defencell PROFILE 300 Instruction sheet

Installation Guidelines

PROFILE 300

DEFENCELL

Prole 300 1.25m high:

Five layers - Prole 300:11 to 300:07

PAS68 - 7500(N2):64/90:0/0

Prole 300 1.50m high:

Six layers - Prole 300:11 to 300:06

PAS68 - 7500(N3):80/90:2.5/0

PROFILE PANEL SIZES Unit Prole

300:04

Prole

300:05

Prole

300:06

Prole

300:07

Prole

300:08

Prole

300:09

Prole

300:10

Prole

300:11

Panel Length mm 4970

Panel Width mm 1273 1591 1909 2227 2546 2864 3182 3500

DEFENCELL Prole 300

Introduction

The DEFENCELL Prole 300 Protection System is a textile,

cellular, containment system which can be lled with

various materials (sand, gravel, soil and small rocks) to

build a variety of structures for perimeter security and

HVM protection.

Site Preparation

The ground should be level and compact to CBR value

of <5%. Where soft spots occur (CBR value of >5%)

the material will be excavated and replaced with 6F1

material compacted in 150mm layers. If the soft spot

locations are extensive, the material will be tested for

its CBR value. In addition, a trial pit will be excavated

to a depth of 1.5m and the sub-strata re-examined and

tested for its CBR value. Appropriate remediation of the

soft spot will be determined by the engineer.

DEFENCELL is to be lled using suitable granular ll with

a maximum stone size 40mm with no clays.

Landscape and Ecology

The designer should ensure that the berm proles takes

into account the following local material (soil) properties

and environmental conditions:

• Compaction: the consolidation of soil (under its own

weight) overtime.

• Erosion: the carrying away or displacement of solids

through weathering or living organisms.

• Slump: gravity causing material to slide down slope.

• Stability: the consistency of the berm form under

loading and over time.

Construction time

A team of four on an average 8 hour shift, with a 16T

excavator with 1m3ditching bucket plus operator, may

achieve the following:

Using the frame method

(Using two Prole frames)

Can complete 25-35 linear metres per shift.

(Not including landscaping.)

Note: These are a guide to installation of Prole300. The

production rate will increase or decrease depending on

the following:

• Distance excavator has to haul the ll

• Type of excavator used and bucket capacity

• The ow and size of granular ll used

• The experience of the excavator operator

• The climatic conditions

• The number of teams available

• Number of frames or pins available

Using the pin method

(Using enough pins for two panels at once)

Can complete 10-15 linear metres of Prole 300 per shift.

(Not including landscaping)

Installation

Prole 300 should be installed on compacted level

ground as per instruction above with consideration

given to drainage. The installation of Prole 300 can be

achieved in six stages:

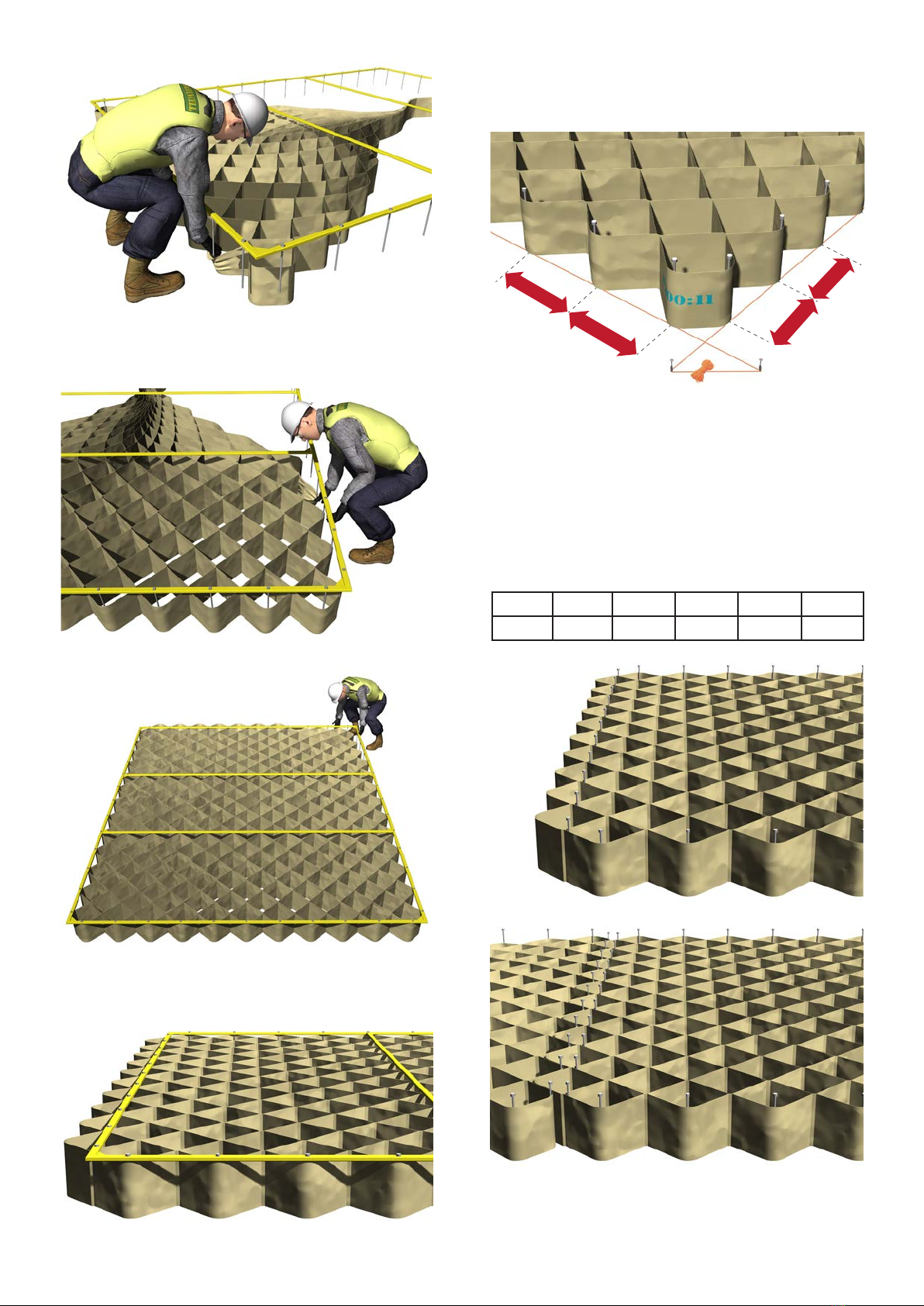

Stage 1 - Panel Placement

The base layer of any Prole 300 PAS 68 design is the

P300:11. Identify the panel by its label which can be

found on either end.

Once the correct Prole 300 is selected, build the

corresponding Prole 300 frame by following the Frame

Installation Guide and position it on your building

site with the long side along the direction of your

construction.

Next identify the female end of the Prole 300. The

female end of a P300:11 has 11 cells while the male end

has only 10 cells.

Start with the labelled corner of the female end, lift the frame

up and place the corner cell onto the two corner pins.

2

368mm

368mm

318mm

318mm

300:06 300:07 300:08 300:09 300:10 300:11

38 40 42 44 46 48

Work your way across, lift the frame slightly and push the

Profile 300 down under the pin and back up so the pin is

located inside the cell. Move along to the next cell and repeat.

Repeat the process along both sides.

Finish at the diagonally opposite corner ensuring that

the male cells at this end protrude halfway past the end

of the frame as shown below.

Using Pins

If the frame is not used the same can be achieved by

using pins.

Using a building line as a guide, pins can be placed into

the ground along the long sides of the construction at

368mm centres and across the ends at 318mm centres.

In the same way as when using a frame, the cells are

placed over the pins until the Prole 300 is tight and

symmetrical. Start with the labelled corner of the female

end then working along both sides and nish with the

male end.

Pin Quantities Required

Note: If you have more than one frame or sets of pins

available, it is recommended you set up more base units.

3

Stage 2 - Subsequent Panels

Ideally, several panels should be pinned out or framed at

anyonetime whichwillallow for thelling machine(front

end loader, excavator, etc.) to continue immediately to

the next panel, therefore keeping momentum of the

installation.

Using frames

Once the rst frame is in position the next frame is tted

with the Prole 300 and positioned in the direction of

construction, so that the male end on the rst frame

interlocks with the female on the second frame. This is

completed by butting the two frames together.

Using Pins

The same can be achieved using pins.

Once the rst Prole 300 is in position, the next Prole

300 is opened out and aligned in the direction of

construction, with the female end of the new Prole

300 interlocked with the male end of the rst. Pin out

the new Prole as previously until the Prole is tight and

symmetrical.

Stage 3 - Filling

Fill should be distributed evenly across the panel width

taking care not to dump ll in one area.

Even distribution of the ll and levelling with the

excavator will aid the compaction process and reduce

manual spreading.

Some manual leveling may be required with some ll

materials.

Once the panel is full and ready for compaction the

frame should be removed by carefully lifting. Use four

people, one on each side of the frame.

If using pins ensure that all are removed before

compaction.

4

D

O

N

O

T

E

N

T

E

R

T

H

I

S

A

R

E

A

Stage 4 - Compaction

Once the cells are lled (or slightly over lled depending

on ll material) the frame is removed and the ll

compacted. A mechanical plate compactor is ideal.

This can be carried out whilst the excavator is lling

the next frame however you must ensure that the

compactor does not enter into the excavator bucket

operating radius at any time.

Compaction of the material is achieved with three passes

of a plate compactor.

Note: Care must be taken not to over compact otherwise

the outer cell walls may be crushed which will aect the

overall cell/berm height.

If the level of ll is too high once compaction is complete

this must be removed before the next layer is laid.

Stage 5 - Subsequent Layers

Once the base level is complete or you have nished a

section (depending on your construction plan) move to

the next layer.

Using frame

First change the frame to the next size down as per the

frame guide. Place on the fabric panel as previously

instructed.

Position the frame on top of the layer below, checking

it is central to the berm. This will give you spacing of

160mm either side of the panel below or roughly half a

cell. Position the end directly in line with the layer below.

Using pins

Pins are placed in the outer cells of the lled layer.

Position them centrally in the cell and step back half

a cell (160mm) from the edge to achieve the desired

angle/prole required for the berm.

Note: It is recommended that sequential panels are laid

to maintain momentum of the lling process.

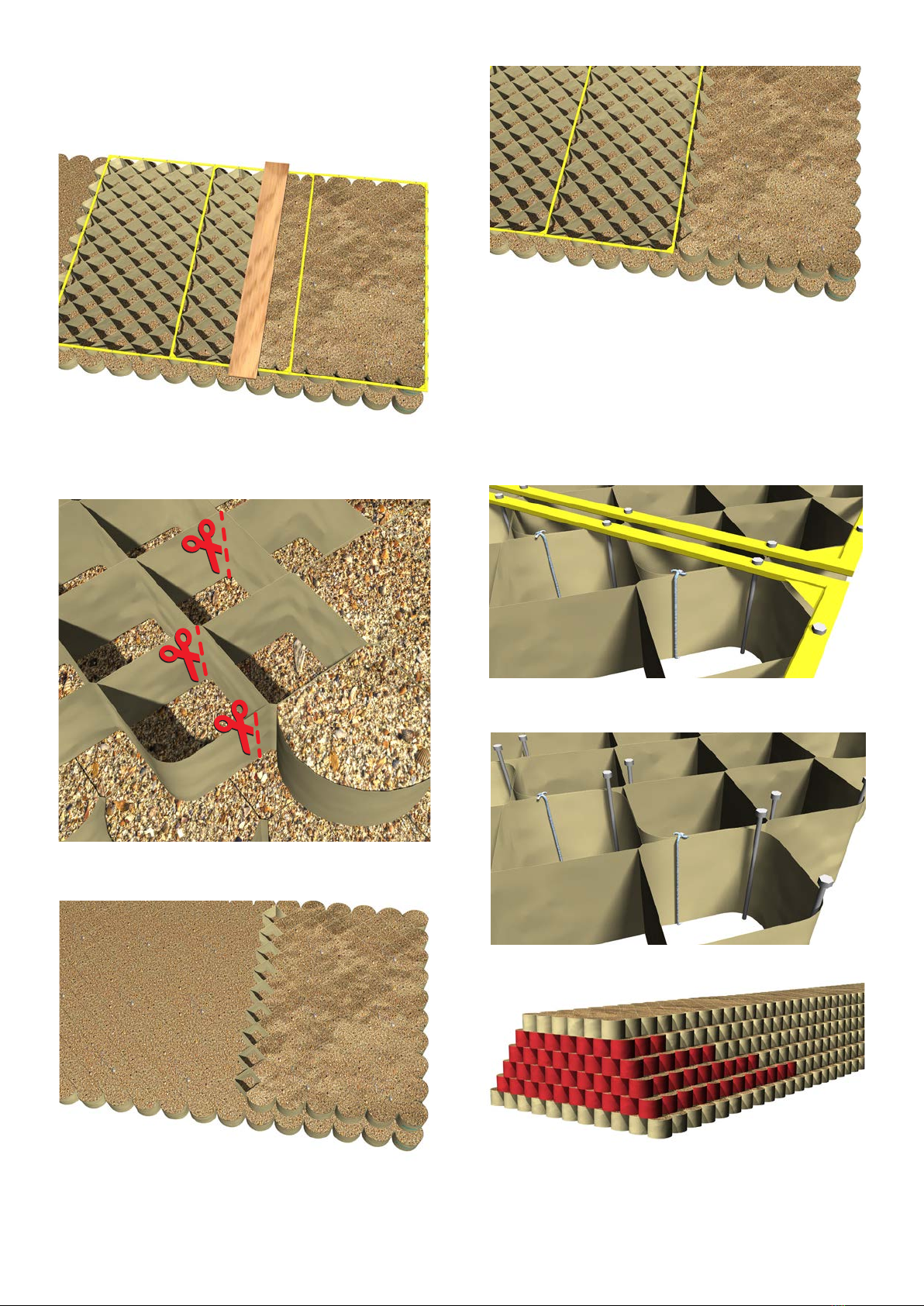

Panel joints. Prole 300 1.25m

Stagger panel joints by using half panels at each end of

the berm to create an interlock between the panels.

Note: Half panels are required on layers 2 and 4

5

This is best achieved by carefully marking a line along

the centre of the panel, using a felt-marker or line-

paint, so you are left with complete cells in the same

conguration as a normal panel end.

It is advisable to cover the end cells with a scaold plank or

similar. Fill to the edge of the plank, leaving the cells below

the plank empty.

Then remove plank and cut cells next to the glue joints.

Remove the frame as usual and keep the unlled section

of Prole 300. Use this at the end of the run to complete

the layer.

Then place a new Prole panel on the frame and join to

the lled half panel.

Prole 300 1.50m

There are three distinct dierences between the Prole

300 1.25m high and the 1.50m high during construction;

1.The Prole 300 1.50m has an extra layer, using the

Prole 300:06 on top.

2. Connect all the end cells between panels with a cord

tied with a reef knot.

The same can be achieved when using pins.

3. Panel joints should be staggered by cutting the end

panels on each layer of a construction. Each layer should

be cut 1m shorter than the layer below to achive the

staggered joints.

6

Stage 6 - Landscaping

Once the berm is completed to the required specication

it can be landscaped.

The berm can be landscaped by topsoil being placed

on the front/rear face of the berm. Once this is done

the berm can be cut into the required angle using the

bucket of the excavator.

Note: Check the angle using a prole board set to the

required angle.

Berm Attack Face: - The granular material chosen for

the berm prole should be graded to between 54-57

deg. This should allow the berm to settle over time but

not below 50 deg. as required.

Top of Berm: - The nished berm level is to be minimum

of 1.25m or 1.50m above existing ground levels after

compaction depending on design.

Berm non attack face: - The granular material chosen

for the berm prole can be sloped at any angle required,

or as instructed by the Engineer on site.

To prevent erosion, the berm can be lined with seed

impregnated hessian with either grass seed/ wild grass

or turf can be laid. This will also allow it to blend in and

be more aesthetically pleasing.

End walls / walk ways and integration of Vehicle

Security Barriers (VSB)

During the construction of the berm, several things may

have been incorporated into the design:

• End berm wall

• Pedestrian aperture

• Integration with Vehicle Security Barrier

Pedestrian aperture can be installed within the berm but

must not be any closer than 10m from end of the berm

and a maximum of 1.2m wide.

Disclaimer

The information contained in this leaet is provided

by DEFENCELL (J & S Franklin Ltd or it’s aliates and

associates) in good faith. While DEFENCELL has made

reasonable eorts to ensure the accuracy, completeness

and appropriateness of such information, any reliance

on such information is entirely at the risk of the

party using it. The installation and conguration of

any of DEFENCELL’s products by a third party is not

DEFENCELL’s responsibility and DEFENCELL (or its

employees, distributors or contractors) shall not be liable

for any failure of any of DEFENCELL’s products caused by

improper installation or subsequent misuse.

7

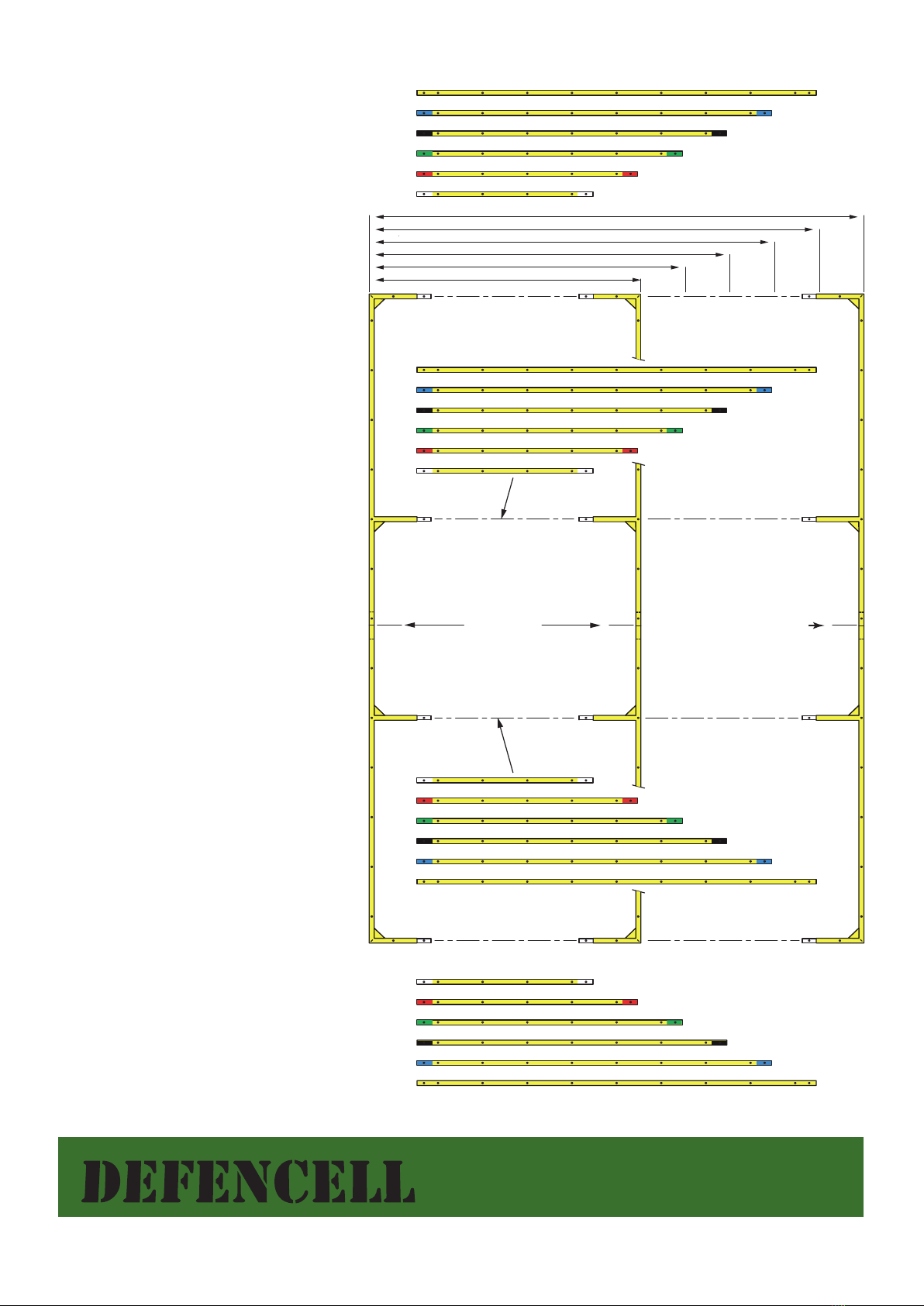

Prole 300 Universal Frame

Assembly Guide

1. The Prole Frame consists of four

corner pieces and six sets of four cross

pieces. The six dierent cross pieces

match the six dierent size Prole 300

panels and are colour coded.

The frame parts all have long pins pre-

tted which are inserted into the Prole

300 cells.

2. Assemble the two side bars using two

corner pieces on each side and connect

using the short nuts and bolts supplied.

3. Insert the four cross pieces (two end

and two centre) and connect using the

short nuts and bolts. The all yellow cross

pieces are used for the Prole 300:11.

4. For subsequent smaller Prole

panels, change the cross pieces to the

corresponding size.

5. After use, disassemble and clean the

frame and return to packing case.

11

10

9

8

7

6

PROFILE

6

7

8

9

10

11

PROFILE

11

10

9

8

7

6

6

7

8

9

10

11

JOINT LINE

JOINT LINE

PROFILE 6

PROFILE 7

PROFILE 8

PROFILE 9

PROFILE 10

PROFILE 11

Tel: +44 (0) 207 836 5746

email: info@defencell.com

www.defencell.com

DEFENCELL

© 2016 J&S FRANKLIN LTD. PROFILE 300 INSTALLATION V04/16