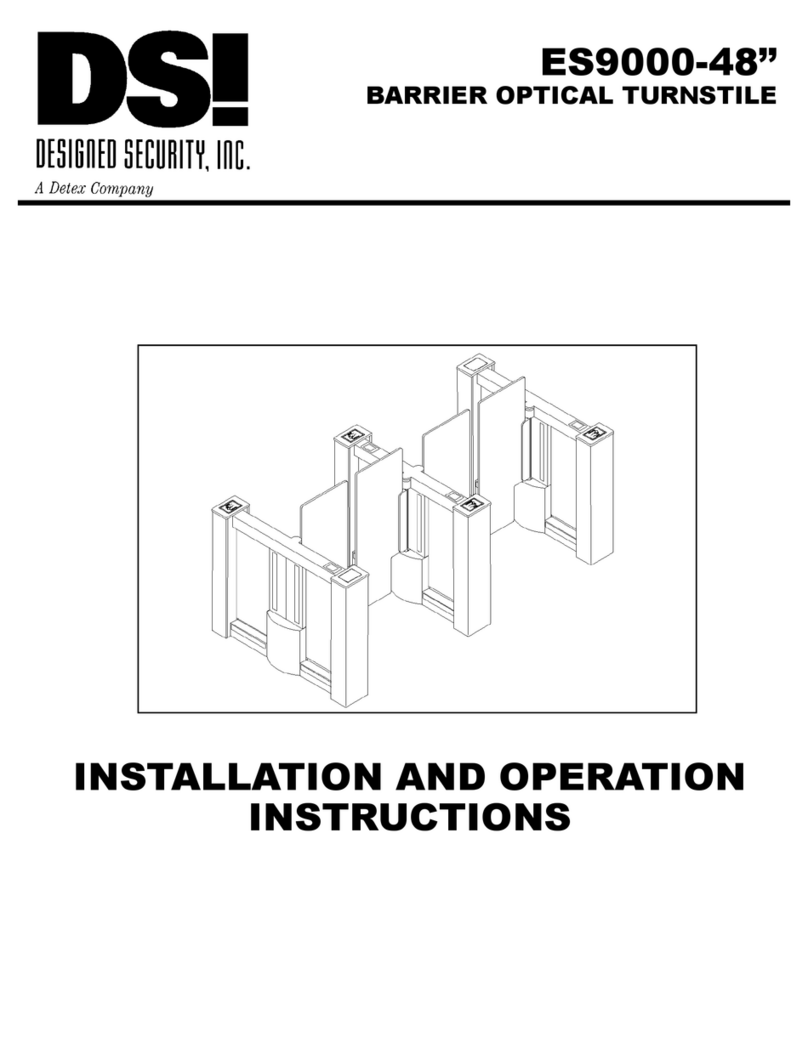

DELEX DSI ES8302 Dual Arm Owner's manual

ES8302 Dual Arm

BARRIER ARM OPTICAL TURNSTILE

INSTALLATION AND OPERATION

INSTRUCTIONS

3

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

CUSTOM NOTES

5

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

SITE PREPARATION

7

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

Refer to LANE PLACEMENT ERGONOMICS in the Appendix for information

regarding planning considerations which can maximize efficient traffic flow and

minimize nuisance alarms. Taking into consideration any installation from the

perspective of providing access control while minimizing the impact on the user’s

daily routine may allow security goals to be met more effectively.

PRE-INSTALLATION REQUIREMENTS

Conduit or other cableway:

1. From Access Control System to Each Lane’s Electronics for Input and Output connections.

2. From each Lane’s Electronics Side to opposite Arm for Motor and Encoder control cabling.

Mounting Anchors or Floor Plate:

A solid, stable mounting point for each bollard is necessary to maintain proper optical alignment.

Refer to information included for Specifications, and Layout, Squaring, and Leveling techniques.

See Base Plate Template or Dimensional drawing for access and mounting detail

PRE-INSTALLATION CONSIDERATIONS

The DSI Barrier Arm Optical Turnstile, although “high-tech”, is really a very straight-forward

installation when a little time is taken to prepare before you begin.

You may choose to take the time now to read and understand the installation and operation instructions

in order to gain an understanding of what the system does and what is required from you to install your

system. Experienced installers will find in this manual everything needed for trouble-free installation.

We are available to assist you by calling 800 272 3555 for Customer Support.

Treat the units as you would any fine furniture or delicate instrument. Keep them out of harsh

environments. Do not store or install them where they will be exposed to inclement weather, or

extremes of humidity, dust, or temperature. This will insure that they will keep their appearance and

functionality for many years to come.

When installing the wiring, be certain to strain-relief the cables to some hard point in the bollard and

leave enough service loop on each cable for any future repairs, component removal or upgrade. In

other words, take the time to route your wires in such a way that they will not be damaged, or in the

way, should the unit require servicing in the future.

Precautions should be taken to properly ground the units to a known “Earth Ground”, during the

mounting process, to prevent any ESD (electro-static discharge) damage to the electronics during

installation and operation.

9

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

INSTALLATION

11

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

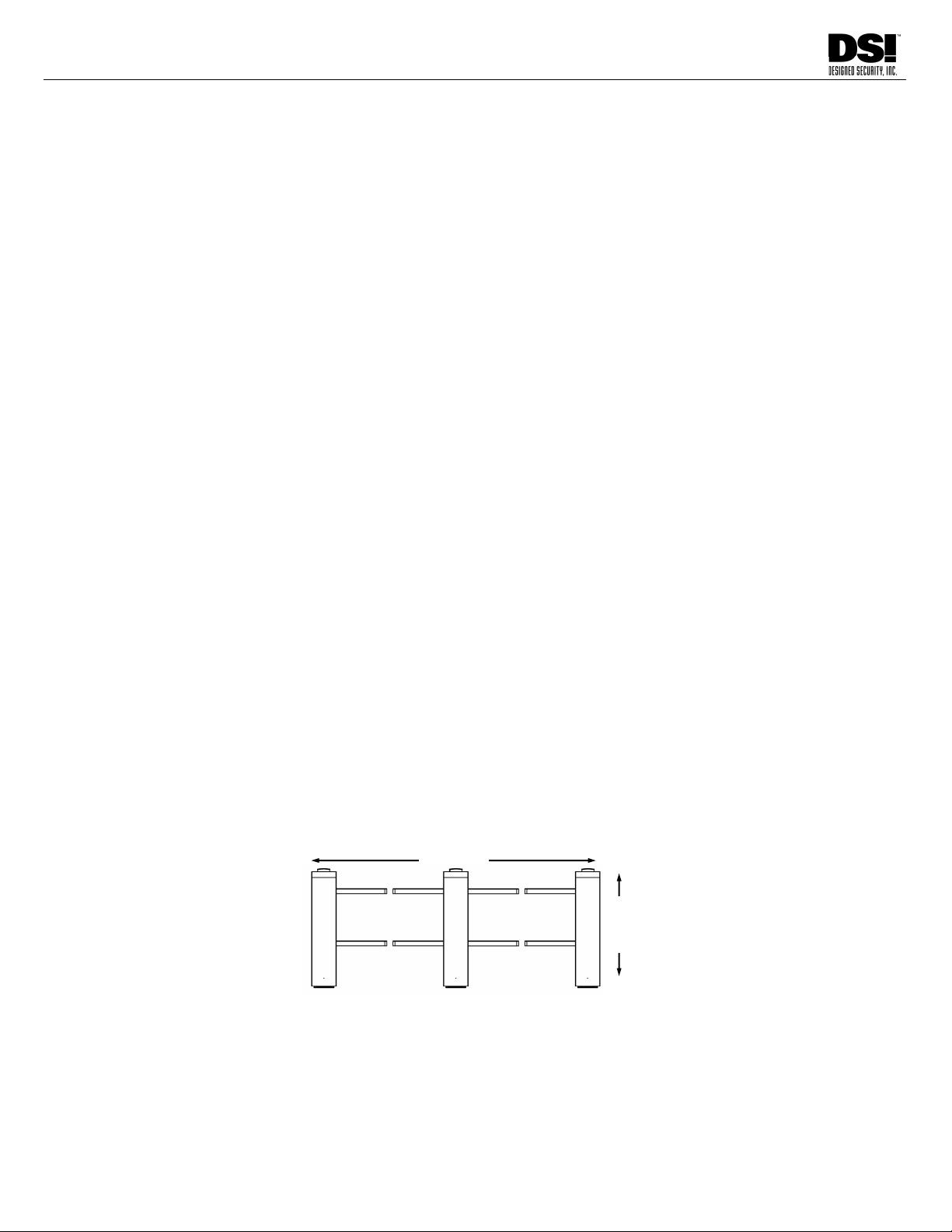

INITIAL LAYOUT

Placement :

The bollards are designed to be placed in a parallel arrangement, not to exceed 48 inches between

bollards.

Spacing of 36” between bollards is our standard.

(Custom ordered lane spacing may differ from standard)

Mounting should leave a 2” gap between extended arms.

Verify the design specification for each lane prior to attachment. Refer to architectural plans, or set

the bollards up in proper order, with arms extended to determine appropriate spacing.

Ergonomics :

The number of lanes required is determined based upon the peak traffic volume and available

space. Contact the DSI Sales team for additional information.

The placement of the lanes should compliment the natural flow of traffic and not impede the flow any

more than necessary to achieve access control goals.

Care should be taken in placing the bollards to ensure that the user may easily access the Reader

System* (I.E.: Mag. Card, Proximity, Biometric, etc. [*provided by installer/integrator]) while

maintaining a reasonable flow of pedestrian traffic. (Readers may be pre-installed on some

applications) If you have any questions regarding Reader mounting, contact the DSI Support team.

Function :

For technical and aesthetic reasons it is very important to insure that the bollards are installed level

and plumb (horizontal and vertical), and in alignment with one another (parallel). Obviously the

installation will look better, and more importantly it will make the setup and adjustment of the optical

sensors much easier. More about this will be covered in the “Leveling and Aligning” section.

Quality Installation :

Experienced installation crews have found how attention

to detail during layout, anchoring, and performing the

leveling techniques will save valuable time and prevent having to spend much more time

later correcting optical alignment issues.

Verify the surface you are installing upon is not bowed or crowned. Shim Bollard to compensate for

uneven surfaces.

HORIZONTAL

VERTICAL

12

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

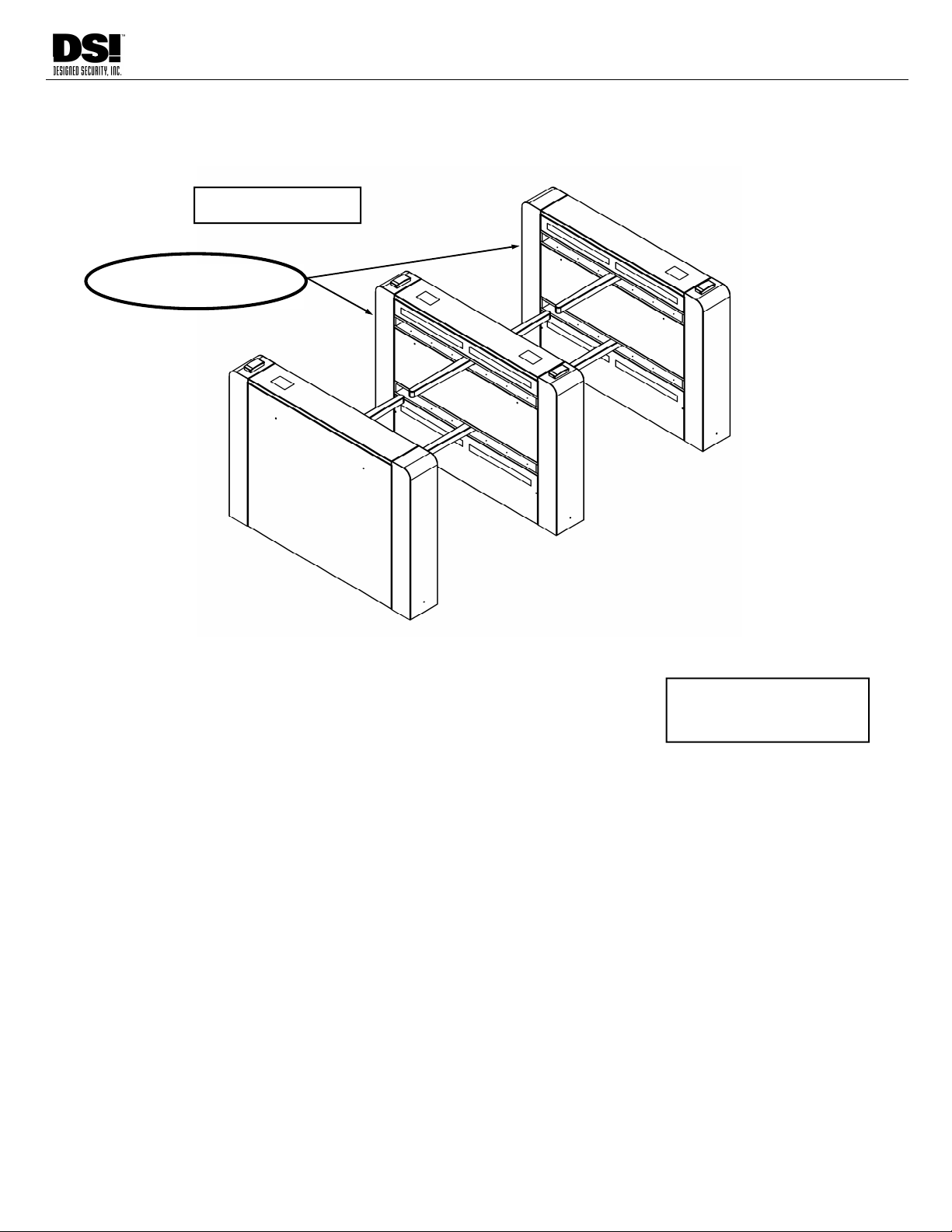

BOLLARD ORIENTATION

SECURE (EXIT)/UN-SECURE (ENTRY) SIDES—

DEFINED

In the above illustration the orientation of the bollards is shown to help installers understand the proper

placement of the Turnstiles in reference to the direction of traffic.

When entering the lane from the Un-Secure side, or Entrance Side, the Electronics Package for that

lane will be located, facing into the lane, in the bollard on the right.

NOTE: Be certain of this orientation prior to bolting the

bollard to the surface and running cables!

ENTRANCE SIDE

(UNSECURE)

ELECTRONICS LOCATION

Secure Side End

SECURE SIDE

13

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

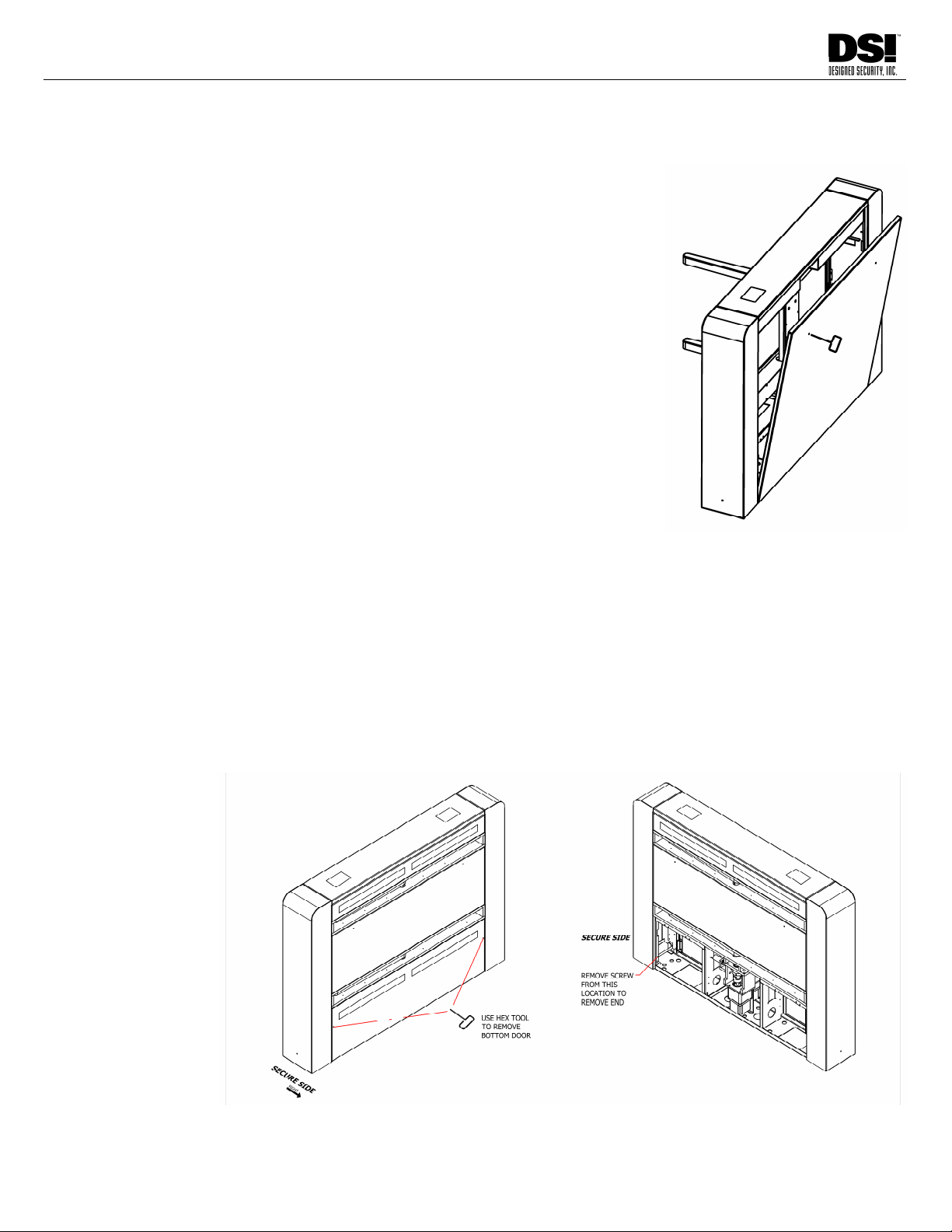

PANEL REMOVAL STEPS

Insert “T-Handle” Hex-key wrench into small hole near the top, side edge of panel.

Turn 3/4 turn Counter-Clockwise to release latch.

Repeat above steps for other small hole at opposite side of panel. Be ready to catch

panel.

Tilt panel away from the Bollard, then lift up to remove from lower pins. Use wrench to

get tilt-out started if necessary, by applying slight pressure down on wrench and

pulling, simultaneously. (minimal force)

Place removed panel in safe location. Take care to avoid damaging finish or creating

a hazard to pedestrian traffic.

PANEL INSTALLATION STEPS

Place panel on Hinge Points.

Tilt into place in Bollard.

Insert “T-Handle” Hex-key wrench into small hole near the top, side edge of panel.

Turn 3/4 turn Clockwise to latch.

Repeat for other small hole on opposite side of panel

BOLLARD INTERNAL ACCESS

14

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

LAYOUT AND MOUNTING

BOLLARD LAYOUT

Using a chalk line, or equivalent method, lay out the bollard arrangement. Bollard’s positions should be parallel and

square with each other.

Verify the “on centers” measurement to accommodate the bollard width and clearance for barrier arm operation prior to

setting anchors or drilling for conduit.

After going over the details of the installation with the architect or designer and you have determined planned

spacing and orientation of the system, you may have some questions regarding how to lay out the array of bollards

with the most accuracy in regard to alignment.

Here are two alignment tips which may be helpful:

Tip 1- Determining a “Right Angle” for alignment.

Without getting into a lot of math, there is a simple way to build a Right-Angle

Triangle by using sides of 3', 4' and 5'.

This method is based upon a geometric Theorem [a² + b² = c²]. Using this you

can calculate the length of the long side (C) of any right-angle triangle based

upon the known length of the other two sides.

Use this device to verify alignment by referencing a chalk line on the

floor.

Tip 2 - Alignment Check

Once you have established a known right-angle to the initial chalk-line, you will

want to verify that each bollard is aligned to the adjacent bollard.

You may do this by choosing a point on each end of a bollard, (for instance the

center of a mounting hole or a corner of a pedestal), you can measure in an “X”

pattern from one point to it’s opposite in the “X”.

When the bollards are the correct distance apart and both lengths of the “X” are

equal, the bollards are in alignment.

VERTICAL ALIGNMENT

Check level of the bollards vertically using a plumb or spirit level, use shims to make final

adjustments.

LEVEL

Level the bollards horizontally using a straight edge and/or a spirit level that will span two or three bollards at once.

ANCHORS

Use appropriate anchors for the mounting surface. Tighten securely to prevent any movement of the bollard.

Some custom models may have special mounting requirements. Additional information will have been provided when

necessary.

A C

B

BOLLARD

CHALK LINE

BOLLARD

BOLLARD

15

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

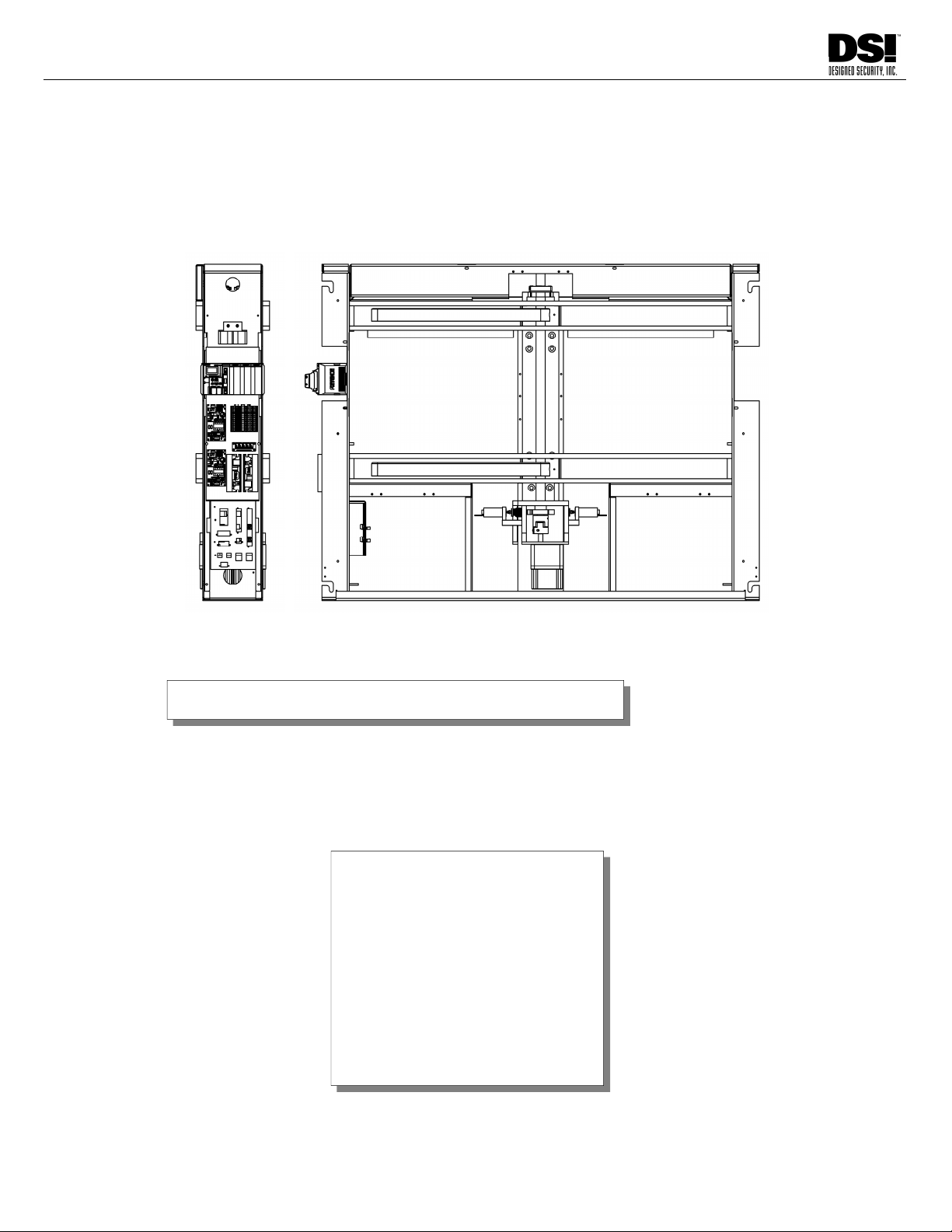

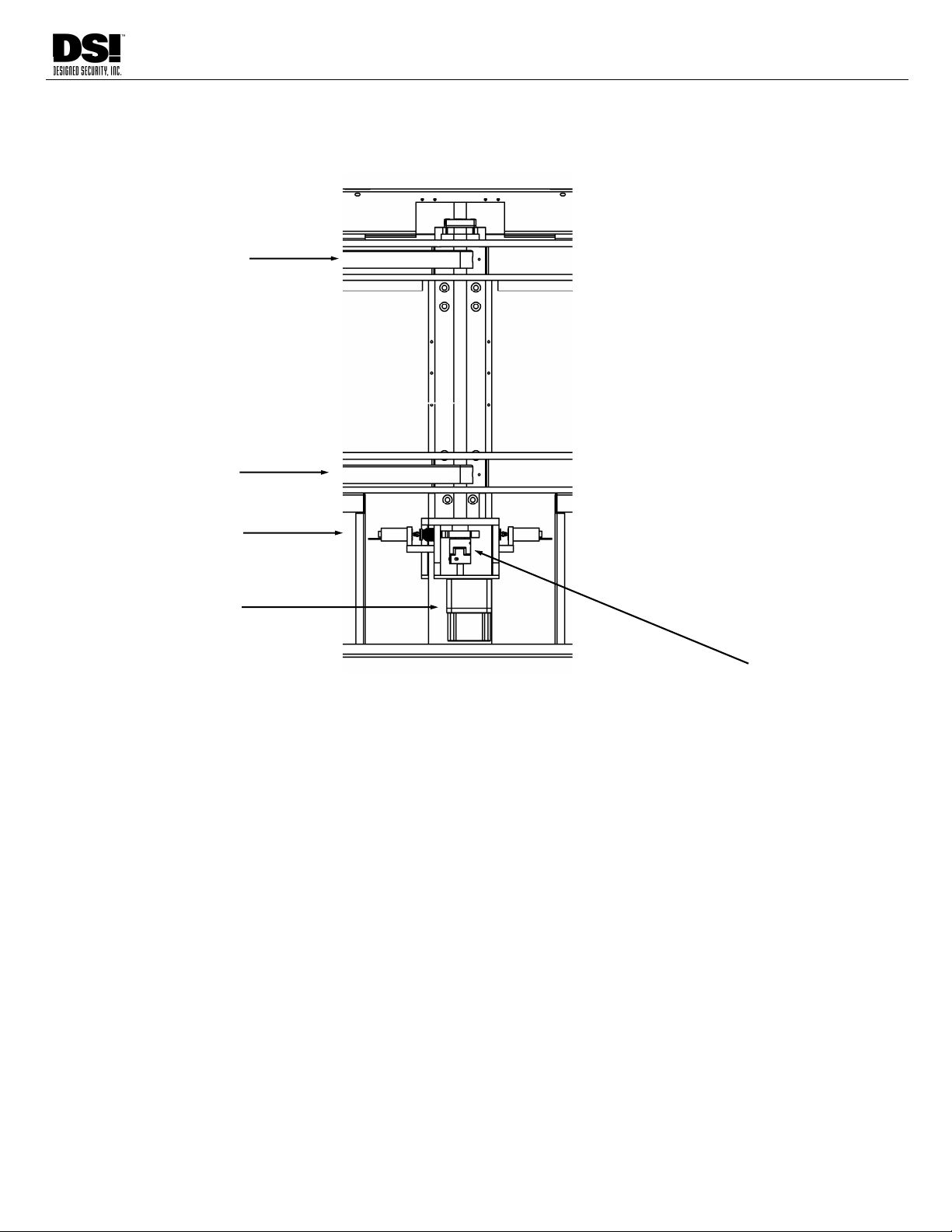

COMPONENT LOCATION

ENCODER

BARRIER ARM

D SENSORS C SENSORS

B & A SENSORS

MOTOR

ELECTRONICS

PACKAGE

MOUNTING

POINTS &

CABLE ACCESS

MOUNTING

POINTS &

CABLE ACCESS

END VIEW B-SIDE SHOWN

The A-Side of each Bollard will

have either;

A Motor/Arm Assembly

and Reflectors, or

Will be blank if it is on the

Right-most end of a set of

lanes when viewed from the

Entrance (Un-secure) side.

BARRIER ARM

16

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

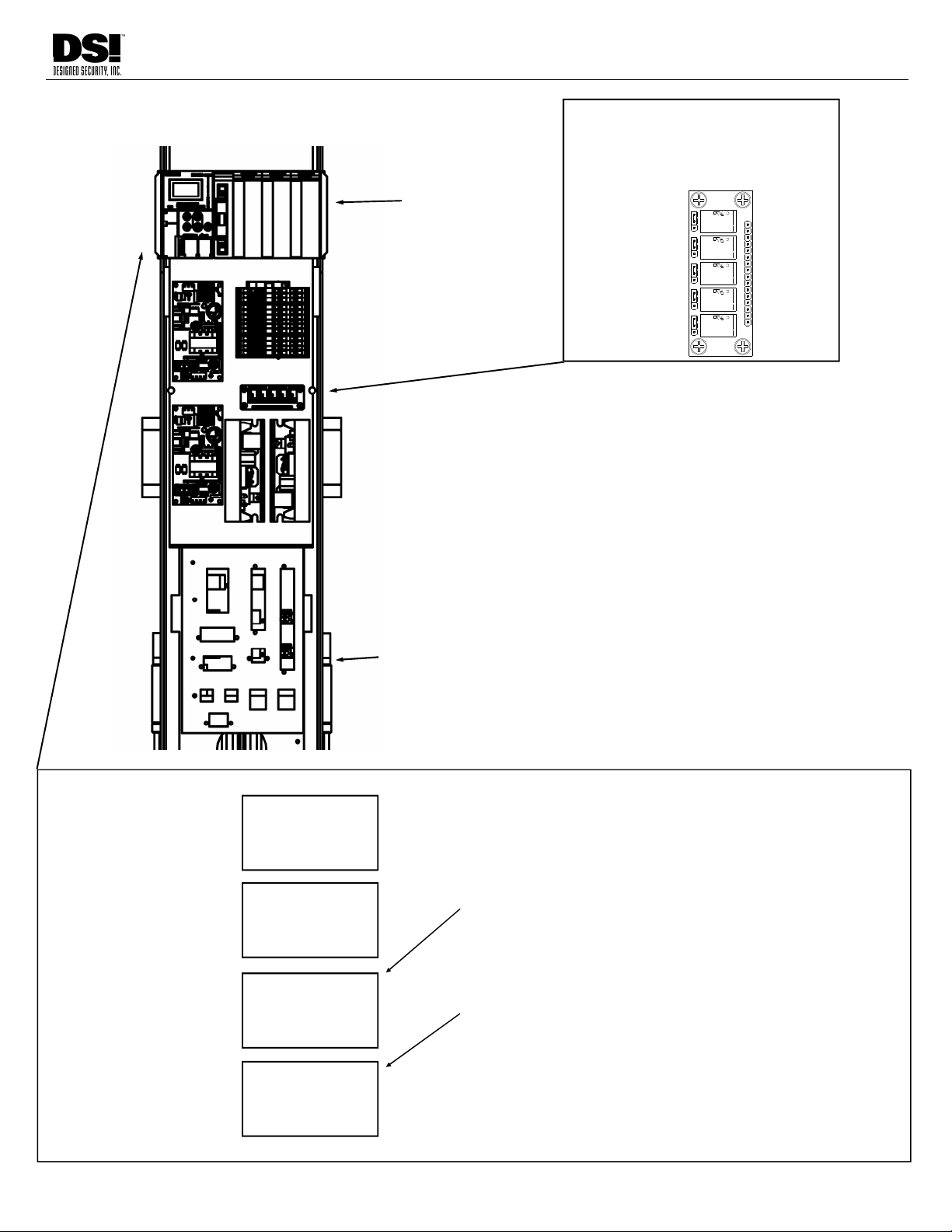

ELECTRONICS PACKAGE

BRIDGE PANEL

PLC

CONTROLLER

N/O OR N/C OUTPUT JUMPER

JUMPER LOCATED BESIDE EACH OUTPUT

RELAY MAY BE CONFIGURED FOR N/O OR

N/C OPERATION (DEFAULT IS N/O)

U10108H

REV0 COMP

BLC052102

TQ2-5V

ATQ202

NAIS

JAPAN

K5

SA

DSI

NAIS

K3

TQ2-5V

TQ2-5V

NAIS

ATQ202

NAIS

J5

U

JAPAN

10108H

J4

SA

K4

ATQ202

U10108H

J3

JAPAN

SA

JAPAN

TQ2-5V

ATQ202

NAIS

TQ2-5V

ATQ202

JAPAN

J2

10108HU

K2K1

SA

831 RELAY

U10108H

J1

SA

GATE FORCED

BYPASS

VALID

PASSAGE

TIMEOUT

ALARM

Move Jumper to

cover center and

lower pins for

N/C Output.

Default-Jumper

covers upper and

center pins for

N/O Output

SET TRIMMERS

(setting of “10” = 1 second)

To reach top menu press “M” key 3 times .

Use down arrow to highlight “3. Trimmers”. Press “Return”

Display will show “TRM0 Direct”. This is the Card Access Delay.

Use Left-Right Button to set Increment Value

Use Up and Down Buttons to change Current setting value

To move to next setting press “Return”

Display will show “TRM1 Direct”. This is the Auto Reset Time.

Use up arrow to increase value from “0” to “50”.

To return to “TRM0” press “Return” 7 times

To return to top menu press “M” key.

1.DeviceMode

2.ErrorClr

3.Trimmer

4.I/O TEST

TRMO Direct

50

L 300

1

TRM1 Direct

50

L 300

1

Project Name

GB030000

Start Screen

Version #

Top Menu

Trimmer 0 Card Access Dly

Current (default 50 = 5 sec)

Max Limit (300=30 sec)

Increment

Trimmer 1 Auto Reset Time

Current

Maximum

Increment

BA120000

17

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

COMPONENT DESCRIPTION

Electronics Package

The Electronics are found in the right-hand pedestal as seen when facing the B-Side of the

bollard. (A-side holds the #2 Motor and reflectors for the lane.)

The Motor Controllers control the local arm and the remote arm. These are mounted in the

upper left-hand corner of the Electronics Package.

The PLC (Programmable Logic Controller) is the Module mounted on the DIN Rail and below

the Motor Controller(s). The PLC controls the arms by reading the Encoder position information

and communicating arm movement information to the Motor Controllers in response to PLC

inputs.

Sensors

The C1 & 2 Sensors are used to detect objects present in the arm path on the un-secure side of

the lane. If something is blocking these beams, the arms will not move to allow a user to exit

from the secure side (although the arms may always be pushed open in an emergency).

The D1 & 2 Sensors work similarly for users exiting from the secure side (IE: blocking this beam

will prevent the arms from moving) and, in addition these sensors will detect the presence of an

exiting user, when in “Free Exit” mode, and tell the PLC to move the arms to allow egress.

PLC Controller

The PLC (Programmable Logic Controller) is made up of several modules. All Inputs terminate

here and all Outputs originate here. The operating software runs on the PLC.

Wall and Bridge Connection Panels

The Wall is a panel located beside the Motor Controllers, on the left side of the Electronics

Package. All wiring for the lane’s local components goes through the Wall panel; including

Motor 1; Encoder 1; optional Lock Solenoid; and all Sensor connections.

The Bridge is a hinged panel located in front of the Electronics Module. All Input and Output

wiring and Remote; Motor 2, Encoder 2, optional Lock Solenoid, and Graphic Array cabling

terminates on the Bridge.

Additional detail regarding the Bridge panel and connectors is found in the Wiring section.

18

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

BARRIER ARM DRIVE ASSEMBLY

The Motor/Arm Assembly is the center section of the bollard, located between the two pedestals.

Located above the Barrier Arm housing is the Encoder. This is a very sensitive encoder used to detect

Barrier Arm position and provide this information to the Indexer. It is attached to the end of the shaft

that drives the Arm.

Below the Encoder is the Barrier Arm. Located on the same shaft.

(Units with optional Locking Arm will have Locking Solenoid hardware mounted on this shaft.)

This shaft goes into a shaft Coupler that allows quick removal of the Motor/Gearbox assembly for

maintenance and repair.

Beneath the Coupler is the Motor/Gearbox Assembly that drives the Barrier Arm.

Below the Arm Housing will be located either the B & A Sensors (below the Motor 1) or the B & A

Retro-reflectors (below the Motor 2). These are the sensor beams that detect direction of travel,

tailgating violations, and passage-complete for valid users.

ENCODER

BARRIER ARM

COUPLER

MOTOR/GEARBOX

ASSEMBLY

“B” & “A” SENSORS

LOCKING ARM

SOLENOID

(optional)

BARRIER ARM

WIRING

20

DESIGNED SECURITY INC

800-272-3555 www.dsigo.com

1402 Hawthorne Street Bastrop, Texas 78602 Fax 512 321 9181 Email: [email protected]

INS8302

WIRING

CABLE ROUTING

The Motor 2 and Encoder 2 cables must be routed between the “A” and “B” Sides of each

lane. (15 ft. cables included)

Optional Locking Arm: Additional Locking Solenoid cable is required to be pulled along with the standard

Motor 2 and Encoder 2 control cables.

If you are installing multiple lanes, you may want to use the next lane’s cable as reference

when reconnecting the cable to the connector to assure correct wire placement. Reference

wire color/pin-out information in this document.

Begin wiring from the Right-most bollard when facing from the Entrance (un-secure) side.

This bollard should have the Electronics Package in the side facing into the lane.

Leave adequate service loop in cables. Route cables neatly in pedestal.

Check conduit or cableway for airflow using a strip of tissue paper. If airflow is detected,

use paper or foam material to block airflow through conduit access hole. Airflow through

chassis may result in rapid dust accumulation on sensor optics which can lead to false alarms

and frequent cleaning requirements.

Power Cable must be of sufficient Gauge to provide 24VDC under load, measured at the

Power Input Connector. (See Power Wire Gauge Calculator in Appendix)

CABLE TERMINATION

Use the included WAGO™ tool to

remove and connect the wires on

each of the WAGO™ connectors.

Photo shows WAGO™ tool in use.

Hook over edge and press tab into

connector to release spring holding

each wire.

Table of contents

Other DELEX Turnstile manuals

Popular Turnstile manuals by other brands

Detex

Detex DSI ES9000-48 Assembly, installation and operation instructions

Rise

Rise RTF installation manual

PERCo

PERCo TTD-12A Assembly and operation manual

Alvarado

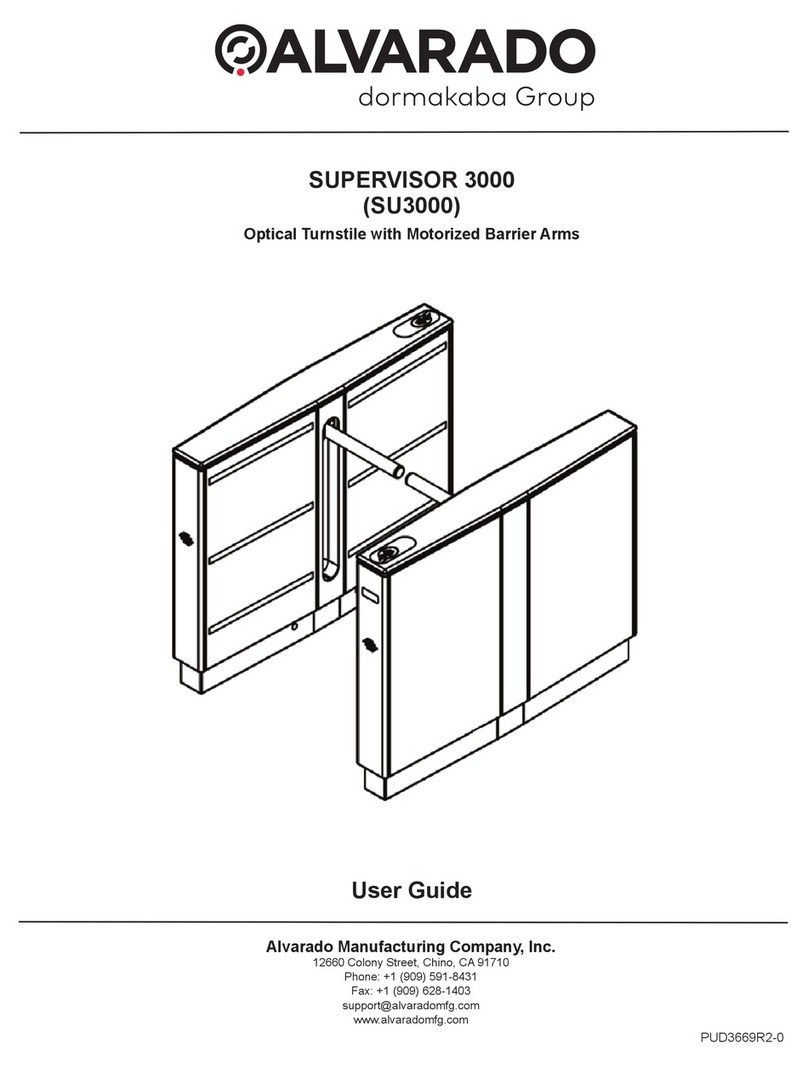

Alvarado SUPERVISOR 3000 user guide

Magnetic Autocontrol

Magnetic Autocontrol MPS-122 operating instructions

CAME

CAME TWISTER LIGHT PSBPS07N installation manual