DeLaval MA200 User manual

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

DeLaval milking automation

MA200 (Test installation)

Instruction Book

© DeLaval 2019.

2019-05-31, Version 1 Original instruction

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Safety precautions

DeLaval milking automation

MA200 (Test installation)

1 Foreword

The safety and operational instructions must be

observed by any person involved with the use or

operation of this equipment. Under no circum-

stances must the equipment be used if it is dam-

aged or if the operation of the equipment is not

completely understood.

2 Disclaimer

The information, instructions and parts listed are

applicable and current on the date when issued.

DeLaval reserves the right to make changes with-

out notice.

3 Definitions of admonishments

Admonishments are safety related warning mes-

sages.

Admonishments provide important information

intended to prevent incorrect or hazardous use of

equipment, machinery or software, and support

risk assessment.

The following list defines the different types of

admonishments used in DeLaval documentation:

Danger: Refers to imminent and severe risk.

Failure to comply with instruction will result in

serious injury or death.

Warning: Refers to a potential but severe risk.

Failure to comply with instruction could result in

injury or death.

Caution: Refers to a limited risk. Failure to com-

ply with instruction could result in minor injury.

Mandatory: Refers to an action or behaviour

which is essential to safe and successful use of

the equipment.

Prohibited: Refers to an action or behaviour

which is incompatible to safe and successful use

of the equipment.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 3 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Note! Is intended to draw attention to specific

points of importance in the text and advice to

prevent equipment damage.

This symbol signals risk of injury.

This symbol signals risk of electric shock.

4 Safety regulations

4.1 Safety regulations - General

Danger!

Electric shock hazard

Disconnect the main power supply

and use appropriate lockout-tagout

procedures before any installation,

inspection, adjustment, or mainte-

nance on the equipment is per-

formed.

Danger!

Electric shock hazard

The electrical installation or any

other work on electrical equipment

must be performed by skilled per-

sonnel. The work must be performed

in accordance with provided wiring

diagrams and must comply with

national electrical safety and EMC

regulations.

Warning!

If the equipment is not properly fas-

tened, it can move and pull the elec-

trical cables loose. This may cause

personal injury and risk of fire.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 4 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Warning!

Risk of injury!

The system must only be operated

by trained personnel. Make sure that

children and unauthorised people do

not come into contact with the sys-

tem.

Warning!

Keep safety signs legible!

Read all the safety signs on the

machine and in this manual.

Replace any lost or damaged signs.

Keep safety signs clean and legible

at all times.

Warning!

Intended use

Do not use the equipment for any

other purposes than the intended

use.

Mandatory!

Read the instructions carefully

before using the equipment. Contact

the local DeLaval dealer if there are

parts of these instructions that are

not understood. Compliance with the

instructions ensures a correct and

safe use of the equipment. Save the

instructions for future reference.

Prohibited!

Do not use inadequate parts or

consumables.

Using products which do not meet

specified requirements, for example

spare parts or consumables, or not

appropriately trained personnel for

the DeLaval product may lead to

risks or damage. Consequently it

may also void or limit the warranty.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 5 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

4.2 Safety regulations - Operating the

equipment

Danger!

Risk of electric shock

Do not spray water on electrical

components even when they are

switched off or disconnected. Water

on electrical components can cause

an electric shock, and could destroy

the equipment.

Warning!

Risk of injury

Never start or operate the equipment

unless all shields, covers and guards

are in place.

Warning!

Risk of electric shock!

Ensure that any cables or wiring is

out of animals’ reach.

Mandatory!

Disconnect the electrical supply

before removing shields, covers or

guards.

Prohibited!

Never use solvents, detergents, sol-

utions or alcohol on any part of the

equipment. Failure to comply can

destroy or harm the equipment.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 6 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Caution!

Risk of damage, injury or electric

shock

Never clean the equipment with a

high pressure cleaner or any other

jet of water. The equipment is sensi-

tive and can be destroyed by the

high pressure cleaning.

Caution!

The DeLaval milking automation

MA200 (Test installation) is intended

to be used in the milking stall. Always

allow for the unpredictable nature of

the animals.

Always ask the dairy farmer about

the behaviour of the animals and

milking methods used.

4.3 Safety regulations - Specific equip-

ment risks

5 Safety labels on the equipment

The safety labels must be placed visible on all

locations where a safety hazard exists according

to.

Label Explanation

A

B

C

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 7 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

6 Safety devices

This system is designed to be safe to operate.

The safety devices that are installed are there for

personal safety and must not be modified,

removed, or disconnected.

Any modification to the equipment's original

design may compromise the personal safety.

Consequently it may also void or limit the war-

ranty.

Note! All safety devices in the system must be

checked by a DeLaval representative before the

system is signed over to the customer.

7 Safe and healthy work routines

nEnsure that the area is well lit.

nKeep the floor dry to avoid slipping.

nWear protective clothing and appropriate

shoes or boots.

nKeep a good milking hygiene.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 8 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

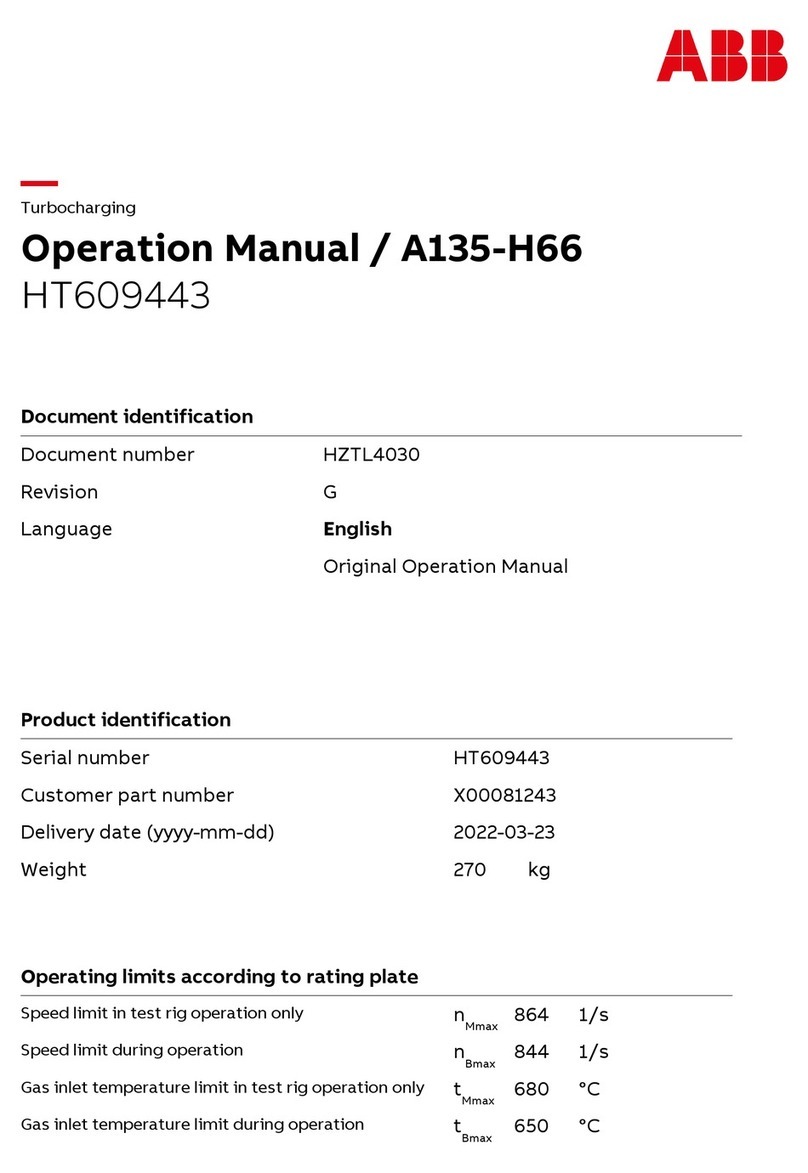

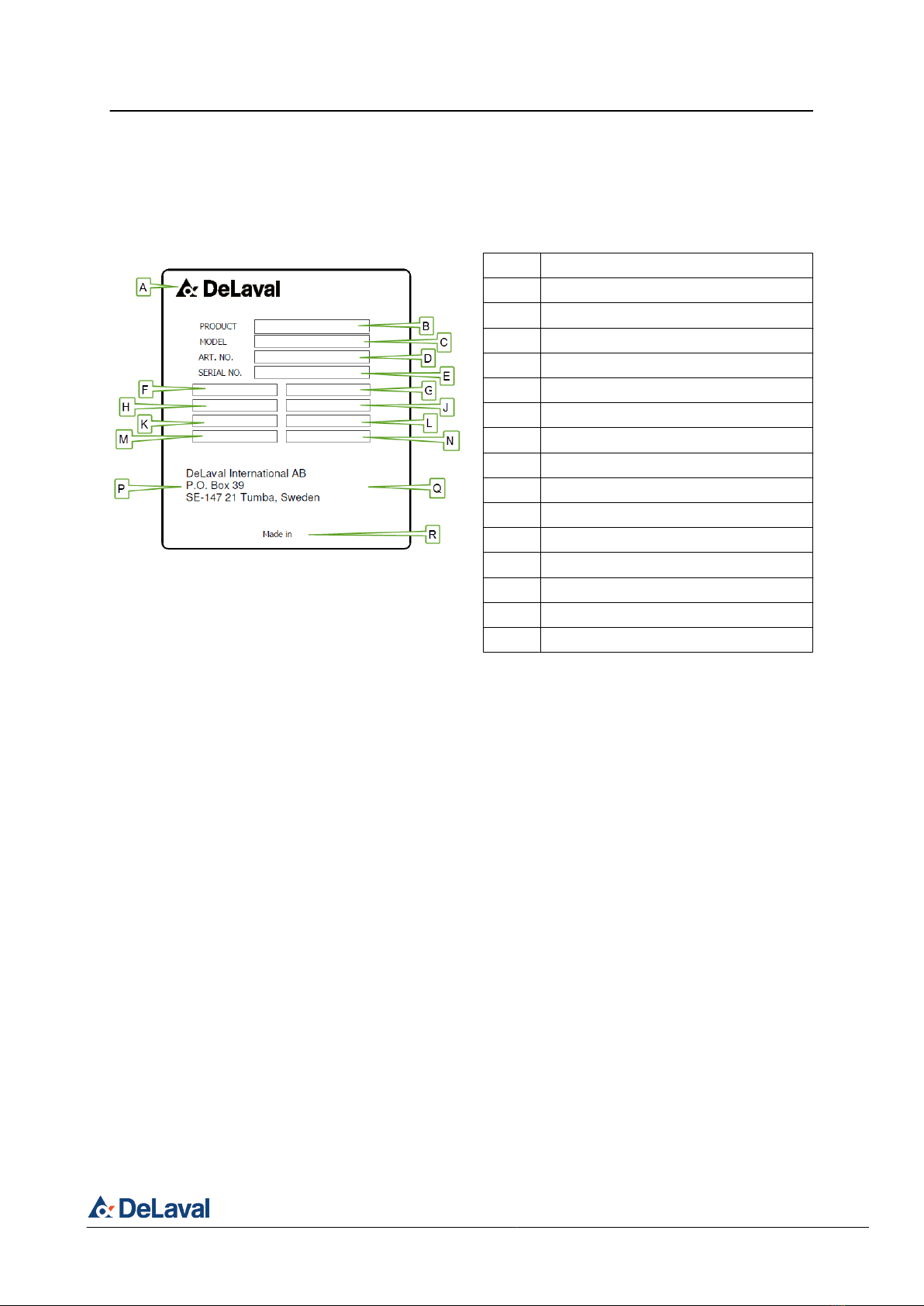

8 Type plates

8.1 Type plate on infrastructure box

A DeLaval logotype

B Product name

C Product model

D Article number

E Serial number

F Voltage rating

G Supply voltage frequency

H Power rating

J Current rating

K Fuse rating

L Equipment class

M Ingress Protection rating

N Empty

P DeLaval address

Q CE and WEEE symbols

R Country of origin

275870

Fig. 1: Infrastructure box type plate.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 9 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

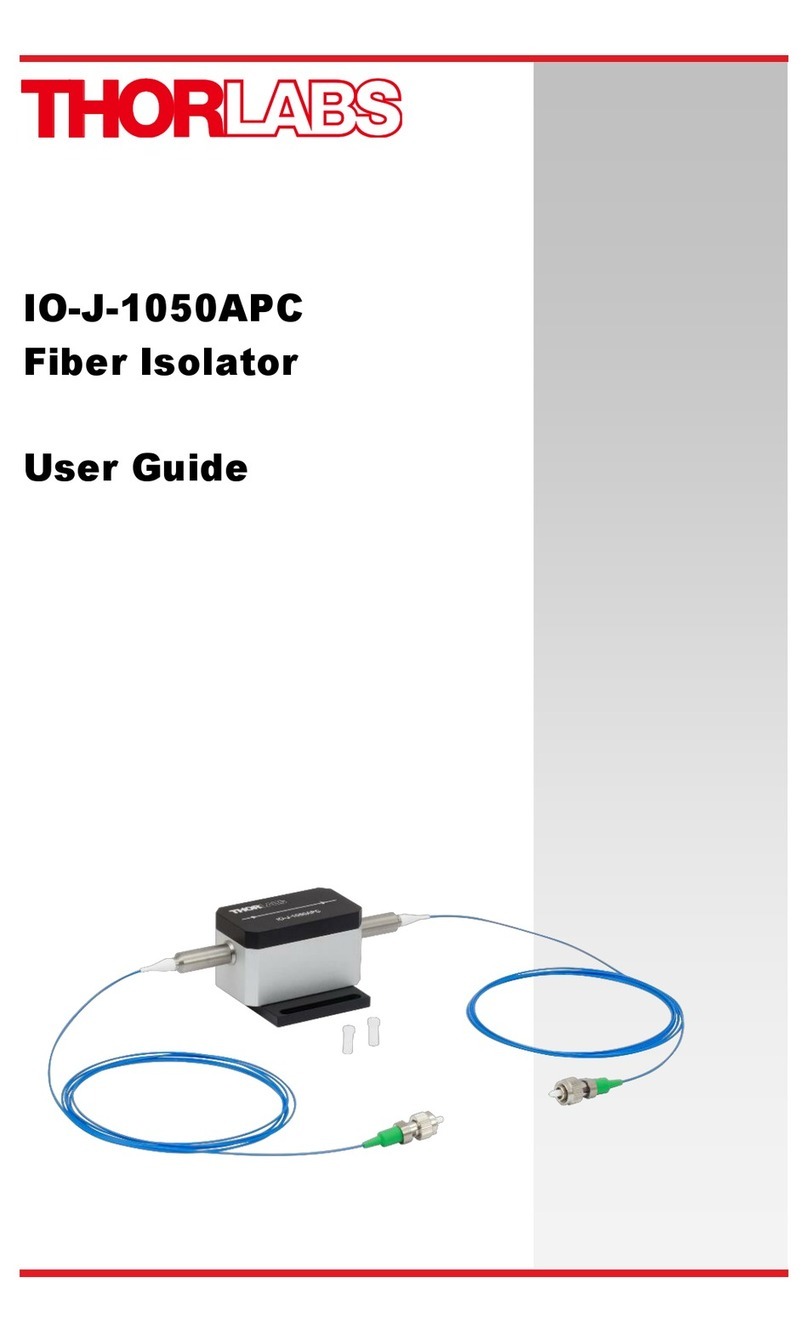

8.2 Type plate on milking automation

modules

The type plates on the modules are located at the

bottom of the module box and on the potting

compund covering the PCB on the inside of the

module, see . The type plates contains the infor-

mation shown in and a field description is given

in the table below.

DeLaval International AB

P.O. Box 39

SE-147 21 Tumba, Sweden

Made in Sweden

Type: Input/Output Module

Model: IOM 200

Art No: 2150003488

Serial no : HB00005

ID: A48E0A800057

Supply voltage: 24VDC, 5W,

output load excluded

DeLaval International AB

P.O. Box 39

SE-147 21 Tumba, Sweden

Made in Sweden

Type: Control and

communication Module

Model: CCM 215

Art No: 2150005045

Serial no : HB00005

ID: A48E0A800057

Supply voltage: 24VDC, 5W,

output load excluded

11 14

15

18

19

22

23

7

6

3

2

5

4

1

8

9

10

13

16

17

20

21

24

12

11

18

19

22

23

7

6

3

2

5

4

1

8

9

10

17

20

21

24

12

ETH

A B

Model:

Art No:

ID:

www.delaval.com Serial No:

275618

Fig. 2: Type plate locations on the modules. The

Button Module is used as an example.

A: Type plate layout for Button module and Input/

output module

B: Type plate layout for Communication and control

module

C: Small type plate layout for all modules

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 10 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

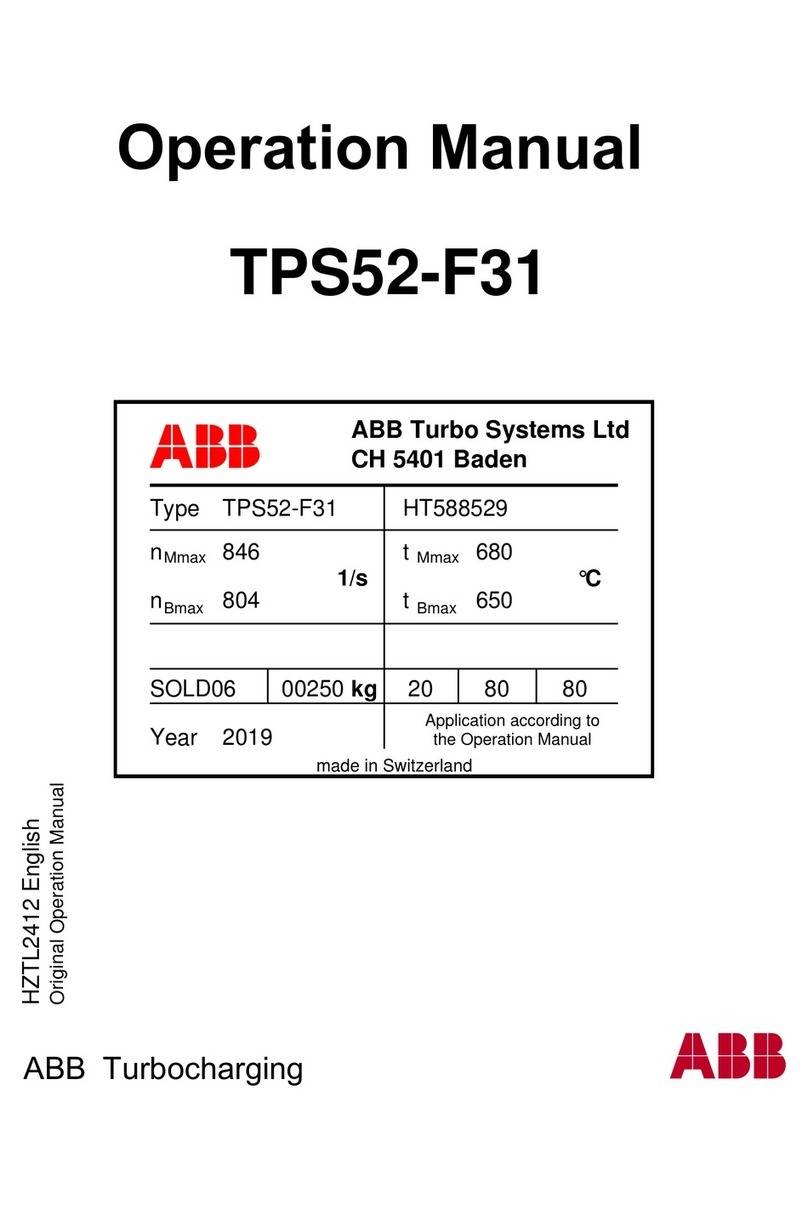

A DeLaval logotype

B CE-marking

C DeLaval address

D Crossed household waste bin

E Country of origin

F Module type

G Module model

H Bar code

J QR-code

K Article number

L Serial number

M Bluetooth address

N Supply voltage

P DeLaval web page address

9 Warranty

Note! DeLaval will not take any responsibility for

damage resulting from faulty installation, opera-

tion, or for improper or inadequate care and

maintenance.

Note! DeLaval will not take any responsibility for

any damage resulting from frost. The owner/user

must take the necessary measurements to pre-

vent the ambient temperature around the equip-

ment from dropping to or below freezing point.

Note! Modification may create risks not covered

by the original construction. Do not make any

modifications which has not been approved by

DeLaval.

DeLaval International AB

P.O. Box 39

SE-147 21 Tumba, Sweden

Made in Sweden

Type:

Model:

Art No:

Serial no :

ID:

Supply voltage:

11 14

15

18

19

22

23

7

6

3

2

5

4

1

8

9

10

13

16

17

20

21

24

12

Model:

Art No:

ID:

www.delaval.com Serial No:

AB

D

J

G

G

MP

K

L

C

H

EF

KL

MN

275619

Fig. 3: Module type plate.

DeLaval milking automation MA200 (Test installation)

Safety precautions

© DeLaval 2019.

2019-05-31, Version 1 11 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Quick guide

DeLaval milking automation

MA200 (Test installation)

1 MA200 quick guide

1.1 Automatic milking

1.1.1 Automatic operations

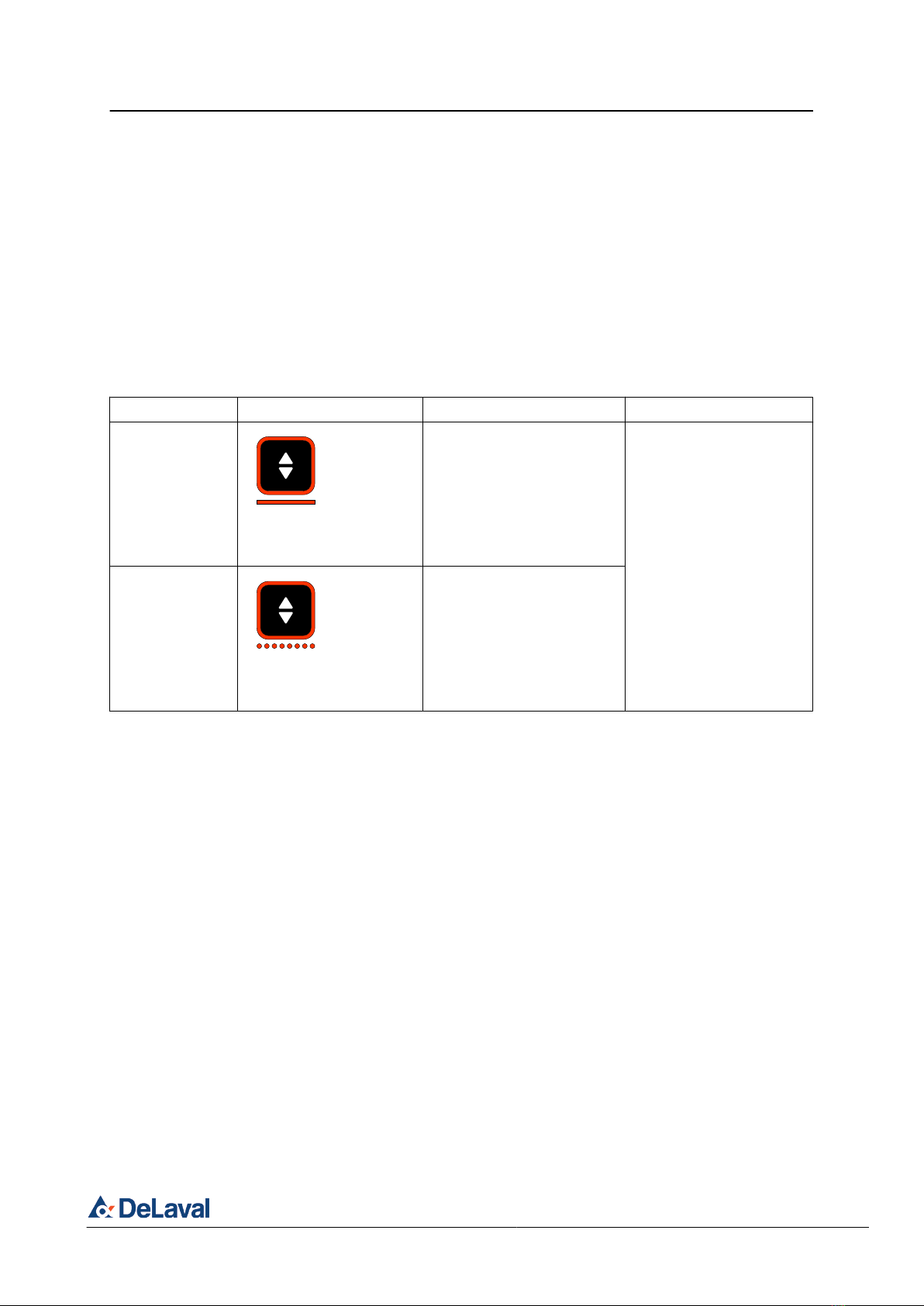

Status Indication Description Possible actions

Ready to operate

The indicator is solid cyan.

The button module is ready

to start milking a new animal.

Press:

Cluster release (Vacuum

and pulsation apply to the

cluster).

Press and hold:

Drop clusters.

Normal take-off

The indicator is solid

green.

On take off, when the animal

has finished milking and

milking alarms have not

been detected, see

Ä

Chapter 1.4 "Milking

alarms" on page 16.

Note! The indication ends

when either cluster releases

or cow exits the rotary.

Press:

Cluster release (reattach).

Press and hold:

Drop clusters.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 12 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

1.1.2 Milk flow phases

Note! The flow limits are set according to the

farm settings.

Status Indication Description Possible actions

Pre milking

phase

The indicator is flashing

white.

The cluster is attached to the

udder, the milk flow is below

low milk flow limit.

Press:

Manual milking

Press and hold:

Cancel Milking

Main milking

phase

The indicator is solid

white.

The milk flow has reached

the low flow limit.

Post milking

phase

The indicator is flashing

rapidly white.

The flow rate is reaching the

take-off limit.

1.2 Manual milking

During manual milking, the milker takes control

of the monitoring of the milking.

The automatic take-off is disabled.

Manual milking can be activated after the start of

the automatic milking and while the button mod-

ule is in any milk flow phase, refer to

Ä

Chapter 1.1.2 "Milk flow phases" on page 13.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 13 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Press the large button to toggle between auto-

matic and manual milking.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 14 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Manual milking indications

Status Indication Description Possible actions

Pre milking

phase

The indicator is solid yel-

low on the left and right

segments while the top

and bottom are white slow

flashing

The cluster is attached to the

udder, the milk flow is below

low milking flow limit.

Press:

Automatic milking, refer to

Ä

Chapter 1.1.2 "Milk flow

phases" on page 13.

Press and hold:

Take-off, refer to

Ä

Chapter 4.3 "Taking off

a cluster manually" on

page 44.

Main milking

phase

The indicator is solid yel-

low on the left and right

segments while the top

and bottom are white

solid.

The milk flow has reached

the low flow limit.

Post milking

phase

The indicator is solid yel-

low on the left and right

segments while the top

and bottom are white rapid

flashing.

The flow rate is reaching the

take-off limit.

Overmilking

alarm

The indicator is flashing

rapidly red the left and

right segments synchron-

ised together with rapid

flashing of the top and bot-

tom segment.

The milk flow has reached

the take-off limit.

Press:

Automatic milking, refer to

Ä

Chapter 1.1.2 "Milk flow

phases" on page 13.

Press and hold:

Take-off, refer to

Ä

Chapter 4.3 "Taking off

a cluster manually" on

page 44.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 15 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

1.3 Herd management alarms

Herd Management alarms are pre-set according

to special conditions of the animal.

Note! To set a herd management alarm to an

animal, see DelPro software.

Note! The indications of the herd management

alarms are shown only by the large button indi-

cator.

Status Indication Description Possible actions

Do not Milk

(Large button is

blocked)

The large button indicator

is solid red

This animal is not eligible to

milk extraction.

Press:

N/A

Press and hold:

Override, refer to

Ä

Chapter 1.5 "Over-

ride" on page 20.

Dump milk

(Large button is

blocked)

The large button indicator

is rapid flashing red.

The milk of this animal is not

eligible to be mixed with the

milk for general collection.

Note! Consider milking in a

bucket, refer to linktarget doesn't

exist but @y.link.required='true'.

1.4 Milking alarms

Note! On rotaries using retention bars, when a

milking alarm is detected, the retention bar can

be lowered immediately on detection or at the

confirmed point according to farm settings. See

Ä

Chapter 1.9.3 "Additional rota-

tion" on page 25.

Note! Cluster take-off can be implemented

immediately on detection of a milking alarm

according to farm settings, unless if manual milk-

ing is active.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 16 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

1.4.1 Low milk yield and premature take-off alarm

indication

Status Indication Description Possible actions

Low milk yield

detection

The indicator is rapidly

flashing yellow in all seg-

ments.

Occurs on take off, when the

milk yield has not reached

the expected yield limit.

Note! The yield limit value is

a seven days average,

weighed with milking Inter-

val.

Press:

Cluster release (reattach),

refer to

Ä

Chapter 4.4

"Reattaching a cluster" on

page 45.

Press and hold:

Cluster drop

Premature take-

off

Occurs when, after take-

off, the minimum milking

time limit, according to

farm settings, is not

reached.

Consider reattach.

Note! The alarm clears

when, whichever occurs

first, cluster release (reat-

tachment) or cluster drop or

on the IDD.

1.4.2 General milking alarms

A number of milking alarms share the same indi-

cation, according to farm settings. When one or

more general milking alarms is detected. Further

information regarding the condition of the Milking

alarm is available on the IDD.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 17 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Note! Cluster attachment can be blocked after

cluster take-off on detection of a General Milking

alarm, according to farm settings. To override,

see

Ä

Chapter 1.5 "Override" on page 20.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 18 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

Status Indication Description Alarm handling Possible

actions

Air leakage

detection

The large button

indicator is flash-

ing yellow slowly

Occurs due to liner slip or

other leakage on teat

cups.

Identify and fix the air leak-

age.

Note! The alarm clears

when, whichever occur first,

the air leakage stops or on

cluster take- off or on the

IDD.

Press:

Cluster

release

(reattach),

refer to

Ä

Chapter

4.4 "Reat-

taching a

cluster" on

page 45.

Press and

hold:

Drop clusters

Note! If clus-

ter attach-

ment is

blocked, see

Ä

Chapter

1.5 "Over-

ride" on

page 20.

Kick-off

detection

Occurs when the animal

has physically kicked-off

and detach the clusters

while milking.

Consider reattachment.

Note! The alarm clears

when, whichever occur first,

cluster release (reattach-

ment) or cluster drop or on

the IDD.

Blocked air

bleed detec-

tion

Occurs when blockage of

the airbleed in the cluster

is detected and the Milk

is not evacuated from the

cluster properly.

Clean the hole to unblock

and consider reattaching.

Note! The alarm clears

when, whichever occur first,

the hole unblocks and the air

levels go back to normal or

on cluster release (reattach-

ment) or on the IDD.

Blood detec-

tion

Occurs when the aver-

age blood concentration

In the milk during this

milking exceeds a

threshold set by the user.

If the cluster is retracted due

to a blood alarm it is not rec-

ommended to reattach the

cluster as the blood detected

is not always visible in the

milk. Consider milking in a

bugget.

Note! The alarm clears

when, whichever occur first,

cluster release (reattach-

ment) or cluster drop or on

the IDD.

Milk conduc-

tivity alarm

Occurs when the relative

deviation between aver-

age conductivity during

ongoing milking and the

expected conductivity for

the cow exceeds a set

threshold (the expected

Conductivity is based on

a 7 days average con-

ductivity).

Follow the farm’s Conductiv-

ity management instruc-

tions.

Note! The alarm clears

when, whichever occur first,

conductivity levels return to

normal, cluster release (reat-

tachment) or cluster drop or

on the IDD.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 19 (62)

Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

•The tubes in the peristaltic pumps should

be replaced at least two times a year.

•The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

1.4.3 Optional milking alarm indication

The indicator turns to solid yellow.

It can be activated and used for one of the gen-

eral milking alarms according to the farm set-

tings.

1.5 Override

Override unblocks the large button.

nPress and hold the large button to unblock

it and enable cluster attachment until the indi-

cator indicates the override remainder. For

more information, see

Ä

Chapter 1.6 "Over-

ride reminders" on page 20.

Note! When herd management alarm overriden,

override alarm appears, see

Ä

Chapter 1.3 "Herd

management alarms" on page 16.

1.6 Override reminders

After overriding a herd management alarm, a

reminder is indicated on the large button indicator

and remains active until the animal exit the rotary.

The reminder indication is a red top segment on

the large button. The rest segments are indicat-

ing according to the function indications.

DeLaval milking automation MA200 (Test installation)

Quick guide

© DeLaval 2019.

2019-05-31, Version 1 20 (62)