Defro Home VITAL 37S User manual

operating manual

gas-fired convection room heater

DEFRO HOME VITA

37 S 51 S

BP B U C T

gas type

G2.350 G20 G27 G31 G30

translation of original operating manual

edition 1.b

May 2021

destination countries:

2

DEKLARACJA ZGODNOŚCI WE

DECLARATION OF CONFORMITY EC

nr 93/A-4/03/2021

DEFRO Spół a z ograniczoną odpowiedzialnością Spół a omandytowa

00-403 Warszawa, ul. Solec 24/253

Zakład produkcyjny:

2 -0 7 Strawczyn, Ruda Strawczyńska 103A

DEKLARUJE / DECLEARS

z pełną odpowiedzialnością, że produkt / with all responsibility, that the product

onwe cyjny ogrzewacz pomieszczeń opalany gazem / independent gas-fired convection heater

(typ/type)

DEFRO HOME VITAL 6,0 W

DEFRO HOME VITAL 5,5 W

typ urządzenia: C11, C31, C91

został zaproje towany, wyprodu owany i wprowadzony na ryne zgodnie z następującymi

dyre tywami:

has been designed, manufactured and placed on the market in conformity with directives:

GAR 2016/426/UE

i niżej wymienionymi normami zharmonizowanymi:

and that the following relevant Standards:

dokumentacja techniczna / technical documentation

PN-EN 613:2002

PN-EN 613:2002/A1:2004

PN-EN 17082:2020-03

PN-EN 437:2019-03

Wyrób oznaczono znakiem:

Product has been marked:

Ta de laracja zgodności traci swą ważność, jeżeli w urządzeniu wprowadzono zmiany, został przebudowany bez naszej zgody lub jest

użyt owana niezgodnie z instru cją obsługi. Niniejsza de laracja musi być prze azana wraz z urządzeniem w przypad u odstąpienia

własności innej osobie.

This Declaration of Conformity becomes invalid if any changes have been made to the device, if its construction has been changed without

our permission or if the device is used not in accordance with the operating manual. This Declaration shall be handed over to a new owner

along with the title of ownership of the device.

Urządzenie jest wy onywany zgodnie z do umentacją techniczną przechowywaną przez:

Device has been manufactured according to technical documentation kept by:

DEFRO Spół a z ograniczoną odpowiedzialnością Sp. ., Za ład produ cyjny: 26-067 Strawczyn, Ruda Strawczyńs a 103a.

Imię i nazwis o osoby upoważnionej do przygotowania do umentacji technicznej: Mariusz Dziubeła

ame of the person authorized to compile the technical documentation: Mariusz Dziubeła

Imię i nazwis o oraz podpis osoby upoważnionej do sporządzenia de laracji zgodności w imieniu producenta: Robert Dziubeła

ame and signature of the person authorized to compile a declaration of conformity on behalf of the manufacturer: Robert Dziubeła

Dwie ostatnie cyfry ro u, w tórym ozna owanie zostało naniesione: 21

Two last digits of the year of marking: 21

Warszawa, dn. 23.03.2021

miejsce i data wystawienia

place and date of issue.

Robert Dziubeła

prezes zarządu / CEO

3

Dear Customer,

We would like to thank ou for choosing the high qualit DEFRO

product which will ensure our safet and operational reliabilit .

As our customers, ou can alwa s count on the help of the DEFRO

Service Centre, which is read to ensure continuous efficienc of our

equipment.

Please note that in order to use the equipment safel and efficientl , it

is crucial to get familiar with the following directions.

Read and follow this Operating Manual - useful remarks

concerning proper operation of the equipment can be found

there.

Determine if all parts have been delivered or the fireplace was

not damaged during transport.

Check data on the rating plate against the warrant card.

Check whether the s stem is in compliance with the

recommendations of this manual and corresponding national

regulations before the start-up.

Basic usage rules are to be obe ed while using the equipment. It is

forbidden to remove the cover during operation of the equipment.

DEFRO Service Centre or Authorized DEFRO Service should be

alwa s contacted when an intervention is necessar because onl these

parties have original spare parts and are properl trained within the scope

of installation and operation of DEFRO products.

For our safet and equipment use convenience, please get

acquainted with this operating manual and send back a correctl filled cop

of the Warrant Card to the following address:

DEFRO Sp. z o.o. Sp. k

-

Centrum

Serwisowe

Ruda Strawcz ńska 103a

26-067 Strawcz n

@

serwis@defro.pl

B sending back our Warrant Card, ou will be registered in our

DEFRO products user’s database and we will be able to provide ou quick

and professional technical support.

If ou do not send back a correctl filled in Warrant Card and the

equipment qualit and completeness receipt within the period of up to two

weeks after the date of installation but no longer than within six months,

after purchasing, the warranty will become invalid! This results in dela s

with repairs and the necessit of covering costs of service and travelling

expenses.

Thank ou for understanding.

Yours sincerel ,

DEFRO Sp. o.o. Sp. k

Content of this Operating Manual is a propert of DEFRO sp. z o.o. Sp. k..

An cop ing, duplicating, publishing of content of this Manual

without prior written consent of DEFRO sp. z o.o. Sp. k. is forbidden.

Dear Customer,

We would like to inform ou that we make ever efforts to offer

products of qualit fulfilling the most restrictive standards and

warranting operational safet . All devices are produced in accordance

with the requirements of relevant EU directives and have CE safet

mark confirmed b the Declaration of Conformit EC.

We appreciate all our comments and proposals regarding our

level of service. We appreciate our comments and proposals

regarding our devices and the level of service provided b our

Partners and Technical Support and Service.

DEFRO Sp. o.o. Sp. K

4

TABLE OF CONTENTS

1. INFORMATION .......................................................................................................................................................................................... 6

2. BASIC SAFETY RULES ............................................................................................................................................................................. 6

2.1. Safet warnings ............................................................................................................................................................................... 6

2.2. Warnings related to operation ........................................................................................................................................................... 6

3. INTENDED USE ........................................................................................................................................................................................ 7

4. TECHNICAL SPECIFICATION ................................................................................................................................................................... 7

4.1. Design ............................................................................................................................................................................................. 7

4.2. Technical data ................................................................................................................................................................................. 8

4.3. Equipment ......................................................................................................................................................................................10

4.4. Fuel parameters..............................................................................................................................................................................10

4.5. Spare parts .....................................................................................................................................................................................10

5. TRANSPORT ...........................................................................................................................................................................................10

6. SYSTEM...................................................................................................................................................................................................10

6.1. Installation location .........................................................................................................................................................................10

6.2. Connection to the gas piping s stem ...............................................................................................................................................10

6.3. Connection to the concentric flue s stem .........................................................................................................................................11

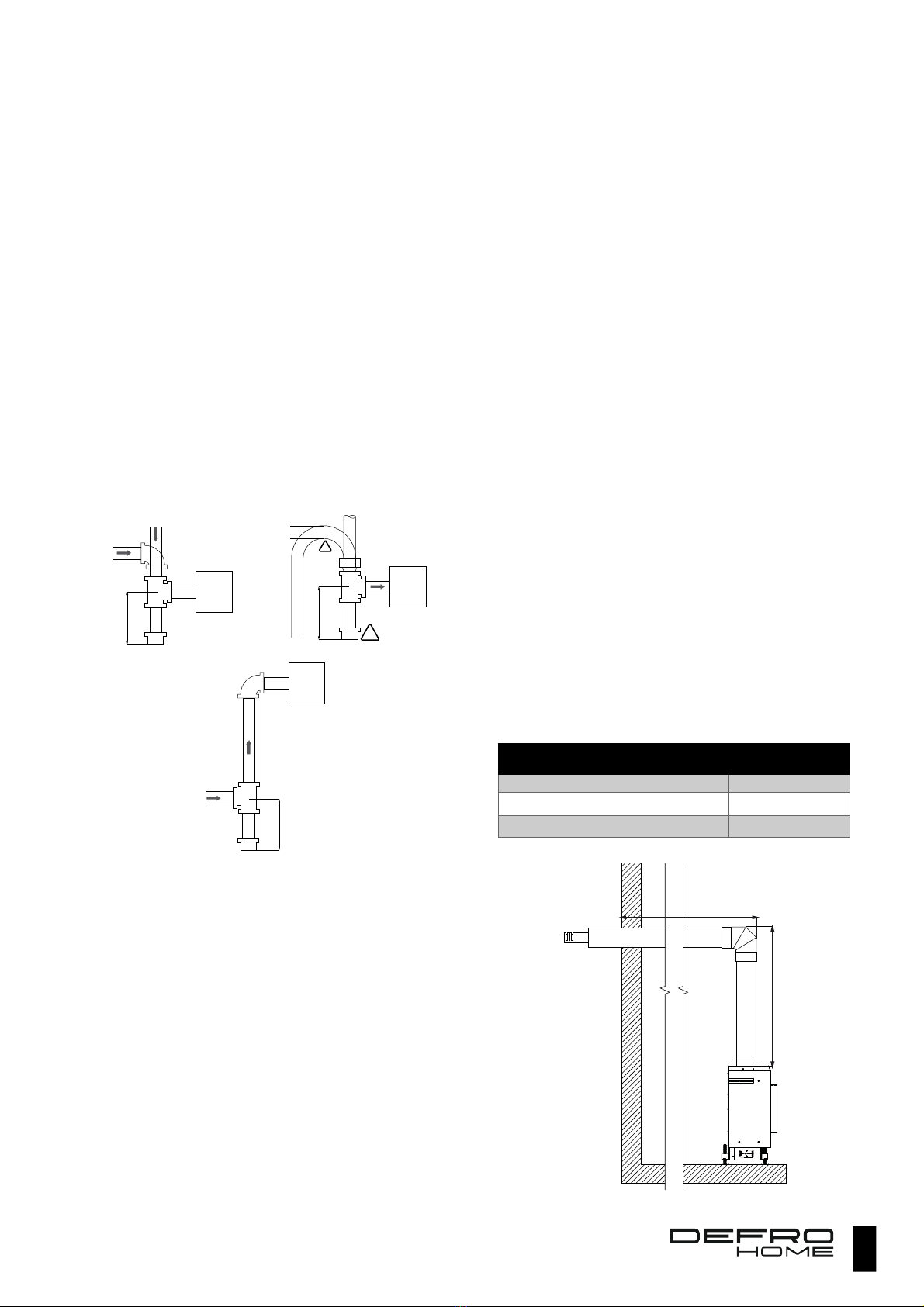

6.3.1. Horizontal outlet of concentric pipe - t pe C11 ............................................................................................................................11

6.3.2. Vertical outlet of concentric pipe - t pe C31 ................................................................................................................................12

6.3.3. Outlet using conventional flue - t pe C91 ....................................................................................................................................12

6.4. Terminals .......................................................................................................................................................................................12

6.5. Installation of control s stem ...........................................................................................................................................................12

6.6. Adjustment .....................................................................................................................................................................................13

6.6.1. Adjustment of flame in the control burner ....................................................................................................................................13

6.6.2. Adjustment of gas exhaust pressure ...........................................................................................................................................13

6.6.3. Adjustment of minimum height of flame of the primar burner ......................................................................................................13

6.6.4. Final operations .........................................................................................................................................................................14

6.7. Tightness control of the balanced flue s stem ..................................................................................................................................14

6.8. Flue gas flow damper adjustment ....................................................................................................................................................14

6.9. Conversion to the other gas ............................................................................................................................................................15

6.10. Installation of the heater ..................................................................................................................................................................15

6.11. First start-up ...................................................................................................................................................................................15

7. OPERATION ............................................................................................................................................................................................16

7.1. Safet rules ....................................................................................................................................................................................16

7.2. Preparation .....................................................................................................................................................................................16

7.3. Information .....................................................................................................................................................................................16

7.4. Deactivation of remote control function ............................................................................................................................................16

7.5. Activation of remote control function ................................................................................................................................................16

7.6. Control of FIREPLACE with a remote control ...................................................................................................................................16

7.6.1. Setting temperature units ...........................................................................................................................................................16

7.6.2. Time settings .............................................................................................................................................................................17

7.7. Parental lock ...................................................................................................................................................................................17

7.7.1. Firing up in manual mode ...........................................................................................................................................................17

7.7.2. Standb mode ...........................................................................................................................................................................17

7.7.3. Fireplace shutdown ....................................................................................................................................................................17

7.7.4. Adjustment of flame height .........................................................................................................................................................17

7.7.5. Adjustment of limit heights for the flame......................................................................................................................................17

7.7.6. Timer.........................................................................................................................................................................................18

7.7.7. Operating modes .......................................................................................................................................................................18

7.7.8. Thermostatic mode ....................................................................................................................................................................18

7.7.9. Program mode ...........................................................................................................................................................................19

7.7.10. Eco mode ..................................................................................................................................................................................19

7.7.11. Behavior of FIREPLACe when there is no signal from the remote control ....................................................................................19

7.8. Power suppl and batter replacement ............................................................................................................................................20

7.8.1. Batter replacement in the remote control ...................................................................................................................................20

7.8.2. Batter replacement in the receiver ............................................................................................................................................20

7.9. Manual control of fireplace ..............................................................................................................................................................20

7.9.1. Firing up ....................................................................................................................................................................................20

7.9.2. Damping a flame of the primar burner .......................................................................................................................................20

7.9.3. Fireplace shutdown ....................................................................................................................................................................20

7.9.4. Error codes ................................................................................................................................................................................21

8. Decorative items .......................................................................................................................................................................................23

8.1. Components of ceramic chunks set .................................................................................................................................................23

8.2. Assembl of ceramic chunks ...........................................................................................................................................................24

8.3. La ing of decoration imitating the stones .........................................................................................................................................32

9. MAINTENANCE AND SERVICE................................................................................................................................................................33

9.1. Window panel cleaning ...................................................................................................................................................................33

9.2. Window panel dismantling ...............................................................................................................................................................33

9.3. Periodic maintenance inspection .....................................................................................................................................................34

10. EMERGENCY PROCEDURES .................................................................................................................................................................34

10.1. When the gas odour is stated ..........................................................................................................................................................34

5

10.2. Flue gas escape .............................................................................................................................................................................34

10.3. Carbon monoxide escape................................................................................................................................................................34

11. TROUBLESHOOTING ..............................................................................................................................................................................34

12. REMOVAL DUE TO WEAR-OUT ..............................................................................................................................................................34

13. PRODUCT WARRANTY TERMS AND CONDITIONS ................................................................................................................................35

13.1. Warrant conditions “48h Service” ...................................................................................................................................................36

14. WARRANTY CARD ..................................................................................................................................................................................37

15. CARRIED OUT WARRANTY REPAIRS AND MAINTENANCE. ..................................................................................................................38

16. WARRANTY CARD /cop to send back/ ....................................................................................................................................................39

17. COMPLAINT FORM ..................................................................................................................................................................................41

18. COMPLAINT FORM ..................................................................................................................................................................................43

19. COMPLAINT FORM ..................................................................................................................................................................................45

20. REGISTER OF INSPECTIONS OF SMOKE DUCTS..................................................................................................................................47

6

1. INFORMATION

Operating manual is an integral and essential part of the product

and must be forwarded to the user also in case when the propert is

transmitted. User should carefull read the manual and save it for the

future because all remarks included there are important guidelines

concerning safet during installation, usage and maintenance.

Installation of the equipment must be carried out in accordance

with the mandator standards in the countr of destination, according

to guidelines of the manufacturer and b qualified personnel. Improper

installation of the device can be a reason for personal injuries and

damage to propert , for which the manufacturer is not liable.

The equipment can be used onl for the purpose it was explicitl

intended. An other use should be treated as inappropriate and in

consequence as dangerous.

In case of error during installation, usage or maintenance works

caused b non-observance of the legislation, regulations in force or

instructions contained in this manual (or others, delivered b the

manufacturer) the manufacturer rejects an contractual or non-

contractual liabilit for resulting damages and the warrant for the

device becomes void.

Versions of the publication

Due to continuous improvement of the product, DEFRO reserves

the right to update this publication without prior notice.

The content of this Operating Manual is a propert of DEFRO. An

cop ing, duplicating, publishing of content of this User’s Manual without

prior written consent of DEFRO is forbidden.

Manual storage and browsing its contents

We recommend taking care of this manual and store it in an easil

and quickl available location. If this manual has been lost, damaged

or destro ed, ou should request a cop in the sales outlet or directl

from the Manufacturer providing identification data of the product. All

the most important information included in the operating manual are

marked with “bold” and have s mbols pointing out user’s attention to

hazards which can be present during operation of the gas-fired heater.

S mbols used in the text are explained below:

Danger!

Direct threat to life and health! Non-compliance with the

recommendations marked in this way and misuse may

result in death or major injuries.

Danger!

Danger from electrical voltage! Incorrect installation and

incorrect electrical connections may cause danger to life

by electric shock.

Note!

Warning symbol indicating that you should read carefully

and understand the given information to which it relates.

Non-compliance with this recommendation may result in

major damage to the equipment and create a hazard for

the user or the environment.

Danger!

Warning symbol indicting hazard to health resulting from

the action of high temperature! Non-compliance with the

recommendations distinguished in this way may cause a

fire or burns.

Hint!

Informative symbol. Useful information and hints are

marked in this way.

2. BASIC SAFETY RULES

2.1. SAFETY WARNINGS

The national and local provisions should be met.

Equipment should be installed in compliance with the

legal standards applicable in the given location, region

or countr .

The equipment should be used b a person

(including

children) of impaired ph sical, sensor , mental

capabilities and b persons without experience and

required knowledge provided that such operation is

not carried out under their supervision or after prope

r

instruction b a person responsible for their safet .

You should alwa s observe the guidelines given in the

operating manual to ensure correct use of the

equipment and to prevent accidents.

Operation and adjustment should be carried out b

adults. Errors

and incorrect setting can cause

hazardous situations and/or incorrect operation.

Prior to an operations,

the user (or an person

operating the equipment) should read and understand

the whole contents of this manual.

Equipment should be used onl as

intended. Each

other use is considered as misuse and hazardous as

a consequence.

In case of disturbances in operation,

the equipment

can be restarted onl when the occurred problem has

been removed and the equipment is brought back to

original condition.

T

he user is full responsible for misuse of the product

and relieves DEFRO from an civil and criminal

liabilit .

All t pes of modifications or replacement of equipment

parts with non-

original components or without

authorization ma present a risk for opera

tor and

relieves DEFRO from an civil and criminal liabilit .

Incorrect installation or maintenance (incompatible

with contents of this manual), can cause injuries of

people, animals or propert damage. Then DEFRO

shall be relieved of an civil or criminal liabilit .

All surfaces of the equipment are working surfaces

and some of them is ver hot. You should avoid direct

contact with such components.

Keep children awa from the equipment when it is

operating because each hot surface can cause burns.

2.2. WARNINGS RELATED TO OPERATION

Equipment should be shutdown in case of failure or

incorrect operation.

Gaseous fuel used in the equipment should meet

the

conditions described in this manual.

Equipment should be installed in rooms with fire

protection and

equipped with all required components

such as suppl (with air) and flue gas discharge.

The equipment should be stored in the rooms free

from moisture and the cannot be exposed to adverse

effects of the weather.

The equipment consumes as much air as it i

s required

for the combustion process.

Do not touch the equipment with wet or moist parts of

the bod and/or barefooted.

Disconnect the equipment from the electric grid

before the cleaning.

ADDITIONAL INFORMATION

7

In case of an

problems,

ou should contact sales

outlet or qualified personnel authorized b DEFRO.

Request original spare parts if the repair is necessar .

Use onl gaseous fuel with properties compatible with

the recommendations of this operating manual.

Check and clean flue g

as discharge ducts (connecting

piece to flue) periodicall .

Store this manual carefull because it should be

available for a whole period of equipment operation.

In case of sale of giving the equipment to the other

user ou should alwa s make sure whether

the

product has the manual enclosed.

Request new cop from authorized sales outlet in

DEFRO compan if it has been lost.

3. INTENDED USE

The room heater is intended for combustion of natural gas (NG) or,

after proper adaptation, propane-butane (LPG) gas, to heat the rooms

where it has been installed.

Gas-fired room heater can be connected multiple times.

4. TECHNICAL SPECIFICATION

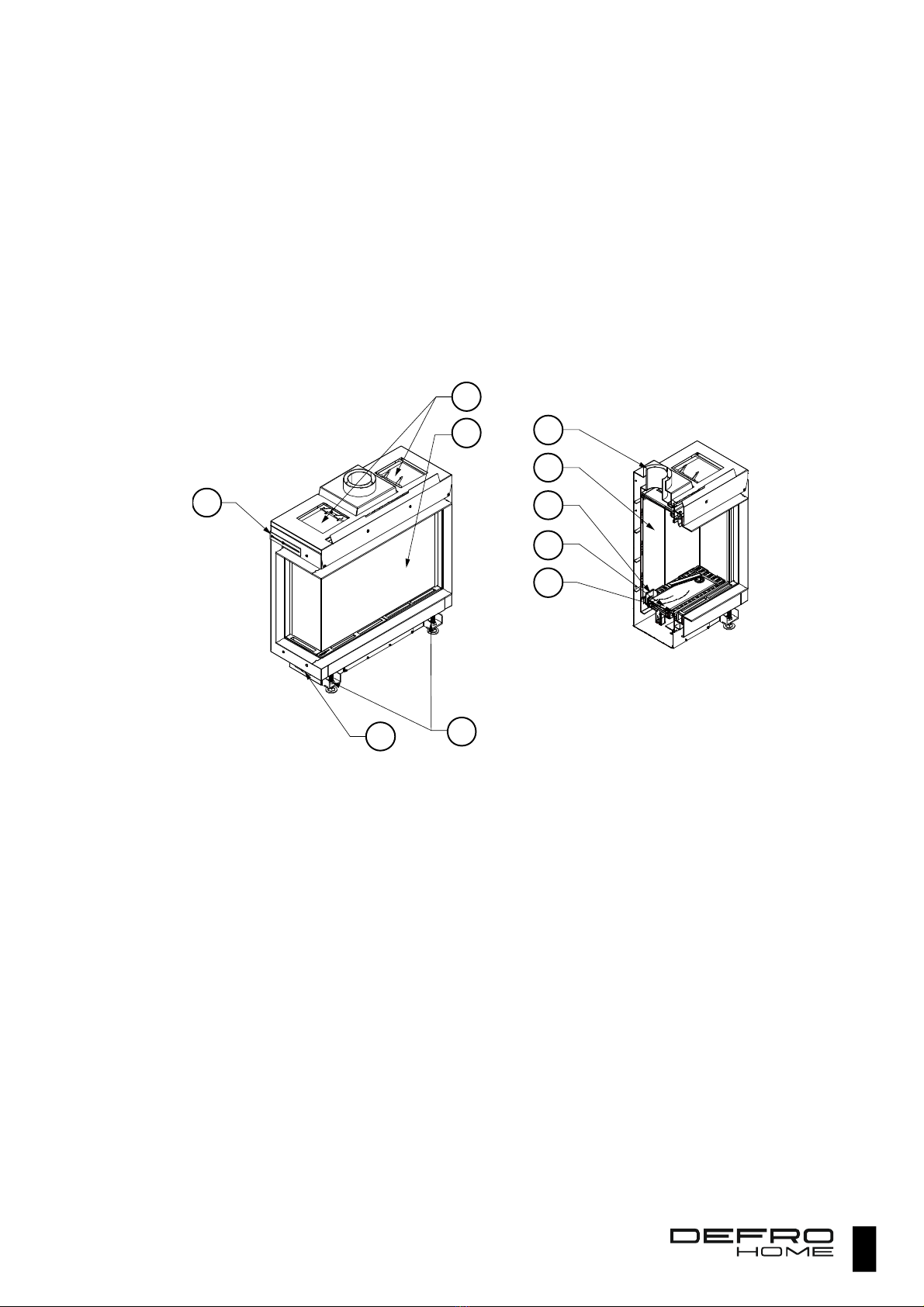

4.1. DESIGN

The bod of the heater is made of steel sheet with combustion chamber located inside and lined with additional panels made of sheet (rear and

sides).

Picture 1 Design of DEFRO HOME VITAL heater.

1 - explosion relief vents, 2 - window panel, 3 - end cap of gland for gas lines, 4 - adjustable feet, 5 - flue, 6 - panels of combustion chamber, 7 - set of

control burner, spark igniter and temperature sensor, 8 - primar burner, 9 - combustion air inlets.

The gas burner supplied with gas and air is located in the floor of the chamber. Gas is supplied from the electronic controlled dosing device GV60,

which is connected to the gas piping s stem. Gas is combusted after initiation of ignition b the spark igniter, which initiates ignition of the ignition burner.

The main burner is started after detection of ignition flame. Flue gas is exhausted through the concentric connector to twin-walled concentric coaxial pipe

(internal pipe). The same pipe (external pipe) is used to suppl air required for combustion. The fireplace is operated b a remote control, which is part

of the control s stem manufactured b Mertik Maxitrol GV60.

1

2

34

7

5

6

8

9

9

8

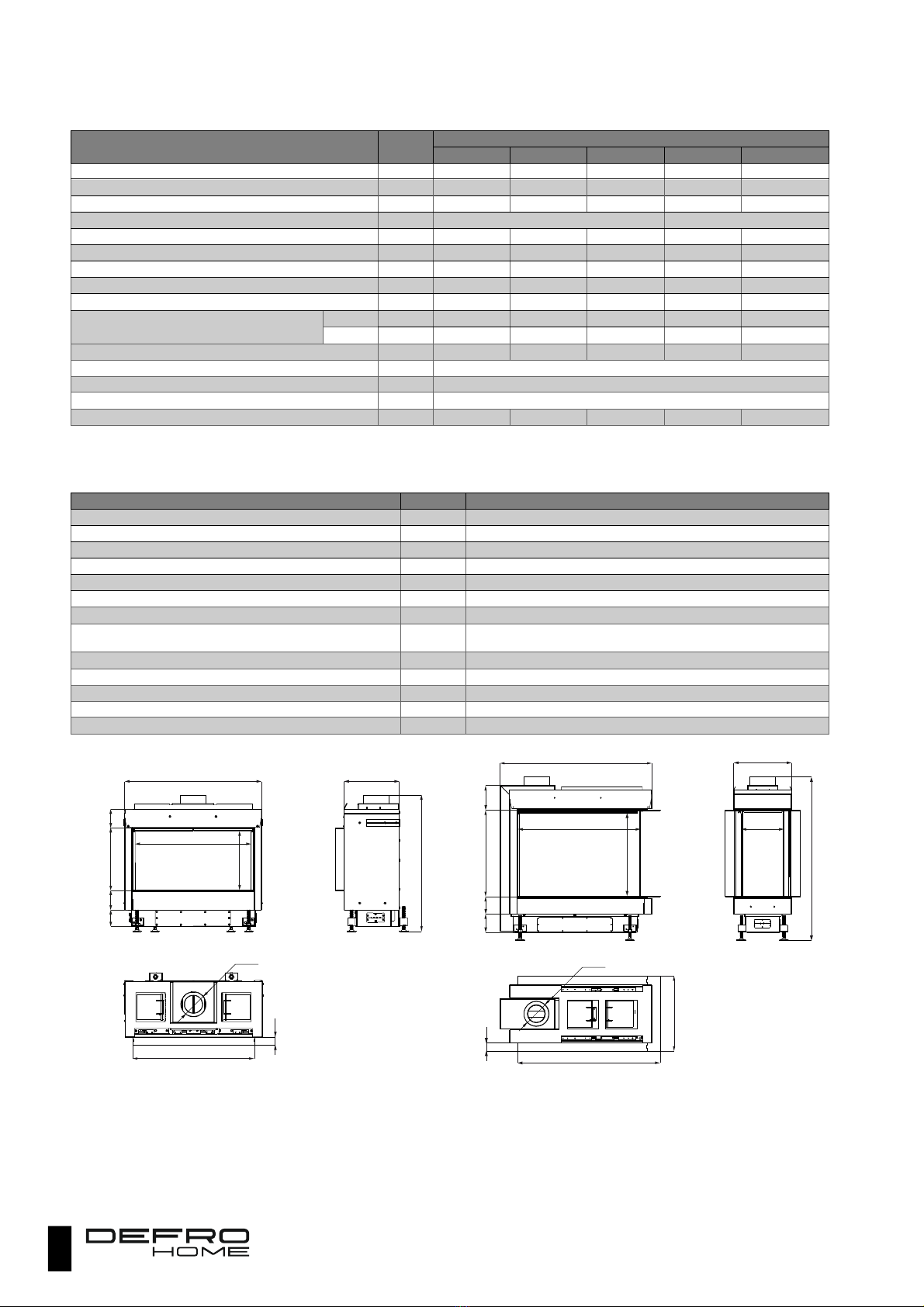

4.2. TECHNICAL DATA

Table 1. Technical data of DEFRO HOME VITAL heater.

Parameter Unit Reference gas

G20 G27 G2.350 3P 3B/P

Nominal connection pressure, pnom mbar 20 20 13 29 / 37 / 50 29 / 37 / 50

Rated maximum heat load acc. to Hi, Qznam(max) kW 6.0 6.0 6.0 5.5 5.5

Rated minimum heat load acc. to Hi, Qznam(min), kW 3.6 3.6 3.6 3.3 3.3

Controller - gas pressure regulator locked gas pressure regulator in operation

Gas pressure downstream of the controller for Qznam(max), preg_Qznam(max) mbar 12.2 12.2 6.8 29.7 29.7

Gas pressure downstream of the controller for Qznam(min), preg_Qznam(min) mbar 4.0 3.4 2.3 12.0 12.0

Stream of consumed gas (15 °C, 1013 hPa) for Qznam(max), V_Qznam(max) m3/h 0.626 0.774 0.881 0.225 0.170

Stream of consumed gas (15 °C, 1013 hPa) for Qznam(min), V_Qznam(min) m3/h 0.376 0.464 0.529 0.135 0.102

Equipment efficienc class - 1 2 2 1 1

NOX emission class2 37 - 4 4 3 4 4

51 - 3 4 3 4 4

Diameter of gas nozzle of the main burner mm 2.00 2.40 3.25 1.45 1.35

Diameter of concentric coaxial pipe mm 100/150

Gas control valve GV60

Receiver suppl V DC 6

Weight1 kg 90 90 90 90 90

1) Device weight depends on selected design version and its equipment.

2) Level for C11 equipment acc. to PN-EN 613:2002/A1:2004.

Table 2. Technical data of GV60 regulator with a receiver and remote control manufactured by Mertik Maxitrol.

Parameter Unit Value

Directives fulfilled - 2009/142/ECC, DIN EN 298, DIN EN 126, DIN EN 14611

Fuel - gas of first, second or third famil acc. to EN-437

Adjustment range - class C acc. to EN 88

Adjustment range for pressure regulator mbar 5÷40

Maximum input pressure mbar 50

Allowable operating temperature for GV60 valve ºC 80

Allowable operating temperature for receiver supplied with batteries ºC 55

Allowable operating temperature for receiver supplied from electric power

s stem

ºC 80

Allowable operating temperature for remote control ºC 60

Allowable operating temperature for ignition cable ºC 150

Connection of main gas inlet inch reduction nipple ½″

Connector of control burner mm 6 mm

Mounting position vertical or within the angle from 0° to 90º from vertical position

Picture 2. Dimensions of DEFRO HOME VITAL 37 S.

Picture 3.3 Dimensions of DEFRO HOME VITAL 37 S U.

720

47

>808

3

2

9

Ø150

8

1

2

3

7

0

1

1

5

9

8

1

1

1

687

350

845

51

>967

3

4

2

Ø150

8

9

6

443

5

1

2

1

0

3

1

0

8

1

4

6

717

490

242

9

Picture 4.4 Dimensions of DEFRO HOME VITAL 37 S C.

Picture 5 Dimensions of DEFRO HOME VITAL 37 S T.

Picture 6 Dimensions of DEFRO HOME VITAL 37 S BP and DEFRO

HOME VITAL 37 S BL (mirror reflection of BP version).

Picture 7. Dimensions of DEFRO HOME VITAL 51 S U.

Picture 8. Dimensions of DEFRO HOME VITAL 51 S T.

Picture 9 Dimensions of DEFRO HOME VITAL 51 S.

983

47

808

3

3

0

2

9

7

Ø150

8

8

3

3

7

0

1

1

5

9

8

1

1

1

783 188

350

8

2

8

3

0

9

>781

3

7

0

1

0

7

9

8

1

5

4

720

404

47 Ø150

4

7

700

360

8

4

8

741 247

3

2

9

>823

3

7

0

1

1

5

9

8

1

1

2

350

850

297

49 Ø150

4

9

845

51

>827

3

4

2

Ø150

8

9

7

444

3

7

2

1

0

3

1

0

8

1

4

6

717

350

242

8

2

8

3

0

9

>918

5

1

0

1

0

7

9

8

1

5

4

720

403

47 Ø150

4

7

4

7

707

506

Ø150

720

3

3

2

>962

8

1

3

919

47

5

1

0

1

1

5

9

8

1

1

2

675

490

10

Picture 10. Dimensions of DEFRO HOME VITAL 51 S BL and DEFRO

HOME VITAL 51 BP (mirror reflection).

Picture 11. Dimensions of DEFRO HOME VITAL 51 S C.

4.3. EQUIPMENT

The gas-fired heater is delivered on a pallet, foil-wrapped and are

full assembled. Scope of deliver can include additional components

and subassemblies, according to the order of the user. Standard

components of the equipment are specified in the table 2.

Table 3. Equipment of DEFRO HOME VITAL room heater.

Standard equipment of gas fireplace Unit Quan

tity

Equipment operating manual pcs. 1

Operating manual and warrant card for electronic

controller

pcs. 1

Controller with a valve set 1

4.4. FUEL PARAMETERS

Gaseous fuel of second or third famil acc. to the EN 437 standard

is used as a primar fuel for the DEFRO HOME VITAL heater.

The heater is factory adapted to one type of fuel acc. to the

customer’s order and can be operated only with this fuel.

Conversion of the equipment to the other type of fuel and

change of gas on your own and without conversion is

forbidden!

Contact the manufacturer if it is required to change a fuel

type.

4.5. SPARE PARTS

To obtain information on availabilit of spare parts for gas-fired

fireplace or inquiries about equipment servicing please contact with

DEFRO Service Center or Authorized DEFRO Service.

DEFRO Sp. o.o. Sp. k

Centrum Serwisowe

Ruda Strawc yńska 103a

26-067 Strawc yn

@

serwis@defro.pl

5. TRANSPORT

Room heater in the packing material should be transported in the

horizontal position using a special trolle . In special cases and on short

distances, it is allowed to transport it in vertical position.

6. SYSTEM

Chec the local conditions for distribution before

installation (identify type of gas and its pressure) and

whether the current settings of a heater are correct.

VITAL heater should be supplied with the same type of gas

as the other gas-fired equipment (if any) in the home of their

installation.

Installation of the gas-fired heater should be performed b qualified

personnel. All assembl operations should be performed in accordance

with the applicable national and local regulations within the scope of

fire protection, requirements of gas distributor and local authorities.

Gas s stem and flue gas handling s stem should be in compliance

with the Regulation of the Minister of Infrastructure of 12.04.2002

(Journal of Laws of 2002, no. 75, item 690) with all subsequent acts

amending this regulation.

Obtain all necessar consents from the appropriate authorities

before the installation: Regional gas compan , chimne sweeping

compan and building administration.

6.1. INSTALLATION LOCATION

Selection of installation location of the gas-fired heater should be

based on meeting of the following conditions:

access to gas piping s stem should ensure ease of

connection; flexible hoses should not be excessivel twisted;

access to chimne s stem should ensure as low number of

bends as possible;

Distance of the heater from non-flammable components of

the housing should not be smaller than 80 mm and

temperature of walls exposed to direct heating b the heater

should not exceed 80 ⁰C.

The room heater is intended for installation onl in vertical position

and should be placed on hard and non-flammable substrate with

suitable load-carr ing capacit . It is forbidden to install the heater as a

unit hanging on the wall!

6.2. CONNECTION TO THE GAS PIPING SYSTEM

The device is intended only for one type of fuel acc. to the

customer’s orders indicated on the first page of the manual

and declaration on the rating plate.

8

4

8

9

4

9

835

510

850

297

49 Ø150

3

2

9

741247

490

989

50

>963

3

3

0

2

9

7

Ø150

8

8

9

5

1

0

1

1

5

9

8

783 189

500

11

Heater connection to the gas system should be in

compliance with the applicable regulations.

Shut off the gas inflow using main valve before

commencing the installation wor s.

Before installation ma e sure that the gas meter has

suitable throughput, also in case when the other

equipment is drawing the gas.

During installation ma e sure to avoid getting of dirt

(dust, water and others) into the gas duct. It is

recommended to install the filter.

Install a gas shut-off valve for the heater.

If not stated otherwise b the local regulations, then gas ducts

should be led outside the wall. It is indicated to install a filter, stopping

the possible contaminants from the gas s stem, on the gas suppl duct.

Check tightness after installation.

To connect the heater to the gas piping s stem, it is required to

remove:

Glazing - description of removal is given in 9.2,

covers of cleanouts in base of the heater.

Install sedimentation trap (acc. to the picture) if it is required to

ensure protection against dirt in the gas piping s stem.

Picture 12 Method of installation of sedimentation trap if required.

GV60 valve with receiver should be located in the box intended for

this purpose. Conditions for cabinet installation

Cabinet should be located in a distance allowed b the

cables of spark igniter and thermocouple. Do not extend

these cables!

Cable of spark igniter should be led awa from the metal

parts,

Cabinet should be located in a location free from moisture,

dust and corrosive agents!

The cabinet should be installed in a location where

temperature does not exceed 25 ºC.

6.3. CONNECTION TO THE CONCENTRIC FLUE SYSTEM

The room heater is adapted for removal of flue gas and uptake of

air for combustion through the concentric flue s stem with a diameter

150/100 mm.

Please note the following rules:

Outlet-aspirating duct should protrude b min. 18 mm from

the wall.

Installation of elbow 90⁰ results in reduction of total

allowable length of the pipe b 2 meters.

Installation of elbow 45⁰ results in reduction of total

allowable length of the pipe b 1 meter.

First elbow connected to the equipment is not taken into

consideration.

Verticall lead pipes should be fixed to the wall using

brackets arranged in approx. 1-meter distance.

Start leading from the chimne side using vertical duct of

length not smaller than 1 metre.

The wall connector is counted as 1 m.

Execute thermal insulation of all flammable walls at the

distance min. 25 cm from the chimne s stem.

Ensure additional 5 cm of clearance between the wall and

duct for flammable walls. Fill the space with thermal

insulation.

Maximum length of chimne s stem should not exceed 10

metres.

Install condensate discharge s stem from the chimne

s stem, e.g. as droplet eliminator, if necessar .

End vertical sections with terminal should be led with 1%

slope towards the outside of the building to prevent flowing

of possible condensate to inside the fireplace.

Concentric coaxial pipe should be ended with a suitable

wind protection cap. For horizontal pipes (led through the

wall) it is required to use (t pe C11) special horizontal cap,

while for vertical variant (led through the roof) - vertical cap

(t pe 31).

6.3.1. HORIZONTAL OUTLET OF CONCENTRIC PIPE - TYPE

C11

It allows removing the flue gas and air intake b horizontal section

of the coaxial pipe led through the wall of the building. Minimum length

of vertical section should be 1 m and length of horizontal section

depends on length of vertical section, but should not exceed 3 m. It is

allowed to use onl one elbow 90 in the s stem. Remember about

suitable slope of the end horizontal section (see previous chapter). A

diagram of C11 t pe outlet is presented on picture 13.

Table 4. Total lengths of C11 type concentric coaxial pipe depending

on minimum length of vertical section.

Total length

of the balanced flue system Dn100-150 Lmin

2.8 m 1 m

10.5 m 2 m

13.9 m 3 m

Picture 13. Diagram of horizontal outlet of concentric pipe – type C11.

level

min 76 mm

s

l

o

p

e

suppl from

gas piping s stem

sediment trap

gas

regulator

level

vertical

min 76 mm

s

l

o

p

e

gas suppl

sediment

trap

gas

regulator

!

1

vertical

min 76 mm

suppl from gas

piping s stem

sediment

trap

gas

regulator

L min 1 m

P max 3 m

12

6.3.2. VERTICAL OUTLET OF CONCENTRIC PIPE - TYPE C31

Concentric pipe is led through the roof or floor slab of the building.

Minimum distance of the vertical section without an elbow is 1 m and

maximum 10 m. Total length of the pipe should not exceed 10 m.

Picture 14. Diagram of outlet of C31 concentric pipe.

6.3.3. OUTLET USING CONVENTIONAL FLUE - TYPE C91

Picture 15. Diagram of outlet of C91 concentric pipe.

This s stem ma use a conventional chimne to remove the flue

gas and for air intake. A pipe with suitable terminal at the outlet is

installed inside the flue and used for this purpose, while flue space

outside the pipe is used for air intake. However, the following conditions

should be fulfilled:

Diameter of flue gas exhaust pipe inside the chimne is 100

mm, its maximum length should not exceed 6 m.

Chimne section should not be lower than 150mm x 150mm.

Flue should be tight, with full flow capacit , clean and eas to

maintain.

Chimne outlet of the existing chimne in connection with a

terminal should be protected against flooding or clogging and

the terminal should be installed in a wa ensuring its correct

operation.

Penetration of concentric pipe through the wall to the

chimne should be equipped with a trim plate.

6.4. TERMINALS

Concentric coaxial pipe should be ended with a suitable terminal

corresponding to the t pe of s stem. Below ou will find terminals for

C11 and C31.

C11 t pe terminal. Designation: A – 151.6, B – 240.

C31 t pe terminal. Designation: A – 97.5, B - 202, C- 228.

C91 t pe terminal.

6.5. INSTALLATION OF CONTROL SYSTEM

The installation should be carried out according to the manual of

control s stem manufactured b Mertik compan and the

recommendations given in this chapter. The GV60 gas valve with

equipment manufactured b Mertik is the onl one intended for

installation in the DEFRO HOME VITAL heater. S stem can be

installed onl in the brand-new fireplace.

During installation, ou should observe the below pictures

presenting the arrangement of the connecting and control components

of the GV60 valve and receiver s stem.

max 10 m

min 1 m

L

max 6 m

kolano 45º

rozeta

H

13

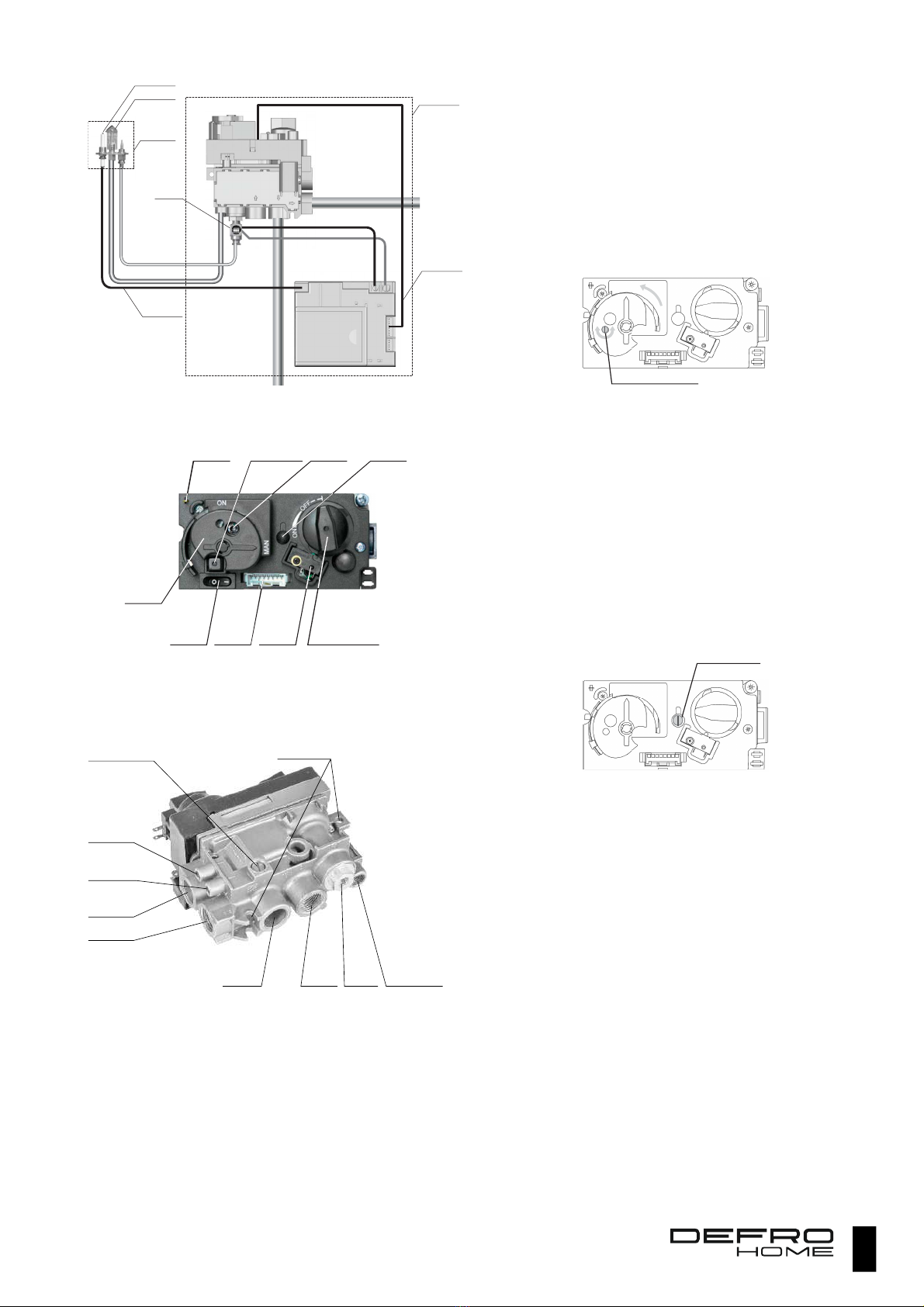

Picture 16. Connection diagram of the GV60 controlled valve with the

other components of the control system.

Picture 17 Arrangement of control components at the GV60 valve.

Attention!!!

The ON/OFF switch is an optional equipment and ma not be used in

the delivered equipment!

Picture 18 Arrangement of connectors at the GV60 valve.

The GV60 valve should be installed verticall or in a position

deviated from the verticalit to 90 degrees. Do not install it in a position

reversed b 180 degrees (upside down).

Unused gas inlets or outlets should be

tightly plugged!

6.6. ADJUSTMENT

The heater is factor adapted for the given t pe of fuel according

to the customer’s order. Also pressure adjustment for exhaust gas for

the pressure regulator is made acc. to the given t pe of gas. The task

of the fitter, after installing the chimne , is to check the settings and

make possible corrections to ensure that pressure values for the given

t pe of fuel corresponds to table 1 for both rated loads (minimum and

maximum).

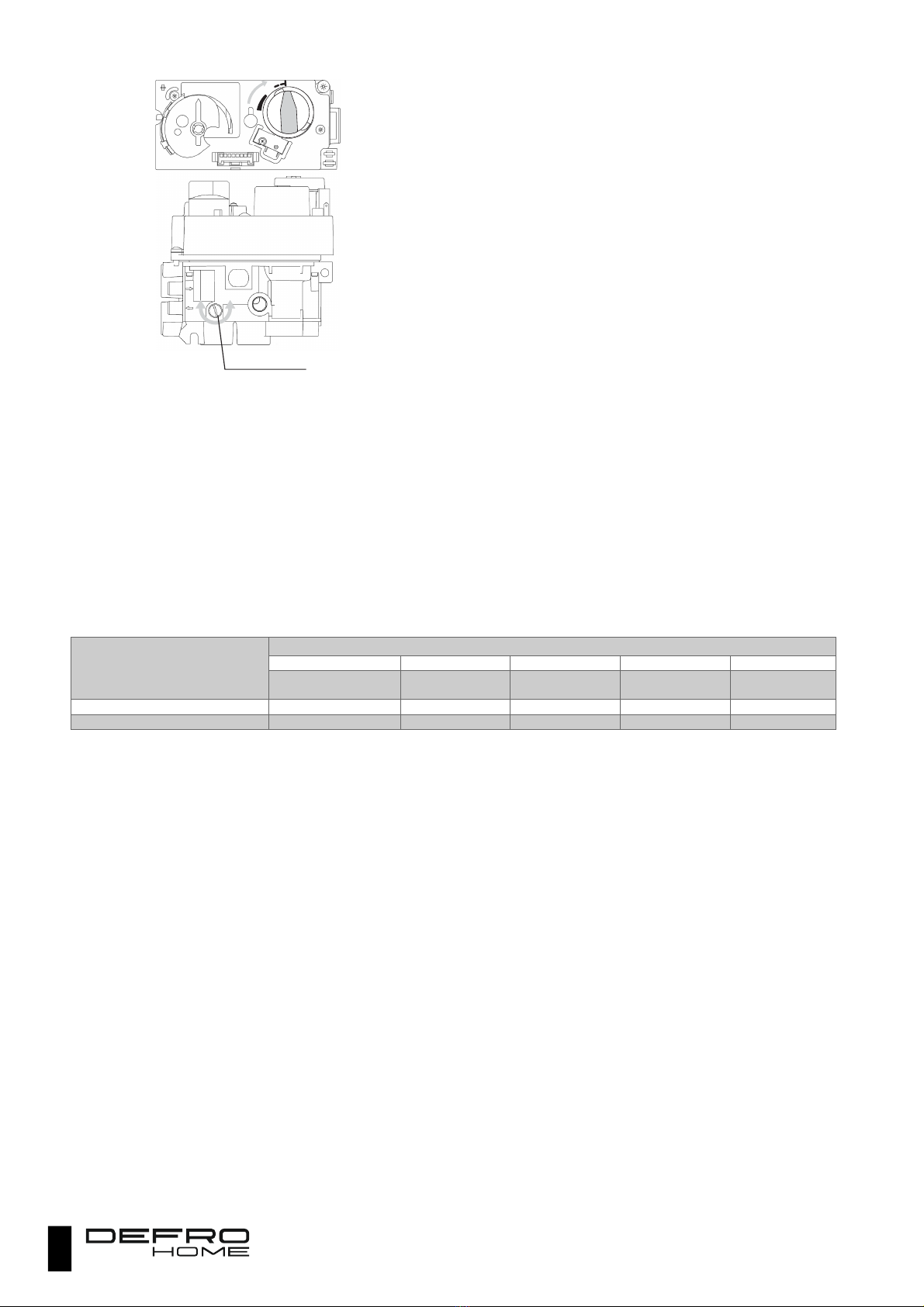

6.6.1. ADJUSTMENT OF FLAME IN THE CONTROL BURNER

The control flame is factor set to the maximum height. To

decrease it:

Set manual mode knob to ON

Pierce the membrane protecting the alignment screw with a

screwdriver

Decrease the flame turning the screw clockwise

Picture 19 Location of screw for adjustment of flame height in the

control burner.

6.6.2. ADJUSTMENT OF GAS EXHAUST PRESSURE

Remove blanking plug from exhaust pressure measurement

opening in the GV60 valve.

Connect a pressure gauge to the measuring point.

Set the main valve knob to ON.

Remove the plastic cap from the screw of pressure regulator.

Adjust the pressure of the primar burner b turning the

screw; clockwise rotation increases the pressure.

When the adjustment has been completed ou should protect

the following fixtures with blanking plugs: pressure control

screw and, after removal of pressure gauge, the opening for

measurement of exhaust pressure.

Picture 20. Location of adjustment screw for gas exhaust pressure.

If there are no effects of adjustment - check exhaust pressure b

connecting the pressure gauge to measuring opening intended for this

pressure. Depending on the measurement, ou should:

If the inlet pressure has a correct value - probabl the valve

is damaged and it should be replaced.

If the inlet pressure is too low - ou should restore the correct

pressure taking the appropriate measures (check the s stem,

contact the gas supplier).

6.6.3. ADJUSTMENT OF MINIMUM HEIGHT OF FLAME OF THE

PRIMARY BURNER

Set the main valve knob to OFF.

Turn the knob clockwise until the valve is open.

Reduce the minimum height of flame of the main burner to

the required value b turning the adjusting screw to the right.

Factor set, minimum height of flame of the main burner is

set to maximum value.

GV60

valve

Receiver

palnik kontroln

control

burner

unit

s

p

a

r

k

i

g

n

i

t

e

r

GV60 valve

and receiver box

8-wire conduct

of receiver

igniter

suppl wire

arrester

gas piping s stem

main burb\ner suppl

ON(I)/OFF(○)

switch

c

o

n

t

a

c

t

of piezoelectric

igniter

2,8x0,8

button

of piezoelektric

igniter

m

a

n

u

a

l

control

of control

burner

pressure

regulator

blanking plug

8-pin

socket

of receiver

mikro-

przełącznik

main

valve

knob (in OFF position)

manual

control

knob

g

as inlet

gas inlet

thermal

flame

arrester

control

burner connector

i

nlet pressure

m

easurement

o

utlet pressure

m

easurement

r

e

g

u

l

a

c

j

a

p

ł

o

m

i

e

n

i

a

p

alnika głównego mounting holes

gas outlet

gas outlet

control flame adjustment screw

ON

MAN

a

d

j

u

s

t

m

e

n

t

s

c

r

e

w

for gas outlet pressure

ON

MAN

14

Picture 21 Position of knob of the main valve and location of screw for

adjustment of main flame.

6.6.4. FINAL OPERATIONS

After connection and making the necessar adjustments ou should:

Check tightness of executed gas connections using a special

detector and, if there are an leaks, shut off the gas suppl

and make these connections once again.

Connect power suppl of the receiver b inserting four AA

batteries.

6.7. TIGHTNESS CONTROL OF THE BALANCED FLUE SYSTEM

After installation of the balanced flue s stem and when the heater

is read for operation, ou should start the equipment at maximum heat

load. Perform measurement of CO2 in the combustion air suppl duct

using flue gas anal ser. If there is no indication of carbon dioxide

presence in the combustion air it means that concentric coaxial pipes

are correctl installed.

6.8. FLUE GAS FLOW DAMPER ADJUSTMENT

After installation of concentric coaxial s stem (acc. to allowed configuration for ducts leading) set the flue gas flow damper in half of opening

position.

Close the window panel and set maximum load of the heater.

Measure ox gen content after 5 minutes.

If the ox gen content deviates from this given in the table, then ou should close the gas suppl to the main burner, leaving the flame of the

control burner.

If the ox gen content is higher than this given in the table, ou should close the opening of flue gas flow damper; if it is lower - increase opening

of flue gas flow damper.

Restore the flame of main burner to maximum value and measure content of ox gen in flue gas.

If the absolute value between the measured content of ox gen in flue gas and the value given in the table does not exceed 0.3% then it ma

be assumed that the flow damper setting is correct.

Tighten the screw to lock the flue gas flow damper position.

Model:

Gas t pe

G20

G27

G2.350

G31

G30

O

2

%

O

2

%

O

2

%

O

2

%

O

2

%

DEFRO HOME VITAL 37

9

.

1

9

.

4

11

.

6

12

.

8

13

.

8

DEFRO HOME VITAL 51

12

.

9

11

.

9

12

.

1

12

.

8

13

.

2

OFF

ON

main flame adjustment screw

15

6.9. CONVERSION TO THE OTHER GAS

Adjustment and conversion to the other gas can be

performed only by the Authorized Service of the

manufacturer.

The rating plate with heater data for the currently used gas

should be always placed on the heater!

If other gas should be used to suppl the heater, then it is required

to perform conversion. These operations can be performed onl b the

authorized service of the manufacturer. The following conversions are

possible:

Heaters adapted for G20 gas can be converted to G27 and

G2.350 gas,

Heaters adapted for G31 can be converted to G30.

The conversion is based on the following operations:

Replacement of nozzle of primar burner with the one

suitable for the used gas,

Screw the bolt in to the burner injector,

Perform adjustment acc. to the instruction in 6.8 choosing

data from table for the required t pe of gas and model of

heater.

After conversion, it is required to stick one of the delivered rating

plates containing information on current t pe of gas.

6.10. INSTALLATION OF THE HEATER

Room heater should be installed in compliance with the

requirements of the currently applicable standards and

legal regulations and detailed regulations of the country

of destination. In Poland these conditions are regu

lated

by the Regulation of the Minister of Infrastructure of 12

April 2002 on technical conditions which should be

fulfilled by buildings and its location. (Journal of Laws

no. 75 of 2002 item 690 as amended).

If the DEFRO HOME VITAL heater is installed

in rooms,

where particularly exposed people (such as children,

physically disabled or people requiring special

attention) may have contact with it, then it is required to

use additional protections. The protections are

intended to prevent contact of expos

ed people with

operating and hot equipment.

Fireplace s stem should be made of non-combustible materials

and its design should allow disassembl of the housing and heater

without an damages.

Installation of the room heater should obe the following safet

rules:

minimum distance 80 mm from side and rear of the non-

flammable materials,

minimum distance 400 mm from side and rear of the medium

inflammable materials,

minimum distance 800 mm from front wall, where the

medium inflammable materials cannot be located,

objects made of highl inflammable materials should be

located in distance minimum 2000 mm from furnace.

If it is not possible to maintain the above indicated distances, then

ou should appl process and building measures to avoid fire hazards.

In case of contact with wooden wall or wall made of other inflammable

material, it is appropriate to insulate flue gas discharge pipe.

In case of floor made of inflammable

materials,

it is

appropriate to prepare a plane protecting the floor and

execute

protection in accordance with the standards

applicable in the given country.

All surfaces of the equipment are wor ing surfaces!

The room heater should be located on a substrate with suitable

load-bearing capacit . In accordance with the Polish Standards each

square meter of the floor slab in a single-famil building should transfer

load of 150 kg. If this condition is fulfilled, the room heater

manufactured b DEFRO can be installed without needing to reinforce

the floor slab.

Nonetheless, if ou are not sure about design of floor slab, where

the heater is to be installed, ou should absolutel contact with building

designer to reinforce the floor slab or execute special structure

distributing the weight on larger area.

The s stem, where the gas-fired room heater is installed, should

be equipped with air suppl and exhaust grilles of corresponding

surfaces. The are intended to ensure heat transfer between the

fireplace and the room. Suppl grille should be located in bottom part

of the s stem to ensure suppl of the cold air from the room. Exhaust

grille should be located in hood. For DEFRO HOME VITAL the size of

suppl grille should be lower than 700 cm2 and 900 m2 for exhaust

grille.

The room, where the DEFRO HOME VITAL room heater has been

installed, should also be equipped with a suppl /return grille to ensure

exhaust of gas in the case of leaks in the gas piping s stem. In the

s stem, the exhaust grille should be located in a place depending on

the fuel used in the fireplace.

For natural gas (NG) the grille should be located under the

ceiling.

For propane-butane (LPG) the grille should be located near

the floor, above the ground level.

Picture 22. Minimum distance that should be kept during installation of

the heater.

ATTENTION!!!

Lac of expansion joint may be a reason of equipment damage

what is connected with loss of the warranty rights.

6.11. FIRST START-UP

Perform lea -tightness test of gas connections to the gas

unit and from gas unit to gas nozzle during operation of the

equipment before first start-up.

First start-up should be performed b the fitter after checking

correctness of installation.

Odour of paint from the bod will be released during the first

several hours of combustion. This is completel normal. You should

strongl vent the room at that time. Check tightness of joints once again

when equipment has been cooled down.

80 mm

housing

insulation made

of non-combustile materials

facade

of fireplace insert

w

a

l

l

80 mm

8

0

m

m

20-30 mm

16

Housing components will be very hot during operation.

You must exercise caution.

Frequent venting of the room, where the heater has

been i

nstalled, remove unpleasant odour emitted at the

beginning of operation and allows avoiding staining of

walls and ceiling by lifted dust.

7. OPERATION

Operation of the gas fireplace is controlled via the remote control.

Equipment can also be controlled in full manual mode.

7.1. SAFETY RULES

During use of the gas-fired heater DEFRO HOME VITAL ou

should remember about the following safet rules.

1. It is forbidden to start the device without window panel

installed.

2. If the window panel is crac ed or damaged, the

equipment should be shutdown and the panel should

be immediately replaced.

3. Do not place flammable items near the equipment

(furniture, cloths, etc.)

4. Do not touch the hot parts of the fireplace (in particular

- window panel) during operation.

5. Do not place the flammable materials in the fireplace

chamber.

6. Do not leave children, physically disabled people or

person unaware of danger unattended near the

operating equipment.

7. Do not start the equipment if the gas escapes.

8. If the fireplace operates incorrectly, it is required to

shut off the gas supply and contact the authorized

service.

9. It is forbidden to lay decorative items on the opposite

side of the control burner.

10. If the control flame goes out you can retry firing after 5

minutes.

7.2. PREPARATION

User controls operation of the DEFRO HOME VITAL heater via the

B6R-H8TV4PBD remote control equipped with 8 buttons. To allow

controlling the fireplace with a remote control, it is required to prepare

it for operation:

Open the gas shut-off valve to the fireplace in control cabinet.

If the s stem is equipped with a cable with changeover switch

then it should be set in switched on position what will result

in switching of knob of the main valve.

Set the manual control knob to “ON”.

Make sure that four (4) AA batteries have been correctl

installed in the receiver.

Remote control operating at the 868 MHz band also requires

preparation. You should enter the transmission code:

Insert two AAA 1.5V batteries to the remote control.

Press and hold the RESET button using a thin metal item

until ou hear two distinctive sounds.

Press and hold button on the remote control until

confirmation with two audible signals.

If one, long signal will be emitted during s nchronisation, then

ou should repeat operations, because the connection, using

code, between the devices have not been established.

7.3. INFORMATION

Simultaneous pressing of and buttons on the remote control

results displa s information on current version of software. Information

of the remote control model used can be obtained pressing the buttons

and .

7.4. DEACTIVATION OF REMOTE CONTROL FUNCTION

1. Insert batteries. All icons on the displa will be flashing.

2. When icons are flashing, press the button corresponding to

the function and press it for 10 seconds.

3. When the icon stops flashing deactivation has been

finished. Function icon will be displa ed with two horizontal

lines.

7.5. ACTIVATION OF REMOTE CONTROL FUNCTION

1. Insert batteries. All icons on the displa will be flashing.

2. When icons are flashing, press the button corresponding to

the function and press it for 10 seconds.

3. When the icon stops flashing, activation has been finished.

Function icon will be displa ed as normal (without two

vertical lines).

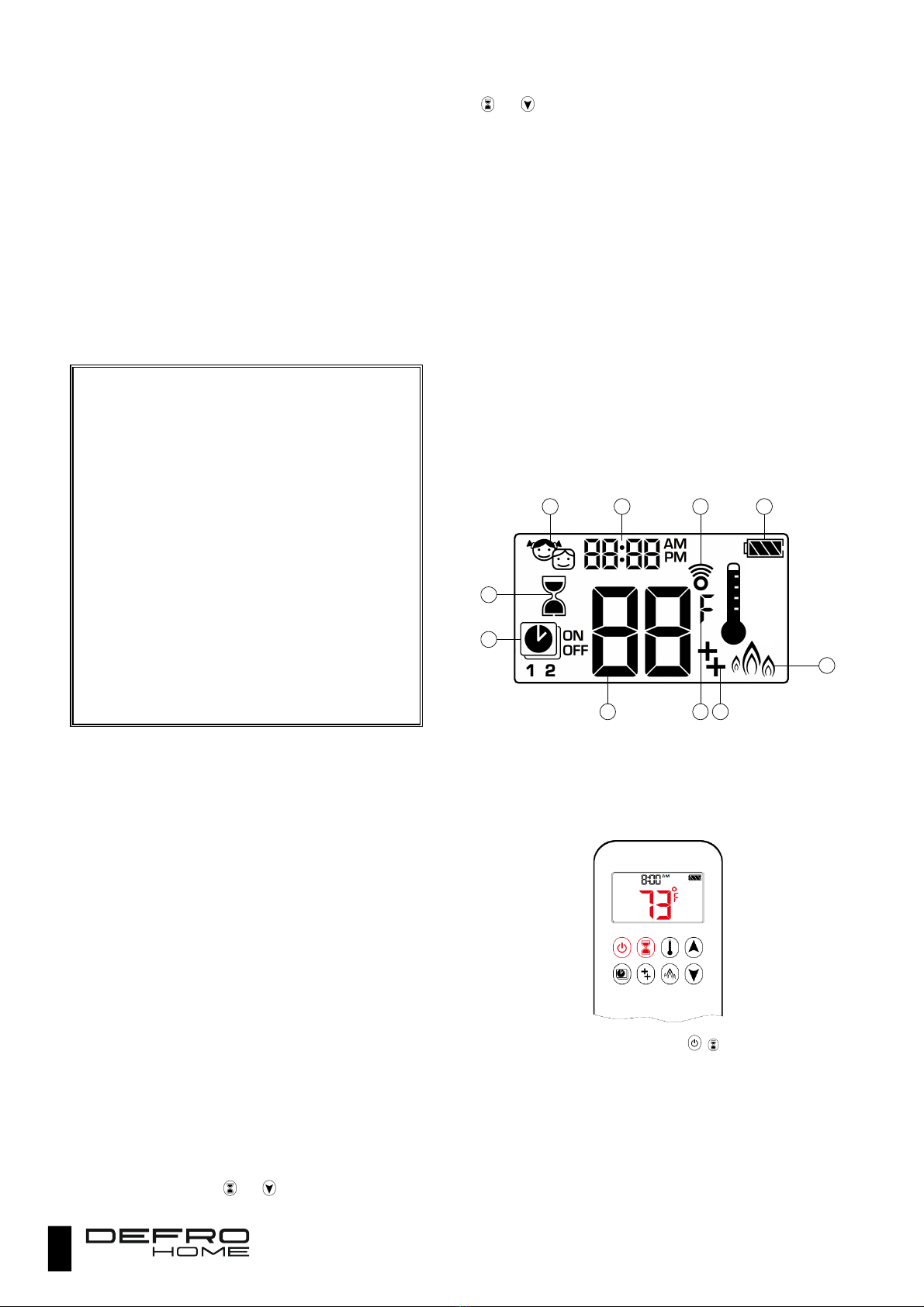

7.6. CONTROL OF FIREPLACE WITH A REMOTE CONTROL

DEFRO HOME VITAL heater is controlled via the 8-button remote

control. The picture presents the remote control screen with a

description of icons and s mbols.

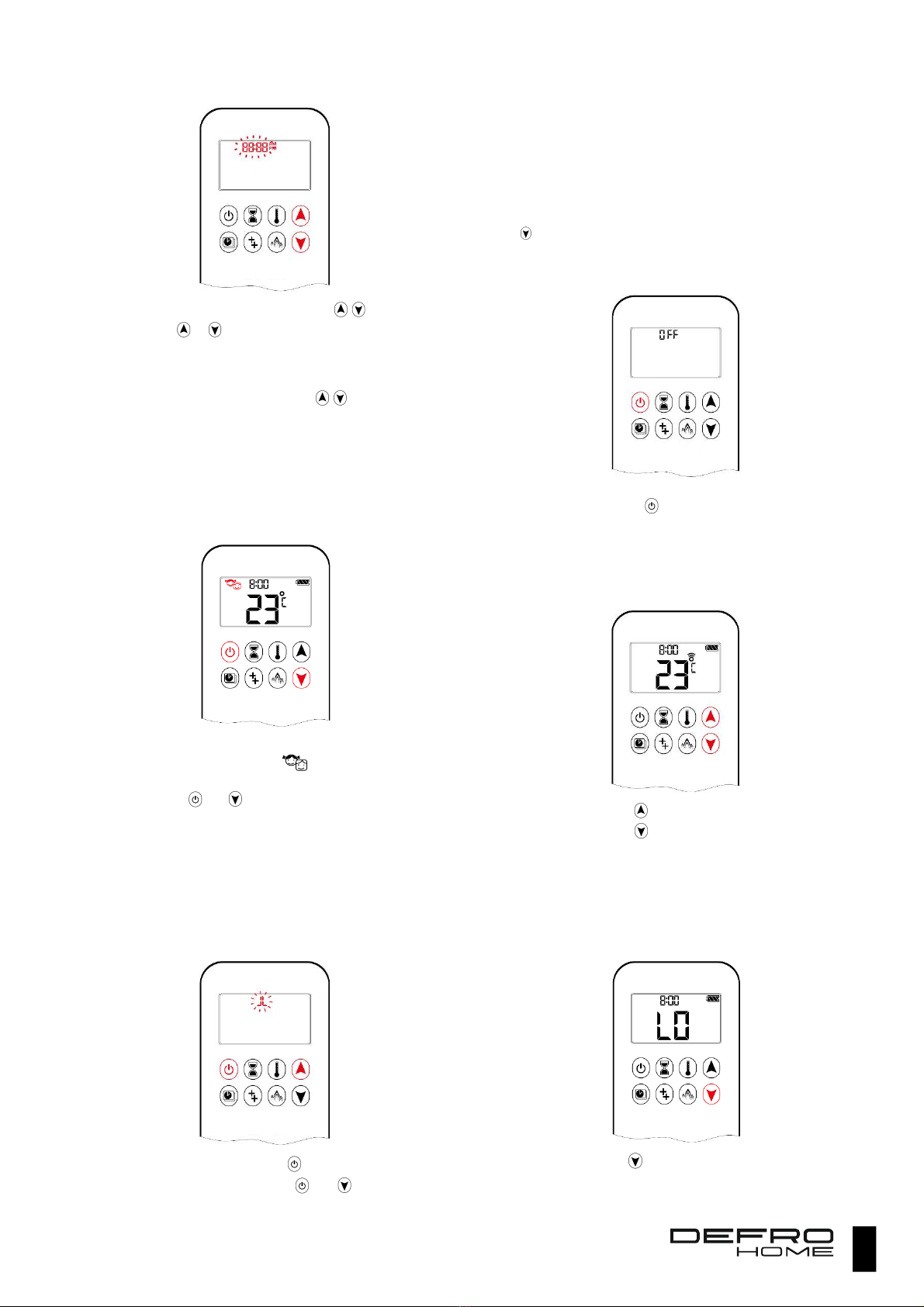

Picture 23. Remote control display screen.

1 - parental lock 2 - time 3 - signal indicator 4 - battery condition 5 -

temperature 6 - timer 7 - programme mode 8 - economy mode 9 -

additional functions 10 - temperature unit.

7.6.1. SETTING TEMPERATURE UNITS

Press both buttons at the same time: . This will change the

temperature units from ⁰C to ⁰F or from ⁰F to ⁰C.

1

6

7

2 3 4

10 95

8

17

7.6.2. TIME SETTINGS

Press both buttons at the same time: .

Using or button select the number for the given da ,

e.g. 1 - Monda , 2 - Tuesda etc.).

Confirm the da b simultaneous pressing of two buttons as

in item 1. Hour field will start flashing.

Select current hour using buttons .

Confirm selected hour b simultaneous pressing of both

buttons. Minutes field will start flashing.

Set the current minute using buttons. Confirm settings with

simultaneous pressing of both buttons or wait for a while.

7.7. PARENTAL LOCK

In parental lock mode onl the switch off button is active.

Press both red buttons simultaneousl to activate the lock.

Lock icon will be displa ed .

The lock is switched off b simultaneous pressing of both

buttons: and .

7.7.1. FIRING UP IN MANUAL MODE

Before manual ignition of the chimne initiated from the remote

control, please make sure that:

MANUAL knob on GV60 valve is in ON position (full rotation

- counterclockwise).

If the ON/OFF switch is part of the equipment, it should be

set to I(ON) position.

Press and hold the button (firing with one button) on

remote control or two button and at the same time

(firing up with two buttons) until two short audible signals will

be heard and an icon confirming the ignition will be flashing

on the displa . Release the buttons.

The gas will flow to the primar burner after confirmation of

ignition.

Remote control automaticall switches to manual control

mode.

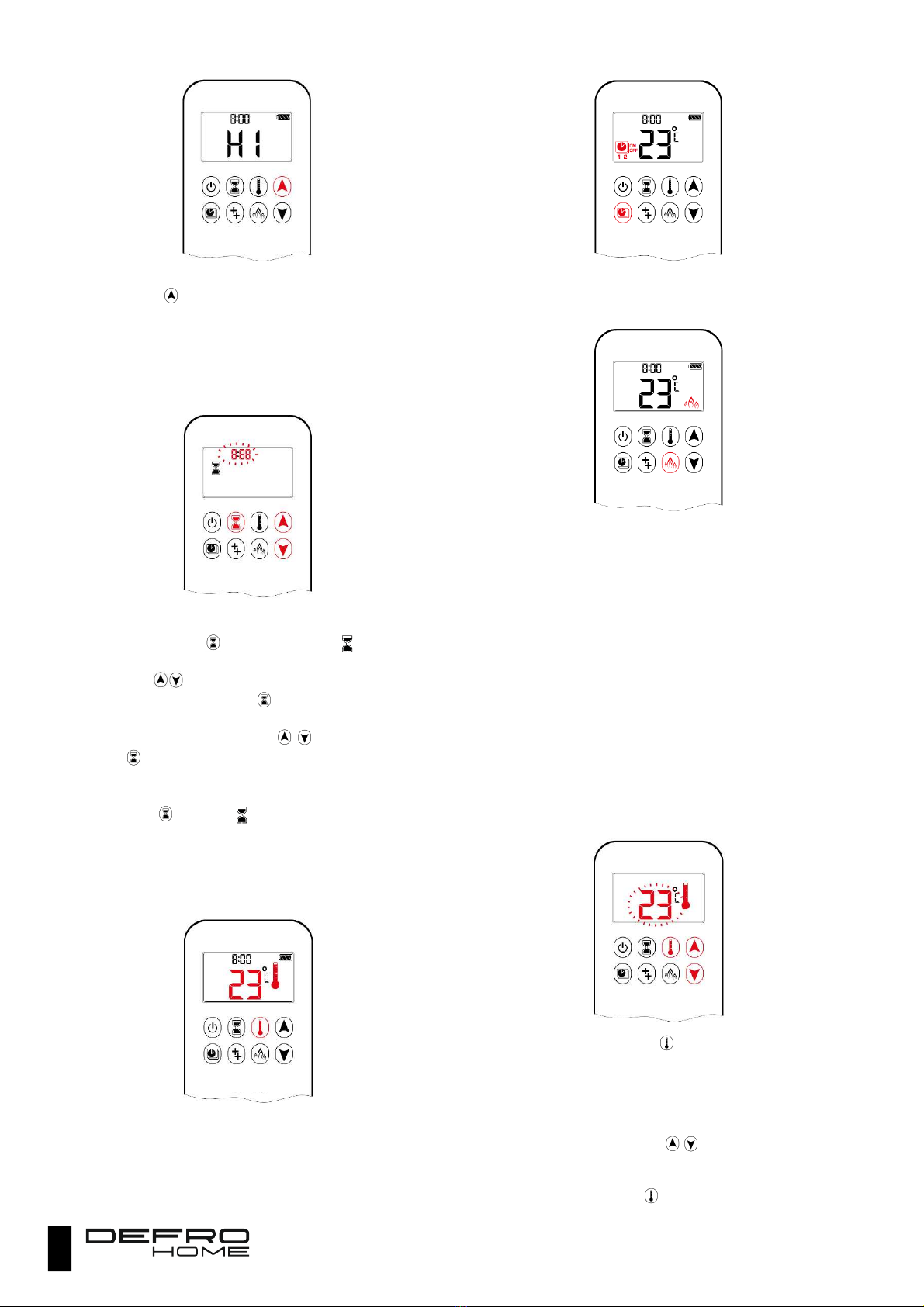

7.7.2. STANDBY MODE

The equipment goes to standb mode after pressing and holding

the button, what results in damping of the primar burner and

maintaining the flame onl in control burner.

7.7.3. FIREPLACE SHUTDOWN

Press the button to switch off the heater, what will be

confirmed b displa ing the OFF text on the remote control

displa .

Attention! Next firing up is possible when OFF stops flashing.

7.7.4. ADJUSTMENT OF FLAME HEIGHT

Press and hold button to increase flame height.

Press and hold button to decrease flame height.

7.7.5. ADJUSTMENT OF LIMIT HEIGHTS FOR THE FLAME

Remote control allows setting maximum or minimum height of the

flame.

Attention! Switch to minimum flame is preceded by its

instantaneous increase.

Double click the button to decrease the flame to

minimum height. Confirmation of executed operation is LO

text displa ed on the screen.

18

Increase to maximum flame height takes place after double

click of button, what is confirmed with HI message.

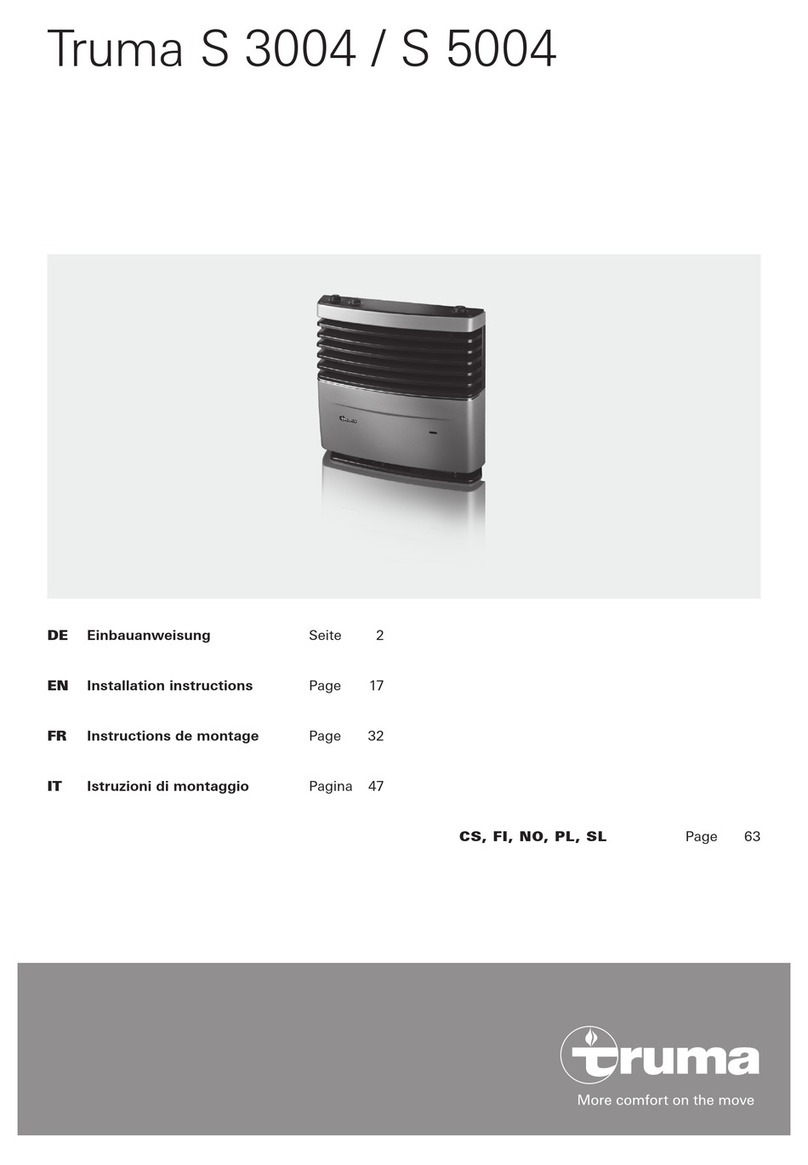

7.7.6. TIMER

Timer operates in Manual, Thermostatic and Eco(nom ) mode.

Flame in the fireplace is damped after the set time has elapsed.

Maximum countdown time until damping is 9 hours and 50

minutes.

Timer switch on

Press and hold the button until an icon will appear on

the screen, and the hour field of the counter start flashing.

Use buttons to set hours of fireplace operation.

Confirm the setting with button. Minute field will start

flashing.

Set additional minutes using buttons. Confirm with

button.

Timer switch off

Press button, icon and counter will disappear from the

remote control screen and counting will be cancelled.

7.7.7. OPERATING MODES

The heater ma operate in one of three modes (buttons activating

the given mode are red on the pictures):

Thermostatic mode is based on measurement of room

temperature where the heater is located and control of flame

height so as to maintain the temperature set in the controller.

Programmed mode is one of two programs set, which

specif when the heater should operate and what

temperature should be maintained.

Eco mode controls the fireplace so as to maintain the set

temperature, but in the more economical wa . The controller

forces maximum height of the flame if the temperature is too

low. If the temperature is too high, then the minimum flame

will be set. One c cle lasts approx. 20 minutes.

7.7.8. THERMOSTATIC MODE

In thermostatic mode, ambient temperature is compared with a

thermostat temperature and the fireplace power is modulated

correspondingl to the difference of both temperatures. Ambient

temperature is measured b a sensor installed in the remote control,

therefore it should not be subjected to additional heat e.g. b exposing

it to the direct sunlight. If the temperature of the remote control exceeds

the ambient temperature, then measuring errors will cause cold spots

in the room.

Attention!!!

Do not store the remote control near the fireplace or in a place

exposed to sunlight.

Switch the mode on with button. A thermometer icon will

be displa ed on the screen. Set temperature will be displa ed

next to this icon for a while and then room temperature will

be shown.

Press and hold the button with thermometer until

thermometer icon starts flashing.

Set the temperature using buttons.

Confirm the temperature using button with thermometer.

The mode is switched off after ou:

o Press the button.

19

o Press the buttons.

o Press the buttons causing switch to the other

modes or .

7.7.9. PROGRAM MODE

The program mode allows setting fireplace operating times for

each da of the week. The heater switches on during operation when

ambient temperature is lower than set switch on temperature and it

switches off after reaching the switch off temperature.

Switch on temperature is the same temperature, which has been

set in the thermostatic mode. So, onl switch off temperature and

operation times are configured after selection of the program mode.

Default values of temperatures:

Switch on temperature 21⁰C,

Switch off temperature: ”--” (onl control flame).

Switch on the mode using button, the following icons will

be shown on the displa :

Temperature configuration:

o Press and hold until the flashing icon will

be displa ed. ON message and switch on

temperature will be displa ed (temperature set in

thermostatic mode),

o To set the switch off temperature, ou should

press or wait a while . OFF message will be

displa ed and temperature will flash.

o Select required temperature with buttons.

o Confirm the with button.

Configuration of operation times:

o The ALL. message should flash on the displa

after confirmation of switch off temperature.

o Pressing selection ke s, ou can switch

between the da s of the week:

ALL – one setting for all da s

SA:SU – separate setting for

Saturda and Sunda

1, 2, 3, 4, 5, 6, 7 – separate settings

for each da of the week (Dail

Timer).

Confirm the selection with a ke . The s stem waits for

configuration of switch on time in the next step.

Mode ALL

Configuration of program switch on time no. 1:

Icon and s mbols 1, ON will be displa ed, message ALL

will be shown for a while and hours field will flash.

Select switch on hour using the buttons

Confirm the hour with . ALL will be displa ed once again

for a while and minutes field will be flashing.

Select minutes using buttons.

Confirm the setting once again with the button . The

s stem will go to configuration of switch off time.

Switch off time configuration:

o The displa will show, except the icon, 1, OFF,

message ALL and flashing hours field.

o Select the hour with the selection buttons.

o Confirm with button. ALL will be displa ed

once again for a while and minutes field will be

flashing.

o Set the minutes using buttons.

o Confirm with button. The s stem will go to

configuration of program no. 2 in the same wa as

for no. 1.

If ou want to avoid configuring program no. 2 - stop entering

the times and program no. 2 will remain inactive.

Mode SA:SU or Daily Timer

Switch on and switch off times are set in the same wa as in

ALL mode

For SA:SU mode ou set one switch on and switch off time

for both da s at the same time.

In Dail Timer mode the unique switch on and switch off times

can be set for one, selected da , several da s or for each da

of the week.

Notes!!!

Program no. 1 and no. 2 uses the same setting of switch on and

switch off temperature setting for each mode. Change of both

temperatures in thermostatic mode results in setting both these

values are new default values and they become switch on and

switch off temperatures for the programmed mode.

Configuration of the switch on and switch off times for the

Programs no. 1 and no. 2 causes that they will become new default

values. Restoring the factory settings for both programmes ta e

place after resetting the remote control by ta ing the batteries out.

7.7.10. ECO MODE

Press button to switch on Eco mode, an icon will be

shown on the displa .

Press button once again to switch off the Eco mode.

7.7.11. BEHAVIOR OF FIREPLACE WHEN THERE IS NO SIGNAL

FROM THE REMOTE CONTROL

The flame will be automaticall reduced to minimum level if there

is no command from remote control within six (6) hours. The control

s stem will shutdown the equipment and shut off the gas suppl if the

20

fireplace operates continuousl without supervision for five (5)

successive da s.

7.8. POWER SUPPLY AND BATTERY REPLACEMENT

If you hear the signal indicating that the batteries are

discharged, it is required to replace them or remove the

worn out pieces if you plan to decommission the heater

.

Do not leave discharged batteries in the remote control

or receiver because it may lead to destruction of both

devices if their contents flow out.

Do not use accumulators to supply the receiver!

Use only appropriate type of batteries for the receiver

and remote control

Batteries used to suppl remote control and s stem of the receiver

are discharged during operation. Both devices inform about discharge

of the batteries. The remote control is equipped with a batter condition

indication icon. The receiver indicates that batter level is low with three

(3) audio signals. If the user does not replace the batter before the

are completel discharged, then the receiver will cut off the gas suppl

to the fireplace.

The receiver can be connected to the power suppl unit operating

at 4.5V connected to the AC network. It is forbidden to use the batteries

if the power suppl unit is in operation. Remove them from the chamber

in the receiver!

7.8.1. BATTERY REPLACEMENT IN THE REMOTE CONTROL

Reverse the remote control and remove the cover.

Remove discharged batteries.

Insert AAA batteries acc. to the designation available in

batter compartment.

Install cover.

7.8.2. BATTERY REPLACEMENT IN THE RECEIVER

Remove cover from the receiver.

Remove discharged batteries.

Insert AA batteries into the recess acc. to the designations.

Install cover.

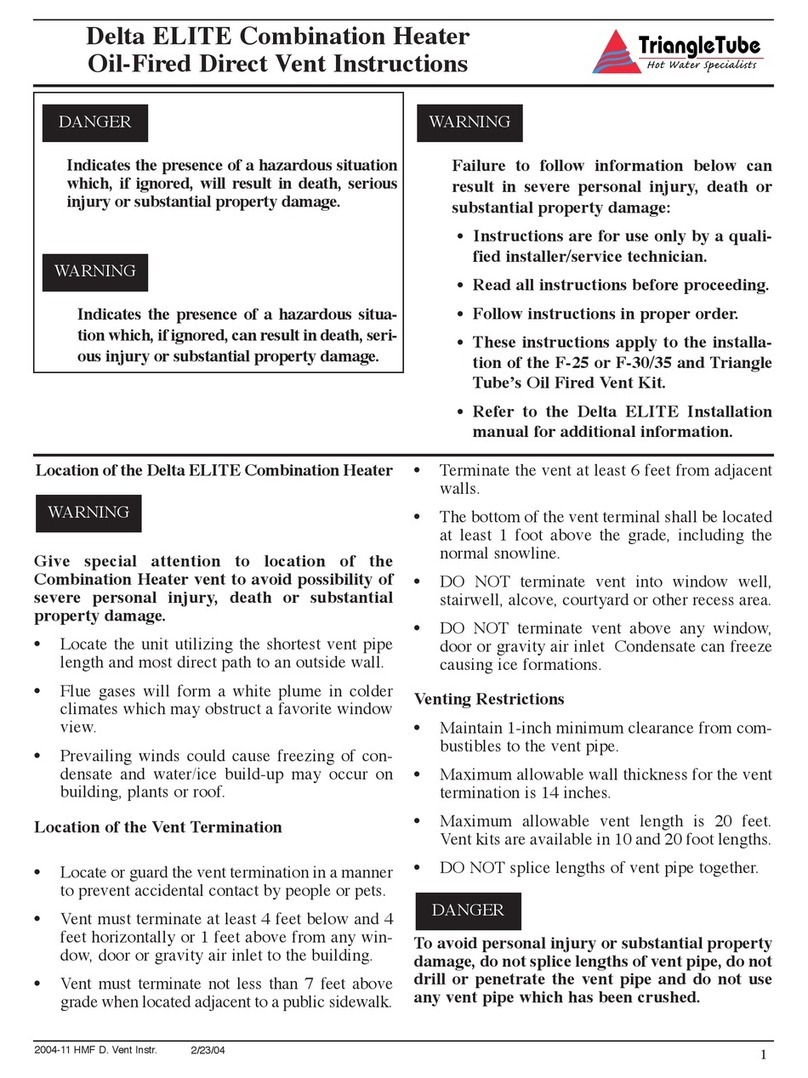

7.9. MANUAL CONTROL OF FIREPLACE

Gas-fired heater can be operated also without remote control in

manual control mode. All operations are then performed directl from

the GV60 valve level located inside the cabinet. Control components

used during manual control are presented on the picture 24.

To perform manual firing up of the fireplace ou should disconnect

cable of spark igniter from receiver module and connect it directl to

the GV60 valve, to contact of piezoelectric igniter (1 on picture 14).

7.9.1. FIRING UP

Open gas suppl valve.

If the ON/OFF switch is installed (3 on picture 24) then set it

to ON position (press s mbol I)

Turn the control knob of the main burner clockwise to the

max. position (4 on picture 24)

Set manual control knob to MAN (2 on picture 24).

This position uncovers a metal button (5 on picture 24) in the

bigger opening of the knob, which should be pressed and

held to suppl gas to the control burner.

Press several times square button of piezoelectric spark

igniter (6 on picture 24) while still pressing the metal button

until control burner ignites.

Press the metal button for another 10 seconds until control

flame appears.

If the control flame goes out before the next manual ignition

attempt, the process can be repeated after 5 minutes of wait.

Set control knob to ON (2 on picture 24). The primar burner

should ignite if the primar burner knob is not set to OFF.

Set flame size using the control knob of primar burner (4 on

picture 24)

Picture 24. Arrangement of controls required for manual control of

fireplace.

7.9.2. DAMPING A FLAME OF THE PRIMARY BURNER

Turn the control knob of primar burner (4 on picture 24) to

the right until a distinctive click will be heard. The primar