DEGREE CONTROLS B-Series User manual

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 1

B-Series Air Velocity Sensors

User Guide

DEGREE CONTROLS, INCORPORATED

18 Meadowbrook Drive

Milford, New Hampshire 03055 USA

Degree Controls, Inc. © Copyright 2018, all rights reserved.

Information in this document is subject to change without notice.

Windows® is a registered trademark of Microsoft Corporation • All other trademarks are property of their respective owners.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 2

Table of Contents

1General Information ................................................................................................................................................................................................ 3

1.1 Overview ...................................................................................................................................................................................................................3

1.2 Features.....................................................................................................................................................................................................................3

1.2.2 Electrical & Performance Features..................................................................................................................................................................3

1.2.1 Mechanical Features .......................................................................................................................................................................................3

2Product Specifications..............................................................................................................................................................................................4

2.1 General Specifications ...............................................................................................................................................................................................4

2.2 Model Specifications .................................................................................................................................................................................................5

2.3 Hardware Configuration............................................................................................................................................................................................5

3Wiring Information ..................................................................................................................................................................................................6

3.1 Configured with Analog Output and UART Digital Communication...........................................................................................................................6

3.2 Configured Only with UART Output ..........................................................................................................................................................................6

3.3 Configured Only with I2C Output...............................................................................................................................................................................6

4Mechanical Information...........................................................................................................................................................................................7

4.1 Probe Sensor Head Mechanical Drawings .................................................................................................................................................................7

4.2 °C Clamp Mechanical Drawing...................................................................................................................................................................................7

5Mounting and Positioning ........................................................................................................................................................................................ 8

5.1 Probe Style Sensors: B300/B500 ...............................................................................................................................................................................8

5.1.1 Gland Installation ............................................................................................................................................................................................8

5.1.2 °C Clamp Installation.......................................................................................................................................................................................9

5.1.3 Airflow Direction ...........................................................................................................................................................................................10

6Communication...................................................................................................................................................................................................... 10

6.1 UART........................................................................................................................................................................................................................10

6.1.1 Hardware.......................................................................................................................................................................................................11

6.1.2 Configuration ................................................................................................................................................................................................11

6.2 I2C............................................................................................................................................................................................................................12

6.2.1 Configuration ................................................................................................................................................................................................12

6.3 Velocity Analog Output (Voltage)............................................................................................................................................................................13

6.3.1 Velocity Analog Output (Voltage) Example ...................................................................................................................................................15

6.4 Velocity Analog Output (Current)............................................................................................................................................................................16

6.4.1 0-20 mA.........................................................................................................................................................................................................16

6.4.2 4-20 mA.........................................................................................................................................................................................................16

6.4.3 Velocity Analog Output (Current) Example ...................................................................................................................................................17

6.5 Temperature Analog Output ...................................................................................................................................................................................17

6.5.1 Temperature Analog Example.......................................................................................................................................................................18

7Sensor Registers..................................................................................................................................................................................................... 19

7.1 Memory Map...........................................................................................................................................................................................................19

8Degree Controls Inc. Product Warranty .................................................................................................................................................................. 23

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 3

1 General Information

1.1 Overview

Thank you for your purchase of a DegreeC B-Series Sensor,

a versatile and rugged, high-performance air velocity sensor

that measures real-time air velocity and directionality values in

both analog and digital communication outputs.

Designed with conformal coated electronics and sealed enclosures, our Sensor Products are suitable for demanding

applications, including those in corrosive or alkaline environments. With their robust, splash proof design and UV

tolerant construction, the B-Series sensors are designed to handle a wide range of product and process control air flow

applications. Additionally, the B-Series is configured to order, with a variety of velocity ranges, mechanical lengths, and

output communication styles available.

1.2 Features

1.2.1 Mechanical Features

• Two available mounting styles: Standard clamp

or special gland fitting used for mounting sensor

assembly, without need for screws, or hands

inside the duct.

• Optimized flow geometry with segregation of

velocity and temperature elements for highest

accuracy.

• Aerodynamic cross section to minimize flow

disturbance.

• Robust, sealed probe assembly uses corrosion

and UV resistant materials.

• Printed insertion depth markers and flow

direction arrow.

• Conformal coated sensing elements for

environmental protection.

• Plenum-rated cabling suitable for HVAC,

laboratory and process control applications.

• Remote head models available for compact

applications or design-in embedded sensing

needs.

• RoHS compliant

• Certified European (CE)

1.2.2 Electrical & Performance Features

• Industry-leading air velocity performance, with

repeatability within ±1%.

• Quick Average velocity reading for fastest

control system response.

• Wide voltage input options 4.5 –15VDC or

24VAC/DC.

• Multiple digital outputs available.

• Multi-sensor addressing capability.

• Intelligent, built-in customizable

averaging/smoothing functions.

• <10 second start-up time and 400ms response

time.

• May be configured as an airflow switch with

open drain output.

• Both air velocity and temperature analog

outputs may be configured as voltage or

current.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 4

2 Product Specifications

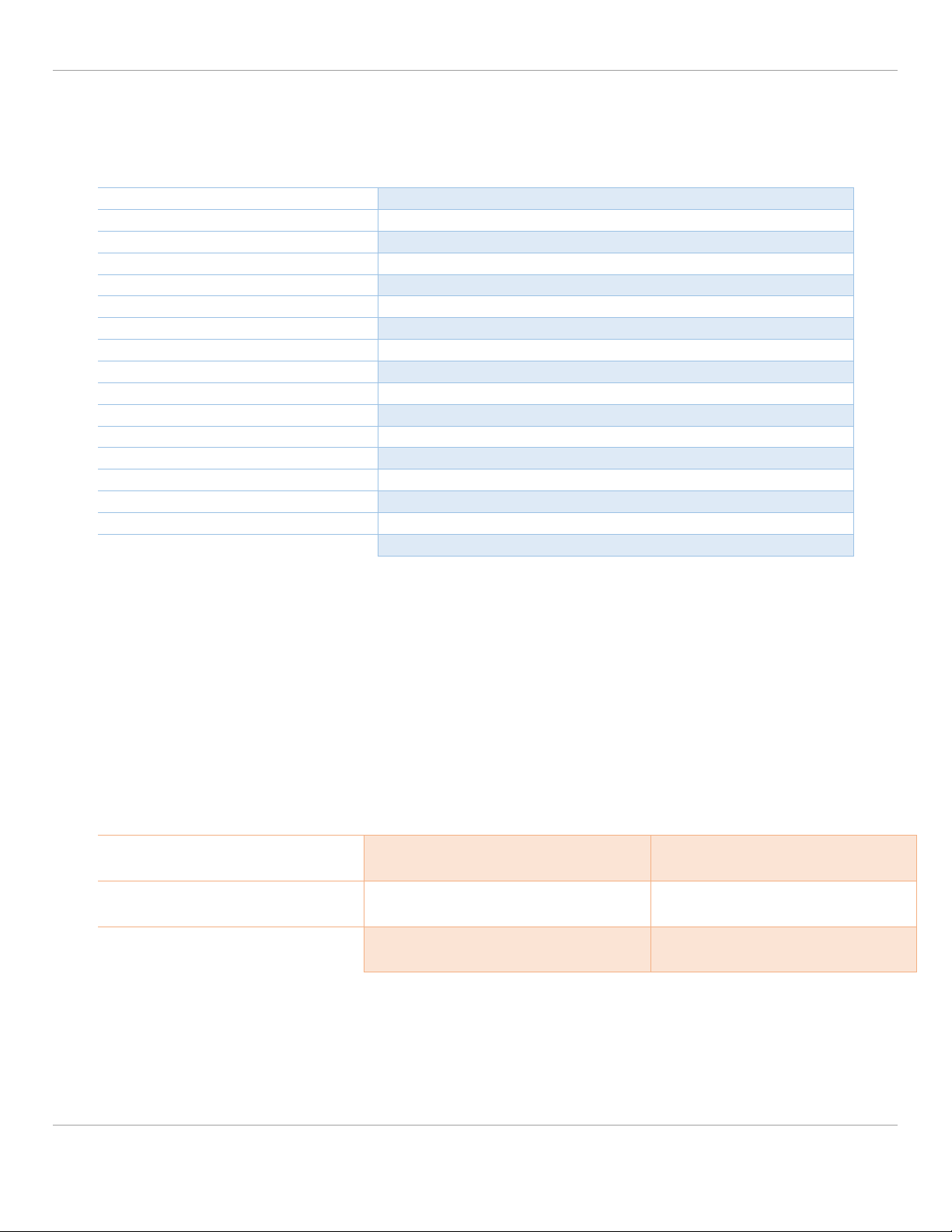

2.1 General Specifications

Operating Temperature

0°C to 60°C (32°F to 140°F)

Storage Temperature

-40°C to 105°C (-40°F - 221°F)

Air Velocity Range

-20m/s to +20m/s (-4000 fpm to +4000 fpm)

Relative Humidity

5 –95%

Repeatability

± 1% of reading (under identical conditions)

Temperature Accuracy

± 1°C*

Response Time

400ms

Airflow Averaging Time

Configurable (3 second default)

Start-up Time

<10 s

Velocity & Temperature Output

0-5V or 0-10V, 0-20mA or 4-20mA output

Digital Output

UART or I2C available for flow and temperature info.

Alarm Output

Open drain, configurable trip point

Communication

I2C (400KHz) or 3.3V UART

Cable Length

2 m (6 ft.)

Housing Construction

Polycarbonate (PC), UL94-V0 (head), UL94-HB (housing)

Plenum Rated Cable

22 AWG

Environmental Protection

IP65 electronics, including conformal coated sensing element

Standard Dimension

Selectable lengths (See Section 2.3, Length)

*The air velocity sensor uses a hot bead algorithm, and at low velocities, the error in air temperature measuring grows due to self-

heating effects. The air temperature accuracy is specified as a function of velocity:

at velocities > 0.5 m/s [100 fpm] = ±1 ˚ C [1.8 ˚ F]

at velocities < 0.5 m/s [100 fpm] = ±2 ˚ C [3.6 ˚ F]

Temperature Compensation: The B-Series is a thermal airflow sensor; it is sensitive to changes in air density and indicates velocity

with reference to a set of standard conditions (21°C (70°F), 760mmHg (101.325kPa), and 0%RH). The B-Series has been designed so

that when used over the stated temperature compensation range, the sensor indicates very close to actual air velocity and minimal

compensation is only required to account for changes in barometric pressure or altitude.

Range

Accuracy*

Deadband**

-1.0 to 1.0 m/s (-200 to 200 fpm)

± (1% of reading + 0.05 m/s [10 fpm])

-0.15 to 0.15 m/s (-30 to 30 fpm)

-10 to 10 m/s (-2,000 to 2,000 fpm)

± (4% of reading + 0.10 m/s [20 fpm])

-0.5 to 0.5 m/s (-100 to 100 fpm)

-20 to 20 m/s (-4,000 to 4,000 fpm)

± (5% of reading + 0.15 m/s [30 fpm])

-1.0 to 1.0 m/s (-200 to 200 fpm)

*within compensation range

**range of velocities where the direction and velocity are not discernible by the sensor

General Specifications Table 1: Air Velocity Performance

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 5

2.2 Model Specifications

Degree Controls offers two models of the B-Series Air Velocity Sensor. The choice of model depends on the user’s

voltage range and current requirements, as noted below:

Name

Input Voltage Range

Current Consumption

B300

4.5 –15VDC

< 100mA nominal @ 12V

B500

24VAC/DC ± 20%

< 65mA nominal @ 24V

Model Specifications Table 1: Input Voltage Range & Current Consumption

2.3 Hardware Configuration

Length

1 = 203mm [8.0”]

max insertion depth = 160mm [6.3”]

2 = 305mm [12.0”]

max insertion depth = 263mm [10.4”]

Velocity Profile

A = -1.0 to 1.0 m/s (-200 to 200 fpm)

B = -10 to 10 m/s (-2,000 to 2,000 fpm)

C = -20 to 20 m/s (-4,000 to 4,000 fpm)

Output Configuration

1 = 0 –5 VDC air velocity output

2 = 0 –5 VDC air velocity and air temperature (dual

outputs)

3 = 0 –10 VDC air velocity output

4 = 0 –10 VDC air velocity and air temperature (dual

outputs)

5 = 0 - 20 mA air velocity

6 = 0 - 20 mA air velocity and air temperature (dual

outputs)

7 = 4-20 mA air velocity

8 = 4-20 mA air velocity and air temperature (dual

outputs)

9 = UART communication

Hardware Configuration Table 1: Ordering Information

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 6

3 Wiring Information

3.1 Configured with Analog Output and UART Digital Communication

Wire Color

Wire Gauge

Description

Red

22 AWG

Power

Black

Ground

White

Velocity Analog Output

Green*

Temperature Analog Output

Orange

UART Receive (RX)

Blue

UART Transmit (TX)

Brown**

Open Drain Alarm

*Only for dual analog

**While the B300 and B500 can be configured as open drain switches; please see the Switch Series manual for

purpose-built airflow switches.

3.2 Configured Only with UART Output

Wire Color

Wire Gauge

Description

Red

22 AWG

Power

Black

Ground

White

UART Receive (RX)

Green

UART Transmit (TX)

3.3 Configured Only with I2C Output

Wire Color

Wire Gauge

Description

Red

22 AWG

Power

Black

Ground

White

SCL

Green

SDA

Notes:

1. For I2C communication, external pull-up resistors to +3.3V for SDA and SCL are required. The B300/B500

does not have internal pull-up resistors.

2. For RS232 communication, an external level shifter is required to convert 3.3V TTL to RS232 voltage

levels. The B300/B500 RX and TX signals are 3.3V TTL.

Caution:

The B300/500 sensors do not have polarity protection. Do not connect positive voltage to ground lead.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 7

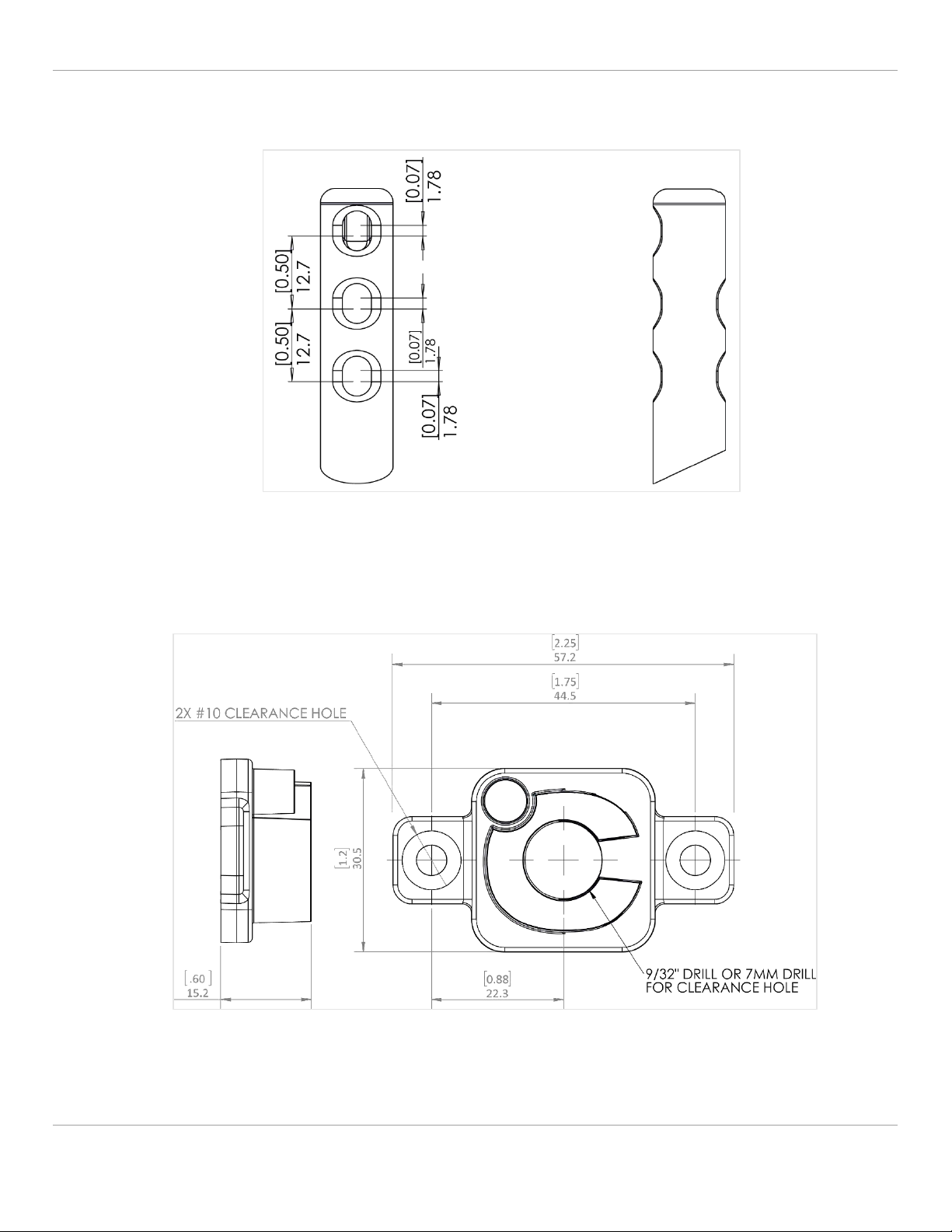

4 Mechanical Information

4.1 Probe Sensor Head Mechanical Drawings

4.2 °C Clamp Mechanical Drawing

Mechanical Figure 2: °C Clamp

Note: [inch]mm

Mechanical Figure 1: B-Series Sensor Head

Note: [inch]mm

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 8

5 Mounting and Positioning

5.1 Probe Style Sensors: B300/B500

Mounting Figure 1: Sensor Dimensions

Note: Multiple sensor lengths are available to accommodate insertion depths of 30mm [1.25"] to 245mm [9.6"]. See Mounting

Figure 1 above for insertion "zero point" datum.

The B-Series Sensor utilizes either a °C Clamp or Gland fitting for installation. Please follow the below instructions for

optimal installation:

5.1.1 Gland Installation

1. Drill a 7/8” 0.75” (20mm) hole into the surface you wish to install the Sensor into.

• Follow the below instructions to install the Sensor via Gland Fitting.

2. Adjust the Sensor’s insertion depth (use the printed ruler on the

Sensor’s body for reference), and tighten the gland nut onto

the Sensor body (“A” in Figure 2 below).

3. Insert the Sensor into the drilled hole wider flange first

(“B” in Figure 2 below), then rotate into position, ensuring that the

sensor is facing the intended direction.

4. Tighten the mounting nut (“C” in Figure 2 below) in the left-hand

direction.

Mounting Figure 2: Gland Nut

B-Series Sensor with Gland Fitting

A

C

Front View

Side View

B

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 9

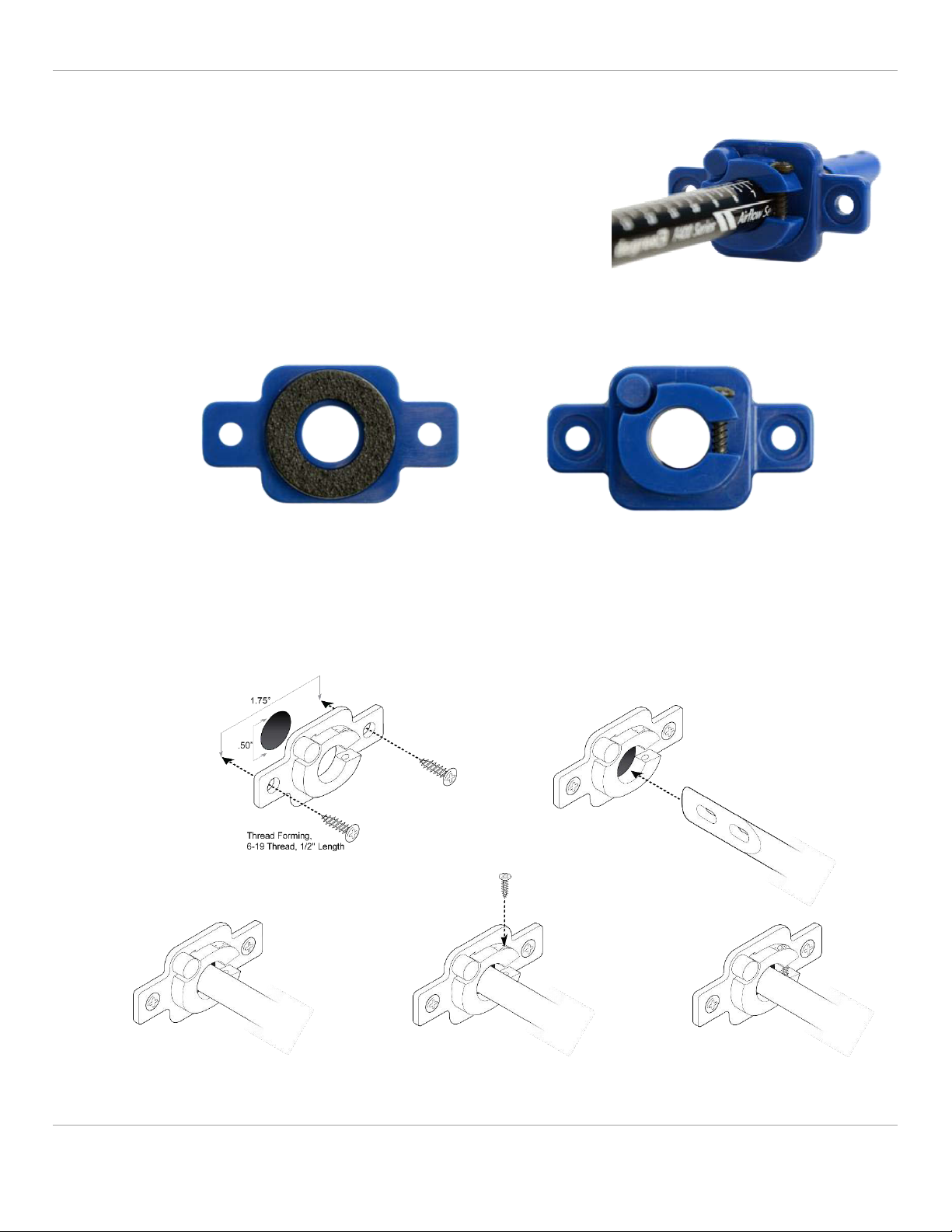

5.1.2 °C Clamp Installation

1. Drill a 7/8” 0.75” (20mm) hole into the surface you wish to install the Sensor into.

• Follow the below text instructions along with the visuals in

Figure 4 to install the °C Clamp.

2. Peel off the adhesive backing on the back of the °C Clamp (see Figure

3 below) and place onto the drilled hole. Using the provided screws,

tighten the °C Clamp on the right and left side to the surface.

3. Insert the Sensor into the hole of the °C Clamp and adjust the

Sensor’s insertion depth (use the printed ruler on the Sensor’s body

for reference), ensuring that the sensor head (see section 5.3

Airflow Direction) is facing the intended direction.

4. Using the provided screw, tighten the °C Clamp onto the Sensor body.

Mounting Figure 3: °C Clamp

Mounting Figure 4: °C Clamp Installation

B-Series Sensor with °C Clamp Fitting

Back View Front View

Step 1

Step 2

Step 4

Step 5

Step 3

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 10

5.1.3 Airflow Direction

To ensure that the Sensor performs within its published specifications, proper mounting precautions must be followed:

• The central airflow cavity that surrounds the flow thermistor must be orientated perpendicular to the airflow

being monitored.

• When monitoring air velocity within a pipe or duct, mount the sensor so that the main flow cavity is in the

center of the pipe or duct. Avoid mounting the sensor in turbulent locations caused by elbows, duct size

changes, etc. If airflow turbulence causes excessive airflow reading variation, increasing the Sample Time (index

63)may solve the problem.

Airflow Figure 2: Direction of Airflow

6 Communication

The B-Series Sensors support two methods of communication: UART and I2C. The choice of communication is set up at

DegreeC prior to shipment.

6.1 UART

The communication protocol described below is for communication between a master host and the slave Sensor

product. This protocol is used to read/write configuration variables and to read process variables from the Sensor.

• The host can configure the Sensor by transmitting a “Memory Write” command which contains the memory

index and the new data within the command.

• The host reads configuration variables using the “Memory Read” command.

• For multi-byte configuration variables, the data format is “little endian”. The lowest address is the least

significant byte.

Four process system variables (Velocity, Tamb, Power, and Raw Velocity) can also be read from the Sensor using the

“Read Velocity”, “Read Tamb”, “Read Power”, and “Read Raw Velocity” commands, as noted in the figure below:

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 11

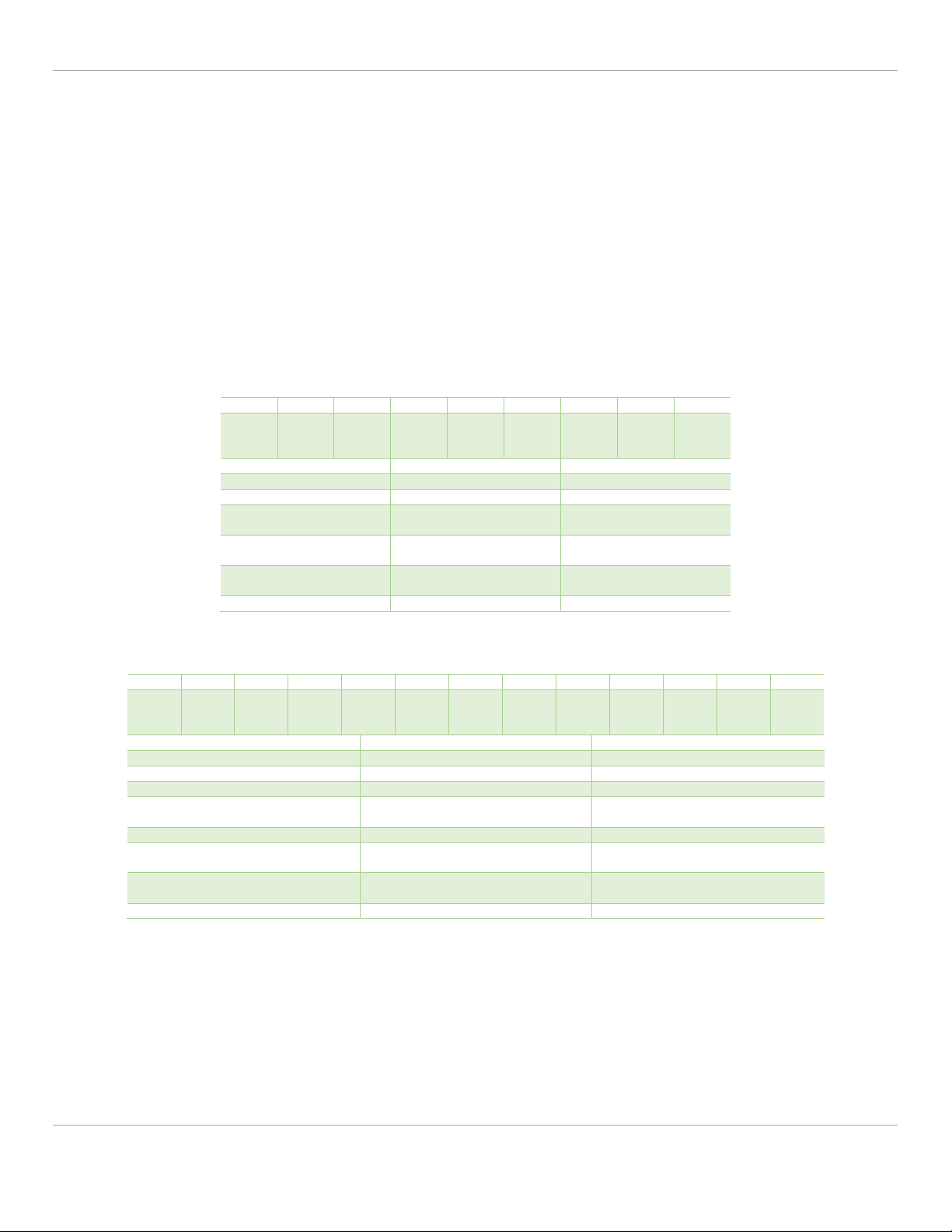

Byte

1

2

3

4

1

2

3

4

Read

Velocity

1

0

0

checksum

Velocity

(Hi)

Velocity

(Lo)

0

checksum

Read

Tamb

2

0

0

checksum

Tamb

(Hi)

Tamb

(Lo)

0

checksum

Read

Power

3

0

0

checksum

Power

(Hi)

Power

(Lo)

0

checksum

Memory

Write

6

Memory

Index

Data

checksum

Memory

Index

Data

0

checksum

Memory

Read

7

Memory

Index

0

checksum

Memory

Index

Data

0

checksum

Read Raw

Velocity

9

0

0

checksum

Velocity

Raw

(Hi)

Velocity

Raw

(Lo)

0

checksum

RESET

12

0

0

checksum

n/a

n/a

n/a

checksum

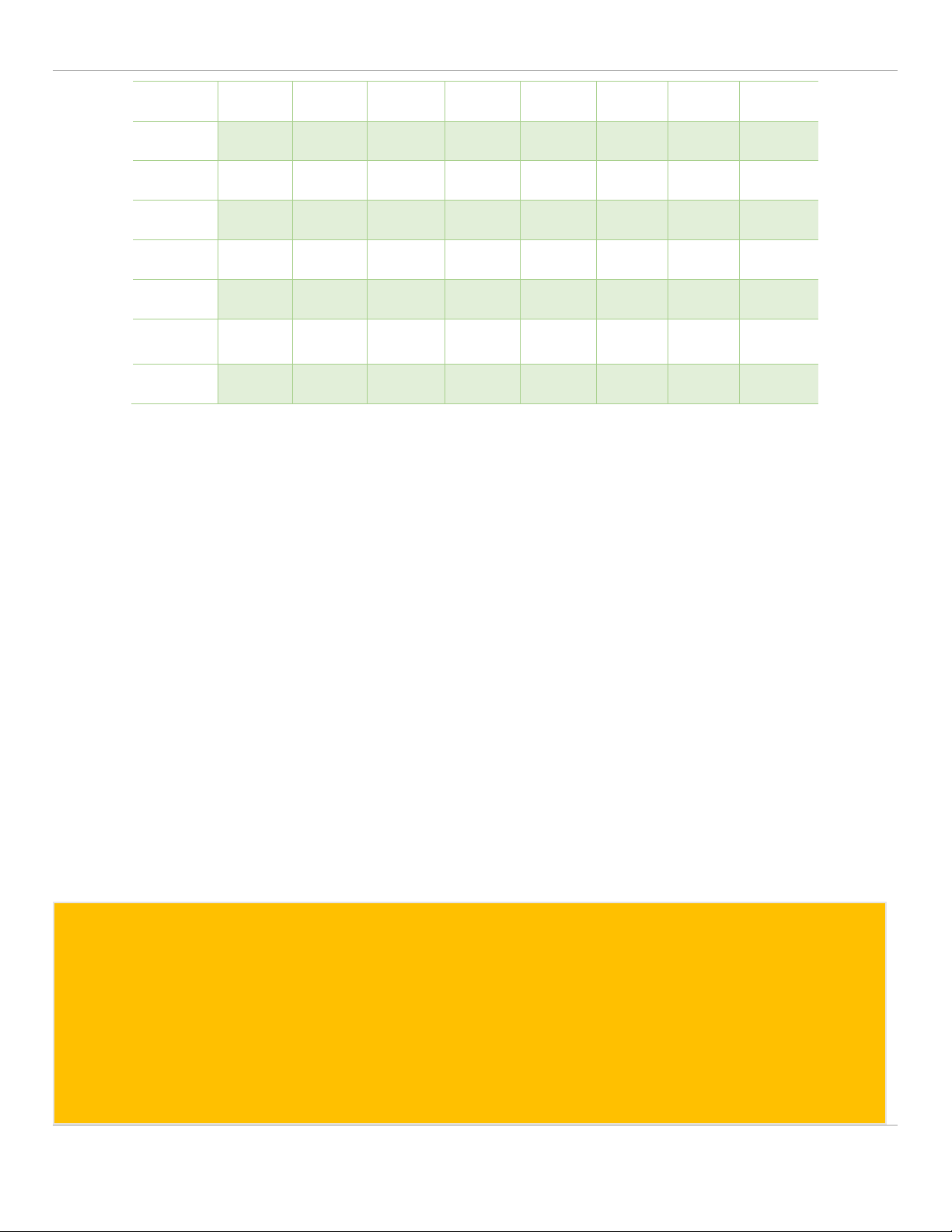

UART Figure 1: Process System Variables

6.1.1 Hardware

The Sensor’s UART RX and TX signals are digital signals from the internal processor’s UART at 3.3V TTL voltage levels.

To convert to true RS232 signals, an external level shifter is required.

6.1.2 Configuration

UART configuration is fixed at 19200 baud rate, 8 data bits, no parity, 1 stop bit.

Protocol

The sensor is a slave device and supports several different commands. Both transmit and reply command message

lengths are four bytes. The fourth byte is a checksum byte to verify message integrity. The checksum byte is determined

by performing an “exclusive or” logic operation of the first three bytes. The tables below define the seven host

commands supported and the appropriate sensor reply.

Password Protection

Memory locations designated as (RWP) in the Memory Map require two consecutive Memory Write commands to

change the setpoint.

• Command #1: Memory Write 0xAA to the Password (index 83).

• Command #2: Memory Write the new value to the password protected register. If valid, Sensor will accept the

commands and write the new value. The Password (index 83) is automatically reset to 0xFF, the protected

default state.

Caution:

• If the sensor receives a message with an invalid command byte or an invalid checksum, the message will be

discarded and the Sensor will not reply.

• If the sensor receives a partial message, the message will be discarded and the Sensor will not reply.

• The host should use the “Read Velocity”, “Read Tamb”, “Read Power”, and “Read Raw Velocity” commands

to read these double byte variables.

• When reading the double byte process variables Velocity (index 67), Raw Velocity (index 69), T Ambient

Temperature (index 71), T Flow Temperature (index 73), Power Average (index 75), using the single byte

“Memory Read” command, read the Low Byte first, then read the High Byte. This prevents a “byte

mismatch” reading error.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 12

6.2 I2C

The communication protocol described below is for communication between the I2C master host and the I2C slave

Sensor. This protocol is used to read/write configuration variables and to read process variables from the Sensor.

Reading and writing to the Sensor uses the same protocol that is commonly used to read and write to EEPROM’s.

For multi-byte configuration and process variables, the data format is “little-endian”, the low order byte of the number

is stored in memory at the lower address.

6.2.1 Configuration

The protocol sequence is as follows:

• Each sensor starts out with a default Address of 192. This address may be changed to an arbitrary 8-bit value by

writing to the sensor’s I2C address register and cycling power.

• The I2C commands for the Sensors are defined as per the following tables:

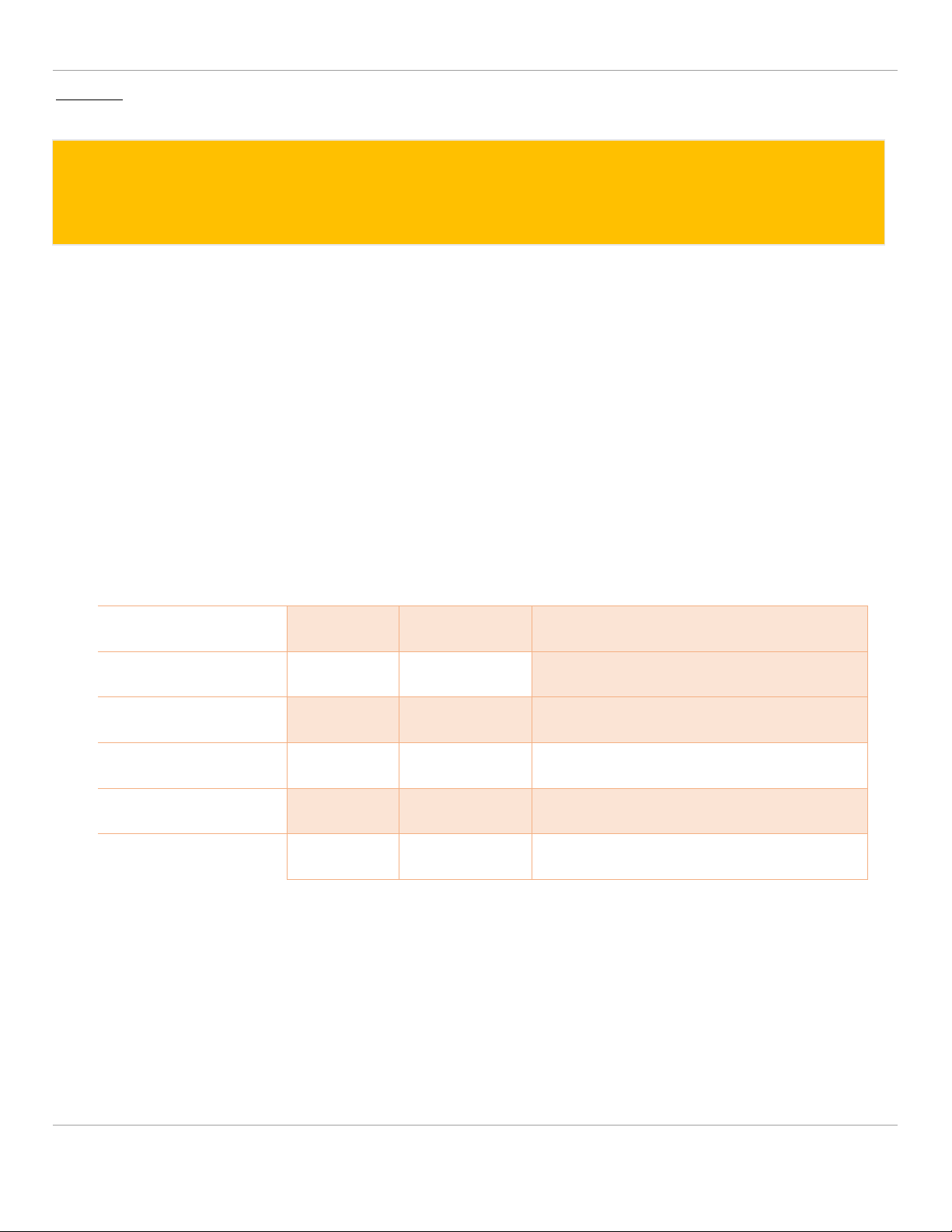

1

7

1

1

8

1

8

1

1

S

Slave

Addres

s

Wr

A

Sub

Addres

s

A

Data

Byte

A

P

S

=

Start bit

Slave Address

=

Sensor Address

Wr

=

0

A

=

Acknowledge from the

Sensor

Sub Address

=

Index into the Sensor’s

Memory Map

Data Byte

=

Data written to the sensor

at the Sub Address

P

=

Stop bit

I2C Figure 1: Write Byte

1

7

1

1

8

1

1

8

1

1

8

1

1

S

Slave

Addre

ss

Wr

A

Sub

Addre

ss

A

S

Slave

Addre

ss

Rd

A

Data

Byte

A

P

S

=

Start bit

Slave Address

=

Sensor Address

Wr

=

0

Rd

=

1

A shaded

=

Acknowledge from the sensor (0 to

indicate Ack)

Sub Address

=

Index into the sensor Memory Map

Data Byte

=

Data from the sensor at the Sub

Address

A non-shaded

=

Acknowledge from the Host (1 to

indicate end of read cycle)

P

=

Stop bit

I2C Figure 2: Write Byte

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 13

1

7

1

1

8

1

1

8

1

1

8

1

8

1

1

S

Slave

Address

Wr

A

Sub

Address

A

S

Slave

Address

Rd

A

Data

Lo

Byte

A1

Data

Hi

Byte

A2

P

S

=

Start bit

Slave Address

=

Sensor Address

Wr

=

0

Rd

=

1

A shaded

=

Acknowledge from the Sensor (0 to indicate Ack)

Sub Address

=

Index into the Sensor Memory Map

Data Byte Lo

=

Data from the sensor at the Sub Address

A1 non-shaded

=

Acknowledge from the Host (0 to indicate read cycle continues if reading a second

byte, 1 to indicate end of read cycle)

Data Byte Hi

=

Data at the next memory address (Only used if A1 was 0)

A2 non-shaded

=

Acknowledge from the Host (1 to indicate end of read cycle)

P

=

Stop bit

I2C Figure 3: Read Byte(s)

I2C Command Restrictions

• The write cycle only supports a single byte write cycle. Multiple byte write cycles are not supported.

• The read cycle supports a single and a double byte read cycle. Read cycles (greater than two) are not supported.

I2C Address

The sensor supports a 7-bit address which is shifted left to become the 7 most significant bits of the Slave Address Byte.

The default value (after shifting) is 0xC0 (192) for write operations and 0xC1 (193) for read operations. This base address

is password protected and can be changed by performing a “Write Byte” command to I2C Base Device Address (index 0)

with the new base address. The new base address will become active after the next power cycle.

Password Protection

Setpoints designated as (RWP) in the Memory Map require two consecutive I2C write commands to change the setpoint.

• Command #1: Write 0xAA to the Password (index 83).

• Command #2: Write the new value to the password protected register. If valid, the Sensor will accept the

commands and write the new value. The Password (index 83) is automatically reset to 0xFF, the protected

default state.

6.3 Velocity Analog Output (Voltage)

The sensor velocity is translated to an analog voltage with a configurable range. The output voltage that corresponds to

the Velocity High Range (index 52) is determined by setting Vout Maximum (index 59) to the desired voltage, units are in

millivolts. As the converted Velocity (index 67) goes from 0 mm/s to Velocity High Range (index 52), Vout goes from 0 to

Vout Maximum (index 59).

Output voltage functionality at velocities exceeding the Velocity High Range (index 52) is configurable by setting bit 0 of

the Config Flags (index 10). With bit 0 set to 0, Vout is clamped at Vout Maximum (index 59). With bit 0 set to 1, Voutput

is not clamped and will continue to rise in a linear fashion at Velocities exceeding the Velocity High Range (index 52).

Caution:

If there is a communication failure in the midst of a read/write sequence, it is NECESSARY to issue a “Stop” bit

before resuming communication with a new “Start” bit.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 14

By default, bit 0 of the Config Flags (index 10) is set to 0 (clamped). See Figure 1 below for the Voutput functionality as

bit 0 is set to 0 (clamped) and 1 (not clamped):

Velocity Analog Output Figure 1: Voutput (0 –5V) with and without Clamping

Note: Velocities below -Velocity Maximum are always clamped to 0V.

For sensors without communications, the velocity can only be determined by measuring Voutput and calculating the

velocity per the equation in Figure 2 below:

Velocity Analog Output Figure 2: Velocity Calculation Equation using Voutput

The Velocity High Range and Vout Maximum can be obtained from the B-Series Part Number. For example, if the sensor

model is “B300–2–A–1”, the Velocity High Range is 1000 mm/s (1.0 m/s) and the Vout Maximum is 5V. In this case,

if Vout is 3VDC, then the velocity can be calculated per the following equation:

Velocity is therefore 0.2 m/s.

Velocity Analog Output Figure 3: Velocity Calculation Example with Vout = 3V

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 15

Voutput: The Voutput value of the B300/500 sensor can also be obtained by the host reading Voutput (index 77) via the

communication port. Units are in (mv).

6.3.1 Velocity Analog Output (Voltage) Example

Note: By default, DegreeC sensors are calibrated in metric format.

• Application airflow range is -10m/s –10 m/s.

• Output Voltage at 10 m/s is 5.0V.

• At airflow velocities exceeding 10m/s, the output voltage should not exceed 5.0V

(Note: Only if Config Flags [register 10] bit 0 != to 0.).

For this application, the Velocity Range of -10 –10 m/s specifies a type “B” Velocity Profile, and the voltage of 5.0V

specifies an Output Configuration Type “1” or “3”. In this case let’s assume this is an air velocity only output with an 8.3”

tube, so the appropriate model is “B300-3-B-1”. Figure 4 illustrates the Vout vs Velocity for this sensor model. Table 1

below lists the internal register configuration for this model:

Name

Index

(decimal)

Value

Description

Configuration Flag

10

0b00000000

Please see section 7.1, Memory Map

Velocity Deadband Limit

50,51

500

Standard Velocity Low Range of 500 mm/s

Velocity High Range

52,53

10000

Standard Velocity High Range of 10000 mm/s

Vout Maximum

59,60

5000

Sets Vout maximum when Velocity equals

Velocity High Range

Velocity

67,68

6000

Velocity of last conversion is 6000 mm/s

Voutput

77,78

4000

Vout in (mv)

Velocity Analog Output Table 1: Internal Memory Map Parameters for Analog Out Example

Caution:

• Vout accuracy specification is only valid within the specified operational airflow range of the B300 and B500

and outside of their deadband. See General Specifications Table 1: Air Velocity Performance

• With the Voutput “not clamped”option, the output voltage is NOT limited to Vout Maximum.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 16

6.4 Velocity Analog Output (Current)

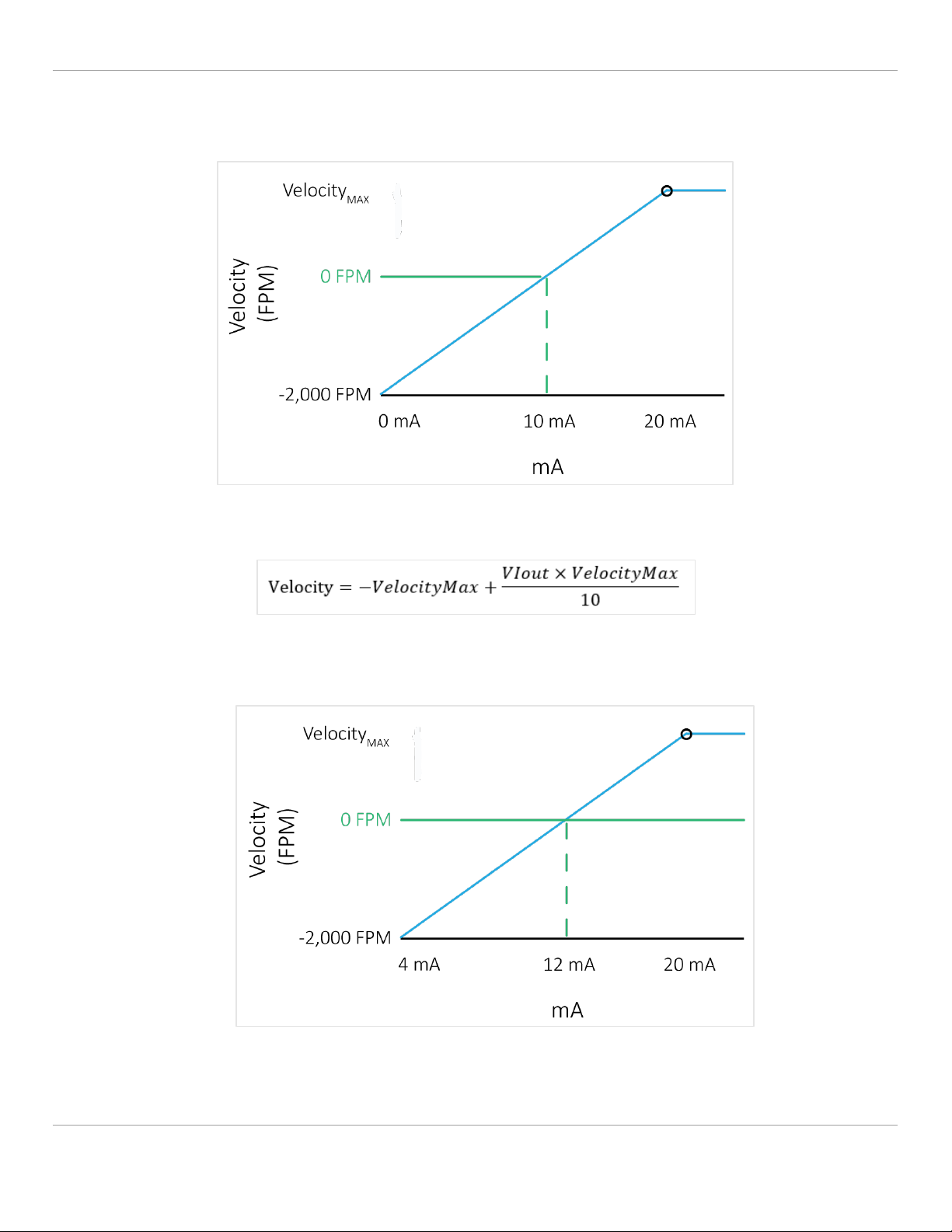

6.4.1 0-20 mA

Velocity Analog Output Figure 5: 0-20 mA Example

Velocity Analog Output Figure 6: 0-20 mA Calculation Equation

6.4.2 4-20 mA

Velocity Analog Output Figure 7: 4-20 mA Example

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 17

Velocity Analog Output Figure 8: 4-20 mA Calculation Equation

6.4.3 Velocity Analog Output (Current) Example

For a B Cal. Range solution when utilizing 4-20 mA output, simply plug in the values found in the Calibration Range Chart

below:

If the mA reading 8 mA for example:

• B Cal. Range Vout Maximum is 10 m/s

Plug in the numbers into the 4-20 mA formula as follows:

Velocity = −10 m/s + (8 mA − 4)×10 m/s

8

Velocity is therefore -5 m/s.

Velocity Analog Output Table 2: Calibration Range Table

Note: If the current outputs are unable to drive the desired current AND the sensor is configured for current out (i.e.

Config Flags [Index 10] bits 1 and 2 have not been set), bit 6 in Memory Location 66 will be set. (However, only if the

current output error bit is set in the config. register).

6.5 Temperature Analog Output

The sensor temperature is translated to an analog voltage with a fixed range. The output voltage that corresponds to the

Temperature High Range (100 °C) is determined by setting Tout Maximum (index 61) to the desired voltage, units are in

millivolts. As the converted T Ambient Average (index 71) goes from 0 °C to 100 °C, Tout goes from 0 to Tout Maximum

(index 61). The linear conversion graph for the (0 - 5V) and the (0 –10V) ranges are displayed on the following page:

Calibration Range

VOUT Max

A

1.0 m/s

B

10.0 m/s

C

20.0 m/s

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 18

Temperature Analog Output Figure 1: Toutput for (0 –5V) and (0 –10V)

Note: If Register 10 Bit 3 is set, the temperature is scaled from -25°C to 75°C.

For sensors without communications the temperature can only be determined by measuring Tout and calculating the

temperature per the equation below:

Temperature Analog Output Figure 2: Temperature Calculation Equation

Tout: The Tout value of the B3/500 sensor can also be obtained by the host reading Toutput (index 79) via the

communication port. Units are in (mv).

6.5.1 Temperature Analog Example

Requirements:

• Application temperature range is 0 –100 °C.

• Output Voltage at 100°C should be 5.0V.

In this example, the Tout signal measures 1.418 VDC. The equation below calculates the corresponding temperature.

The table below lists the internal register configuration for this model:

Temperature (°C) = Tout * TemperatureRange(°C)

ToutMaximum(VDC) =Tout * 100

ToutMaximum(VDC)

Caution:

• Tout accuracy specification is only valid within the specified operational temperature range of the sensor.

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 19

Temperature Analog Output Figure 3: Tout vs Temperature Example

Name

Index

(decimal)

Value

Description

Tout Maximum

61,62

5000

Sets Tout maximum when Temperature

equals Temperature High Range (100 °C)

T Ambient Average

71,72

2836

Temperature of last conversion is 28.36°C

Toutput

77,78

1418

Tout in (mv)

Temperature Analog Output Table 1: Internal Database Parameters for Temperature Analog Example

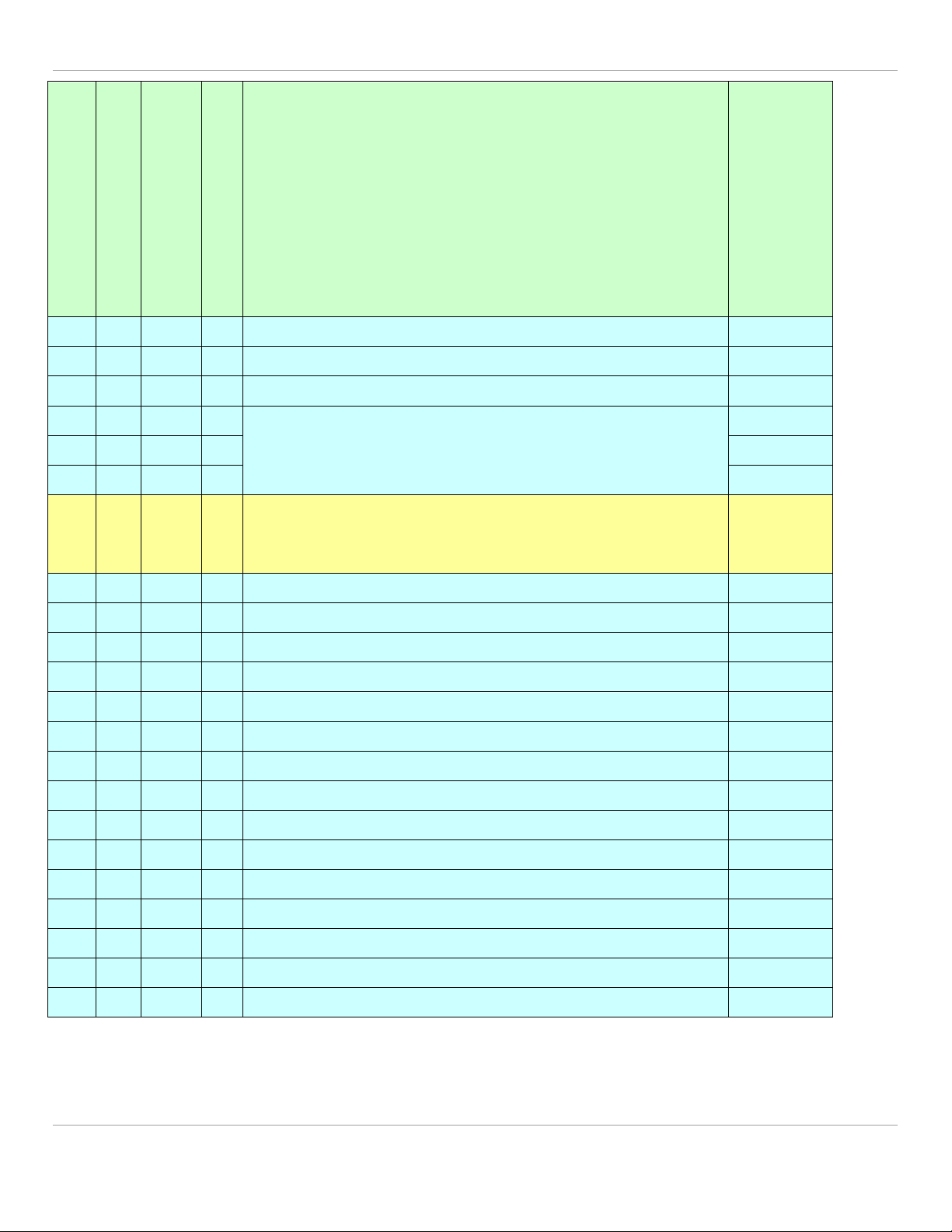

7 Sensor Registers

The sensor setpoints and process parameters can be accessed by reading and writing into the memory map using the

appropriate serial communications interface. The table below provides specific details for these parameters:

7.1 Memory Map

Index

Type

Size

Name/Description

Default

Dec

Hex

0

0x00

RWP

1

I2C Base Device Address: (used in I2C Communication Mode Only).

0xC0

1

0x01

RO

1

Communication Mode:

5=UART

6=I2C

per Model P/N

2

0x02

RW

1

Reserved for Alarm Upgrade

0

3

0x03

RW

2

Reserved for Alarm Upgrade

0

5

0x05

RW

2

Reserved for Alarm Upgrade

0

7

0x07

RW

1

Reserved for Alarm Upgrade

0

8

0x08

RW

1

Reserved for Alarm Upgrade

0

9

0x09

RW

1

Reserved for Alarm Upgrade

0

Temperature (°C)= =

Toutput * 100

Tout Maximum

1.418 * 100 = 28.36 °C

5

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01

B-Series Air Velocity Sensors USER GUIDE 67500MN00-A01 20

10

0x0A

RW

1

Configuration Flag: (bit mapped)

bit 0: 0=Vout clamped at VoutMaximum; 1=Vout NOT clamped at VoutMaximum

bit 1: 0=Vout set to 0v if sensor failure detected; 1=Vout set to VoutMaximum if sensor

failure detected

bit 2: 0=Tout set to 0v if ambient sensor failure detected; 1=Tout set to ToutMaximum if

ambient sensor failure detected

bit 3: 0 Tout Scaled from 0-100°C; 1: Tout Scaled from -25-75°C

bit 5: 0 0-20mA current out; 1: 4-20mA current out

bit 6: 0 enable current output error; 1: disable current output error

0

11

0x0B

RO

1

Calibrated (0=UNCALIBRATED, 1=CALIBRATED)

1

12

0x0C

RO

4

Reserved

ID Data

16

0x10

RO

4

Reserved

ID Data

20

0x14

RO

4

Serial Number: Combination of the Date Code (aka Year Week; Index 24), Work Order

(Index 30) number, and Serial Number (i.e. the order in which a particular sensor was

processed on a Work Order.

ID Data

24

0x18

RO

6

ID Data

30

0x1E

RO

4

ID Data

34

0x22

RWP

4

Multidrop UART Address: 1 Byte Identifier which can be used as an address for support of

multidrop UART communications protocol. A value of 0 means that mulitidrop messages will

be ignored. In order to set this byte, Sensor Power Average (address 75) must be over

35mW.

0

35

0x23

RO

1

Reserved

CAL Data

36

0x24

RO

1

Reserved

CAL Data

37

0x25

RO

1

Reserved

CAL Data

38

0x26

RO

4

Reserved

CAL Data

42

0x2A

RO

4

Reserved

CAL Data

46

0x2E

RO

1

Reserved

CAL Data

47

0x2F

RO

1

Tamb Velocity High Offset: Used to calculate Tamb, (sbbb.bbbb)

CAL Data

48/49

0x30

RO

2

Reserved

CAL Data

50

0x32

RO

2

Velocity Deadband Limit: From Model P/N, (mm/sec)

CAL Data

52

0x34

RO

2

Velocity High Range: From Model P/N, also used to determine V output, (mm/sec)

CAL Data

54

0x36

RO

1

Reserved

CAL Data

55

0x37

RO

1

Reserved

CAL Data

56

0x38

RO

1

Reserved

CAL Data

57

0x39

RO

1

Reserved

CAL Data

58

0x40

RO

1

Reserved

CAL Data

Table of contents

Popular Accessories manuals by other brands

AUSTRALIAN MONITOR

AUSTRALIAN MONITOR AMIS DI1 introduction

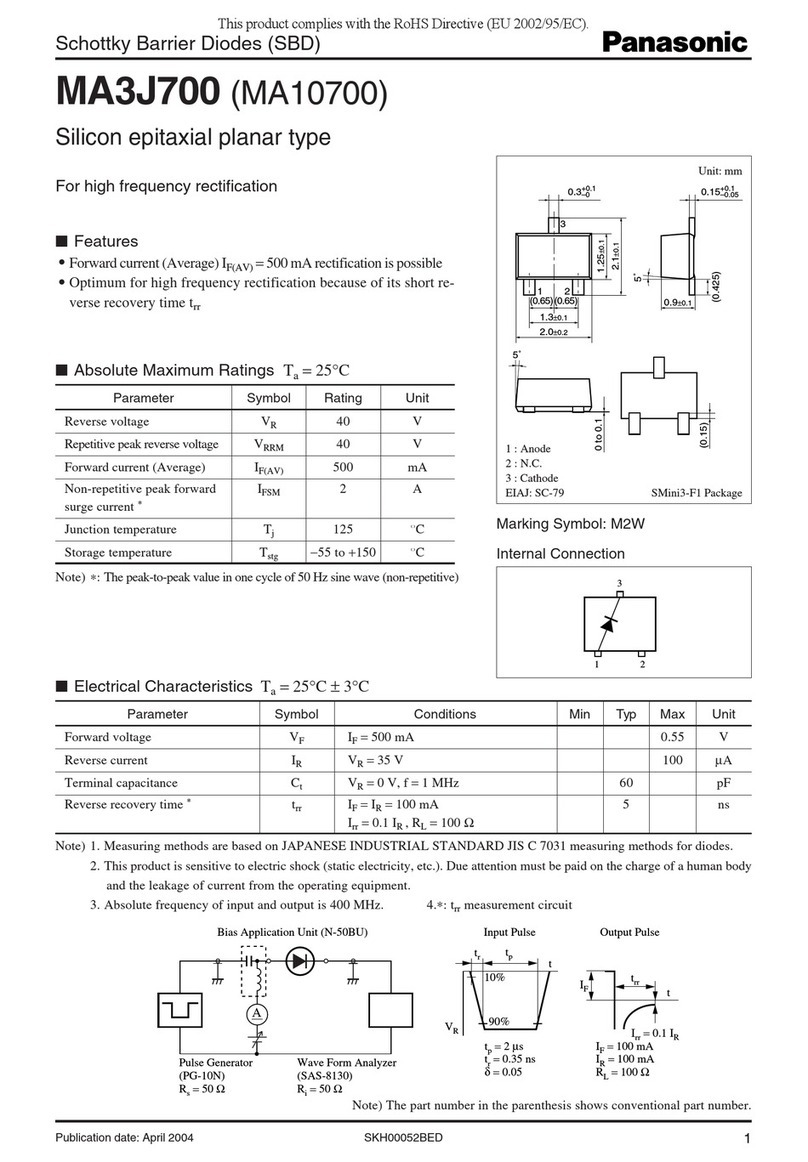

Panasonic

Panasonic MA3J700 Specification sheet

Yaohua Weighing System

Yaohua Weighing System XK3190-A23p user manual

Craftsman

Craftsman 944.511572 instruction manual

W4RT Electronics

W4RT Electronics ONE BOARD FILTER OBF-817 Installation

Orion

Orion 4411 quick guide