Dedy 220 User manual

Operating Instructions

Dedy enrobing machine

2

20 mm

320 and

2Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

Contents

1. General information 4

1.1. About these operating instructions 4

1.2. Symbols used 4

1.3. Copyright 4

1.4. Warranty 5

1.5. Applicable standards 5

2. Security 6

2.1. Intended use 6

2.2. Fundamental risks 6

2.3. Risks from electric energy 6

2.4. Mechanical hazards 6

2.5. Responsibility of the operating company/operator 7

2.6. Personnel requirements 7

2.7. Safety devices 7

2.8. What to do in the event of hazardous situations and accidents 7

2.9. Warning and information signs 8

2.10. Maintenance and repair work 9

2.11. Environmental protection 9

3. Build and function 10

3.1. Scope of delivery 10

3.2. Optional accessories 10

3.3. Build and function of the Dedy chocolate enrobing machine 10

4. Transport and storage 13

4.1. Safety information for transport and storage 13

4.2. Machine transport 13

4.3. Machine storage 13

4.4. Coating storage 13

5. Assembly and initial use 14

5.1. Safety information for assembly and initial use 14

5.2. Assembly 14

5.3. Temperature limits 14

5.4. Operation 15

6. Operation 16

6.1. Safety notices for operation 16

6.2. Chocolate enrobing machine controls 17

6.3. Taking the enrobing machine out of operation 30

7. Maintenance 31

7.1. Safety information relating to maintenance 31

7.2. Servicing and maintenance 31

7.3. Servicing and maintenance schedule 31

7.4. Cleaning and care schedule 32

3Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

Contents

8. Faults 33

8.1. Safety information relating to troubleshooting and

fault rectification 33

8.2. Malfunction causes and troubleshooting 33

9. Dismantling and disposal 35

9.1. Safety information relating to dismantling 35

9.2. Dismantling 35

9.3. Disposal 35

10. Technical data 36

10.1. Dedy chocolate enrobing machine specifications 36

10.2. Dimensions 36

10.3. Replacement parts 38

10.4. List of replacement parts for Dedy enrobing machines 38

11. Appendix 42

11.1. Declaration of conformity 42

11.2. Information on the processing of chocolate 43

11.3. Documentation for outsourced products 45

General information

4Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

1. General information

1.1. About these operating instructions

These operating instructions will enable you to use your Dedy enrobing machine

safely and efficiently. The instruction manual is key component of the machine

and must be accessible to the operating personnel at all times.

The instruction manual is supplied with the enrobing machine and must be

passed on to the new owner if the machine is sold.

Due to technical developments, diagrams and descriptions in these operating

instructions may vary slightly from the enrobing machine actually supplied.

We cannot accept liability for damages arising as a result of failure to follow

these instructions.

1.2. Symbols used

All safety notices in these operating instructions are marked with appropriate

symbols. The signal words at the beginning of the safety notice express the

level of risk.

DANGER!

This combination of symbol and signal word indicates a situation that

constitutes an imminent danger of death or serious injury if it is not

avoided.

WARNING!

This combination of symbol and signal word indicates a situation that

constitutes a possible danger of death or serious injury if it is not

avoided.

CAUTION!

This combination of symbol and signal word indicates a situation that

constitutes a possible danger of minor injury if it is not avoided.

ATTENTION!

This combination of symbol and signal word indicates important infor-

mation that will help to avoid material or environmental damage.

1.3. Copyright

This operating manual and all the documents supplied with this machine are the

property of Dedy GmbH and are protected by copyright.

They may and should be consulted in connection with the use of the machine.

These documents may be neither reproduced nor made available to third par-

ties, in particular competing companies, without the express authorisation of

Dedy GmbH.

General information

5Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

1.4. Warranty

The machine is guaranteed by the manufacturer in accordance with the condi-

tions of sale and delivery. Warranty claims may not be made as a result of:

• Damage caused by incorrect operation

• Repairs or alterations carried out by unauthorised persons

• Failure to use original Dedy accessories and spare parts for the machine

• Delays in repairing defective components, thereby failing to minimise the

extent of damage or preserving the safety of the machine (duty of mainte-

nance)

1.5. Applicable standards

The following European and national standards were applied in the develop-

ment, design and construction of the machine:

• Machinery Directive 2006/42/EC

• Amendment 91/368/EEC

• Second Amendment 93/44/EEC

The following standards, trade association regulations (BGV), trade association

rules (BGR), trade association information (BGI) and further rules were consulted

for the machine risk assessment:

• DIN EN ISO 12100-1, -2, DIN prEN ISO 12100

• DIN EN ISO 14121-1

• DIN EN 349

• DIN EN 614-1

• DIN EN 894-1

• DIN EN 953

• DIN EN 982

• DIN EN 1037

• DIN EN 1127-1

• DIN EN ISO 11688

• DIN EN ISO 11690

• DIN EN ISO 13849-1

• DIN EN ISO 13850

• DIN EN ISO 13857

• DIN EN 50178

• DIN EN 60204-1 (VDE 0113)

• DIN EN 60529

• DIN EN 61310-1 (VDE 0113-101), -2 (VDE 0113-102), -3 (VDE 0113-103)

• BGV A 1; A 3, A 8, B 11

• BGR 237

• BGR 500

• BGI 5049

• German health and safety ordinance BetrSichV, German technical regulations

for operational safety TRBS 2111 and TRBS 2131, German hazardous sub-

stances act GefStoffV, German regulations on noise and vibrations LVArbSchV

Security

6Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

2. Security

2.1. Intended use

The machine is designed to coat baked goods and cakes of all kinds, fruit (e.g.

dates) or cream cheese with couverture, fondant icing, frosting or glaze.

The enrobing machine can also be used to fill chocolate moulds.

Any other use or use beyond that specified is considered improper use.

Intended use also includes compliance with these operating instructions.

2.2. Fundamental risks

As a general principle, hazards can arise when using enrobing machines. You

should therefore observe the statutory health and safety requirements (VSG) as

well as other generally recognised occupational health and safety rules and the

accident prevention regulations (hereinafter UVV) for power-operated equipment.

Do not make any modifications to the mechanics or electrics of the machine.

The manufacturer shall not accept liability for damage resulting from improper

modifications to the machine.

2.3. Risks from electric energy

Note the voltage and current ratings when installing the machine (see technical

specifications).

Work on the electric drive or control unit may only be carried out by qualified

electricians.

Always unplug the mains plug before starting maintenance work.

Check the mains plug and power cable regularly and have them replaced by an

electrician if damaged.

Always obey the five safety rules:

• Disconnect

• Prevent reconnection

• Check that there is no voltage

• Earth and short-circuit

• Cover or encase any neighbouring parts which are still live

2.4. Mechanical hazards

The machine is built according to the latest technological standards and with

the applicable directives and norms. Nevertheless, there may still be residual

risks if the machine is used improperly or incorrectly.

WARNING!

Risk of entanglement in drives (gear wheels) due to removal of cover

panels.

Removing the cover panels during operation is strictly forbidden.

Security

7Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

2.5. Responsibility of the operating company/operator

The operator is responsible for the following:

• Safe installation of the machine

• Appropriate storage of the operating instructions for ease of access

• Compliance with environmental protection requirements

• Qualification of the operating, servicing and repair personnel (knowledge of the

operating instructions, training in the jobs carried out on the machine, etc.)

The areas of responsibility for the various jobs on the machine must be clearly

defined and complied with in order to avoid any confusion which could adversely

affect safety.

2.6. Personnel requirements

The machine may only be set up, operated and serviced by authorised and

trained staff with the requisite skills.

The personnel who work on the machine must be duly authorised and be capable

of the following:

• carrying out the jobs safely and independently or

• carrying out the work after prior instruction under the supervision of an au-

thorised person.

2.7. Safety devices

The machine is fitted with various safety devices and thus meets the require-

ments laid down in the relevant directives and standards.

The machine may only be operated with the required safety devices, protective

mechanisms, locks and couplings in use and in working order. These devices

may not be bypassed or disabled.

The following safety devices are included:

• EMERGENCY OFF button

• Safety thermostats

2.8. What to do in the event of hazardous situations and accidents

Take the machine out of service immediately in the event of a hazardous situa-

tion or an accident by pressing the EMERGENCY OFF button (see Fig. 1).

Fig. 1: Position of EMERGENCY OFF button

In the event of an injury, skin irritation or allergic reaction, contact a doctor

immediately.

Security

8Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

2.9. Warning and information signs

There are warning and information signs on the machine.

• Type plate on the front of the enrobing machine:

Fig. 2: Type plate (example)

• Sign warning of dangerous high voltages at the relevant danger points.

Fig. 3: Danger: high voltage

• Sign warning of hot surfaces at the relevant danger points.

Fig. 4: Danger: hot surface

• Sign warning of entanglement hazard at the relevant danger points.

Fig. 5: Danger: risk of entanglement

Damaged or detached warning and information signs must be replaced promptly.

Security

9Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

2.10. Maintenance and repair work

Maintenance and repair work may only be carried out by trained and authorised

specialists. These are people who, on the basis of their training, instruction or

experience, are qualified to carry out the jobs required in any given case and to

identify and avoid the potential risks involved. They must be able to demonstrate

knowledge of the relevant safety standards, safety regulations and accident

prevention regulations and have read the operating instructions.

The recommended servicing intervals should be observed in order to guarantee

the operational reliability of the machine.

Before carrying out repairs and servicing work, take measures to prevent unau-

thorised, accidental or unexpected starting of the machine and to prevent the

onset of hazardous movements as a result of stored energy.

2.11. Environmental protection

When carrying out servicing and repair work, always observe the applicable

environmental protection regulations, such as the German hazardous substances

act (GefStoffV), the German water legislation (WHG), the German waste man-

agement law (AbfG) and the German ordinance on waste recovery and disposal

records (AbfNachwV).

Apply careful selection criteria before buying lubricants and lubricating oils,

researching their safety for use with foodstuffs, their environmental impact,

health risks, regulations for their disposal, and local facilities for their correct

disposal.

Build and function

10 Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

3. Build and function

3.1. Scope of delivery

The parts supplied with the chocolate enrobing machine are packed in several

units:

• Chocolate enrobing machine

(base frame including some main assemblies)

• Castors (4)

• Mesh conveyor

• Curtain box / bridge

• Rear panel

• Perforated sheet for base coating

• Covers for mesh conveyor infeed and discharge

• Switch cabinet key (VDE) for rear panel (2)

• Pull-off tool for chocolate wheel

• Spare rubber belts for evener cylinder (2)

• Operating manual

Additional parts for 220 mm model:

• Delivery table, 1 m

• Paperweight

• Cutter

• Lift-off plate

• Paper roll (2)

The machine must be assembled on site (see section “Assembly and initial use”).

Various custom-built models can be supplied on request.

3.2. Optional accessories

• Heated mesh conveyors for truffles

• Powder truffle tables

• Vibrating tables

• Special mesh conveyors for gingerbread

• Delivery table with dedicated drive unit and photo eye, 1.5 m

• Heating cabinets

• Cooling tunnel

3.3. Build and function of the Dedy chocolate enrobing machine

Build

The mobile Dedy chocolate enrobing machine is made entirely of stainless steel.

It can be supplied in various belt widths.

The standard capacity of approx. 20 kg or 30 kg of chocolate can be extended

to a total of approx. 60 kg or 90 kg respectively of melted chocolate (due to

two heated baths in a base cabinet).

The integrated (removable) chocolate bath is fitted with a drain valve.

This makes it easier to clean the machine and change the chocolate.

The infinitely variable belt speed ranges from approx. 0.5 to 4 m per minute.

An evener cylinder prevents the coating from becoming stringy to ensure a

smooth end result.

The chocolate temperature is controlled precisely to 1/10 of a degree.

A device for pouring chocolate into moulds is supplied as standard.

All the parts of the machine are easy to clean and extremely durable.

Build and function

11Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

The mesh conveyor, chocolate wheel and chocolate bath are easy to remove

and replace.

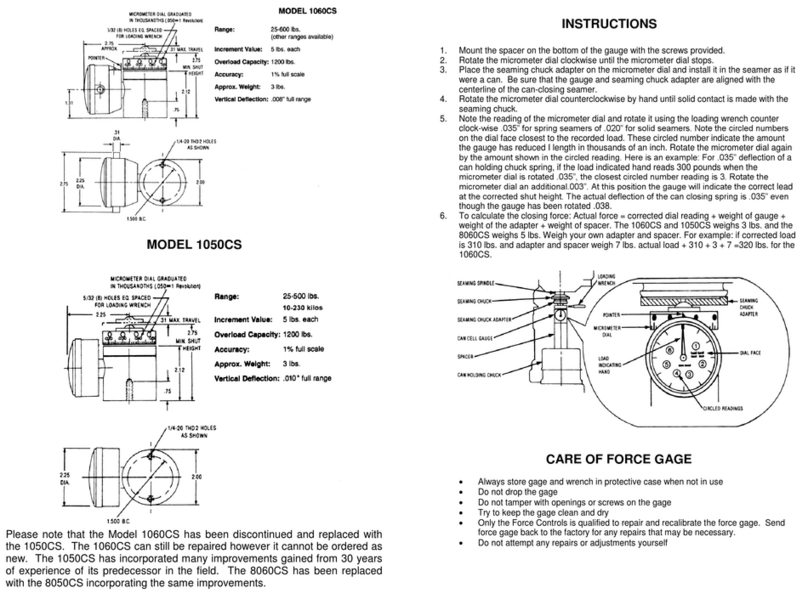

Fig. 6:

8

6

3

4

11

10

9

5

2

1

2

5

6

7

8

9

10

12

13

11

Diagram of chocolate enrobing machine

1 Base frame with castors

2 Feeding conveyor

3 Mesh conveyor

4 Immersion bath

5 Chocolate wheel

6 Chocolate spout

7 Curtain box

8 Fan

9 Hood heating unit (2)

10 Heated chocolate baths in base cabinet

11 Evener cylinder

12 Rubber belt for evener cylinder

13 Hood

Build and function

12 Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

Function

The Dedy chocolate enrobing machine can be used to coat all types of praline

fillings, baked goods, cakes (up to 10 cm in height), fruit (e.g. dates) or cream

cheese with couverture, fondant icing or glaze. Full coatings, base coatings and

combined base, side and half coatings are possible.

It can also be used to pour chocolate into moulds (spout supplied as standard).

The machine operates on 230 V / 50 Hz alternating current.

The products for coating are carried on the feed conveyor to the coating belt

and are routed under the curtain box (for complete coating) or under the bridge

(for base and edge coatings).

At the same time, the chocolate wheel carries the coating (e.g. chocolate) from

the chocolate bath over the chocolate spout into the curtain box and coats the

products from above.

If the bridge is used, the chocolate is routed via the bridge into a bath fitted

in the mesh conveyor so that the products are not coated with chocolate from

above.

If the products are also to be coated on the base and/or on the sides, they are

then dipped in the immersion bath.

The sides can be coated to different heights by adjusting the lever (depth of

immersion in the bath).

The fan mounted behind the immersion bath blows the excess coating off the

products in order to achieve an even coating thickness.

The two hood heating units (one over the chocolate lip and one behind the fan)

help to keep the coating at the required temperature at all times (both during

idle times (standby) and during production).

The enrobing machine can be operated with the hood open or closed.

Transport and storage

13Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

4. Transport and storage

4.1. Safety information for transport and storage

Attachments, lifting equipment and means of transport capable of bearing the

weight of the machine must be used to transport the machine.

4.2. Machine transport

The machine is delivered in several packing units. The weight is approx. 145 kg

(excluding base cabinet) and approx. 185 kg (including base cabinet).

The machine is assembled at the place of installation.

4.3. Machine storage

• The machine must be stored under the following conditions:

Temperature: -15 to +60 °C

Relative humidity: max. 80 %

4.4. Coating storage

The room temperature should not be above 22 °C. The optimum room temper-

ature for working with the chocolate is between 20 °C and 22 °C.

The air humidity should not be above 50 % (max. 55 %).

Chocolate coatings are very sensitive to moisture.

White chocolate does not keep as well as dark chocolate and has a shorter shelf

life. White chocolate is more susceptible to moisture and, if affected, can no

longer be used for coating.

Assembly and initial use

14 Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

5. Assembly and initial use

5.1. Safety information for assembly and initial use

Installation and initial operation of the machine may only be carried out by

authorised personnel with the relevant skills and training.

The owner is responsible for compliance with the general health & safety and

accident prevention regulations in the vicinity of the machine.

IMPORTANT!

Risk of injury through incorrect installation or assembly!

Incorrect installation or assembly can lead to serious injuries or damage

to property!

IMPORTANT!

Risk of injury through high voltage!

Work on the electric drive or control unit may only be carried out by

qualified electricians.

ATTENTION!

Operate the machine only within the specified temperature range

(0 °C – 60 °C).

5.2. Assembly

The machine is delivered in several packing units.

• Screw the four castors under the enrobing machine and set the machine up-

right.

• Fit the rear panel on the machine and secure in place with the VDE keys pro-

vided.

• Adjust the castors to set the correct working surface height. This should be

approx. 900 mm.

• Use a spirit level to position the machine so that it is level.

• Affix the mesh conveyor with the two knurled screws on the machine.

• Position the curtain box or bridge under the chocolate spout.

• Fit the rear panel on the machine and secure in place with the locking screws

provided.

• Take measures to prevent the machine from rolling away.

5.3. Temperature limits

The safe and reliable operation of the coating machine can only be guaranteed

at an ambient temperature of between 15 °C and 22 °C.

Assembly and initial use

15Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

5.4. Operation

• Connect the machine to the mains supply by plugging the power cable into a

230 V earthed Schuko socket.

All the switches must be set to “0” or “Off”.

• Plug in the heating unit connector at the mesh conveyor discharge.

• Set the main switch to “ON”.

• Press the RESET button (above the EMERGENCY OFF button).

• Check the EMERGENCY OFF button.

The machine can only be switched on when the EMERGENCY OFF button is

unlocked.

The machine is now ready for operation.

Operation

16 Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

6. Operation

6.1. Safety notices for operation

WARNING!

Risk of injury through high voltage!

Never operate the machine with damaged cables or connectors!

WARNING!

Risk of injury when machine is running!

Take the machine out of service immediately in the event of a hazardous

situation or an accident by pressing the EMERGENCY OFF button.

CAUTION!

Risk of burns due to contact with hot surfaces!

Do not touch hot surfaces!

CAUTION!

Risk of entanglement!

Do not reach into the machine between its moving parts while the

machine is running!

ATTENTION!

Risk of damage to the machine!

Always check that the mesh conveyor is running freely before starting

the machine!

Staff are to be selected by the managers and trained in the safe use of the

machine.

Staff training:

• Do not remove guards and covers!

• Do not place foreign objects (knives, scissors) in or on the machine.

• Do not switch on the mesh conveyor and chocolate wheel while the chocolate

in the machine is still solid/hard.

• Do not exceed the prescribed machine parameters.

• Do not wear loose clothing.

Operation

17Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

6.2. Chocolate enrobing machine controls

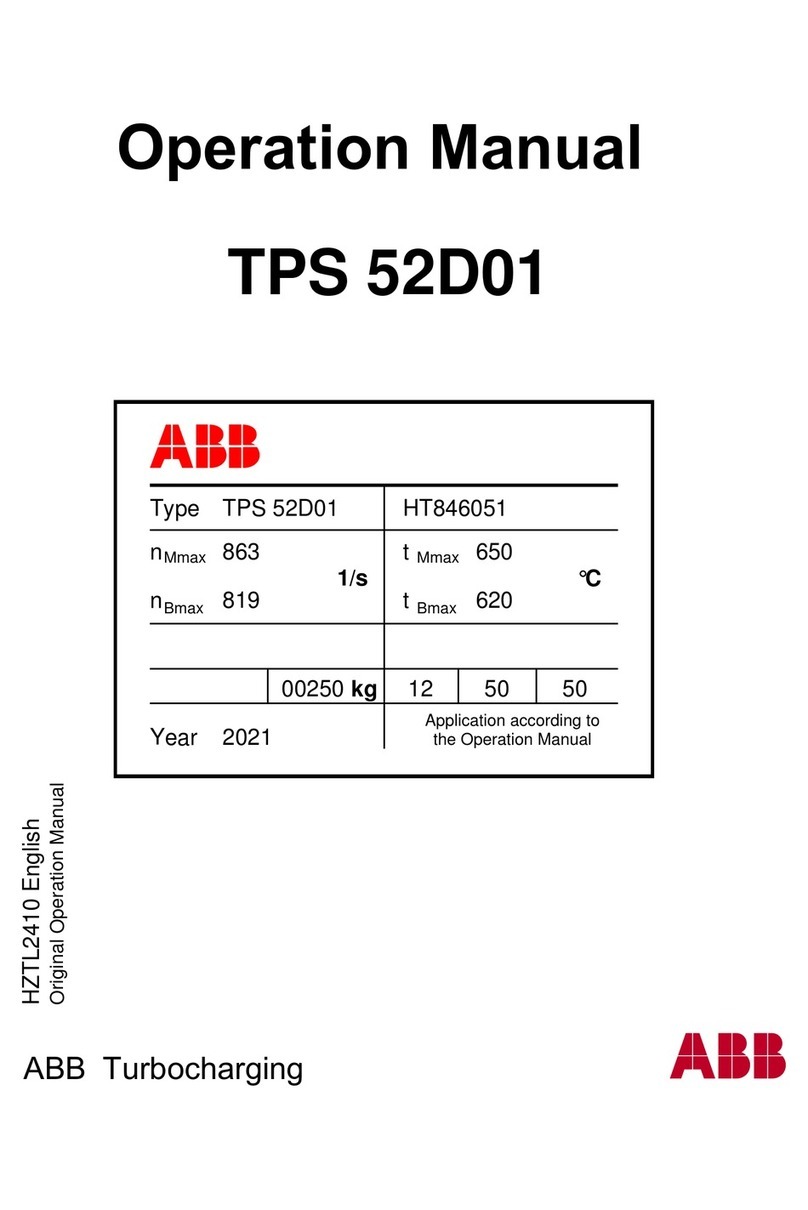

Fig. 7:

12

10

8

6

4

3

11

9

7

5

3

2

1 1

13

14

15

16

Chocolate enrobing machine controls

1 Controller: “Standby temperature / operating temperature”

2 Switch: “Standby - 0 (off) - operation”

3 Controller: “Hood heating unit”

4 Switch: “Chocolate wheel” (off - on)

5 Potentiometer: “Chocolate wheel” (speed)

6 Switch: “Mesh conveyor” (off - on)

7 Potentiometer: “Mesh conveyor” (speed)

8 Switch: “Fan” (off - on)

9 Potentiometer: “Fan” (speed, continuously variable)

10 Switch: “Evener cylinder (E-cylinder)” (left - 0 (off) - right)

11 Potentiometer: “Evener cylinder (E-cylinder)” (speed)

12 Main switch

13 Reset button to acknowledge faults

14 EMERGENCY OFF button

15 Potentiometer: “Chocolate bath heating unit”

16 Connector for heating unit at mesh conveyor discharge

Operation

18 Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

Getting started

• Always check that the mesh conveyor is moving freely before starting up the

enrobing machine!

• Proceed as follows:

Undo the two knurled screws (Fig. 8), pull the mesh conveyor out slightly

(Fig. 9) and check that the mesh conveyor coupling is free.

Insert the VDE key provided (Fig. 10) into the casing and turn it. If the key

can be turned easily, the mesh conveyor is moving freely. Take the key out

again, push the mesh conveyor in and tighten the two knurled screws.

Fig. 8: Undo knurled screws on mesh conveyor

Fig. 9: Pull out mesh conveyor and check coupling

Fig. 10: Insert special key and check mesh conveyor is moving freely

• Connect the machine to the 230 V mains supply.

• Set the main switch to “ON” (Fig. 7; No. 12).

• Press the RESET button (13) until the red lamp goes out.

Operation

19Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

Working with solid chocolate

• Undo the two knurled screws (Fig. 8) and remove the heating unit connector

(Fig. 7; No. 16).

• Remove the rubber belt from the evener cylinder (Fig. 6; No. 12).

• Take out the mesh conveyor.

• Fill the machine with pieces of chocolate.

Make sure that the drain valve is closed (Fig. 20).

• Fit the mesh conveyor, fix it in place with the knurled screws and connect the

heating unit connector.

• Close the hood.

• Heat up the machine by setting the “Standby / Operation” switch

(Fig. 7; No. 2) to “Standby” and set the left-hand control (standby) (1) to

a temperature setting of approx. 45 °C. The heating and fan will now operate

until the temperature setting is reached.

• Preheat the chocolate baths in the base cabinet (where applicable) by press-

ing the button (Fig. 11; No. 1) and set the control (3) to the required tem-

perature (e.g. 45 °C).

The heating cycle in the base heating cabinet is regulated by the control. This

is to protect the chocolate and allow it to melt slowly. The setting also pre-

vents significant increases in temperature. If the control (3) is set to 0, the

heating will not be activated. The normal setting is approx. 1.5.

Fig. 11:

2

13

Heating up the chocolate baths

Operation

20 Operating Instructions - Dedy Chocolate Enrobing Machine 220 mm and 320 mm

Working with warm chocolate which has already melted

• Preheat the machine to approx. 45 °C (see above).

• Undo the two knurled screws (Fig. 8) and remove the heating unit connector

(Fig. 7; No. 16).

• Remove the rubber belt from the evener cylinder (Fig. 6; No. 12).

• Take out the mesh conveyor.

• Fill the machine with warm chocolate (45 – 50 °C).

Make sure that the drain valve is closed during this process (Fig. 20).

• Fit the mesh conveyor, fix it in place with the knurled screws and connect the

heating unit connector.

• Temper the chocolate (see separate instructions).

• Close the hood (Fig. 12).

Fig. 12:

1

1

Chocolate enrobing machine with open and closed hood

This manual suits for next models

1

Table of contents

Popular Industrial Equipment manuals by other brands

Shop fox

Shop fox W1767 owner's manual

Magnum Industrial

Magnum Industrial MI-93850 manual

Zimmer

Zimmer GEP2000 Series Installation and operating instructions

Excelitas Technologies

Excelitas Technologies OmniCure AC7 Series user guide

Drester

Drester RDX 9012 manual

Nordson

Nordson Encore HD Powder Spray System with Prodigy... Customer product manual

Kärcher

Kärcher HD 9000 E USA operating instructions

Baileigh Industrial

Baileigh Industrial DEM-1717 operating instructions

Viessmann

Viessmann Sub Mounting Kit installation instructions

rotork

rotork Pakscan IIS Technical manual

AVMATRIX

AVMATRIX TS3019 user manual

Habasit

Habasit Rossi A Series operating instructions