7

Outdoor temperature sensor

Mount outdoor temperature sensor

on the north or northwest outside

wall of the building. If the boiler is

intended to supply heat to the

south side of the building only (split

piping system), mount the sensor

on the south side.

Mount the sensor so that water

cannot infiltrate the sensor

housing.

Install sensor where it will not be

affected by heat sources such as

windows or ventilation openings.

The sensor should be installed far

enough above ground to prevent

accidental damage or tampering.

The outdoor sensor must not be

covered with mortar, stucco, paint

or any form of coating or siding. If

the outside wall is finished after the

sensor is installed, the sensor

should be removed and placed on

the finished wall.

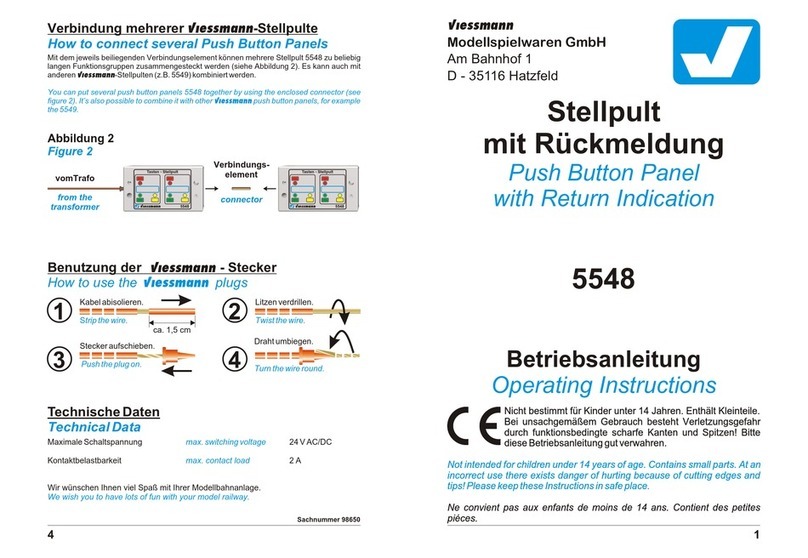

To make the electrical connection,

use a 2-wire cable with a maximum

lengthof115ft./35mandwitha

minimum wire size of AWG 16

copper.

1.Slide protective cover from sen-

sor body.

2.Loosen the two slot-head screws

from main body and remove sen-

sor cover.

3.Fasten sensor body to wall with

single screw through middle of

body.

4.Remove cone-shaped strain relief

from sensor cover.

5.Cut wide end of cone to allow

wire/cable to be inserted into

sensor body. Size cone by

pushing wire/cable into wide end

of cone. Cut cone at the spot

where wire stops.

6.Remove wire/cable from cone

and reinsert into narrow end.

7.Push wire into body of sensor

and connect to screw terminals.

8.Secure wire in place with

supplied strain relief.

Re-attach sensor cover, tighten

screws and slide protective cover

into place.

5285 781 v1.5

When extending wire, there is the

possibility of exposure to

electromagnetic interference.

Avoid running wires beside or near

high voltage 120/240 VAC

conductors. If proximity to high

voltage conductors cannot be

avoided, use stranded, twisted pair

or shield design wire. Ensure that

only one end of the shielding is

grounded.

WARNING