DEEP SEA ELECTRONICS DSE7400 Mounting instructions

7400 Configuration Suite Software Manual Issue 2

DEEP SEA ELECTRONICS PLC

DSE7400 Configuration Suite Software

Manual

Document Number 057-160

Author: Allan Jones

http://bestgenerator.spb.ru/?page_id=6765

7400 Configuration Suite Software Manual

2

DEEP SEA ELECTRONICS PLC

Highfield House

Hunmanby

North Yorkshire

YO14 0PH

ENGLAND

Sales Tel: +44 (0) 1723 890099

Sales Fax: +44 (0) 1723 893303

E-mail : sales@Deepseaplc.com

Website : www.deepseaplc.com

DSE7400 Series configuration suite

© Deep Sea Electronics Plc

All rights reserved. No part of this publication may be reproduced in any material form (including photocopying

or storing in any medium by electronic means or other) without the written permission of the copyright holder

except in accordance with the provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be

addressed to Deep Sea Electronics Plc at the address above.

The DSE logo is a UK registered trademarks of Deep Sea Electronics PLC.

Any reference to trademarked product names used within this publication is owned by their respective

companies.

Deep Sea Electronics Plc reserves the right to change the contents of this document without prior notice.

Amendments List

Issue Comments Minimum

Module

version

required

Minimum

Configuration Suite

Version required

1 Initial release V1.0.0 2011.10v1.07

2 Added CT Location feature and corresponding Mains Current Options V1.3 205.16v1.242.6

Typeface: The typeface used in this document is Arial. Care should be taken not to mistake the upper case letter I with the numeral 1. The

numeral 1 has a top serif to avoid this confusion.

http://bestgenerator.spb.ru/?page_id=6765

7400 Configuration Suite Software Manual

3

TABLE OF CONTENTS

1 BIBLIOGRAPHY ..............................................................................................6

2 DESCRIPTION.................................................................................................6

3 INSTALLATION AND USING THE DSE CONFIGURATION SUITE...............6

4 EDIT CONFIG...................................................................................................7

4.1 SCREEN LAYOUT.......................................................................................................................7

4.2 MODULE .....................................................................................................................................8

4.2.1 MODULE OPTIONS ...............................................................................................................................................9

4.2.2 CONFIGURABLE STATUS SCREENS ..............................................................................................................11

4.2.3 EVENT LOG .........................................................................................................................................................12

4.2.3.1 DISPLAY OPTIONS..........................................................................................................................................................12

4.2.3.2 LOGGING OPTIONS ........................................................................................................................................................12

4.2.3.3 SMS MESSAGING............................................................................................................................................................12

4.2.4 DATA LOGGING..................................................................................................................................................13

4.2.4.1 CONFIGURATION............................................................................................................................................................13

4.2.4.2 OPTIONS ..........................................................................................................................................................................13

4.3 APPLICATION...........................................................................................................................14

4.3.1 APPLICATION......................................................................................................................................................14

4.3.2 ECU (ECM) OPTIONS..........................................................................................................................................15

4.3.3 DISABLE PROTECTIONS...................................................................................................................................16

4.3.4 AUTO VOLTAGE SENSING................................................................................................................................16

4.4 INPUTS......................................................................................................................................17

4.4.1 OIL PRESSURE ...................................................................................................................................................17

4.4.2 COOLANT TEMPERATURE ...............................................................................................................................18

4.4.2.1 COOLANT TEMPERATURE ALARMS.............................................................................................................................18

4.4.2.2 COOLANT TEMPERATURE CONTROL..........................................................................................................................19

4.4.3 FUEL LEVEL ........................................................................................................................................................20

4.4.4 FLEXIBLE SENSOR ............................................................................................................................................21

4.4.5 EDITING THE SENSOR CURVES ......................................................................................................................22

4.4.6 DIGITAL INPUTS .................................................................................................................................................23

4.4.7 DIGITAL INPUT FUNCTIONS .............................................................................................................................24

4.5 OUTPUTS..................................................................................................................................30

4.5.1 DIGITAL OUTPUTS .............................................................................................................................................30

4.5.2 VIRTUAL LEDS....................................................................................................................................................31

4.5.3 OUTPUT SOURCES ............................................................................................................................................32

4.6 TIMERS.....................................................................................................................................41

4.6.1 START TIMERS....................................................................................................................................................41

4.6.2 LOAD / STOPPING TIMERS...............................................................................................................................43

4.6.3 MODULE TIMERS................................................................................................................................................43

4.7 GENERATOR ............................................................................................................................44

4.7.1 GENERATOR OPTIONS......................................................................................................................................44

4.7.1.1 GENERATOR BREAKER CONTROL ..............................................................................................................................45

4.7.1.2 GENERATOR PHASE ROTATION...................................................................................................................................45

4.7.1.3 GENERATOR RATING.....................................................................................................................................................45

4.7.2 GENERATOR VOLTAGE ALARMS ...................................................................................................................46

4.7.3 GENERATOR FREQUENCY ALARMS..............................................................................................................47

4.7.4 GENERATOR CURRENT....................................................................................................................................48

4.7.4.1 GENERATOR CURRENT OPTIONS ...............................................................................................................................48

4.7.4.2 GENERATOR CURRENT ALARMS.................................................................................................................................49

4.7.4.3 SHORT CIRCUIT ..............................................................................................................................................................53

4.7.4.4 NEGATIVE PHASE SEQUENCE......................................................................................................................................54

4.7.4.5 EARTH FAULT..................................................................................................................................................................55

4.7.5 GENERATOR POWER ........................................................................................................................................56

4.7.5.1 OVERLOAD PROTECTION..............................................................................................................................................56

4.7.5.2 LOAD CONTROL..............................................................................................................................................................57

4.7.5.3 REVERSE POWER...........................................................................................................................................................58

4.8 MAINS.......................................................................................................................................59

4.8.1 MAINS OPTIONS .................................................................................................................................................59

4.8.2 MAINS VOLTAGE ALARMS...............................................................................................................................61

4.8.3 MAINS FREQUENCY ALARMS..........................................................................................................................62

4.8.4 MAINS CURRENT................................................................................................................................................63

4.8.4.1 OVERCURRENT ALARM.................................................................................................................................................64

4.8.4.2 SHORT CIRCUIT ..............................................................................................................................................................67

4.8.4.3 EARTH FAULT..................................................................................................................................................................68

4.9 ENGINE.....................................................................................................................................69

4.9.1 ENGINE OPTIONS...............................................................................................................................................69

4.9.1.1 SENSING OPTIONS.........................................................................................................................................................70

4.9.1.2 STARTUP OPTIONS ........................................................................................................................................................70

4.9.1.3 OVERSPEED OPTIONS...................................................................................................................................................70

4.9.1.4 DROOP .............................................................................................................................................................................70

4.9.2 CAN OPTIONS .....................................................................................................................................................71

4.9.3 CAN ALARMS......................................................................................................................................................71

4.9.3.1 CAN DATA FAIL................................................................................................................................................................71

4.9.3.2 DM1 SIGNALS ..................................................................................................................................................................72

4.9.3.3 ADVANCED.......................................................................................................................................................................72

http://bestgenerator.spb.ru/?page_id=6765

7400 Configuration Suite Software Manual

4

4.9.5 GAS ENGINE OPTIONS ......................................................................................................................................73

4.9.6 CRANKING ...........................................................................................................................................................74

4.9.7 SPEED SETTINGS...............................................................................................................................................75

4.9.8 PLANT BATTERY ................................................................................................................................................76

4.9.9 INLET TEMPERATURE .......................................................................................................................................77

4.10 COMMUNICATIONS...................................................................................................................78

4.10.1 COMMUNICATION OPTIONS.........................................................................................................................78

4.10.2 RS232 PORT....................................................................................................................................................79

4.10.2.1 BASIC................................................................................................................................................................................79

4.10.2.2 ADVANCED.......................................................................................................................................................................81

4.10.3 TROUBLESHOOTING MODEM COMMUNICATIONS..................................................................................83

4.10.3.1 MODEM COMMUNICATION SPEED SETTING ..............................................................................................................83

4.10.3.2 GSM MODEM CONNECTION ..........................................................................................................................................83

4.10.4 RS485 PORT....................................................................................................................................................84

4.10.5 ETHERNET PORT ...........................................................................................................................................85

4.11 SCHEDULER .............................................................................................................................86

4.12 MAINTENANCE ALARM............................................................................................................87

4.13 ALTERNATIVE CONFIGURATIONS...........................................................................................88

4.13.1 ALTERNATIVE CONFIGURATION OPTIONS...............................................................................................88

4.13.2 ALTERNATIVE CONFIGURATIONS EDITOR...............................................................................................88

4.13.3 EXAMPLE OF USAGE ....................................................................................................................................89

4.13.3.1 ENABLING THE DEFAULT CONFIGURATION...............................................................................................................89

4.13.3.2 USING THE ALTERNATIVE CONFIGURATION TO HANDLE SPEED CHANGE..........................................................90

4.14 EXPANSION...............................................................................................................................91

4.14.1 DSE2130 INPUT MODULES...........................................................................................................................92

4.14.1.1 DIGITAL INPUTS (A-D).....................................................................................................................................................92

4.14.1.2 ANALOGUE INPUTS (E-H)...............................................................................................................................................93

4.14.2 DSE2131 RATIOMETRIC EXPANSION INPUT MODULE............................................................................94

4.14.2.1 EDITING THE SENSOR CURVES ...................................................................................................................................97

4.14.3 DSE2133 RTD / THERMOCOUPLE INPUT MODULE ..................................................................................98

4.14.4 DSE2152 ANALOGUE OUTPUT MODULE.................................................................................................100

4.14.4.1 EDITING THE OUTPUT CURVE....................................................................................................................................101

4.14.5 DSE2157 RELAY MODULES........................................................................................................................102

4.14.7 DSE2548 LED EXPANSION .........................................................................................................................103

4.15 ADVANCED .............................................................................................................................104

4.15.1 ADVANCED OPTIONS..................................................................................................................................105

4.15.1.1 PROTECTIONS...............................................................................................................................................................105

4.15.1.2 OTHER TIMERS..............................................................................................................................................................105

4.15.2 PLC LOGIC ....................................................................................................................................................106

4.15.2.1 MENU ..............................................................................................................................................................................106

4.15.2.2 FLAGS.............................................................................................................................................................................107

4.15.2.3 TIMERS ...........................................................................................................................................................................107

4.15.2.4 COUNTERS.....................................................................................................................................................................108

4.15.2.5 PLC FUNCTIONS............................................................................................................................................................109

4.15.2.6 CREATING AND EDITING RUNGS................................................................................................................................111

4.15.2.7 CONDITIONS ..................................................................................................................................................................112

4.15.2.8 ACTIONS.........................................................................................................................................................................114

4.15.2.9 EXAMPLES .....................................................................................................................................................................116

4.15.3 CONFIGURABLE GENCOMM PAGES........................................................................................................117

5 SCADA .........................................................................................................118

5.1 GENERATOR IDENTITY ..........................................................................................................119

5.2 MIMIC.......................................................................................................................................119

5.3 LANGUAGES...........................................................................................................................120

5.4 DIGITAL INPUTS......................................................................................................................120

5.5 DIGITAL OUTPUTS..................................................................................................................121

5.6 VIRTUAL LEDS........................................................................................................................121

5.7 MAINS......................................................................................................................................122

5.7.1 FREQUENCY AND VOLTAGES........................................................................................................................122

5.7.2 POWER ...............................................................................................................................................................123

5.8 GENERATOR...........................................................................................................................124

5.8.1 FREQUENCY, VOLTAGES AND CURRENT ...................................................................................................124

5.8.2 POWER ...............................................................................................................................................................125

5.9 ENGINE....................................................................................................................................126

5.10 FLEXIBLE SENSOR.................................................................................................................126

5.11 ALARMS..................................................................................................................................127

5.12 STATUS...................................................................................................................................128

5.13 EVENT LOG.............................................................................................................................129

5.14 ENHANCED CANBUS..............................................................................................................130

5.15 REMOTE CONTROL................................................................................................................131

5.16 MAINTENANCE .......................................................................................................................132

5.16.1 RECALIBRATE TRANSDUCERS.................................................................................................................132

5.16.3 EXPANSION CALIBRATION ........................................................................................................................133

5.16.4 HOURS RUN AND NUMBER OF STARTS..................................................................................................133

5.16.5 TIME................................................................................................................................................................133

5.16.6 ACCUMULATED INSTRUMENTATION.......................................................................................................134

5.16.7 MAINTENANCE ALARM RESET .................................................................................................................135

5.16.8 MODULE PIN .................................................................................................................................................135

http://bestgenerator.spb.ru/?page_id=6765

7400 Configuration Suite Software Manual

5

5.17 DATALOG ............................................................................................................................... 136

5.18 PLC .........................................................................................................................................137

5.19 EXPANSION............................................................................................................................138

6 ALARM TYPES............................................................................................139

http://bestgenerator.spb.ru/?page_id=6765

Bibliography

7400 Configuration Suite Software Manual Issue 2

1 BIBLIOGRAPHY

This document refers to and is referred to by the following DSE publications which can be obtained from the

DSE website www.deepseaplc.com:

DSE PART

DESCRIPTION

057-004 Electronic Engines and DSE wiring

057-161 DSE7400 Operators Manual

057-082 DSE2130 Input Expansion Manual

057-139 DSE2131 Input Expansion Manual

057-140 DSE2133 Input Expansion Manual

057-141 DSE2152 Input Expansion Manual

057-083 DSE2157 Input Expansion Manual

057-084 DSE2548 Input Expansion Manual

The following third party documents are also referred to:

ISBN DESCRIPTION

1-55937-879-4 IEEE Std C37.2-1996 IEEE Standard Electrical Power System Device Function Numbers

and Contact Designations. Published by Institute of Electrical and Electronics Engineers

Inc

2 DESCRIPTION

This manual covers the operation of the DSE Configuration Suite for DSE7400 series modules. Separate

manuals cover the remaining DSE modules supported by the software

The DSE Configuration Suite allows the DSE7400 family of modules to be connected to a PC via USB ‘A –

USB B’ cable. Once connected the various operating parameters within the module can be viewed or edited

as required by the engineer. This software allows easy controlled access to these values and also has

diagnostic monitoring facilities.

The configuration suite should only be used by competent, qualified personnel, as changes to the operation of

the module may have safety implications on the panel / generating set to which it is fitted. Access to critical

operational sequences and settings for use by qualified engineers, may be barred by a security code set by

the generator provider.

The information contained in this manual should be read in conjunction with the information contained in the

appropriate module documentation. This manual only details which settings are available and how they may

be used.

A separate manual deals with the operation of the individual module (See section entitled Bibliography

elsewhere in this document).

3 INSTALLATION AND USING THE DSE CONFIGURATION SUITE

SOFTWARE

For information in regards to instating and using the DSE Configuration Suite Software please refer to DSE

publication: 057-151 DSE Configuration Suite PC Software Installation & Operation Manual which can

be found on our website: www.deepseaplc.com

http://bestgenerator.spb.ru/?page_id=6765

Edit Configuration module

7

4 EDIT CONFIG

This menu allows module configuration, to change the function of Inputs, Outputs and LED’s, system timers

and level settings to suit a particular application.

4.1 SCREEN LAYOUT

The type of

configuration

file being edited

Close this

configuration file

Move to the

Previous or Next

configuration page

The coloured

shading shows

the currently

selected page.

Click + or – to

show or hide

the sub settings

within each

sections.

Click to select

the subsection

to view / edit

Click to return

to this page at

any time

Step forward or

backward through

previously viewed

pages

Edit Configuration - Module

8

4.2 MODULE

The module page is subdivided into smaller sections.

Select the required section with the mouse.

This section allows the user to change the options related to the module itself.

Edit Configuration - Module

9

4.2.1 MODULE OPTIONS

Miscellaneous

Options

Enable fast loading

feature

= Normal Operation, the safety on timer will be observed in full. This feature is useful if the

module is to be used with some small engines where pre-mature termination of the delay

timer can lead to overspeed alarms on start up.

= The module will terminate the safety on timer once all monitored parameters have

reached their normal settings. This feature is useful if the module is to be used as a standby

controller as it allows the generator to start and go on load in the shortest possible time.

NOTE: - Enabling Fast Loading is only recommended where steps have been

taken to ensure rapid start up of the engine is possible. (For example when fitted with

engine heaters, electronic governors etc.)

Audible alarm prior

to starting

= The module will start with no audible indication

= The module will give an audible warning during the pre-heat timer as an indicator that

the set is about to run. This is often a site’s specification requirement of AUTO mode

operation.

Free entry boxes to allow the user to

give the configuration file a

description. Typically this is used to

enter the job number, customer

name, engineers name etc.

Allows the user to

select the function

of the modules

user configurable

LED indicators.

For details of

possible

selections, please

see section

entitled Output

sources

elsewhere in this

document.

Allows the user to

create logo and text

insert cards

Edit Configuration - Module

10

Miscellaneous

Options

All Warnings Are

Latched

= Normal Operation, the warnings and pre-alarms will automatically reset once the

triggering condition has cleared.

= Warnings and pre-alarms latch when triggered. Resetting the alarm is performed by

either an external reset applied to one of the inputs or, the ‘Stop/Reset’ pushbutton must be

operated (once the triggering condition has been cleared).

Enable Alternative

Breaker Button

Control

Not DSE7410

Default breaker button control is transfer to Generator/ Transfer to mains:

Alternative breaker button control is:-

Open Mains breaker / Close mains breaker

Open Generator breaker / Close breaker.

Enable sleep mode

=Normal operation

=The module goes into "sleep mode” if left in manual mode for a prolonged time with no

button presses.

Enable manual fuel

pump control

=Normal operation

=Allows manual fuel pump control when the “fuel level” instrument page is being viewed.

Support right-left

languages in

module strings

Determines the direction of text input where supported (i.e. configurable input text)

=left to right language support

=right to left language support

Edit Configuration - Module

11

4.2.2 CONFIGURABLE STATUS SCREENS

Configurable Status Screens allow the operator to design the status screen to match the requirements of the

end user or application more closely. For instance it is possible to configure the module to show the factory

set ‘summary screen’ and then cycle the display to show instruments specified by the end user. This display

cycling occurs with no user intervention.

This is the page that appears

automatically when the engine is

running (either instrumentation or status)

These instruments are displayed one after the other when

the set runs. If an entry is set to ‘Not Used’, or is not

applicable, the entry is skipped over and not displayed.

Edit Configuration - Module

12

4.2.3 EVENT LOG

4.2.3.1 DISPLAY OPTIONS

The module display option allows the operator to choose between `Date and Time` or `Engine Hours`

displayed on the bottom of the screen.

4.2.3.2 LOGGING OPTIONS

The event log can be configured to allow users to select which events are stored.

4.2.3.3 SMS MESSAGING

When using the controller, logged events will also cause modem ‘dial outs’ and SMS messages to be sent if

the module is configured to do so and connected to a suitable external GSM modem with functioning SIM

card.

Edit Configuration - Module

13

4.2.4 DATA LOGGING

NOTE: - Data logging to internal and external memory is available.

The Data Logging page is subdivided into smaller sections.

Select the required section with the mouse.

4.2.4.1 CONFIGURATION

4.2.4.2 OPTIONS

Setting Description

Only log when engine

is running

= The module will log data regardless of engine running state.

= The module will only log data when the engine is running.

Log to USB drive

= The module will log data to the modules internal memory.

= The module will log data to an external USB device connect to the USB host

socket on the module.

Keep oldest data

= When the logging memory is full, the module will overwrite the oldest data first

with the new data.

= When the logging memory is full, the module will stop recording new data.

Select the instrument / item to

be logged. Twenty (20)

selection points are possible.

Select the logging interval

of the data.

Edit Configuration - Application

14

4.3 APPLICATION

4.3.1 APPLICATION

See overleaf for description of the parameters....

Allows selection of the Engine type

being used (ie Conventional Diesel

Engine, Gas Engine or Electronic

Engine)

Auto Voltage Sensing to

automatically select the

module configuration from

available ‘alternative

configurations’

Edit Configuration - Application

15

4.3.2 ECU (ECM) OPTIONS

Parameter

Description

Engine type Select the engine type appropriate to your system

Conventional Engine: Select this if you have a traditional (non ECU) engine, either Energise

to Run or Energise to Stop.

Conventional Gas Engine: Select this if you have a traditional (non ECU) engine and require

GAS engine functionality. This enables control of configurable outputs for Gas Choke and

Gas Ignition and instructs the module to follow the gas engine timers.

Other Engines: The list of supported CAN (or Modbus) engines is constantly updated, check

the DSE website at www.deepseaplc.com for the latest version of Configuration Suite

software.

Enhanced J1939

= The module will read ‘Basic’ instrumentation from the engine ECU and display (where

supported by the engine) :

•Engine Speed

•Oil Pressure

•Engine Coolant Temperature

•Hours Run

= The module will read and display an ‘Enhanced’ instrumentation list (where supported

by the engine) :

•Engine Speed

•Oil Pressure

•Engine Coolant Temperature

•Hours Run

•Engine Oil Temperature

•Exhaust Temperature

•Fuel Pressure

•Total Fuel used

•Fuel Consumption

•Inlet Manifold Temperature

•Coolant Pressure

•Turbo Pressure

Where an instrument is not supported by the engine ECU, the instrument is not displayed.

DSE Reserve the right to change these lists in keeping with our policy of continual

development.

Alternative

Engine Speed

= The engine is instructed to run at its

Nominal Speed

as configured by the Engine

Manufacturer.

= The engine is instructed to run at its Alternative Speed as configured by the Engine

Manufacturer.

Modbus Engine

Comms Port

RS485

Port

:

The modules RS485 port is used to communicate to the engine (when a

Modbus engine type is selected.

DSENet Port: The modules DSENet port is used to communicate to the engine (when a

Modbus engine type is selected. This ‘frees’ the RS485 port in case connection to BMS or

other RS485 compatible equipment is required.

Edit Configuration - Application

16

4.3.3 DISABLE PROTECTIONS

This feature is provided to assist the system designer in meeting specifications for “Warning only”,

“Protections Disabled”, “Run to Destruction”, “War mode” or other similar wording.

Options

Description

Enable

= The module will operate as normal and provide engine shutdown if required.

= Protections disabled function is activated. Operation depends upon the following

configuration.

NOTE:-Writing a configuration to the controller that has “Protections Disabled”

configured, results in a warning message appearing on the PC screen for the user to

acknowledge before the controller’s configuration is changed. This prevents

inadvertent activation of the feature.

Disable All

Protections

Never

: The protections are not disabled

Always : Protections are always overridden by the DSE controller.

On Input : Protections are disabled whenever a configurable input set to Protections

Disabled is activated

Protections

Disabled Alarm

Action

If

Disable All Protections

is set to

On Input

, this selection allows configuration of an alarm to

highlight that the protections have been disabled on the engine.

Indication : Any output or LCD display indicator configured to Protections Disabled will be

made active, however the internal alarm sound will not operate.

Warning : Any output or LCD display indicator configured to Protections Disabled will be

made active, and the internal alarm sound will operate.

When protections are disabled, Protections Disabled will appear on the module display to

inform the operator of this status.

4.3.4 AUTO VOLTAGE SENSING

Applicable to DSE 7410 only

Auto voltage sensing instructs the controller to monitor the generators output during the safety delay timer.

During this time, the controller identifies the nominal voltage, frequency and topology of the alternator output

and selects the most appropriate ‘alternative configuration’ to use.

This is particularly useful where a generator is switched from 50Hz/60Hz or 120V/240V for example.

NOTE: - During the safety delay timer, the module factory set status page will display the L-N

voltage, based upon the generator being 3 phase, 4 wire. This can lead to incorrect status display

during the safety timer if Auto Voltage Sensing is enabled and the generator is not 3ph 4w. To prevent

this, the status page can be customised to display other parameters if required. At the end of the

safety timer, the correct voltages will be displayed.

Application

Options Description

Enable Auto

Voltage Sensing

= The module will operate as normal.

= Auto voltage sensing is enabled. During the safety delay timer, the module attempts to

measure the system’s nominal voltage and frequency and determine the topology of the

alternator wiring. At the end of the safety timer, the main and alternative configurations are

analysed to see which one is most appropriate to suit the connected system and the module

continues to operate, using the most appropriate configuration to provide protection.

Over Voltage

During Auto

Sensing Trip

During the Auto sensing there is no over voltage trip protection from the main settings until

after the safety on timer has elapsed. Therefore the overvoltage trip value is taken from this

setting.

Edit Configuration - Inputs

17

4.4 INPUTS

The inputs page is subdivided into smaller sections.

Select the required section with the mouse.

4.4.1 OIL PRESSURE

Click to edit the

‘sensor curve’. See

section entitled

Editing the sensor

curve

.

Enable or disable

the alarms. The

relevant values

below will appear

greyed out if the

alarm is disabled.

Select the

sensor type

Click and drag to

change the settings

Type the value or click the up and

down arrows to change the settings

Edit Configuration - Inputs

18

4.4.2 COOLANT TEMPERATURE

4.4.2.1 COOLANT TEMPERATURE ALARMS

Options

Description

Pre alarm

= Pre-alarm is disabled

= If the temperature exceeds the trip setting, an alarm is generated. The temperature

must fall below the return setting to cease the alarm.

Electrical Trip

= Electrical trip is disabled

= If the temperature exceeds the trip setting, an alarm is generated, the load switch is

opened and the module enters the cooling timer after which the set is stopped.

Shutdown If the temperature exceeds the

trip

setting, an alarm is generated, the load switch is opened

and the set is immediately stopped.

Click to edit the

‘sensor curve’. See

section entitled

Editing the sensor

curve

.

Select the

sensor type

Click and drag to

change the settings

Type the value or click the up and

down arrows to change the settings

Enable or disable

the alarms. The

relevant values

below will appear

greyed out if the

alarm is disabled.

Edit Configuration -Inputs

19

4.4.2.2 COOLANT TEMPERATURE CONTROL

The Coolant temperature control settings provide for control of coolant heaters / coolers using the Coolant

Temperature Sensor as the control input.

Outputs should be configured to Coolant Cooler Control and/or Coolant Heater Control to achieve this.

Coolant

temperature control

Coolant heater

control

= Coolant Heater Control function is disabled

= Coolant Heater Control function is enabled. If the engine coolant temperature falls

below the On setting, any output configured to Coolant Heater Control will be energised.

This is designed to control an external engine heater.

If the coolant temperature rises above the Off setting, the output is de-energised.

Coolant Cooler

control

= Coolant Cooler Control function is disabled

= Coolant Cooler Control function is enabled. If the engine coolant temperature rises

above the On setting, any output configured to Coolant Cooler Control will be energised.

This is designed to control an external engine cooling system, for instance an additional

cooling fan.

If the coolant temperature falls below the On setting, the output is de-energised.

Fan Control An output configured to

Fan Control

will energise when the engine becomes available (up to

speed and volts). This output is designed to control an external cooling fan.

When the engine stops, the cooling fan will remain running for the duration of the Fan

Overrun Delay.

Enable or disable

the alarms. The

relevant values

below will appear

greyed out if the

alarm is disabled.

Click and drag to

change the settings

Type the value or click the up and

down arrows to change the settings

Click and drag to

change the settings

Edit Configuration - Inputs

20

4.4.3 FUEL LEVEL

Fuel level options

Fuel Pump Control If enabled, allows the module to control an external fuel pump to transfer fuel from a bulk

tank to the generator set’s day tank.

Fuel Usage Alarm Provides an alarm to monitor the usage of the generator set’s fuel.

There are two settings, one to monitor fuel usage when the set is running and another to

monitor the fuel usage when the set is stopped.

These alarms are provided to check for fuel leakage problems or potential fuel theft.

Click to edit the

‘sensor curve’. See

section entitled

Editing the sensor

curve

.

Select the

sensor type

Click and drag to

change the settings

Type the value or

click the up and

down arrows to

change the settings

Click to enable or

disable the alarms.

The relevant values

below will appear

greyed out if the

alarm is disabled.

Hint : Set an

output to “Fuel

pump control’.

This can be

used to transfer

fuel from a bulk

tank to the day

tank, for

example.

Select the type of

alarm required.

For details of these,

see the section

entitled Alarm

Types elsewhere in

this document.

Click and

drag to alter

the time

delay

SMS logging of

Fuel monitoring

Table of contents

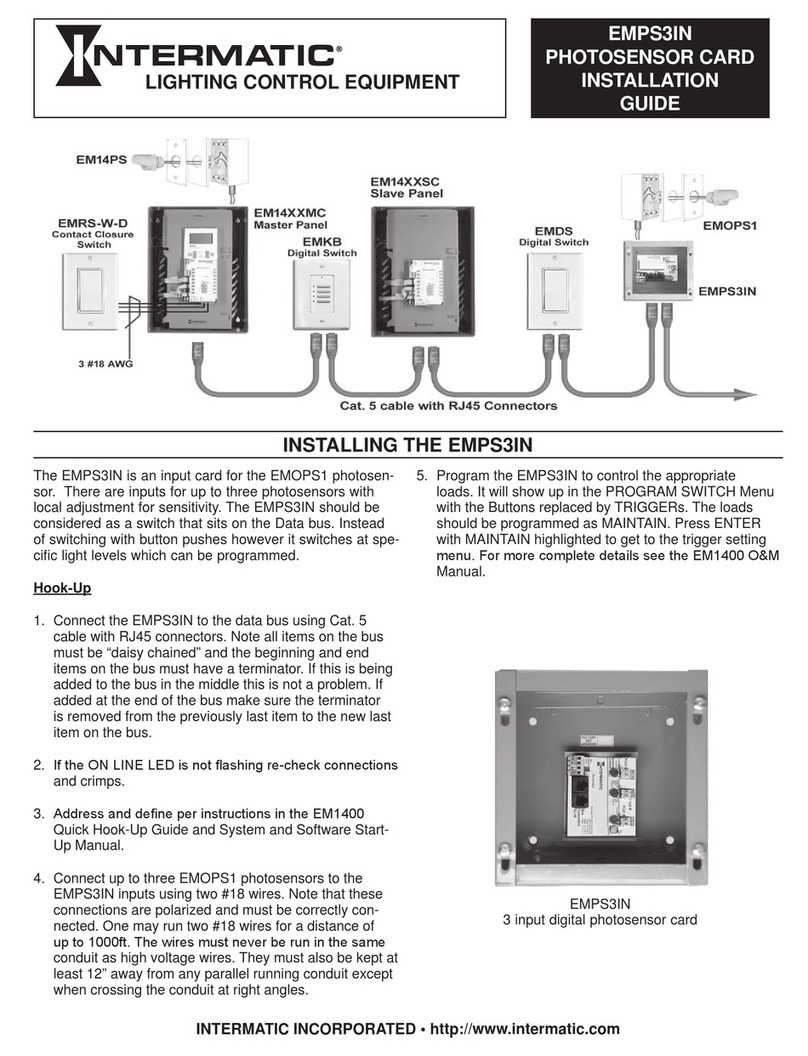

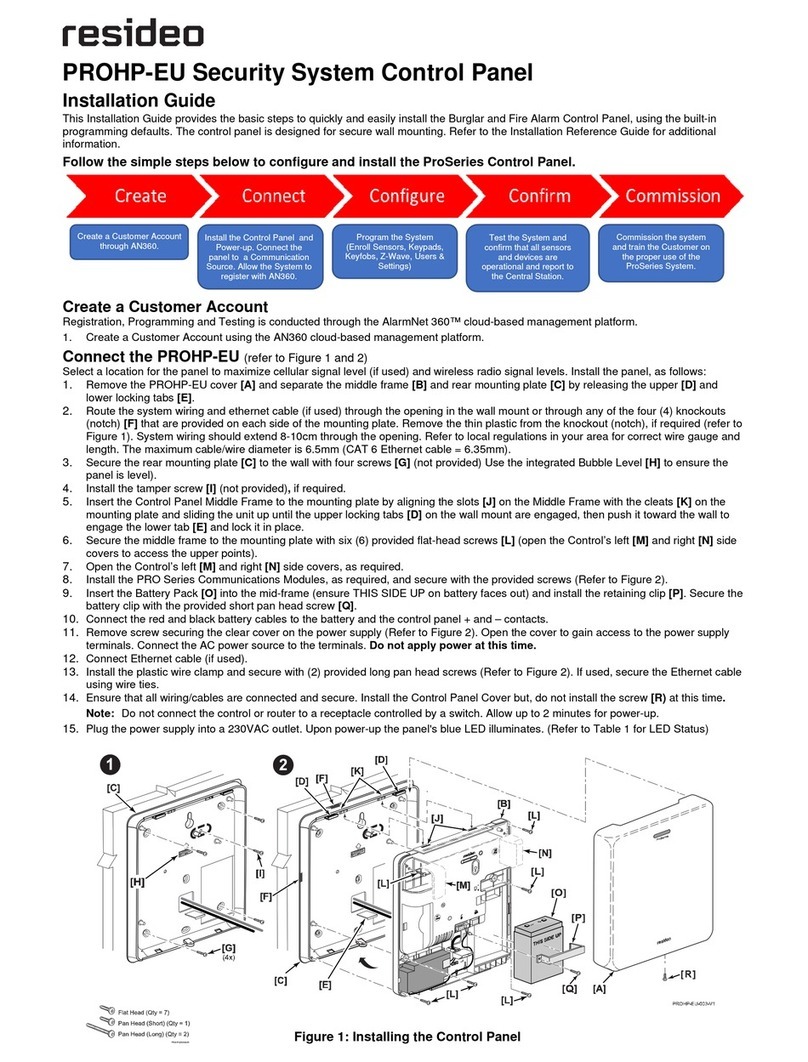

Popular Control Panel manuals by other brands

AUTOTERM

AUTOTERM PU-27 operating manual

MA lighting

MA lighting dot2 XL-F user manual

MOOSE

MOOSE Z1100 Installation, programming & operation guide

Steamist

Steamist TSC-250 Installation and operating instructions

Viessmann

Viessmann Vitocontrol-S, WB2 Installation, Start-Up and Service Instructions

Balboa

Balboa TP200 PANEL user guide