Detex DSI ES9000-48 Owner's manual

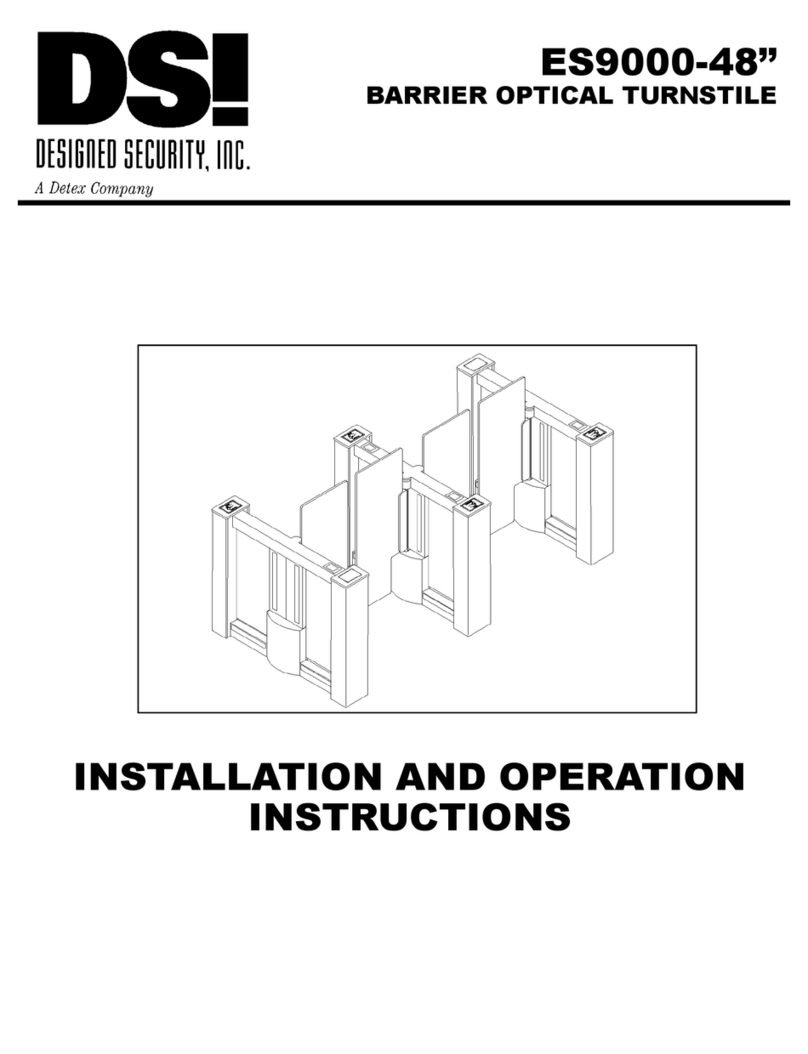

ES9000-48”

BARRIER OPTICAL TURNSTILE

INSTALLATION AND OPERATION

INSTRUCTIONS

3

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

INTRODUCTION

Welcome to the DSI family! The DSI ES9000 Barrier Optical Turnstile, although “high-tech”, is really

a very straight-forward installation when a little time is taken to prepare before you begin.

You may choose to take the time now to read and understand the installation and operation instructions

in order to gain an understanding of what the system does and what is required from you to install your

system. Experienced installers will find in this manual everything needed for trouble-free installation.

We are available to assist you by calling 800 272 3555 for Customer Support.

Treat the units as you would any fine furniture or delicate instrument. Keep them out of harsh

environments. Do not store or install them where they will be exposed to inclement weather, or

extremes of humidity, dust, or temperature. This will insure that they will keep their appearance and

functionality for many years to come.

When installing the wiring, be certain to strain-relief the cables to some hard point in the pedestal

and leave enough service loop on each cable for any future repairs, component removal or upgrade.

In other words, take the time to route your wires in such a way that they will not be damaged, or in

the way, should the unit require servicing in the future.

Precautions should be taken to properly ground the units to a known “Earth Ground”, during the

mounting process, to prevent any ESD (electro-static discharge) damage to the electronics during

installation and operation.

Your product may include customizations not described in the main text of this manual. The next page

includes notes outlining these customizations.

4 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

CUSTOM NOTES

5

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

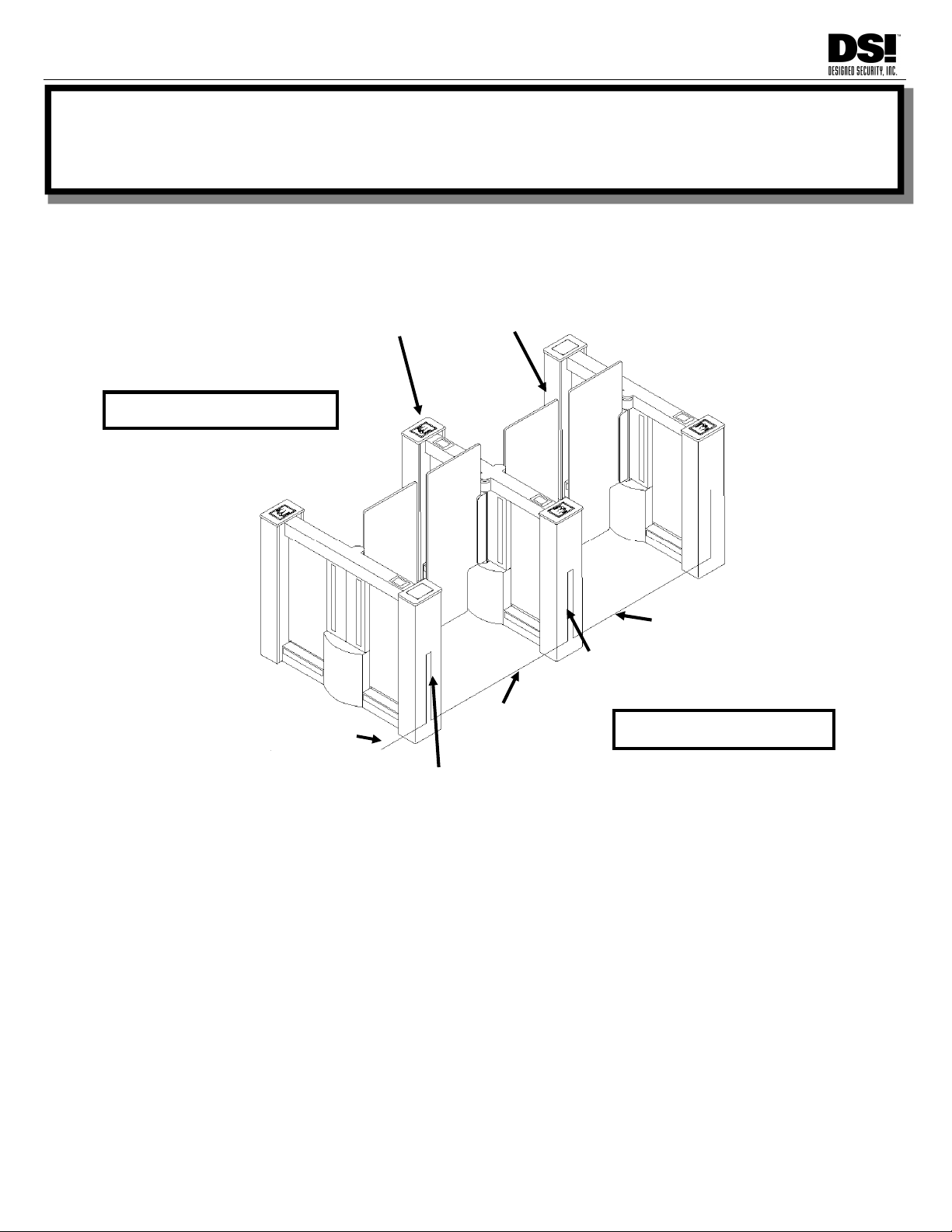

Precise placement and alignment of pedestals is critical for both functional and aesthetic

performance. Ensure pedestals are properly spaced and aligned square, level, and plumb.

Refer to the following diagram for expressions used in this section

LOCATING YOUR TURNSTILE SYSTEM

There are three key technical considerations for locating the turnstiles. Two fairly obvious, the other,

not as much.

The first obvious consideration is that a solid, stable mounting point for each pedestal is necessary to

maintain proper alignment. Select a location that is flat and level, minimizing crowns or bows that would

require pedestal shimming.

The second fairly obvious placement consideration is not to put turnstiles such that either vestibule is

too close to a perpendicular barrier such as a wall, door, or velvet rope. This can cause queueing

issues that will slow traffic and possibly leave users stranded in the lane waiting for traffic to clear.

Pedestals placed too close to walls may make cover removal difficult.

The not-so-obvious consideration concerns Free Exit applications. If the Exit side approach is too long,

users may be encouraged to achieve speeds such that they will get to the gate before it fully opens.

ENTRY/PUBLIC SIDE

EXIT/SECURE SIDE

PRIMARY/LOCAL

ELECTRONICS

REMOTE ELECTRONICS

EXIT

VESTIBULE

EXIT

VESTIBULE

ENTRY VESTIBULE

PRIMARY/LOCAL

ELECTRONICS

2 “B” WIRE GROUPS

1 “A” WIRE GROUP

1 “B” WIRE GROUP

1 “A” WIRE GROUP

ENTRY VESTIBULE

SITE PREPARATION

6 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

LAYOUT AND MOUNTING

PEDESTAL LAYOUT

Using a chalk line, or equivalent method, lay out the pedestal arrangement. Pedestal positions should be parallel and

square with each other.

PEDESTAL SPACING

Verify the “on centers” measurement to accommodate the pedestal width and clearance for barrier operation prior to

setting anchors or drilling for conduit.

Lanes are specified by open walkway space—typically 36”. The pedestals measure 8” wide, so, in this case, the on-

center measurement would be 44”

This spacing will maintain a minimum 3.5” between the extended gate panels.

After going over the details of the installation with the architect or designer and you have determined planned

spacing and orientation of the system, you may have some questions regarding how to lay out the array of

pedestals with the most accuracy in regard to alignment.

Here are two alignment tips which may be helpful:

Tip 1- Determining a “Right Angle” for alignment.

Without getting into a lot of math, there is a simple way to build a Right-Angle

Triangle by using sides of 3', 4' and 5'.

This method is based upon a geometric Theorem [a² + b² = c²]. Using this you

can calculate the length of the long side (C) of any right-angle triangle based

upon the known length of the other two sides.

Use this device to verify alignment by referencing a chalk line on the

floor.

Tip 2 - Alignment Check

Once you have established a known right-angle to the initial chalk-line, you will

want to verify that each pedestal will be aligned to the adjacent pedestal.

You may do this by choosing a point on each end of a pedestal mount, (for

instance the center of a mounting hole), you can measure in an “X” pattern from

one point to it’s opposite in the “X”.

When the pedestals are the correct distance apart and both lengths of the “X” are

equal, the pedestals are in alignment.

ANCHORS

Use appropriate anchor system for the mounting surface.

DSI recommends 1/2” diameter anchors

A C

B

PEDESTAL

CHALK LINE

PEDESTAL

PEDESTAL

7

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

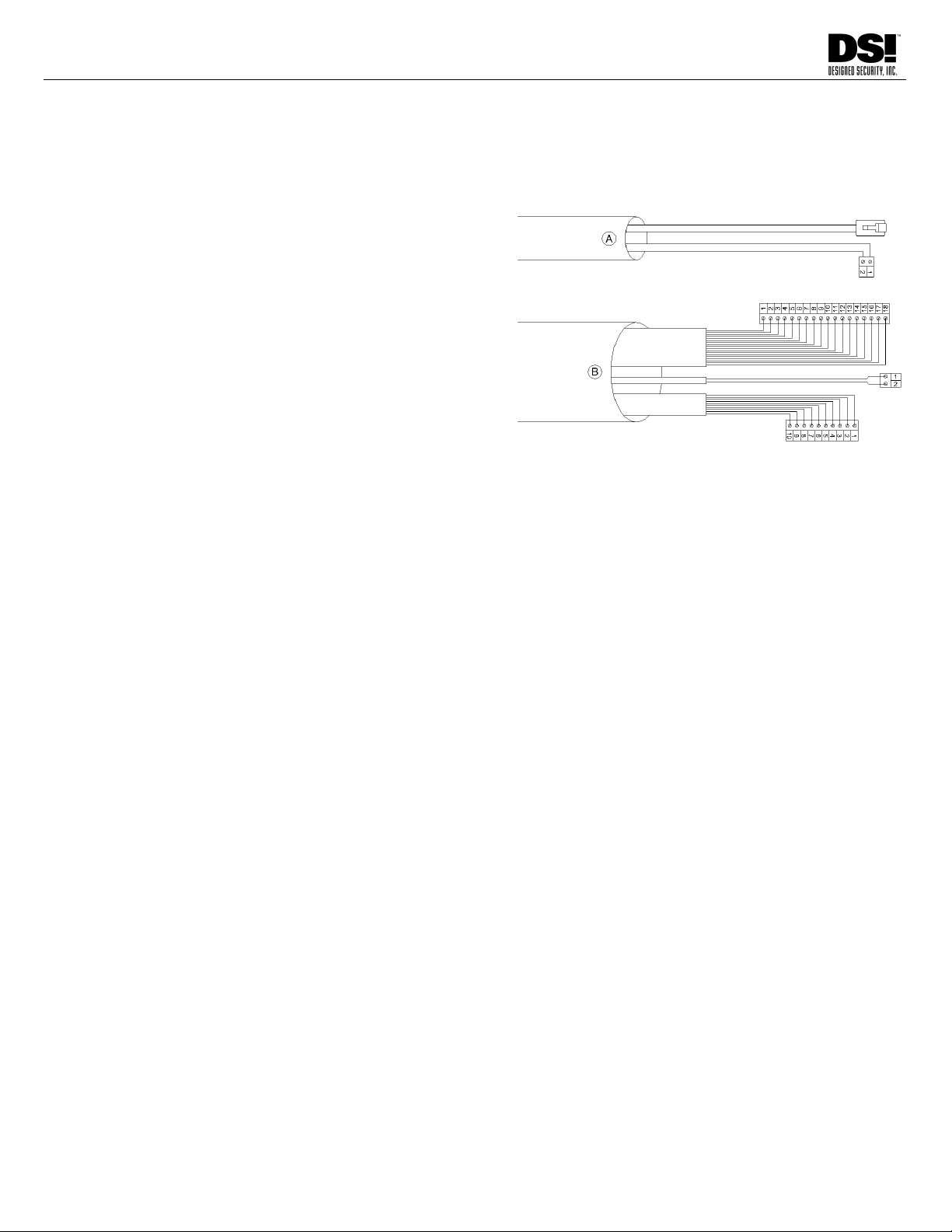

CONDUIT OR OTHER CABLEWAY PLACEMENT

The pedestals will be oriented so the Primary Electronics is located on the Secure side. The Conduit

should be located below this end of the pedestal. There are two wiring groups:

A. Lane Power and Lane Data from each Lane’s

Primary Electronics to opposite pedestal for

remote pedestal control cabling.

B. From Access Control System to Each Lane’s

Primary Electronics for Input, Output, and

Power connections.

See Base Plate Template or Dimensional drawing for access and mounting detail

8 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

BASE PLATE TEMPLATE

9

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

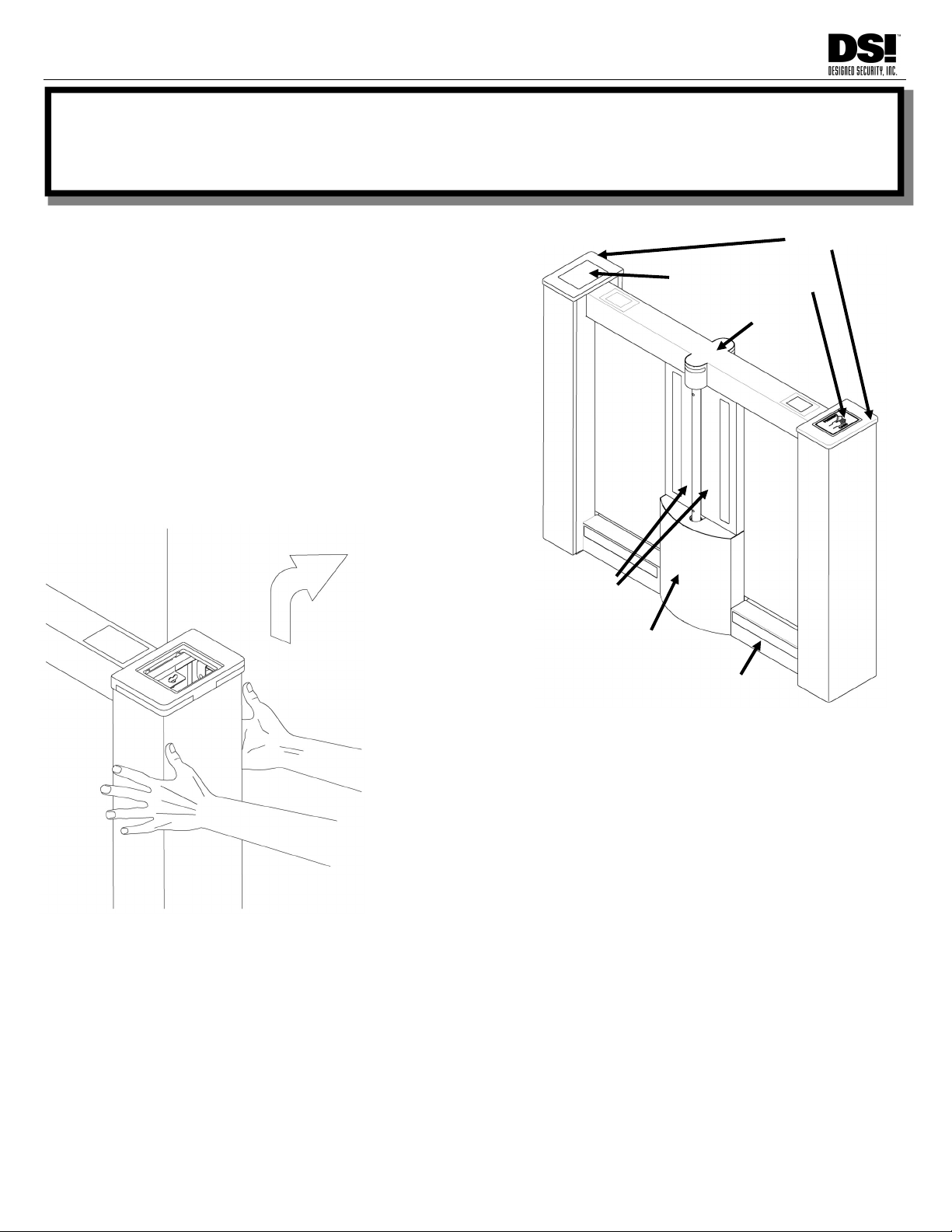

If site preparation is complete, you are ready to mount the

pedestals. The pedestal cladding is assembled with

fasteners hidden by acrylic covers. These covers are held

with magnetic strips and can be removed with a suction

cup. Due to characteristics of the magnetic strips used to

fasten the acrylics, each cover must be returned to its

original location and orientation. Each acrylic is labeled

and a corresponding label is found at its location. Return

removed acrylics to matching label location and

orientation.

To mount the pedestal to the floor, you will need to

remove the End Cover, Center Sensor Covers and Motor

Cover.

END REMOVAL STEPS

Remove Card Reader acrylic cover with suction cup.

Turn thumbscrew 1/4 turn CCW to unlatch.

While gripping sides of end with the palms of your hands, lift straight up

approximately 3/4” then pull away.

Do not lift by Solid Surface top.

Repeat for both ends.

CENTER SENSOR COVER REMOVAL STEPS

Remove acrylic sensor covers from center panels with suction cup.

Each cover is attached with 2 Philips-head truss bolts. Remove bolts.

Remove panels and set aside.

MOTOR COVER REMOVAL STEPS

Remove Center Sensor Cover as noted above. Remove 2 Philips-head truss bolts located toward top of cover.

Remove motor cover by lifting directly up approximately 1/2”.

Place removed covers in safe location. Take care to avoid damaging finish or creating a hazard to pedestrian traffic.

End Cover

Top Cover

Card Reader Acrylic

Motor Cover

Center Sensor Covers

Lower Sensor Cover

INSTALLATION

10 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

ANCHOR TO FLOOR

With pedestal mounting holes and conduit access

exposed, place pedestal on mounting point. Orient

pedestal such that Primary Electronics are located

toward the Secure Side. The right-most pedestal, when

viewed from the secure side will only have the Remote

Electronics located toward the Public side. Refer to

“Site Preparation”, Page 5 to verify these orientations.

Verify the surface you are installing upon is not bowed

or crowned. Use leveling bolts to level pedestal, then

shim pedestal to compensate for uneven surfaces.

Snug mounting fasteners, but do not fully tighten yet.

This will allow you to fine-tune the pedestal alignments.

INSTALL BARRIER PANELS

With pedestals attached to floor, next install the barrier

panels. The barrier shaft has two mounting holes.

Each mounting hole has a counterbore on one end.

Rotate the shaft to orient the mounting hole lengthwise

to the pedestal and counterbore toward the Secure

Side. The barrier panel clamp has visible screws on

one surface. Orient panel as shown with clamp screws

visible. If screws are not visible, you have the incorrect

panel for this location. This orientation will allow a

more cosmetic finish when viewed from the Public side.

Remove mounting bolts stored in threads of clamp, and

mount barrier panel to shaft by inserting mounting bolts

through shaft from counterbore side and thread back

into clamp. Tighten to 20 ft-lb.

SQUARE PEDESTALS

Check that pedestals are square to each other using

techniques outlined in Site Preparation, Page 6.

VERTICAL ALIGNMENT

Check level of the pedestals vertically using a plumb or

spirit level, use shims to make final adjustments.

LEVEL ELEVATION

Level the elevation of the pedestals using a straight edge and/or

a spirit level that will span two or three pedestals at once.

ANCHORS

Tighten securely to prevent any movement of the pedestal.

If you are ready to wire turnstiles, Skip to Wiring section. Otherwise, see next page for cover installation.

ADJACENT PEDESTAL SHOWN

Mounting Points

Barrier Panels

Leveling

Bolts

Primary

Electronics

Barrier

Mounting

Bolts

Visible

Screws

PUBLIC SIDE

SECURE SIDE

Earth

Ground

11

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

COVER INSTALLATION

When all covers are removed, some must be installed in a specific order. The following order accounts

for that sequence.

All fasteners should easily install using hand tools—PLEASE DO NOT USE POWER TOOLS.

LOWER SENSOR COVER

In the rare case the Lower Sensor Cover is removed, it can be reinstalled at any time.

Align cover approximately 1/2” above finish location.

Lower onto hook system.

Install 2 Truss Bolts in mounting holes under acrylic cover

Replace labeled acrylic cover to original location.

MOTOR COVER INSTALLATION

Align cover approximately 1/2” above finish location.

Lower onto hook system.

Install 2 Truss Bolts in top tabs to anchor cover.

CENTER SENSOR COVER INSTALLATION

Return cover to original location.

Align mounting holes.

Install 2 Truss Bolts in mounting holes.

Replace labeled acrylic cover to original location.

TOP COVER INSTALLATION

Return top cover to original location, noting orientation so Entry and Exit Displays are on correct ends.

Rounded center protrusions are a tight fit. Align precisely.

Plug in displays. Entry is 8-pin modular connector. Exit is 6-pin modular connector.

Lower onto pedestal.

END COVER INSTALLATION STEPS

Stand at end, grip both sides of end-panel and align straight onto pedestal, approximately 1”above finish location.

Lower end-panel onto hook system.

Rotate fastener 1/4 turn clockwise to latch.

Install card reader acrylic cover.

13

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

CABLE ROUTING

Route Input and Output cables from Access Control System (ACS) to each Primary Electronics,

located on Secure Side.

Route power cable from each 24VDC @ 4A power supply to each Primary Electronics. Power Cable

must be of sufficient Gauge to provide 24VDC under load, measured at the Power Input Connector.

(See Power Wire Gauge Calculator, Page 24)

The Lane Power and Lane Data cables must be routed between the Primary and Remote Electronics

of each lane. (20 ft. cables included).

The recommended installation is to have lane conduit under the Secure Side, Therefore, to route

cables to the Remote Electronics, remove Top Cover of remote pedestal to access the upper wiring

tray. Top Cover simply lifts off once both End Covers are removed. Unplug displays to fully remove

Use provided wire anchors to contain wires in tray. This will prevent wire damage when reinstalling

cover.

Leave adequate service loop in cables. Route cables neatly in pedestal.

Attach Earth Ground to provided locations.

Check conduit or cableway for airflow. If airflow is detected, block airflow through conduit access hole.

Airflow through chassis may result in rapid dust accumulation on sensor optics which can lead to false

alarms and frequent cleaning requirements.

TERMINATIONS

POWER CONNECTOR

Connect 4 Amp 24 Volt DC Power Supply to the “24VDC POWER INPUT” connector. Pin 1 is “+”, 2 is “-”.

See page 24 for Power Wire Gauge Calculator to determine proper gauge for your application.

ADJACENT PEDESTAL INTERCONNECTIONS

Plug Lane Power cable into LANE POWER connector.

Plug Lane Data cable into LANE DATA connector.

Once powered, Data Status LED on each Electronics will indicate Lane Data quality.

ON = Data Good.

OFF = No Connection - Cable not plugged in.

Flashing = Data corrupted – plug not fully seated; connector reterminated incorrectly; noisy cable path.

INPUT AND OUTPUT CONNECTIONS

Terminate all Input and Output wiring to Connectors (provided).

Input connector is inserted from bottom of board with screw-heads oriented toward backplate.

WARNING: Multiple lanes sharing a common Input Source (i.e. Fire Alarm) must be isolated through a unique

relay contact for each lane input. Wiring common inputs in parallel can cause damage to electronics.

Configure output jumpers for N/O or N/C operation.

J1 and J2 for Alarm Output.

J3 for Valid Exit Complete Output.

J4 for Valid Entry Complete Output.

J5 for Bypass Status Output.

WIRING

N/C OUTPUT - 2 to 3

N/O OUTPUT - 1 to 2

3

2

1

14 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

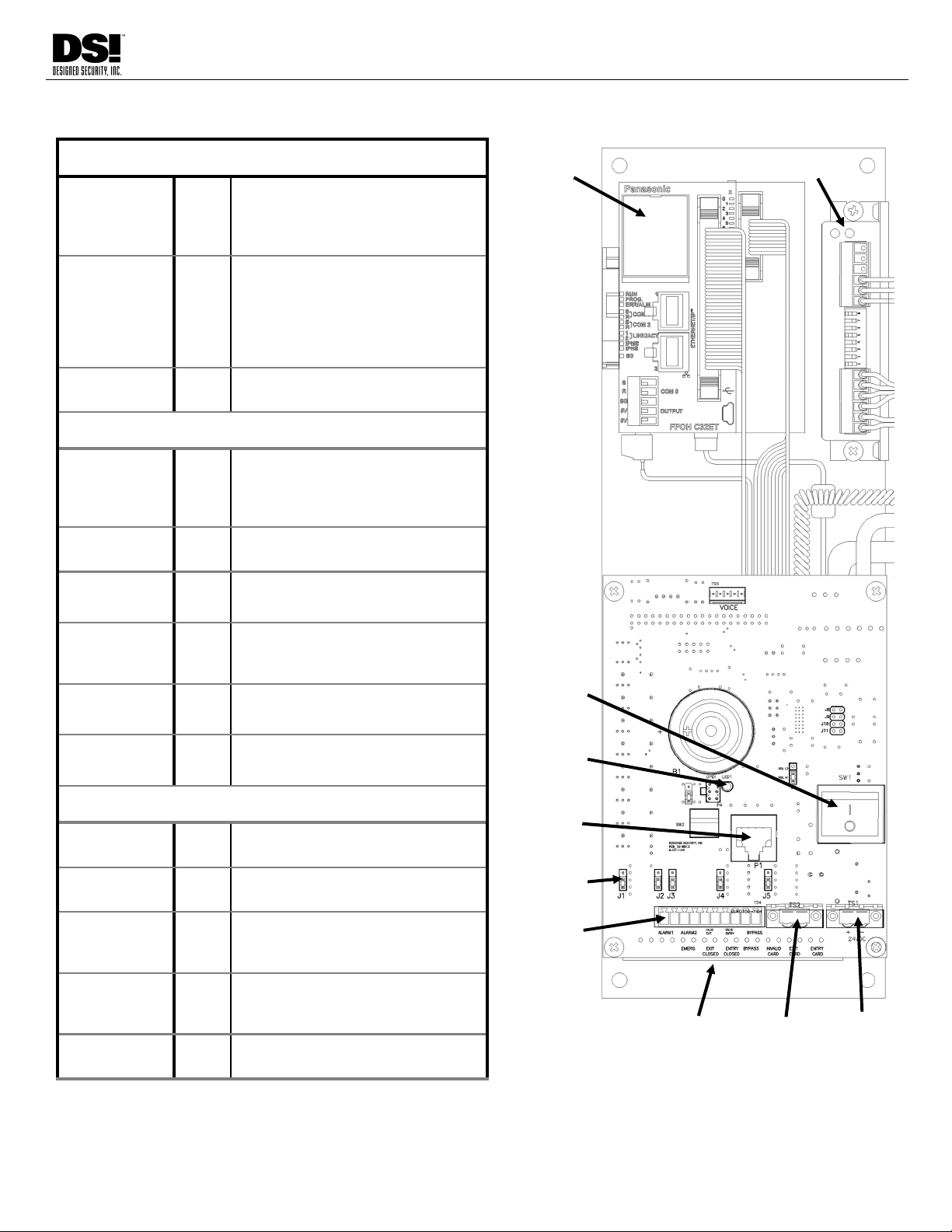

PRIMARY ELECTRONICS DETAIL

Inputs from Access Control System

Entry Valid

Card Read

1-2 Dry contact closure indicating valid

Entry card read

(Momentary Closure of .3 to .5

second recommended)

Exit Valid

Card Read

3-4 Dry contact closure indicating valid

Exit card read

(Momentary Closure of .3 to .5

second recommended)

Hold input for more than 20s for

Free Exit

Invalid Card 5-6 Dry contact closure when an invalid

card has been presented.

Inputs for Remote Control

Reset/Bypass 7-8 Dry contact closure to reset alarms

or to bypass the lane, stow the

barriers and allow unrestricted

traffic flow.

Entry Closed 9-10 Dry contact closure disables Entry

mode.

Exit Closed 11-12 Dry contact closure disables Exit

mode.

Emergency 13-14 Dry contact closure, moves

Barriers to Exit, activates alarm

graphics, and alarm relay output.

Reserved 15-16 Reserved for future use.

Reserved 17-18 Reserved for future use

Outputs for Remote Monitoring

Alarm 1-2 Indicates that unit is in Alarm

Mode.

Alarm 3-4 Indicates that unit is in Alarm

Mode.

Valid Exit 5-6 Indicates that an Exit passage was

completed. Closes for .3 sec when

triggered.

Valid Entry 7-8 Indicates that an Entry passage

was completed. Closes for .3 sec

when triggered.

Bypass 9-10 Indicates when unit is in Bypass

Mode.

Inputs

Outputs

Lane

Data

Lane

Power

24VDC

Power

N/O - N/C

Jumpers

PLC Motor Driver

Power

Switch

Data

Status

LED

WARNING: Multiple lanes sharing a common Input Source (i.e. Fire Alarm) must be isolated

15

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

SETUP & OPERATION

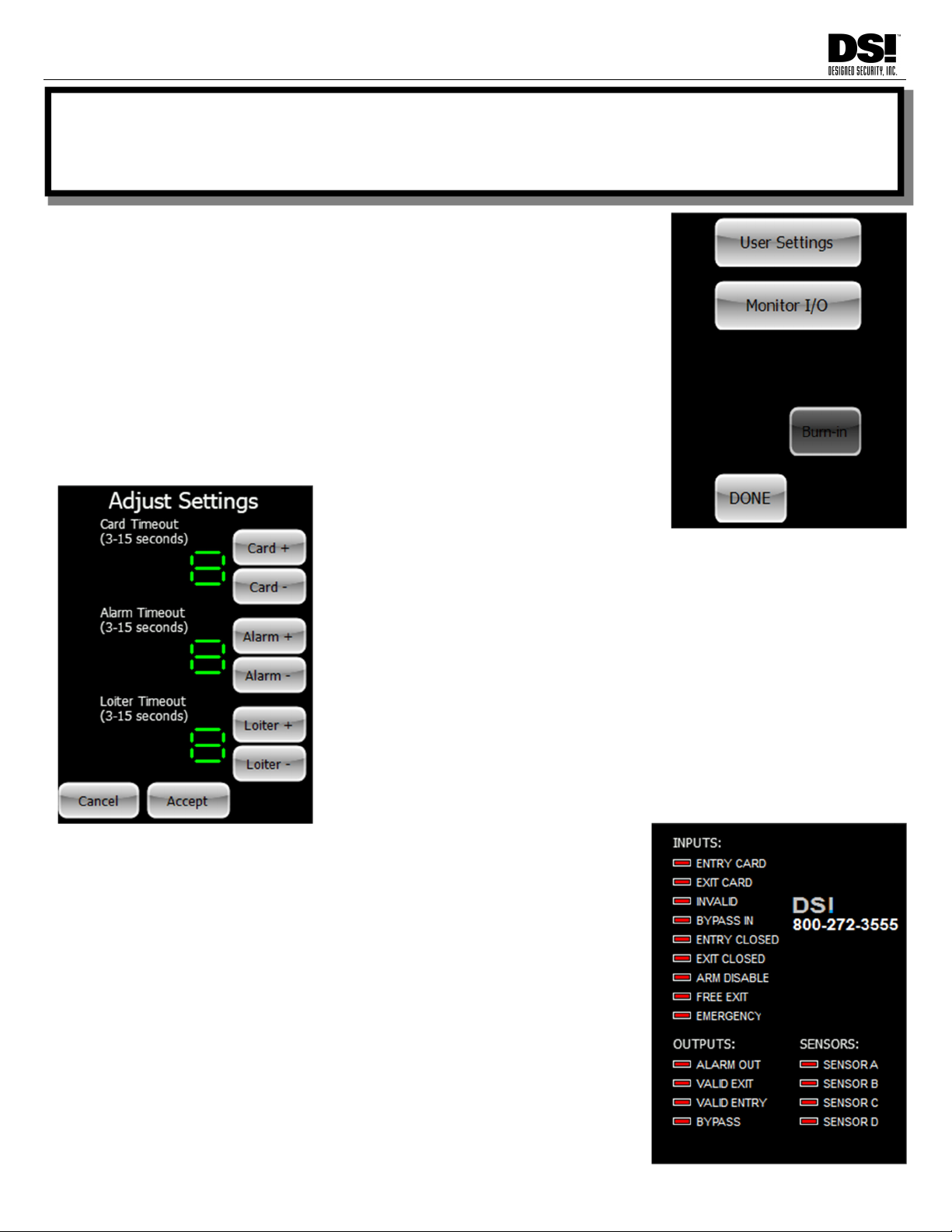

Setup of the pedestal is accomplished via the LCD display located

on the Public side. Use a suction cup to remove acrylic cover, then

touch powered LCD. The main menu will display. User Settings al-

lows adjustment of internal timers, and Monitor I/O helps diagnose

connection issues by showing Inputs and Outputs in real time. Burn-

In is a factory function.

Tap Done to return to normal operation. Replace acrylic cover.

Tap the User Settings button to access the Timer Adjustments. As one

would expect, tap “+” for each timer to increase, and “-” to decrease.

Click Accept to save and return to main menu.

Card Timeout is the valid access grant time. It starts when valid card is

retrieved from the queue. System rearms at end of Timeout period.

Alarm Timeout is the minimum alarm duration. Many users with a latch-

ing device that monitors the Alarm Relay will set this 3s so the lane is

quickly available for next passage.

Loiter Timeout sets duration that a valid user can stand in lane after

crossing the center threshold.

Tap Monitor I/O to launch a diagnostic tool that monitors the In-

puts and Outputs. Red means the input is open/deactivated.

Green means the contact is closed/active. This is useful to verify

that the signals from the ACS are on the correct I/O pins. Green

on a Sensor Input indicates that channel is blocked. Sensor C is

a vestibule sensor on the Public Side. Sensor A is an anti-

tailgate sensor on the Public Side of the gate near center. Sen-

sor B is the Secure Side version of Sensor A. Sensor D is the

Secure Side vestibule sensor.

Arm Disable and Free Exit are legacy images that haven’t been

removed from this screen. The legacy Arm Disable feature was

almost never used, and Free Exit is now invoked by holding the

Exit Card input for 20 seconds or more.

16 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

COMPONENT LOCATION

ENCODER

BARRIER PANEL

D SENSORS C SENSORS

A SENSOR

GEARMOTOR

ELECTRONICS

PACKAGE

MOUNTING

POINTS &

CABLE ACCESS

MOUNTING

POINTS &

CABLE ACCESS

B SENSOR

COUPLER

LOCK

(OPTIONAL)

PLASTIC BUMPER PLASTIC BUMPER

17

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

COMPONENT DESCRIPTION

Electronics Package

The Primary Electronics are found in the end of the left pedestal of each lane when viewed from the Secure side.

The Remote Electronics are found in the left pedestal when viewed from the Public side.

The Motor Controllers control the local and remote barriers. These are mounted on each electronics panel,

immediately above and to the right of the electronics control board.

The PLC (Programmable Logic Controller) is the Module mounted on the DIN Rail at the top of the Primary

Electronics Package. The PLC controls the barriers by reading the Encoder position information and

communicating barrier movement information to the Motor Controllers in response to PLC inputs.

Sensors

The “C” Sensors are used to detect objects present in the barrier path on the Public side of the lane. If something

is blocking these beams, the barriers will not move to allow a user to exit from the secure side (although the barriers

may always be pushed open in an emergency).

The “D” Sensors work similarly for users exiting from the secure side (IE: blocking this beam will prevent the

barriers from moving in the Entry direction) additionally, when set for Free Exit, these sensors will detect the

presence of an exiting user and tell the PLC to move the barriers to allow egress.

On either side of the Barrier will be located the A & B Sensors or the A & B Transmitters. These are the sensor

beams that detect direction of travel, tailgating violations, and passage-complete for valid users.

Connection Panels

All Input and Output wiring, Power input, Lane Power and Lane Data terminate on the Primary

Control Board.

The Motor/Barrier Assembly is the center section of the pedestal.

Located above the Barrier is the Encoder. This is a very sensitive encoder used to detect Barrier

position and provide this information to the PLC. It is attached to the end of the shaft that drives the

Barrier Panel.

Below the Encoder is the Barrier Panel. Located on the same shaft.

Units with optional Locking will have Locking Solenoid hardware mounted on this shaft.

This shaft goes into a shaft Coupler that allows quick removal of the Motor/Gearbox assembly for

maintenance and repair.

Beneath the Coupler is the Motor/Gearbox Assembly that drives the Barrier.

18 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

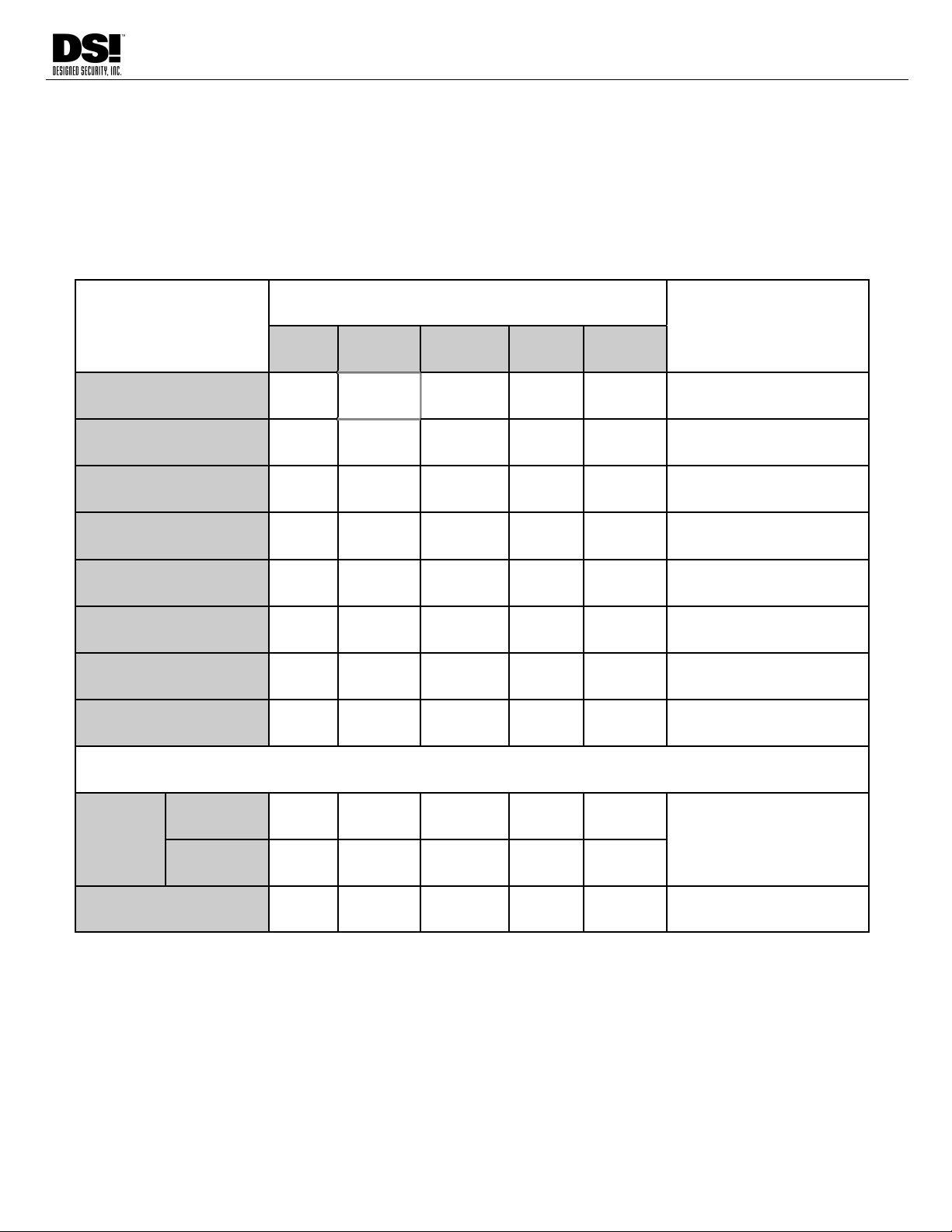

FINAL TESTING PROCEDURE

With all wiring and setup completed, turn on power switch. Barriers will slowly move toward the Public

side until they both come in contact with the Plastic Bumper on the Top Cover. They will then swing

180° toward the Secure side to verify a clear path. They will then return to the center position and be

ready for operation. Follow the table below to test basic functions. Apply the designated input, then

check for the indicated responses. Once finished, if you haven’t already, install all covers as indicated

on Page 11.

INPUTS

OUTPUTS BARRIER

POSITION

ALARM VALID

ENTRY

VALID

EXIT BYPASS AUDIBLE

ENTRY CARD O Entry direction for duration

of Card Access Time

EXIT CARD O Exit direction for duration of

Card Access Time

INVALID CARD O Centered/Armed

RESET/BYPASS O Entry direction

ENTRY CLOSED Center if no other activity

EXIT CLOSED Center if no other activity

FREE EXIT

(EXIT HELD 20s) Exit direction when “D”

Sensor is broken by user

EMERGENCY O Exit direction

BARRIER AND SENSOR STATES

FORCED

BARRIER

& PASSAGE O O BARRIERS WILL

PROVIDE RESISTANCE

AGAINST ATTEMPTS TO

FORCE PASSAGE

NO

PASSAGE

TAILGATE O O

19

INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

GUIDELINES FOR EVERYDAY USE

(PROVIDE COPIES TO ALL TURNSTILE USERS)

Optical Turnstiles are provided for greater security in your workplace.

They help ensure that only authorized individuals will be allowed into the secure areas of your facility.

You may find daily use of Optical Turnstiles becomes routine as you follow these basic guidelines:

USER VALIDATION

“ID” for access control can be of many types, from card readers to biometric systems.

Please refer to instructions provided for reader operation by the manufacturer, or by your security director.

Look at display for LANE READY status, then

present ID to the Reader mounted on, or in, the

right-hand pedestal of the lane you are using. It

may beep to indicate your ID was read.

Listen for a BEEP after the ID has been

validated and/or watch the Display on the top of

the right-hand pedestal to indicate authorization.

Next Look for a PROCEED/BYPASS message to

indicate that you are now authorized to pass

through the lane. The barriers will

automatically swing out of the way allowing

passage.

CAUTION: AVOID TOUCHING THE BARRIER, except in an Emergency, otherwise AN ALARM MAY SOUND

MOVE THROUGH THE LANE PROMPTLY. Avoid stopping or moving backward, as this will trigger the alarm.

TIP: During passage through the lane, swinging items (purses, briefcases, etc.) could be interpreted by the

turnstile as a person tailgating you, or moving in the other direction, thus causing an alarm. To avoid delays

caused by false alarms, hold items high and close to your body, or at your side as you pass through the lane.

IF ALARM SOUNDS, exit the lane, STOP and wait for security personnel to respond.

Once through the lane, continue moving ahead to clear the lane for other users.

FREE EXIT MODE

Some turnstiles may be configured for “Free-Exit,” meaning there is no requirement to present ID when leaving the secured

area. Look for PROCEED/BYPASS graphic on the right-hand side of the lanes when in Free-exit mode.

As you enter the lane, the turnstile will sense your presence and direction allowing you to exit the

secured area of the building. Barriers will automatically open for Free Exit. Pass through turnstile as

outlined above.

Keep in mind that the sensors are active during Free-exit mode. Keep any bags or packages high and close to

your body, or at your side, and avoid swinging them, as this may cause an alarm, even in Free Exit mode.

EMERGENCY USE

During an emergency you may push through the Barriers. Follow established procedure for emergency egress

of the building.

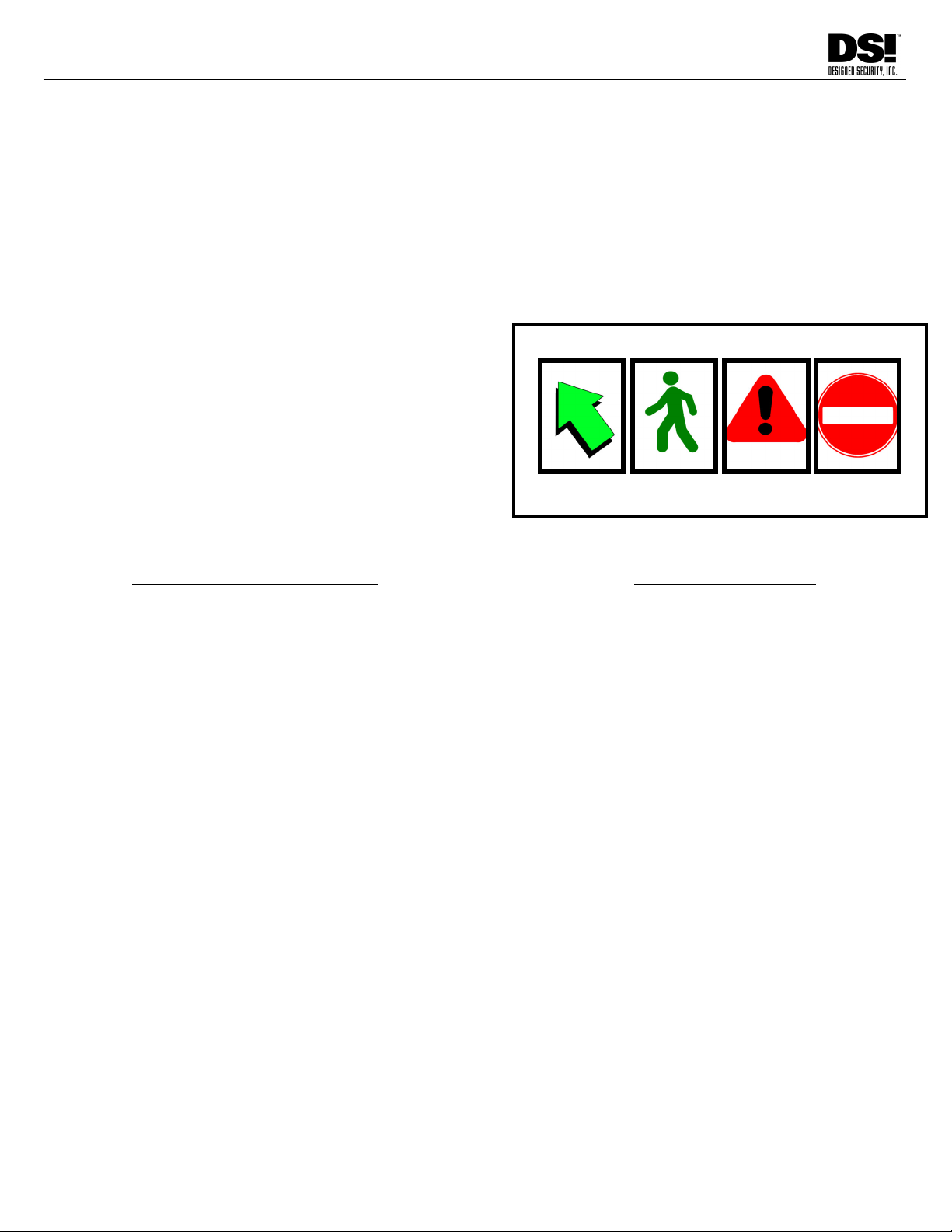

DISPLAY GRAPHICS

LANE READY PROCEED ALARM CLOSED

/BYPASS

20 INS9000 220523

DESIGNED SECURITY INC.

1402 Hawthorne Street Bastrop, Texas 78602

800-272-3555

Fax 512 321 9181

www.dsigo.com

Email: dsi@dsigo.com

GUARD/OPERATOR - OPTICAL TURNSTILE GUIDELINES

(LEAVE COPY AT GUARD OR OPERATOR DESK FOR REFERENCE)

Making an optical turnstile installation work well depends upon a number of factors being present.

Users must be provided adequate instruction. Written, and First-hand / One-on-one.

Users must know that a consequence to them exists for improper use, in order to

avoid abuse of the access control system. Without consequence, abuse will continue.

Guards must be knowledgeable in proper operation of the turnstiles, and be able to

effectively provide training to new or errant Users.

Guards must have an established policy and the authority to act on any Security

violation.

TRAINING USERS

Optimally, all Users need to be provided with a written instruction, and, be shown at least one time, one-on-

one, how to properly use the turnstile.

Instruction should include having the User identify the Reader location and be asked to explain to the

instructor what is expected of the User as they approach and use the lane.

The Users need to know that they are to always AVOID touching the barriers, except in an emergency.

This is a violation. IF THE USER TOUCHES THE BARRIERS, THEY SHOULD VISIT THE GUARD.

NOTE: The single most frequent violation, and cause of abuse, results from Users “pushing through” the

barriers. It is important that the User be trained to NEVER touch the barriers, they are automatic.

GUARD TRAINING AND AUTHORITY

The Guard MUST have the authority to stop Users who have violated a lane. Even Free Exiting Users who

cause an alarm should be encouraged to use the lane properly through some consequence to their action

after causing a violation. Without consequence, the User will continue to abuse the Security system.

TIP: Some of our customers get good results by having their Guard call an errant User over to the desk and verify

the User’s ID. This inconvenience to the User’s routine encourages them to use the lane properly and to avoid

causing alarms. This also provides the Guard an opportunity to help the User learn how to use the turnstile.

It is important that the Guard deal with the User from a frame of mind of “What can I do to help you learn how

to use the Security system and avoid causing alarms?”

Having copies of the User Instructions available to give users is suggested. Taking time to lead the user

through the process will also help build rapport and reinforce that the relationship between the Guard and the

User is complementary rather than adversarial.

If you have questions, or would like further assistance drawing from over a decade of experience with Optical

Turnstiles, please contact DSI Customer Support at 800 272 3555.

Table of contents

Other Detex Turnstile manuals

Popular Turnstile manuals by other brands

ZKTeco

ZKTeco FHT2300 installation guide

digicon

digicon dGate AW product manual

Magnetic Autocontrol

Magnetic Autocontrol MPH 112 operating instructions

Ier

Ier Automatic Systems PNG3 Series installation manual

digicon

digicon Turnstile Duo product manual

BOON EDAM

BOON EDAM Turnlock 100 Safety and operation instructions