dehn DEHNrecord SD User manual

Publication No. 2086 / Update 01.00 Mat-No. 3015953 © Copyright 2021 DEHN SE + Co KG

DEHNrecord SD

Multifunctional measurement and analysis device

for monitoring power quality

Manual

Page 2 from 69

Imprint

Manufacturer

DEHN SE + Co KG

Hans-Dehn-Str. 1

92306 Neumarkt

Germany

Tel. +49 9181 906-0

www.dehn.de

Service Hotline – Technical Support

Tel. +49 9181 906-1750

Page 3 from 69

Table of contents

Imprint 2

Manufacturer 2

Service Hotline – Technical Support 2

1. Terms and abbreviations 6

2. Safety 7

2.1 Intended use 7

3. Scope of delivery 8

3.1 Accessories (optional) 8

4. Service description 9

4.1 Measuring the power quality according to EN 61000-4-30, class A 10

4.2 Additional measurement capabilities 10

4.3 Device variants 11

4.4 Measurement locations, measurement tasks 11

4.5 Measured values – recording 12

4.6 Measured values – evaluation of power quality (PQ) 13

4.7 Measurement site concept 14

4.8 Configuration 16

4.9 Events and output channels 17

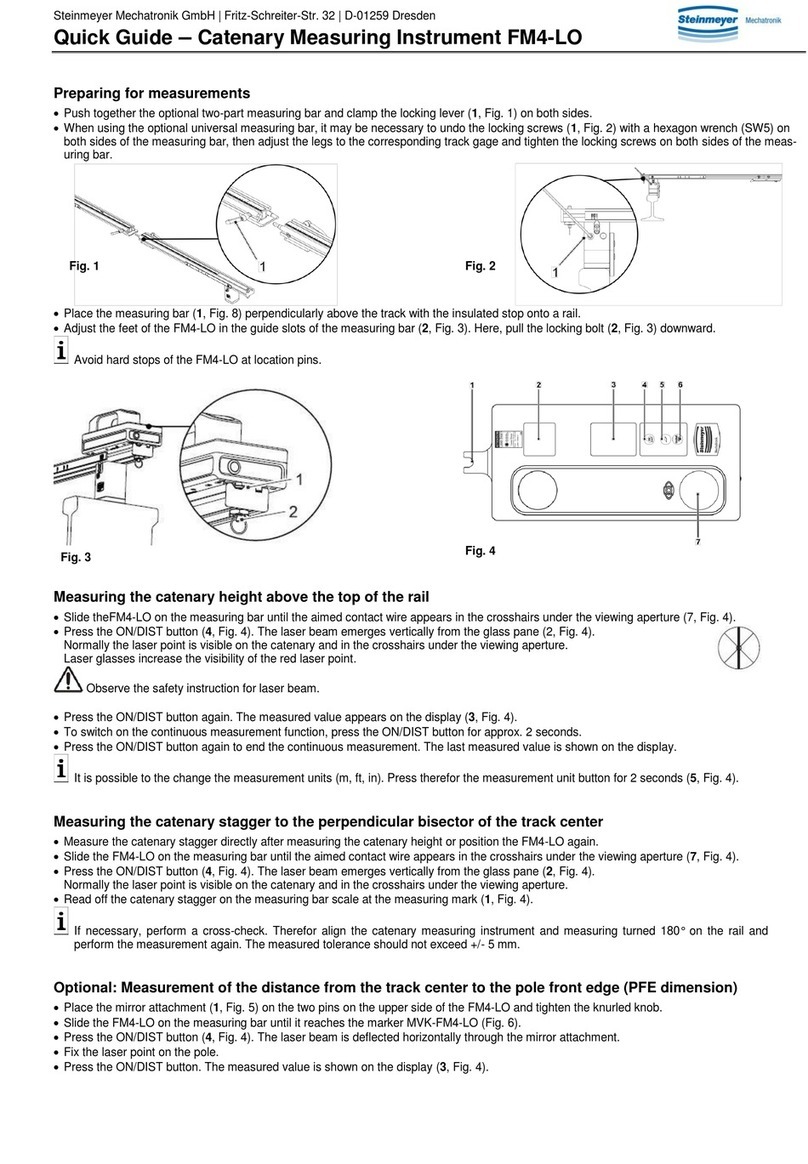

5. Device description 18

6. Mounting 20

6.1 Mounting as a single device 20

6.2 Mounting with surge protective device and busbar 21

6.3 Use with overvoltage category IV 22

Page 4 from 69

Table of contents

* Variant with impulse current measurement expected to be available from Q4 - 2021

7. Connection 24

7.1 Connection DRC SD 1 1 – Part No. 910 920 24

7.2 Connection DRC SD 2 1 – Part No. 910 921 25

7.3 Impulse current sensor DRC SD ICS (Part No. 910 935) * 26

7.4 Current sensors 27

8. Commissioning 28

8.1 Step 1 – Apply the voltage 28

8.2 Step 2 – Connection to the web server 28

8.3 Step 3 – Check 28

8.4 Step 4 – Configuration 29

9. Functionality 30

9.1 User interface 30

9.2 Block diagram 32

9.3 Measured values 33

9.4 Modbus 34

9.5 Communication via the network 35

10.Device settings 36

10.1 Device settings expert mode 36

10.2 General 36

10.3 LED indicator 36

10.4 Digital inputs, digital outputs and logic 37

10.5 Network 41

10.6 Power frequency overvoltages according to EN 50550 - POP 43

10.7 Current measurement 45

10.8 Mains signalling voltages 47

10.9 Factory reset 47

Page 5 from 69

Table of contents

11.PQ Configuration 48

11.1 General 48

11.2 Voltage magnitude 48

11.3 Frequency 49

11.4 Flicker 49

11.5 Voltage dip, voltage swell, voltage interruption 50

11.6 Voltage dip 50

11.7 Voltage swell 50

11.8 Voltage interruption 51

11.9 Unbalance 51

11.10 Total harmonic distortion THD, harmonics, interharmonics 52

11.11 Mains signalling voltages 52

11.12 Rapid voltage changes 53

11.13 Values for PQ characteristics 54

12.Technical data 57

13.Maintenance 69

13.1 Check 69

13.2 Cleaning 70

13.3 Dismantling 70

13.4 Disposal 70

Page 6 from 69

1. Terms and abbreviations

PQ Power Quality

DRC SD DEHNrecord SD

SPD Surge Protective Device

POP Power frequency overvoltage protective device

UTC Coordinated Universal Time

MSRL Equipment for measurement, control, and laboratory use according to EN 61010-1

PLC Programmable logic controller

Page 7 from 69

2. Safety

WARNING

Risk of electric shock

Installation and connection of a DEHNrecord SD may only be carried out by a qualified electrician

in accordance with the installation standards of the country.

Before mounting, check the DEHNrecord SD (DRC SD) and the accessories for external damage.

If any damage or other defect is detected, do not mount the DRC SD.

Loads exceeding the specified values may destroy the DRC SD and the electrical equipment connected to it.

Tampering with and modifying the DRC SD will void the warranty.

If the DRC SD is used together with a surge protective device (SPD) in environments with overvoltage category IV,

make sure that the SPD is functional before accessing the device.

If the SPD indicates a defect, the SPD must first be repaired before the DRC SD can be accessed.

The installation instructions for the SPD must be observed for this purpose.

2.1 Intended use

The DRC SD is permitted for use in the control cabinet and only within the conditions specified in this manual.

If the device is used in a manner not specified, the protection supported by the device may be impaired.

Only approved accessories may be used.

An external time signal from a time server is required for synchronization (see chapter 9.5 Communication via the network)

Page 8 from 69

3. Scope of delivery

DEHNrecord SD *

Connector IO

Connector CM

Installation instructions

3.1 Accessories (optional)

Impulse current sensor DRC SD ICS 100, Part No. 910 935 *

Split core current sensors, Part No. 910 936

Current sensors (Rogowski coils), Part No. 910 937

Busbar (suitable for surge protective device)

for use in combination with a surge protective device (SPD)

Impulse current sensor DRC SD ICS

* Variant with impulse current measurement expected to be available from Q4 - 2021

L1

L2

L3

N/PEN

24 VDC

5

6 4

3

11 14 12

300 V CAT III

300 V CAT IV

L1

L2

L3

N/PEN

5

6 4

3

11 14 12

Publication No. 2084 / Update 01.03 Mat. No. 3015951 © Copyright 2021 DEHN SE + Co KG

DEHNrecord SD

Multifunctional measurement and analysis device

for monitoring power quality

Installation instructions

Connection

DRC SD 2 1 – Part No. 910 921

24 V DC external power supply

Detects interruptions and drop > 5 s

as per EN61000-4-30, class A for

24 VDC uninterruptible power supply.

Supply voltage UB: 24 VDC, max. 100 mA

Cross-sectional area L1/L2/L3/N: 1.5 - 6 mm2

Plug cross-sectional area: 0.25 - 1.5 mm2

Test

After applying the voltage:

LED 1 flashes green if power supply correct

LED 2

lights up green if voltage quality good (in factory configuration)

Commissioning

Connect DEHNrecord SD directly to computer

1. Configure computer: IP 192.168.0.10, Sub. 255.255.255.0

2.

Connect computer and DEHNrecord directly with network cable

3.

Activate Web server:Press button 2 briefly, LED 1 lights up blue

4. Access with browser: http://192.168.0.200

Connect DEHNrecord SD via network

1. Connect DEHNrecord SD with network (DHCP)

2.

Activate Web server:Press button 2 briefly, LED 1 lights up blue

3.

Access with browser: http://DRC-SD-serial no. (e.g. http://DRC-SD-FHA12345678)

Factory-set password: smartdevice

Testing

After successful registration, properties such as the following can be checked:

Rotational field direction of the voltage connections, Current measuring coil

connection, Impulse current sensor connection

Configuration

The DEHNrecord SD can be suitably configured via the Web server.

Access to

the cloud server is preconfigured (MQTT, port 8883).

LED 1 lights up green once access to the DEHNmonitor PQ is working.

Product registration

For product registration in the DEHNmonitor PQ,the serial number and the

four digits after the serial number are required. These are only printed on the

device itself! Example: „0000“ in „FHA12345678-0000“.

Example wiring of an SPD with remote

signalling contact:

· Connect SPD contact (connection 11) with

supply voltage 24 VDC (plug I/O tmnl 3)

· Feedback from SPD contact (connection 12 or 14)

to digital input I1.1 (plug I/O tmnl 5)

· Ground connection (plug I/O tmnl 4 and 6)

Installation

The device is installed on a 35 mm DIN rail as per EN 60715.

Backup fuse

The backup fuse

must be chosen to

match the connecting cable;

e.g. for 1.5 mm2-> B16 A

It can be installed together with a surge protective device (SPD).

There are matching busbars for the connection with an SPD.

The snap-on elements of the devices have a permanent unlock-

ing position to facilitate their joint attachment to and removal

from the DIN rail.

Backup fuse

The specifications of the

respective SPD

must be observed.

Connection

DRC SD 1 1 – Part No. 910 920

Power supply via L1 of the measuring voltage

The device can bridge interruptions of supply

for up to 5 s.

Supply voltage UB: 230 VAC (50 Hz), max. 30 mA

Cross-sectional area L1/L2/L3/N: 1.5 - 6 mm2

Plug cross-sectional area: 0.25 - 1.5 mm2

Example wiring of an SPD with remote signalling

contact:

· Connect SPD contact (connection 11) with

auxiliary voltage 12 VDC (plug I/O tmnl 3)

· Feedback from SPD contact (connection 12 or 14)

to digital input I1.1 (plug I/O tmnl 5)

· Ground connection (plug I/O tmnl 4 and 6)

Dehn DRC SD Einbauanleitung 01.03 DE+EN 9Juni2021.indd 1-3Dehn DRC SD Einbauanleitung 01.03 DE+EN 9Juni2021.indd 1-3 10.06.21 18:2210.06.21 18:22

Input Output

Digital

LED

Cloud

DEHNrecord SD

Ethernet

Modus TCP

MQTT

Page 9 from 69

4. Service description

Schematic overview of functions

front end

DEHN server

Measured value acquisition

Measured value evaluation Control center, PLC, PC, ...

Current

Voltage

Push button

Digital

Impulse current (ICS)

SPD monitoring

Web server

Page 10 from 69

4. Service description

4.1 Measuring the power quality according to EN 61000-4-30, class A

Monitored are: Voltage magnitude, frequency, flicker, voltage dips, voltage swells, interruption, unbalance, harmonics, interharmonics,

mains signalling voltages, rapid voltage changes.

Measurement/recording Analysis and evaluation

Power quality according to EN 61000-4-30:2015, class A According to standard EN 50160 and

at the same time according to individual specifications

4.2 Additional measurement capabilities

Measurement/recording Analysis and evaluation

Impulse current 8/20 µs and 10/350 µs to 100 kA * By maximum, duration, rise time, and single/sum charge.

Current, power, energy via up to 4 current sensors

(Rogowski coils or split core current transformers)

Limit values for current, power (P, Q, S), current direction, zero current

and energy (global) can be parameterized separately for each phase or

the neutral conductor

Power frequency overvoltages (POP) According to standard EN 50550 and also individually with differentia-

tion exceedance/undershot

Digital states at 3 inputs

According to state/change with counter function.

After status / change with counter function. The inputs can be logically

linked to one another and to other device functions.

* Variant with impulse current measurement expected to be available from Q4 - 2021

Page 11 from 69

4. Service description

4.3 Device variants

DRC SD 1 1, Part No. 910 920: Power supply 230 volts via L1 of the measuring voltage.

The device can bridge supply interruptions for up to 5 seconds.

DRC SD 2 1, Part No. 910 921: Power supply 24 volts DC external.

Records interruptions and voltage dips even over 5 seconds in accordance with EN 61000-4-30,

class A if the external power supply is uninterruptible.

4.4 Measurement locations, measurement tasks

Energy supplier

Power quality (monitoring, evaluation)

energy consumption, load profile

Energy consumer

Energy measurement and monitoring

Power quality (monitoring, analysis)

Installation location

Local network stations, cable distribution cabinets,

measuring transducer cabinets, transfer points to customer facility, main distributions, sub-distributions, terminal device level.

For a normative evaluation of the power quality according to EN 50160, the preferred installation location is the transfer point

from supplier to consumer.

Page 12 from 69

4. Service description

4.5 Measured values – recording

Cyclic measurement

(SoL – sign-of-life-data)

Measured values are transmitted cyclically

to the cloud and are available there for

graphical display in the grid of observation

periods (1 week).

For evaluation and transmission, the

measured values are calculated to 5-minute

intervals (current, power, energy) or 10-mi-

nute intervals (PQ) UTC time-synchronously.

Event-based

An event is generated when a parameteri-

zed limit value is violated. The device trans-

fers the determined characteristic values

and detailed event data to the cloud.

This reduces the scope of measured values

obtained to the relevant data.

This can be done from all measurement

functions. In conjunction with the high-re-

solution temporal detailed data, this func-

tion provides a detailed fault record.

Events can also be assigned to different

output channels: LED, digital output, e-mail.

Events are categorized by basic device

functions (device, PQ, impulse current, ...)

and their sub-functions – e.g. for PQ:

voltage magnitude, frequency, unbalance

User-controlled

The user can start a fast data transfer by

pressing a button on the device or via the

cloud.

The 3-second average values are continu-

ously sent to the cloud over a period of 10

minutes.

This enables a detailed insight into the

current status quo.

Page 13 from 69

4. Service description

4.6 Measured values – evaluation of power quality (PQ)

Standard parameter set

To ensure that the results obtained in the field of public electricity

supply networks are comparable, the limit values according to EN

50160 are applied. These cannot be changed by the user.

PQ overview

If the device is registered in DEHNmonitor PQ (cloud of DEHN), the

results of the standard analysis are visible for all users in the cloud.

The positions of the devices are generalized.

Individual parameter set

At the same time, it is possible to monitor user or site-specific

issues at the same time. The limit values for event detection can be

specified individually for this purpose.

The start of application of an individual parameter set can also be

defined (immediately or by date). This allows a parameter set to be

set specifically for an observation period.

Example: A desired target corridor for the voltage characteristics

can be monitored

Example: Monitoring for an industrial environment according to the

specifications of the IEC 61000-2-4 standard

Page 14 from 69

4. Service description

4.7 Measurement site concept

Measurement site

The measurement site concept is only available in DEHN‘s cloud,

the DEHNmonitor PQ. Each device is assigned to a virtual mea-

surement site in the DEHNmonitor PQ via its serial number from

the time of manufacture. The DEHNrecord SD is configured via the

measurement site and returns data to the measurement site.

The virtual measurement sites have a name and can be configured

individually. The user can manage “his” devices via his own mea-

surement sites (name, position, ...).

When a DEHNrecord SD is replaced, the “historical“ data is retai-

ned in the measurement site. Via the serial number, a new/different

device can be assigned to the measurement site again.

Measurement sites can also be shared with other users/organizati-

ons. Registration in the cloud is required.

Measurement site type

A measurement site type defines a specific configuration (parame-

ters, limit values, output channels) that can be assigned to several

DRC SD.

Example: The measurement site type “IT customer” evaluates spe-

cial parameters that are relevant for data centers.

Changes to the measurement site type are automatically trans-

ferred to all measurement sites with the corresponding measure-

ment site type.

Measurement site node

Measurement sites can be grouped. This allows e.g. common

evaluations. Within the groups, the measurement site types can be

different and, for example, evaluate different limit values for the

current.

Example: All measurement sites of the city “Augsburg” are

grouped. This enables a regional evaluation of e.g. 100

measurement sites.

Page 15 from 69

front end

DEHN server

Cloud

DRC SD

DRC SD

DRC SD

DRC SD

DRC SD

DRC SD Group

2

Group

1

Group

1

Group

1

Group

2

Group

2

Type A

Type A

Type A

Type B

Type B

Type C

4. Service description

Principle of the measurement site

concept

Measurement sites of the same measure-

ment site type behave in the same way and

can be parameterized easily and with little

effort via the cloud. This is a key benefit for

managing many devices.

This concept is available in DEHNmonitor

PQ.

Page 16 from 69

4. Service description

4.8 Configuration

Web server

The basic settings can be entered via the

internal web server: Location, assignment

and type of external coils/transducers for

current measurement, parameters of the

mains signalling voltage.

More detailed explanations of the device

settings can be found in chapter 10.4.

Modbus TCP

Device access via Ethernet interface enables

access to parameters, limit values, current,

cyclical data / status and event data.

Cloud access

The device can be configured via the

DEHNmonitor PQ. You have access to the

current, cyclic and past data/status/event

data including detailed histories.

At present, the DEHNmonitor PQ is still in

test mode.

Page 17 from 69

4. Service description

4.9 Events and output channels

Events

Events are generated by:

• Evaluation of measured values (every exceeding of a limit

value of all measurement functions generates an event)

• Digital input

• Keystroke

• Command from the cloud

• The device itself

Example: voltage measurement, exceeding a limit value

Example: digital input, SPD monitoring

Example: briefly press button 2 -> Start web server,

LED 1 (device) lights up blue.

Example: device update -> “Firmware update successful“

is reported to the cloud

Output channels

There are three output channels:

• Ethernet (Cloud, Modbus TCP)

• LED

• Digital output

The e-mail notification is provided

via the cloud (DEHNmonitor PQ)

Example: connection establishment cloud -> LED 1 (device) green

Example: SPD monitoring, a digital input triggers an e-mail

at the measurement site and switches LED 2 (status)

to red/yellow

Page 18 from 69

5. Device description

LED 1 (Device)

LED 2 (Status)

Push button 1 (Option)

Push button 2 (Basic)

Ethernet

I/O connection

CM connection

L2L1 L3 N/PEN

Description Function

L1 Measurement input and

power supply for model DRC SD 1 ...

(L1), L2, L3, N Measurement input

LED 1 (Device)

Green (flashing): Start

Green (lights up): Cloud connection active

Blue: Web server active

Yellow: Action 1 active

Red: Action 2 active

(RGB-LED, active status messages are

displayed consecutively)

LED 2 (Status)

Lights up green: power quality OK

(in factory setting, RGB-LED, can be assigned to

other device functions)

Push button 1 (Option)

Short (< 1 s): Action 1: start fast data transfer

Long (> 5 s): Action 2: device stop/start

Long (> 10 s): factory reset

Push button 2 (Basic) Short (< 1 s): activate Web server

Long (> 5 s): device reset

Ethernet

Network connection:

Connection to internal Web server,

Modbus TCP, cloud

I/O connection

Connections for impulse current sensor,

Power supply int./ext.,

digital inputs and outputs

CM connection Connections for current sensors

Cross-sectional area: 1.5 - 6 mm² fine-stranded/stranded-wire

1.5 - 10 mm² solid-wire

A slotted screwdriver (size 0) is required to

unlock the push-in connectors

PZ 2 4 Nm

Page 19 from 69

I/O connection (Input, output, supply, impulse coil)

Description Terminal

Impulse current sensor Imp2 2 1 Imp1

24 Volt version (Model DRC SD 2...)

Ext. power supply +24 VDC

Ue- 4 3

Ue+

(+24 V in)

230 Volt

version

(Model DRC SD 1...)

Auxiliary voltage, output +12 VDC,

exclusively for the operation of

the potential-free digital inputs

Ue+

(+12 V out)

⊖Observe polarity! ⊕

Input 1: max. 30 VDC I1.2 6 5 I1.1

Input 2: max. 30 VDC I2.2 8 7 I2.1

Input 3: max. 30 VDC I3.2 10 9 I3.1

Output 1 (potential-free contact)

max. 30 V, max. 500 mA O1.2 12 11 O1.1

Output 2 (potential-free contact)

max. 30 V, max. 500 mA O2.2 14 13 O2.1

5. Device description (plug)

Cross-sectional area plug (push-in):

0.08 - 2.5 mm² solid-wire

0.25 -1.5 mm² with ferrule

A slotted screwdriver (size 0) is required

to unlock the push-in connectors

CM connection (Current sensors)

Terminal 12345678

Description IL1.1 IL1.2 IL2.1 IL2.2 IL3.1 IL3.2 IN.1 IN.2

Current Sensor

L1 L2 L3 N

Page 20 from 69

6. Mounting

6.1 Mounting as a single device

The device is mounted on a 35 mm DIN rail according to EN 60715.

Use in areas with overvoltage category III.

Backup fuse

The backup fuse must be selected to match the connection line, e.g. for 1.5 mm2-> B 16A

300 V CAT III

This manual suits for next models

2

Table of contents

Other dehn Measuring Instrument manuals