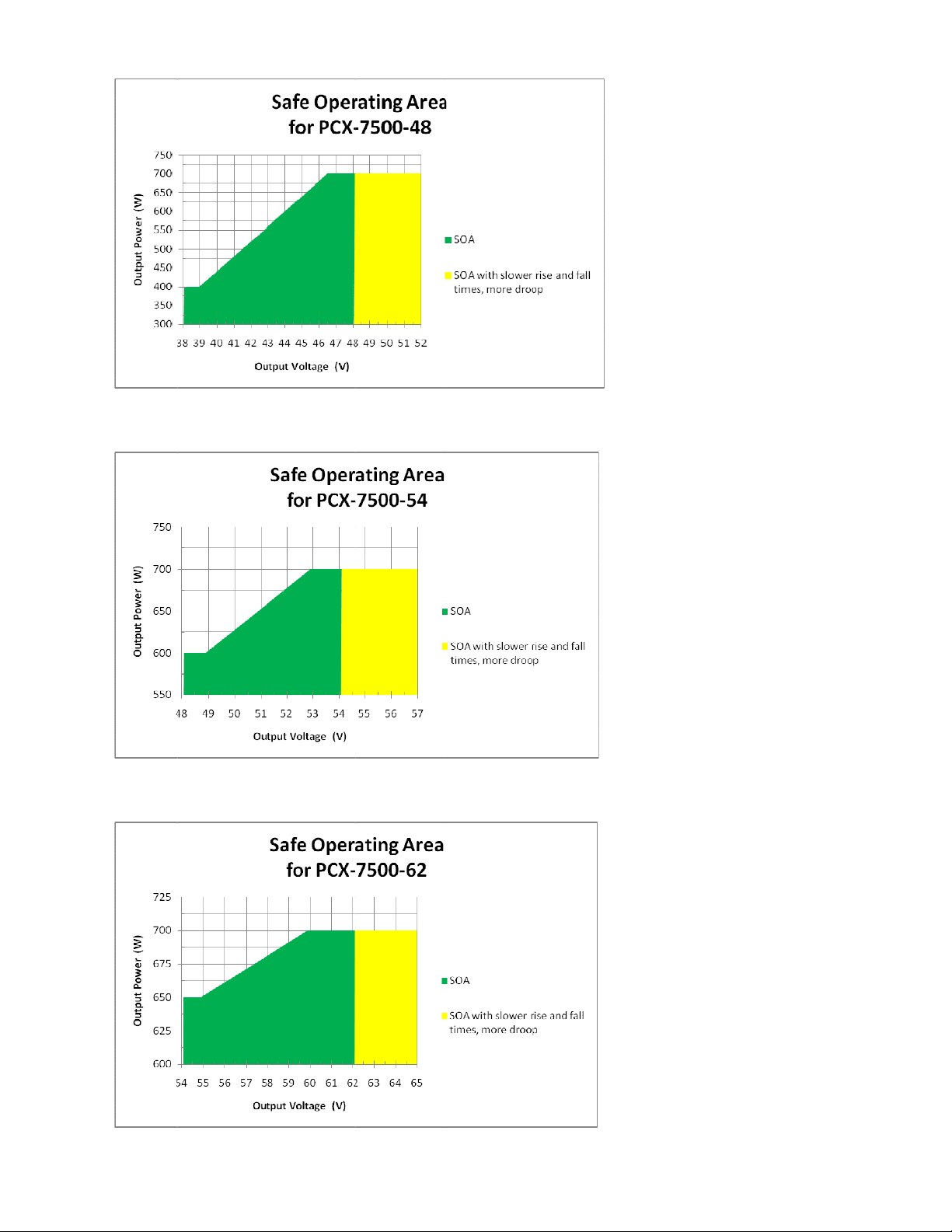

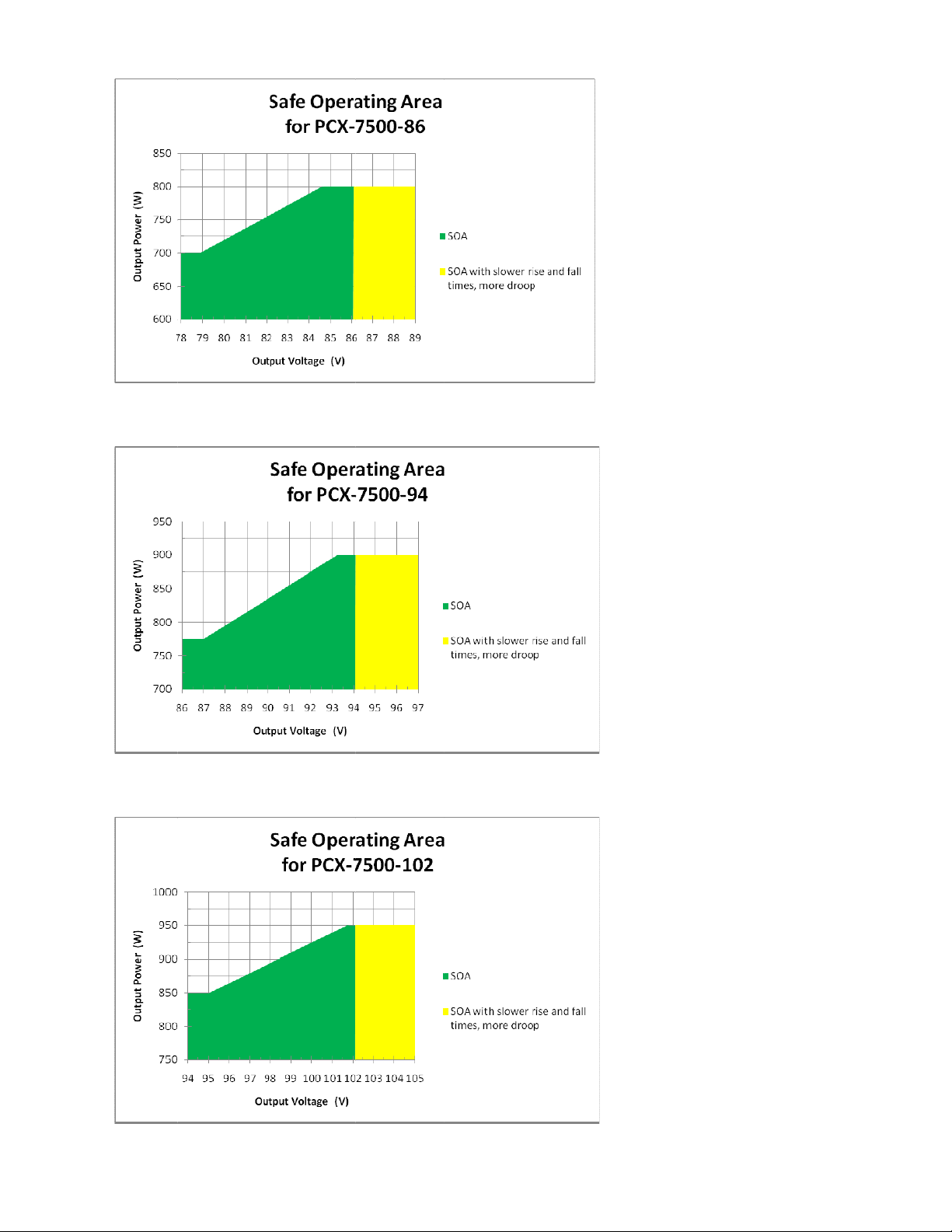

Safe Operating Area

This section contains Safe Operating Area (SOA) graphs for all PCX-7500 models. In

each graph, the Safe Operating Area consists of the green and yellow shaded areas.

IMPORTANT: Do not operate the instrument outside of the Safe Operating Area!

Although the PCX-7500’s internal and external triggering system allow it to operate

outside the Safe Operating Area, such operation will result in permanent damage to the

PCX-7500, the laser diode, or both.

The green region represents operating parameters for which the instrument functions

safely and all pulse specifications are met. It is best to always operate in this region, but

operation in the yellow region does not cause damage to the instrument or laser.

The yellow region represents operating parameters for which the instrument functions

safely but pulse specifications may not be met. Operation in this area has not been

characterized by DEI, is not guaranteed by specification, and may vary slightly from

instrument to instrument. For example, rise and fall times may be slower and droop may

be greater than specified.

Here is an example of how to use the SOA graph to calculate maximum pulse width:

Assumethelaserisratedat5V200W,thepulserisaPCX‐7500‐5,andthedesiredpulseis400

Aat500Hz.

AccordingtothePCX‐7500‐5SOAgraph,at5Vthemaximumoutputpoweris100W.

Inthiscasetheinstrument(100W),notthediode(200W),isthelimitingfactor.Ifthediode

wasratedbelow100W,usethelaser’smaximumpowerandnottheSOAvalueinthenextstep.

Findthemaximumdutycycle:

power=voltage*current*duty_cycle

duty_cycle=100W(SOAgraph)/[5V(laserforwardvoltage)*400A]=0.050

Findtheperiod:

period=1/frequency=1/500Hz=0.002s

Findthemaximumpulsewidth:

maximumpulsewidth*=period*duty_cycle=0.002s*0.050=100µs

*Theabsolutemaximumpulsewidthshouldneverexceed5milliseconds,eveninsingleshot

operation.

Aslongasthepulsewidthis100usorless,theinstrumentwillberunningintheSOA.

Tocalculatethemaximumpulsewidthforasingle‐shotpulse(usingexternaltrigger),use1Hz

asthepulsefrequency.Remember,theoutputpulsewidthshouldneverexceed5milliseconds.