can be shown, it is possible to switch between the

faults by pressing the ">>>" menu key. The display is switched from showing a fire alarm to a fault by

pressing the "FIRE"/"A" or "FAULT"/"A" key. The display always shows the newest and the oldest fire

alarm and the newest and oldest fault for 30 s after the last interaction.

Resetting a fault must be undertaken out of the menu entry "Accepted Fault" (repeated pressing of the

"FAULT"/"A" key). In this menu entry, all accepted faults are shown. Pressing the "RESET" key now

only resets the fault selected with an arrow.

After the successful resetting of all faults, the "FAULT" symbol illuminated green again and the relay at

output JP10 of the main module picks up again (common status contact).

If the power supply (mains or emergency supply) fails, the "MAINS" field illuminates yellow. After a

configurable time, a fault also occurs.(shown in the display + blinking "FAULT" field). If both power

supplies are restored, the "MAINS" field turns green again. If the power supply fails completely (also

the emergency battery), the AFMS switches off completely. This means that all relays of the modules

and also the relay behind the "JP10" drop out!

2.8. Operation functions

The main menu can be reached from any sub-menu by pressing the "HOME" key. Pressing the

"BACK" key returns to the previous menu tab, not to the main menu.

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 16 of 24

After about 30 seconds (without any further key being pressed), the main panel (AHT) returns

automatically to the main menu screen or it will be updated only (e.g. in TEST mode).

2.8.1. Show firmware

This menu tab enables the firmware of all modules to be shown. It can be reached from the main

menu by selecting the sub-menu tabs:

èService èSystem Status èFirmware

2.8.2. RESET of the AFMS

This menu entry enables a restart of the whole AFMS system. It can be reached from the main menu

by selecting the sub-menu tabs:

èService èSystem Reset

Three RESET functions are available:

1. Reset with deleting all (with password): The previously accumulated fire alarms and

faults will be all deleted and the system is restarted.

2. Reset with hold all: The system will be only restarted (holds all data).

3. Reset with new init modules (with password): All fire alarms and faults will be deleted,

the modules and detectors are newly initialised and the system is then restarted.

In case the restart does not happen, it is possible to use the "Reset" key on the main module to

activate a restart manually.

2.8.3. Set date and time

This menu entry enables the settings of time and date. It can be reached from the main menu by

selecting the sub-menu entries:

èService èSettings èSet Date and Time

2.8.4. Perform lighting test of the illuminated fields

This menu entry enables a test of the lighting of the illuminated fields to be performed. It can be

reached from the main menu by selecting the sub-menu entries:

èService èSettings èLamp Test

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 17 of 24

2.8.5. Set background brightness of display

This menu entry enables the background lighting of the display to be adjusted. It can be reached from

the main menu by selecting the sub-menu entries:

èService èSettings èDimmer LED/TFT èDisplay èDisplay Backlight

2.8.6. Set display colours

This menu entry enables the type of display to be changed (black text on white background or vice

versa). It can be reached from the main menu by selecting the sub-menu entries:

èService èSettings èDimmer LED/TFT èDisplay èDisplay Colours

2.8.7. Set brightness of green LED

This menu entry enables the brightness of the green LEDs to be adjusted. It can be reached from the

main menu by selecting the sub-menu entries:

èService èSettings èDimmer LED/TFT èGreen LED

2.8.8. Set brightness of yellow and red LEDs

This menu entry enables the brightness of the yellow and red LEDs to be adjusted. It can be reached

from the main menu by selecting the sub-menu entries:

èService èSettings èDimmer LED/TFT èFault LED (red/yellow)

2.8.9. Change password and/or change display language

The password has to be entered!

This menu entry enables the password and/or the menu language to be changed. It is necessary to

know the old password or the master password. 2 menu languages are available (depending on the

firmware). The password has four characters. It can be reached from the main menu by selecting the

sub-menu entries:

èService èSettings èUser Settings èSet Operator Code or Set Language

2.8.10. Activate one man test

The one man test is used for the automatic processing of fire alarms. Accepting and resetting of the

fire alarms is undertaken automatically by the AFMS. This can be activated or deactivated in this sub-

menu (with RESET). It can be reached from the main menu by selecting the sub-menu entries:

èFire Alarm System èControl èStart test Mode èOne Man Test

Should no new fire be detected within 30 minutes while the one man test is activated, the one man

test is automatically terminated and the AFMS returns to normal operation.

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 18 of 24

2.8.11. Activate/deactivate detectors, zones or outputs

The password has to be entered!

This menu entry enables individual detectors, fire zones or outputs from the two output modules to be

activated or deactivated. It can be reached from the main menu by selecting the sub-menu entries:

èFire Alarm System èManagement èDisconnections

2.8.12. Set delay times of the detectors

The password has to be entered!

This menu entry enables delay times to be set for individual detectors. It can be reached from the

main menu by selecting the sub-menu entries:

èFire Alarm System èManagement èDelay

2.8.13. Set thresholds for detectors

The password has to be entered!

This menu entry enables thresholds for the individual detectors to be adjusted. It can be reached from

the main menu by selecting the sub-menu entries:

èFire Alarm System èManagement èAdjustments

2.8.14. Overview display status of the detectors

This menu entry enables the status of all detectors to be displayed in a tabular overview. The display

shows all detectors in the currently (selected) loop (selected using the number block). It can be

reached from the main menu by selecting the sub-menu entries:

èFire Alarm System èManagement èLoop (and key "More Information”)

2.8.15. Activate/deactivate loops

The password has to be entered!

This menu entry enables a loop to be deactivated. It can be reached from the main menu by selecting

the sub-menu entries:

èFire Alarm System èManagement èLoop (and key "Change Connect Status”)

2.9. Main panel in parallel operation

A second main panel can be connected to the AFMS. This only enables "parallel" operation. In

contrast to the first main panel, which runs as principal ‘master’, the second main panel in parallel

operation has a few restricted functions only.

The main panel in parallel operation cannot be used, for example, to change the configuration of the

AFMS. It serves only simple information (as some kind of monitor) for any users. Faults and fire

alarms are shown as on the principal main panel (including acoustic sounder, the LEDs and alarm

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 19 of 24

messages). The acoustic sounders must be switched off individually (at any location) on each main

panel (principal or parallel operation). Faults and fire alarms can however only be accepted and reset

at the main panel (operating as principal master). Both panels are otherwise 100% identical (same

hard- and software). The needed (or wanted) operating mode (from such displays) is set by changing

a jumper in the black connector plug housing! So the connector is responsible for the working mode.

Independent of the mode of operation, the brightness of the illuminated fields, the LEDs and the

display can be adjusted on any panel separately. The lamp test can also be performed locally (in both

operating modes) and the unit firmware can be displayed.

3. Glossary

3.1. Acoustic sounder

An acoustic sounder emits a "loud" tone. It is located only on the back side of every main panel and

serves to provide a local acoustic notification of a fire or a fault event.

3.2. Fire detector

The FMS3000 can only be used with non-addressable sensors. The alarm resistance should be

between 390 and 560 Ohm. The AFMS can likewise operate with non-addressable fire detectors, but

can also administrate addressable detectors (sensors working with HOCHIKI ESP telegrams). The

AFMS is mainly designed to operate only with HOCHIKI ESP sensors. Manual call points and also all

address units (different CHQ modules are possible) are counted like other detectors. The functional

principle of a detector (in the example a smoke detector is used) is explained in little more detail in

section 3.13.

3.3. Fire zone

A number of detectors can be collected into a group or fire zone, independent of whether they are

connected to one loop. If a fire is activated in a certain fire zone or group, a defined outcome can be

switched for that zone or group.

3.4. Graphic display

A large display, on which both text and graphics can be displayed.

3.5. Configuration (Config Tool)

This is where all the basic settings of the AFMS are configured. A system configuration is "written" with

an Excel tool or the DECKMA Config Tool. These aids create 35 text files from the inputs, which are

copied onto the "root" of an SD card. The SD card is inserted into the data module at the back of the

AHT. The data module must be continuously connected with the AHT (it is secured to the AHT with 2

screws or bolts). The configuration contains:

·Which modules are being used (type).

·The number of outputs and fire loop assemblies (+ active loops).

·The events linked with the outputs of the fire loop and output assemblies.

·The names of the detectors (detector location), fire zones, detector sensitivities …

·Delay in case of fault due to failure of mains or emergency power supply.

·Charging current for the accumulator(s)

Technical documentation 20140208BA

AFMS3000

Tel.: +49 (0)4105 / 65 60 – 0 * DECKMA GmbH * Fax: +49 (0)4105 / 65 60 – 25

Email: info@deckma-gmbh.de * Internet: www.deckma-gmbh.de

Operating instructions Version 1.0 2018/03/17 page 20 of 24

·Language and menu files for the display in the soft key fields

·Definition of timers and switching off e.g. smoke detectors

·Definition of MODBUS-Ident data for external SPS systems

3.6. LED

Light emitting diodes (LED) create light.

3.7. Loop

The physical connection (through plugs JLD1, JLR1, JLD2, JLR2) of the fire loop module (AFM), to

which the detectors are connected. Outcomes can be configured independently of the loop, to which a

detector is connected. Each fire loop module has 4 terminals for altogether 2 fire detector loops (loop

1 with "drive" and "return" and loop 2 with "drive" and "return").

3.8. Illuminated fields

Illuminated fields are provided on all main panels. Some are above the keys or located next to the

LEDs they are assigned to. They have a symbol or are labelled. The illuminated fields can light up in

various colours (red, green, yellow) depending on the situation. Their brightness can be adjusted

(daytime/night time operation). Fires or faults always light up with the full brightness on first

occurrence until they have been accepted (daytime operation with dimmed display)!

3.9. Power supply

There is a mains and an emergency power supply. If one fails, the AFMS reports a fault. If the mains

power fails, the AFMS switches to emergency power. If both power supplies fail, the AFMS switches to

accumulator emergency operation until the accumulator has run down. Then the system switches off

(protection against full discharge for the accumulator(s)).

3.10. Loops

Up to 16 conventional fire detectors can content a conventional loop in parallel. In the last fire detector

of a loop, a termination resistor of 3kΩ(+/-10%) must be fitted. With non-addressable fire detectors,

which can only by used by the FMS3000, a fires can only be detected in one loop and not in one

detector.

Up to 127 addressable fire detectors (better sensors) can be present in an addressable loop. There is

no termination resistance or "EOL device" needed. All detectors are connected in parallel to one cable

and each sensor can be only identified through HOCHIKI’s ESP telegram. All ESP sensors must be

programmed with a programmer (TCH-B100 [old]/TCH-B200 [new]) or the relevant address is set on

site by using the dip switches on the sensor itself (this applies to some CHQ modules). The maximum

possible loop current is limited to 400mA. Any loop current is monitored by the existing energy

management system to keep any loop current as low as possible. So that data can be transmitted

over long distances, the loop current is kept as low as possible by the ESP-supported special energy

management (keywords: “line loss”, “voltage drop on cables” and “line load”).

3.11. Loop name

A conventional loop can be given a name in the configuration. This can describe the location of the

detectors connected to the loop. In an addressable system, the detectors possess a clear detector text

(and its group/fire zone), such as e.g. "Steering Gear Room 125 Aft" and the fire zone "Engine Room

Aft" and its address 38.

This manual suits for next models

1

Table of contents

Popular Control Panel manuals by other brands

Bosch

Bosch D9412GV4 Quick reference guide

Heatcraft Refrigeration Products

Heatcraft Refrigeration Products Beacon II H-IM-79G Installation and operation manual

urmet domus

urmet domus 925 manual

Spectron

Spectron BE56-2U-VCR user manual

IDS

IDS X64 manual

fisair

fisair CCE2.0 Installation and operation manual