Vitronics Soltec MR620A User manual

Installation Guide myReflow.com

Version 38.1.0.003

VITRONICS SOLTEC BV

Visit adress Innovatiepark 12 - 4906 AA Oosterhout - the Netherlands

Mail adress P.O. Box 143 - 4900 AC Oosterhout - the Netherlands

Telephone +31-162-483000

Fax +31-162-483269

www.vitronics-soltec.com

ii

Rights

COPYRIGHT 2005 VITRONICS SOLTEC BV

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Vitronics Soltec BV.

This publication remains the property of Vitronics Soltec BV and may not be passed, loaned or given to any third party.

Vitronics Soltec BV reserves the right to make changes in design and specifications without notice.

EUROPE

VITRONICS SOLTEC BV VITRONICS SOLTEC GmbH

Innovatiepark 12 An der Köhlerei 7

4906 AA Oosterhout 97828 Marktheidenfeld

the Netherlands Germany

Tel. +31-162-483000 Tel. +49-9391-98820

Fax +31-162-483269 Fax +49-9391-988228

AMERICAS

VITRONICS SOLTEC Inc.

2 Marin Way

Stratham, New Hamphire 03885

USA

Tel. +1-603-772-7778

Fax +1-603-772-7776

ASIA PACIFIC

VITRONICS SOLTEC PTE LTD. VITRONICS SOLTEC SHANGHAI

135 Joo Seng Road Room 902, Ocean Towers,

#02-01 PM Industrial Building No. 550 YanAn Road (E)

Singapore 368363 Shanghai, 200001, China

Tel. +65-484-3010 Tel. +86-21-6360-9936

Fax +65-484-1910 Fax +86-21-6360-9449

VITRONICS SOLTEC KOREA VITRONICS SOLTEC MALAYSIA

A-1001, Poonglim Iwant Bldg., 8-2-5 Sunny Point Complex

255-1 Seohyun Dong, Jalan Sultan Azlan Shah, Batu Uban,

Bundang Gu, Seongnam 463-862, Korea 11700 Penang, Malaysia

Tel. +82-31-783-7020 Tel. +60-4-658-4227

Fax +82-31-783-7021 Fax +60-4-655-4227

VITRONICS SOLTEC (SUZHOU) Co. Ltd

10 Huangpu Street

Lion Mountain Industrial Estate

Suzhou New District, China 215009

Tel. +86-512-6841-3378

Fax +86-512-6841-1711

Installation Guide myReflow.com iii

Preface

During the composition of this manual much attention is given to avoid errors

and mistakes. Also we aimed to give the contents a clear structure.

If during the use of this manual errors or incomplete descriptions are found, or

the reader considers that improvements are necessary to overcome any in-

accuracies, please inform us. We appreciate any comments which will help us to

improve this documentation.

For corrections or clarifications please contact:

1. By mail:

VITRONICS SOLTEC BV

HEAD OFFICE

TECHNICAL PUBLICATIONS

P.O. BOX 143

4900 AC OOSTERHOUT

THE NETHERLANDS

TEL NR. (31) - 162483000

FAX.NR. (31) - 162483285

OR

2. By e-mail:

hoosterhout@nl.vitronics-soltec.com

iv

Installation Guide myReflow.com v

Table of Contents

Preface iii

Table of Contents v

1 Installation 1-1

1.1 General . . . . . . . . . . . . . . . . . . . 1-1

1.2 Transport . . . . . . . . . . . . . . . . . . 1-1

1.2.1 Symbols used . . . . . . . . . . . . . . . 1-1

1.3 Unpacking . . . . . . . . . . . . . . . . . . 1-2

1.3.1 Packet in crate . . . . . . . . . . . . . . . 1-2

1.3.2 Packed on wooden pallet . . . . . . . . . . . 1-2

1.3.3 Lifting with forklift . . . . . . . . . . . . . 1-3

1.4 Connections . . . . . . . . . . . . . . . . . 1-4

1.4.1 General . . . . . . . . . . . . . . . . . 1-4

1.4.2 Electrical connection . . . . . . . . . . . . . 1-4

1.4.3 Nitrogen connection . . . . . . . . . . . . . 1-4

1.4.4 Exhaust system . . . . . . . . . . . . . . 1-4

1.4.5 Personal computer . . . . . . . . . . . . . 1-5

1.5 Opening cover for leveling . . . . . . . . . . . . . 1-6

1.6 Leveling . . . . . . . . . . . . . . . . . . . 1-7

1.7 Installation Sheet . . . . . . . . . . . . . . . . 1-8

1.8 Installation requirements . . . . . . . . . . . . . 1-10

Index vii

vi

ICON DESCRIPTION ICON DESCRIPTION

Only Qualified personnel is allowed to work on the

equipment.

Never eat, drink or smoke while working on the

machine.

Wash thoroughly before eating, drinking or smoking.

High voltages are present on various parts of the sys-

tem.

Before working on the electrical circuit, turn main

power off and block the mainswitch with a padlock.

Always wear heat resistant gloves and protective

clothing when working on the machine.

If possible allow the machine to cool down before

starting working on the machine.

When burned, immerse in cold water immediately.

When the burn is severe, consult a physician as soon

as possible.

Always wear heat resistant gloves and protective

clothing when working on the machine.

If possible allow the machine to cool down before

starting working on the machine

When burned, immerse in cold water immediately.

When the burn is severe, consult a physician as soon

as possible.

No smoking or open fire near the machine.

Be sure a fire-extinguisher is in the surroundings of

the machine.

No smoking or open fire near the machine.

Be sure a fire-extinguisher is in the surroundings of

the machine.

All moving parts of the system, including pulleys,

belts, chains, coolingfans, sprocketwheels, vacuum-

doors and cylinders presents a potential danger.

Be careful with covers and doors. Always pay atten-

tion to opening and closing.

The vapours in the board preparation module are

chemical.

Also the dust on the surface of the solderpot is dan-

gerous when inhaled.

Avoid inhaling this vapours / dust by using mouth

protection.

When working on the machine, always protect your

eyes with safety glasses.

Signal light RED

- E-stop Active Nitrogen

N2

Follow the safety precautions and procedures

described in the Material Safety Data Sheet of

the Nitrogen supplier.

Signal light ORANGE

- Steady = Overload (outfeed full), Machine will

block,

- Flashing slow = Alarm

- Flashing fast = Critical alarm. Machine will block

UPS

Uninterruptible

Power Source

When mainswitch is switched OFF, always switch

the UPS to OFF.

Signal light GREEN

- Steady = Machine Run,

- Flashing slow = Machine not at setpoint, machine

stop

If these rules are not observed it can cause personal injury and/or damage to the machine

SAFETY RULES

GENERAL INFORMATION

.

Technical Reference myReflow.com CHAPTER 1 1

Installation 1

1.1 GENERAL

Installing only by trained Vitronics Soltec / Agent personnel.

At the end of this chapter an installation sheet is located.

1.2 TRANSPORT

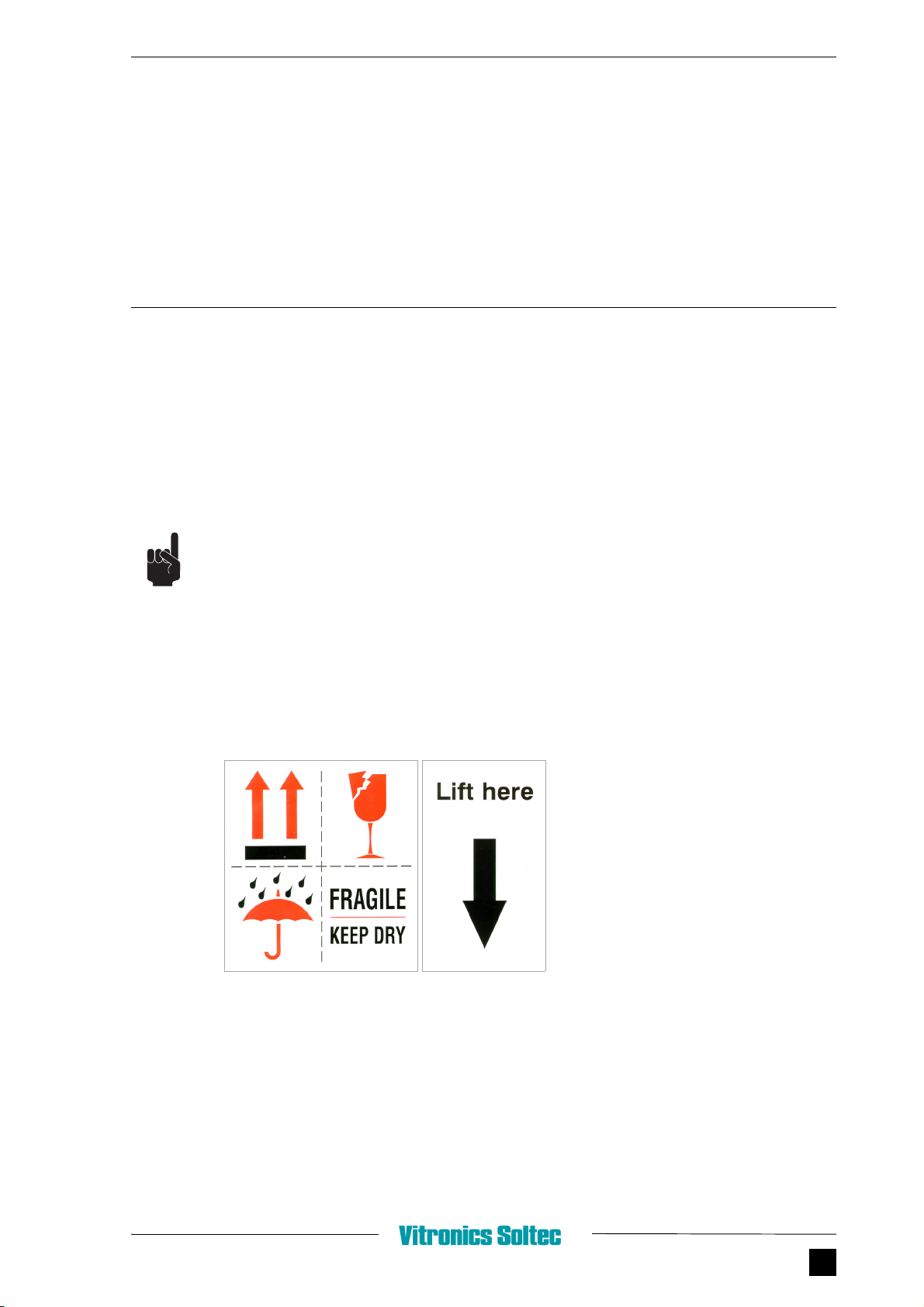

1.2.1 SYMBOLS USED

FIGURE 1.1 SYMBOLS ON PACKAGING

1. Position pallet/box for transport

2. Breakable

3. Keep dry

4. Lift here (labels are placed on

position where forklift should lift)

12 4

3

VERSION 2005 March

INSTALLATION

2CHAPTER 1

1.3 UNPACKING

The Vitronics Soltec myReflow is packed on a wooden pallet. When necessary, the machine is

packed in crates (e.g. when shipped).

If packed in crates the following procedure (paragraph 1.3.1 and 1.3.2) should be followed.

When the machine is packed on a wooden pallet follow instructions in paragraph 1.3.2.

1.3.1 PACKET IN CRATE

FIGURE 1.2 CRATE

Use the above figure order A,B,C to uncrate. Other order can result in damaging the machine or

personal injury.

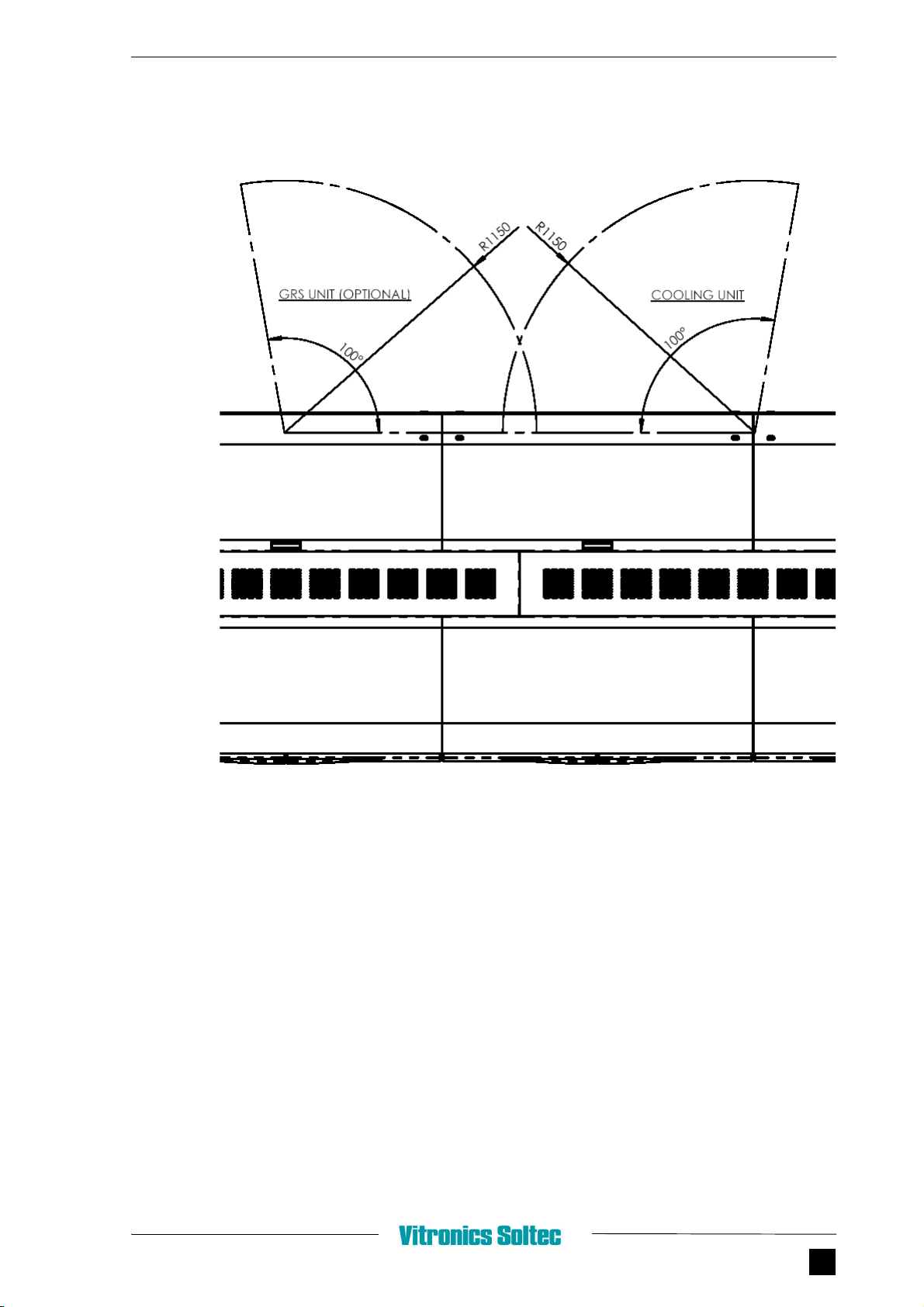

1.3.2 PACKED ON WOODEN PALLET

FIGURE 1.3 PACKING REMOVAL

CB

AUncrating order:

1. Take off top cover A.

2. Remove side panels B.

3. Remove front and backcover C.

1. Remove packing material

1.3 - UNPACKING

Technical Reference myReflow.com CHAPTER 1 3

FIGURE 1.4 STRAPS REMOVAL

1.3.3 LIFTING WITH FORKLIFT

When the transporting straps are removed, the myReflow can be placed on the place the cus-

tomer has provided.

FIGURE 1.5 FORKLIFT UNDER MACHINE

To lift and transport the myReflow use the positions as shown in the installation sheet at the end

of this document.

2. Remove the coverdoors at the

strap-positions (total 4).

3. Remove straps

coverdoor

strap

* = DISTANCE BETWEEN FORKS minimum 1200mm

*

INSTALLATION

4CHAPTER 1

1.4 CONNECTIONS

1.4.1 GENERAL

See for connection specifications the “install sheet” at the end of this chapter.

1.4.2 ELECTRICAL CONNECTION

Only qualified electricians should work on the electrical circuits of the machine.

1. Connect the mains leads in accordance with the diagrams.

Check the Current rotation of the phases. The current rotation of the phases L1, L2, L3 must be

clockwise.

2. Block the mainswitch in the “OFF” position with a padlock to prevent dangerous situations.

1.4.3 NITROGEN CONNECTION

1. Connect the supply hose to the hose connector at the infeed side of the machine.

1.4.4 EXHAUST SYSTEM

One exhaust gauge of 165 mm (6.5”) is provided. This should be connected with the customer’s

exhaust system (not supplied by Vitronics Soltec).

• Inflammable and/or explosive gas might develop in the machine because of the evaporation of

the solvent in the flux.

• An exhaust system that functions well, will bring the gases below the explosion concentra-

tions.

• It is therefore necessary to have a sufficient exhaust in the machine.

• The exhaust system also has to be checked continuously on its well functioning.

• The machine is prepared to interfere in the E-stop circuit of the machine with a potential free

contact of the exhaust system. This contact has to be normally open, and therefore closed

when the exhaust functions well (fail safe).

NEVER USE THE MACHINE WITHOUT THE EXHAUST SYSTEM.

1.4 - CONNECTIONS

Technical Reference myReflow.com CHAPTER 1 5

1.4.5 PERSONAL COMPUTER

The complete Personal Computer is packed in boxes for transporting.

FIGURE 1.6 INSTALLING PC

1. Unpack all boxes.

2. Unpack PC arm.

3. Slide signal column in position.

4. Install keyboard holder.

5. Install keyboard and mouse.

6. Install the monitor on PC arm.

7. Connect all cables to the PC.

❷

❸❹

❺

❼

❻

INSTALLATION

6CHAPTER 1

1.5 OPENING COVER FOR LEVELING

Before the machine can be leveled the power on the machine must be on.

Switching on is only allowed by qualified personnel.

1. Switch on the mainpower and PC.

2. Select the myReflow icon on your desktop to start the PC program.

3. Select from the Status Menu Reset.

4. Enter your username and password.

5. Select the E-stop reset.

FIGURE 1.7 OPEN COVER AND SET CONVEYOR AND WIDE POSITION

6. Open with key switch the cover.

7. Set conveyor at widest position.

❻❼

1.6 - LEVELING

Technical Reference myReflow.com CHAPTER 1 7

1.6 LEVELING

After the machine is placed on its location and the cover is opened, the next steps should be fol-

lowed.

FIGURE 1.8 ADJUSTING LEVEL

FIGURE 1.9 LEVELING

1. Adjust the threaded feet of the machine until it stands perfectly in both X and Y direction.

A spirit level should be placed on the frame for checking the X direction. For the Y-

direction the spirit level should be placed on both conveyorbars.

2. When machine is leveled, tighten the nuts (A). See Figure 1.8)

After this procedure the machine is mechanically correct installed.

36 mm open

17 mm open

A

B

ended spanner

ended spanner

57-139mm

X- level

TOPVIEW

SIDEVIEW

Y- l e v e l spirit-level

INSTALLATION

8CHAPTER 1

1.7 INSTALLATION SHEET

SideView

SideView

FrontView

TopView

DISTANCE BETWEEN FORKS minimum 1200mm

centre of lifting point

Forks complete under myReflow

ABD

ABD

ABD

A

C

D

BC

365.8

1700

Exhaust ø 165

Main

Electrical

Supply

120

188

164

1660

2154

1296

1380

150

Nitrogen 98

109

SideView

1352

1551

520

*

* = PCB width

50-508

57- 139

775

Conveyortofloor

832-914

All dimensions in mm

POS

ABCD

10

12

14

16

574

929

1284

2840

2840

2840

2840

-

-

-

2840

3988

4698

6118

5408

10951639

MR620A, MR620N, MR710A,

A = Air

N = Nitrogen

MR710N, MR730A & MR820A

MR730N, MR820N, MR840A &

MR840N, MR930N, MR1040A &

MR1130A

MR1040N & MR1130N

10

12

14

16

MR930A

1.7 - INSTALLATION SHEET

Technical Reference myReflow.com CHAPTER 1 9

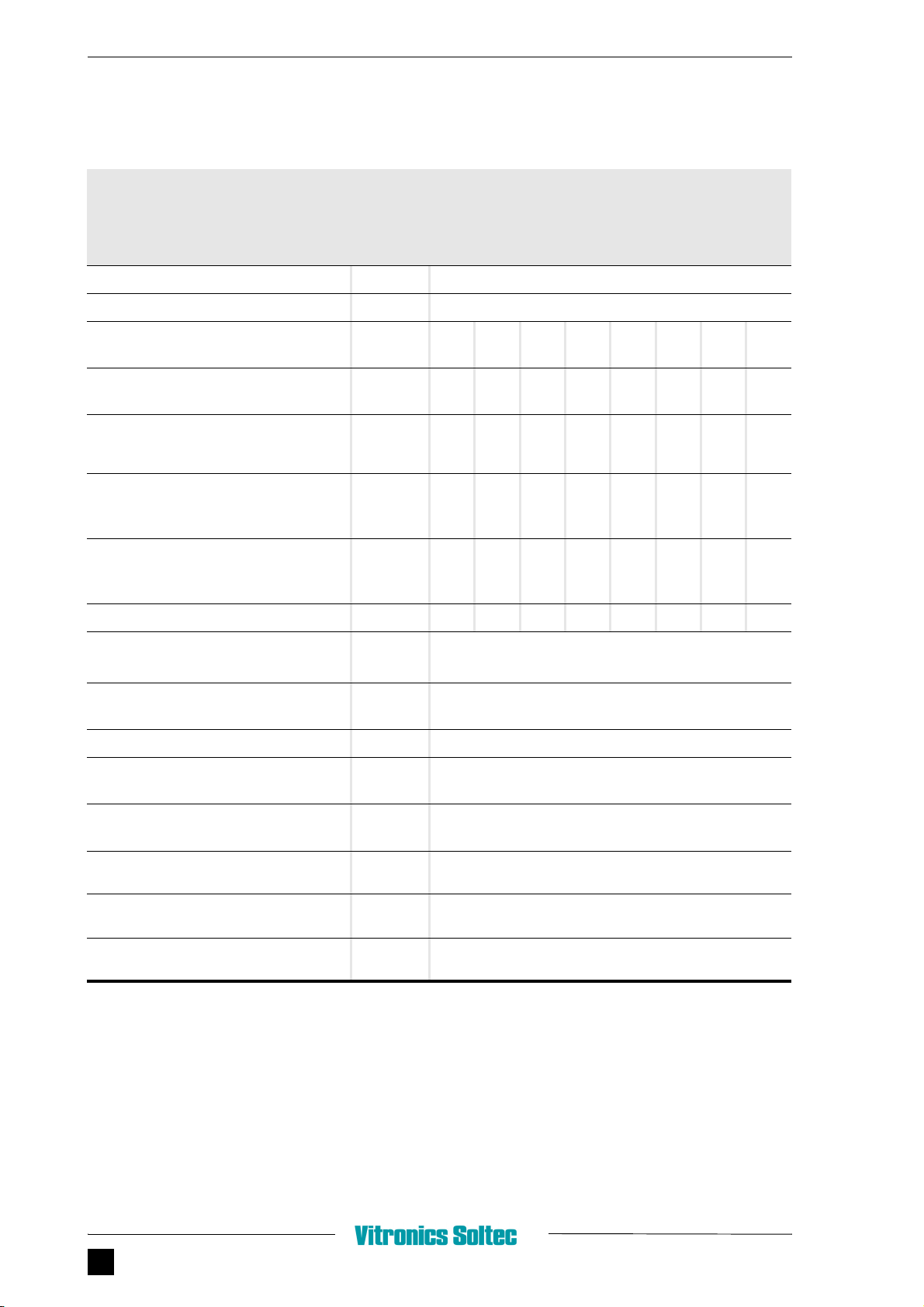

FIGURE 1.10 SLIDING OUT DIMENSIONS GRS AND COOLING UNIT

FRONTSIDE

INSTALLATION

10 CHAPTER 1

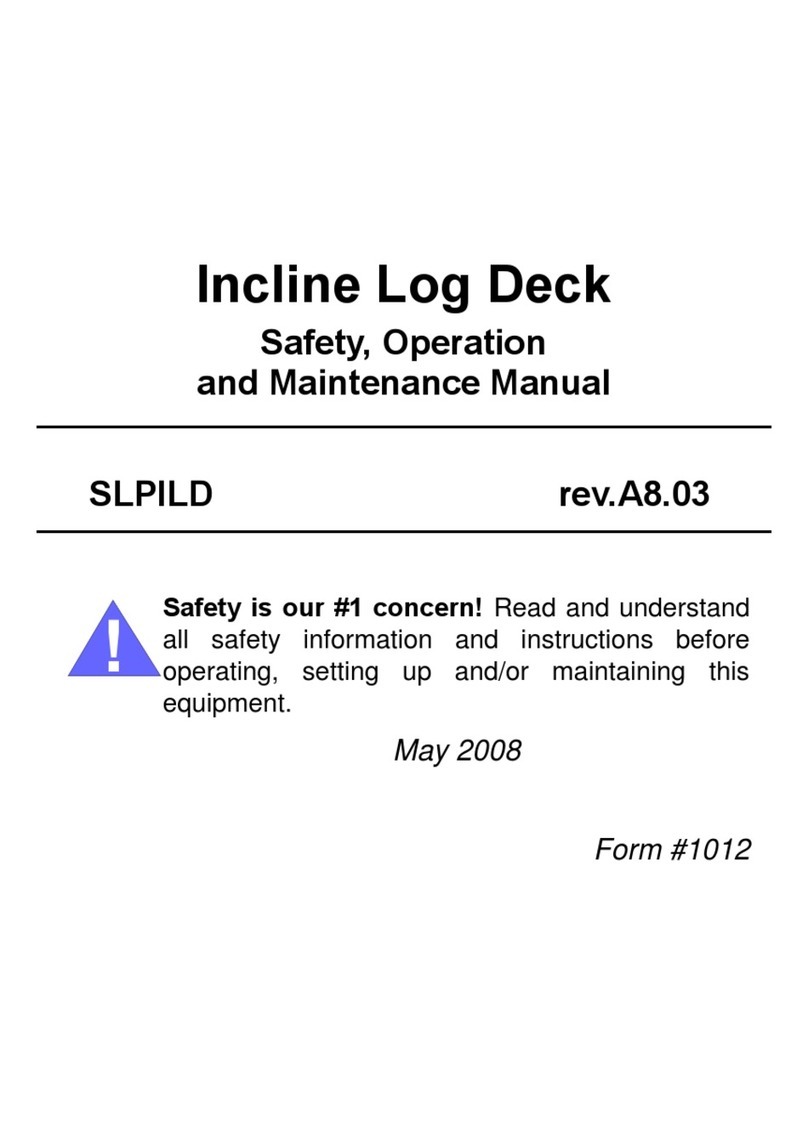

1.8 INSTALLATION REQUIREMENTS

DESCRIPTION UNITS

MR 620

MR 710

MR 730

MR 820

MR 840

MR 930

MR 1040

MR1130

Input Voltage V3 x 400 (Supply tolerance +10%, -10%)

Frequency Hz 50/60

Start-Up power kVA

52

52

54

54

55

56

56

Slow Start-Up power kVA

44

44

44

44

44

44

44

Power required at setpoint

(depending on configuration, load and

setpoints)

kVA

8

8

9

9

10

11

11

Weight machine Air (maximum) kg/lb

2300 /

5071

2300 /

5071

2300 /

5071

2300 /

5071

2500 /

5522

2500 /

5522

2700 /

5952

2700 /

5952

Weight machine Nitrogen (maximum) kg/lb

2300 /

5071

2300 /

5071

2500 /

5522

2500 /

5522

2700 /

5952

2700 /

5952

2900 /

6393

2900 /

6393

Carrying capacity per leveling feet kg/lb

Nitrogen requirements minimum

(only for nitrogen machine)

bar/PSI 4.8 / 70

Nitrogen supply, maximum rate m3/hr /

cfm

50 / 29.43

Nitrogen connection type ½” female NPT

Exhaust volume at single connection

Air Mode - No GRS

m3/hr /

cfm

450 / 265 at 300 Pa

Exhaust volume at single connection

Air Mode - GRS - Nitrogen

m3/hr /

cfm

200 / 118 at 100 Pa

Exhaust connection mm /

inch

165 / 6.50

Clearance for operate & maintenance

front,-, infeed,- and outfeedside

mm /

inch

120 /47.25

Clearance for operate & maintenance

backside

mm /

inch

150 / 59.05

This manual suits for next models

15

Table of contents

Other Vitronics Soltec Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Ebmpapst

Ebmpapst D4E133-DL01-H9 operating instructions

woodmizer

woodmizer Incline Log Deck Safety, operation and maintenance manual

Con-form

Con-form Walkway Assembly & instruction manual

preVent

preVent BR12b instruction manual

StoneAge

StoneAge BJV-M Operation and maintenance manual

Delta

Delta ASRTU-EC16AP1TA Operation manual

System air

System air SAVE-P VTR 250/B installation instructions

Spraying Systems

Spraying Systems AutoJet VC10 owner's manual

woodmizer

woodmizer SlabMizer MB200 quick start guide

LaserMech

LaserMech FiberMINI 2.0 Operation manual

MYPV

MYPV ESW AC-THOR 9s Assembly instructions

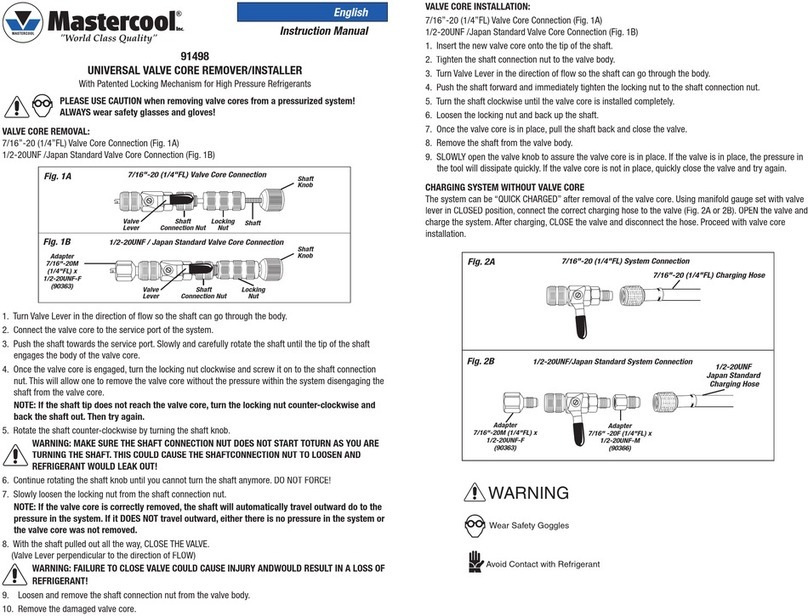

Master cool

Master cool 91498 instruction manual