Table of Contents

Table of Contents

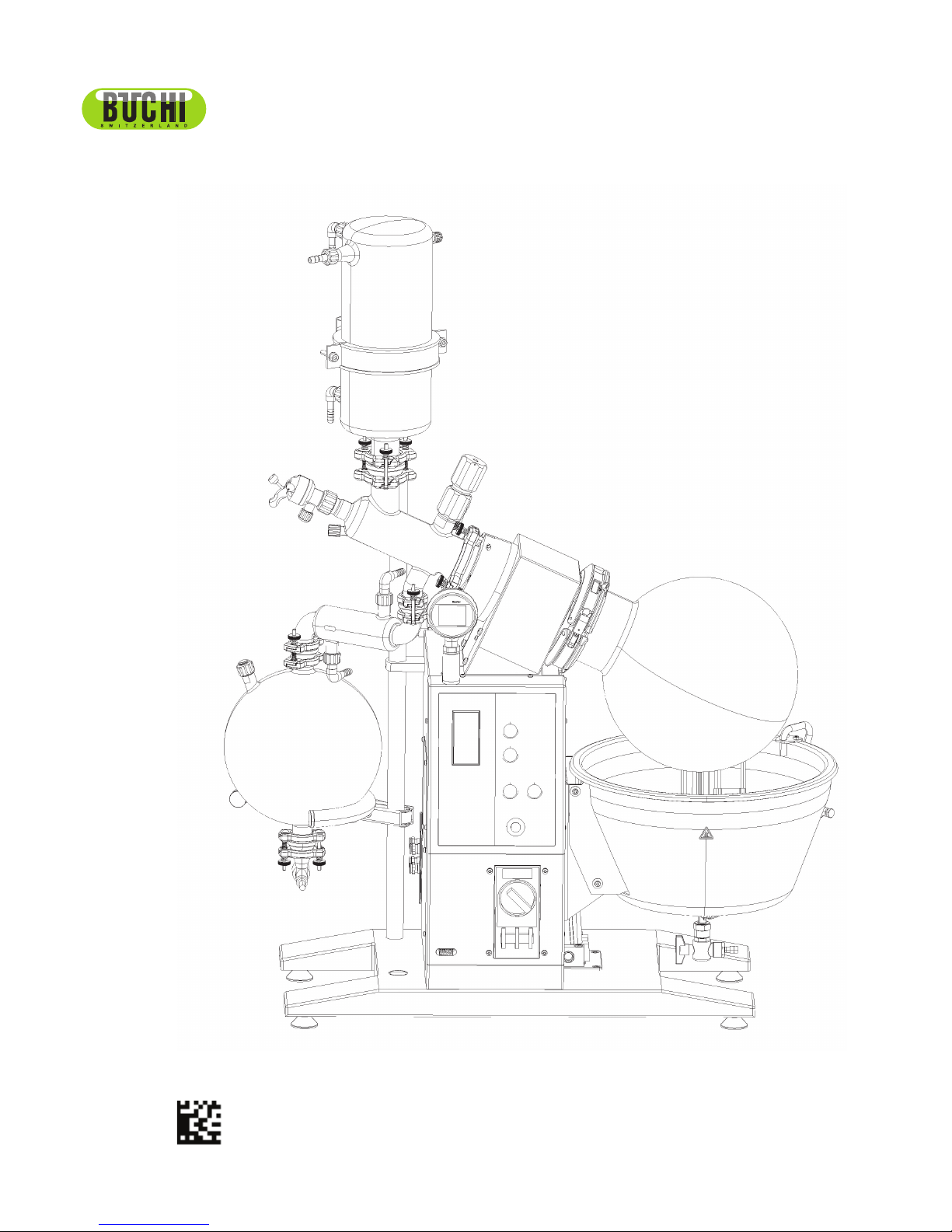

Read this Operating Manual through carefully

before using the Rotavapor R-220 EX.

Always keep these Instructions readily avai-

lable in the immediate vicinity of the unit so

that they make be consulted at any time.

Chapter 2 contains important safety rules

which must be observed to ensure the safe

operation of the rotary evaporator.

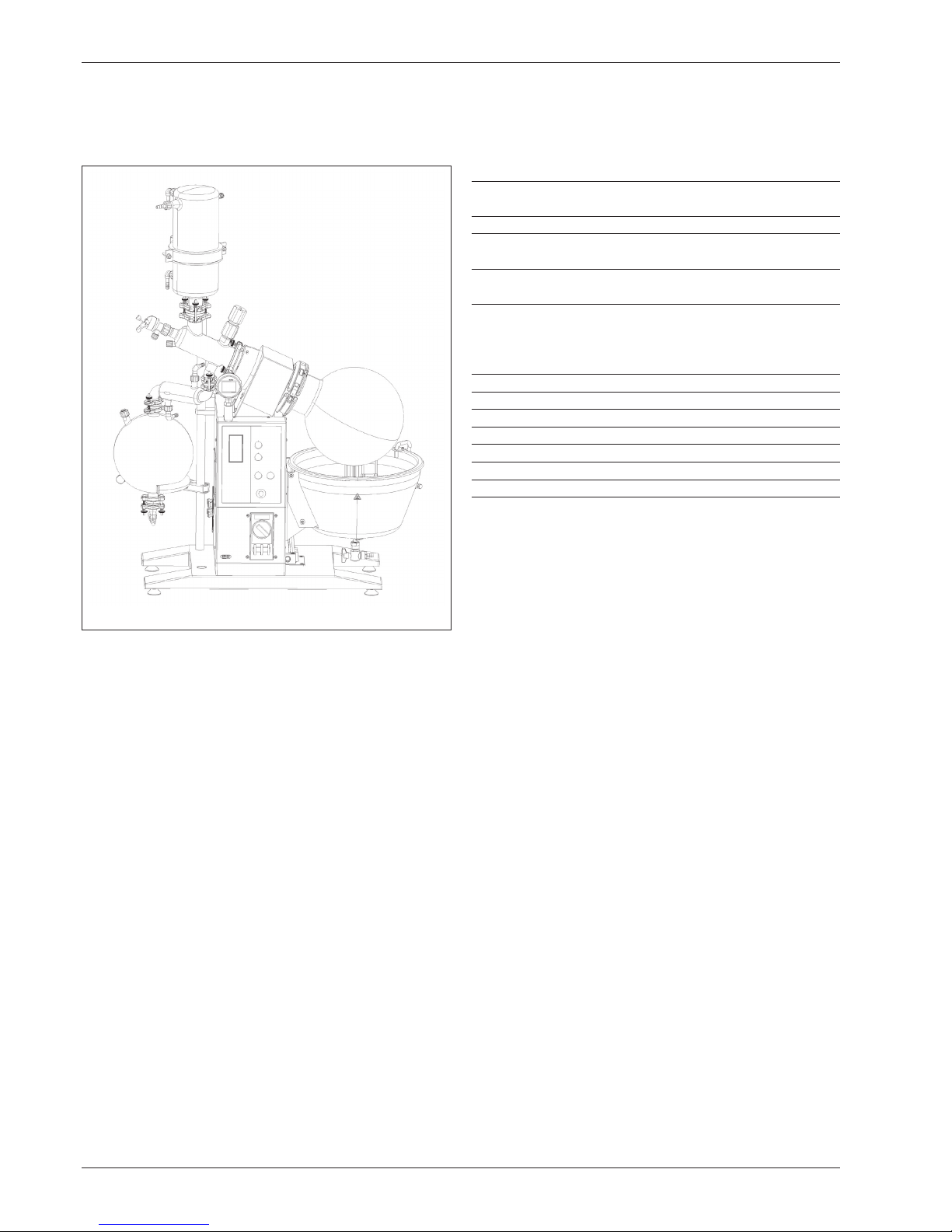

1 Scope of Delivery 4

2 Safety 5

3 Function 10

3.1 Principle of Operation 10

4Putting into Operation 11

4.1 Installation Location 11

4.2 Unpacking 11

4.3 Connecting to the Source of Energy 12

4.4 Setting up the Support Rod 12

4.5 Attachment of the EasyClamp 13

4.6 Removal of the EasyClamp 13

4.7 Installation of the Reflux Glass Assembly 14

4.8 Installation of the Downgrade Glass Assembly 15

4.9 Installation of the Downgrade Glass Assembly

with a 2nd Cooler 16

4.10 Installation of the Receiving Fixtureg 17

4.11 Attaching and Removing Flasks 18

4.12 Hose Couplings 20

4.13 Operating the Shut-off tap 22

4.14 Bath Replenishment (Optional) 22

4.15 Reset of the over-temperature protection 23

4.16 Heating Medium 24

4.17 Compressed Air Connection 24

4.18 Vacuum Controller 24

4.19 Splash Protector 25

4.20 Checking Installation 25

5Operation 26

5.1 Arrangement of the Operator Control and

Display Elements 26

5.2 Setting the Parameters 27

5.3 Vacuum Controller 28

5.4 Splash Protector 32

5.5 Tips and Tricks 33

5.6 Table of Solvents 35

6Maintenance 35

6.1 Troubleshooting 35

6.2 Taking Apart the Snap Flange Coupling 35

6.3 Assembling the Snap Flange Coupling 36

6.4 Removing the Evaporating Flask Seal 36

6.5 Inserting the Evaporating Flask Seal 37

6.6 Replacement of the Seals for the Distribution Head37

6.7 Replacement of the Vacuum Seal 38

6.8 Cleaning 38

6.9 Vacuum Seal 39

6.10 Testing for Leaks 39

6.11 Customer Service 39

7 Taking out of Operation 40

7.1 Storage 40

7.2 Packing/Transport 40

7.3 Waste Disposal 40

8 Spare Parts and Accessories 41

8.1 Glass Assemblies D, D2, DB, DB2 43

8.2 Glass Assemblies R, RB, C 45

8.3 Miscellaneous 46

8.4 Accessories 49

9 Appendix 51

9.1 Technical Data 51

9.2 Materials Used 51

9.3 Error Messages 52

9.4 FCC requirements (for USA and Canada) 52

9.5 Declaration of conformity 53

We reserve the right to make technical changes without prior

notification. No portion of this Operating Manual may be re-

produced, processed using electronic or optical systems,

duplicated, or distributed in any form without the prior written

approval of BÜCHI Labortechnik AG.

All rights reserved. © BÜCHI Labortechnik AG, 2015

en, Ordering No.

R-220 EX Operation Manual 096987